CASE STUDY: Winter Gardens Conservatory · 2014-01-04 · German Glass and Scandinavian Sealed...

Transcript of CASE STUDY: Winter Gardens Conservatory · 2014-01-04 · German Glass and Scandinavian Sealed...

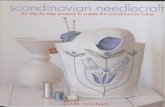

CASE STUDY:Winter Gardens Conservatory

The house itself was constructed under somewhat controversial circumstances. The government of the day had temporarily relaxed planning and building regulations within the green belt on the proviso that the new build home was of significant architectural interest*. The project came within that particular window prior to the act being abolished but the building is certainly architecturally interesting both in its design and perhaps more-so its materials.

The client is a wealthy industrialist with a very substantial engineering business employing 100’s of staff nearby. The whole ethos of this project from inception was high quality engineering and functionality where ‘Can’t be done’ was never an option for the architect or any of the contractors. The ‘Conservatory’ does in fact house a ‘Winter garden’ so the well documented issues such as Solar Gain and Insulation were interwoven into the whole fabric of the building using a combination of both natural and hi-tech mechanical solutions to combat these problems.

Whilst many architects may be presented with a fairly transparent brief this was certainly not the dilemma faced by Aaron Terry of Roberts Limbrick Architects. The client had sketched out the conservatory which in simple terms was akin to a Rugby ball profile curving in both planes. The many stipulations included no internal columns, despite being the length of a Five-a-side football pitch, and that all of the profiles within the roof framework were not to be any larger than 150 x 100mm. At its highest the conservatory reaches to 9.7 metres providing an Atrium space for three storeys of the main house at one end giving stunning views of the interior garden space. The glass facade includes triple glazed units 3.5 metres high.

The combined glass specification with ultra low UV targets , along with the argon filling and blinds within sealed units were beyond even the likes of Saint Gobbain and required sourcing from continental Europe. Whilst a whole raft of computerised climate control systems were employed, the building included a more fundamental approach with regards to wall thickness. The 700mm thick wall profiles may well have been akin to Roman specification and the tried and trusted method offered a substantial contribution to retaining an ambient constant temperature

within the conservatory.Both prior and during the 30 month build programme the client and architects were trawling the great and good within the UK Construction sector but the understandable refusal of both parties to lower their standards to meet availability eventually bore fruit.

MERO-SCHMIDLIN bestride the continent and Asia as part of the privately owned TSK group. With the UK office in Camberley backed with hi-tech manufacturing in Germany, Switzerland, Italy France, Dubai, Kuala Lumpur & Singapore, MSUK are able to offer bespoke envelope solutions to meet the exacting standards readily available outside the UK. A few telephone calls and it became apparent to the architect and client that a company with both a bespoke ability and bespoke attitude did exist here and the journey continued.

Having seen a number of large span MSUK glass roofed structures in the UK and in particular Italy, it became apparent that not only could they deliver the project but also that MSUK are very familiar with working with partners from all corners of the continent.

German Glass and Scandinavian Sealed Units joined a diverse range of continental products such as cladding, ventilation and computerised building control and were coordinated on site by MERO-SCHMIDLIN who produced a whole raft of structural and design drawings to prove that the demanding technical engineering requirements of the client could be achieved. The undulating facade, interfacing on to a hill and curved walls of the house created a huge challenge but fortunately MERO-SCHMIDLIN have a vast experience with such complicated geometry in both roofing and facades.

The ultra high performance glass was sourced in Germany and assembled, complete with internal motorised blinds in Scandinavia. it is to the constant chagrin of the whole team that much of the material specification to meet the clients, albeit exacting, standards were beyond the capability of UK manufacturing.

The resulting U value of the glazing was just 0.6 W/m2k and was directly fixed to the primary structure using a Raico System hidden toggle fixing.

CASE STUDY: Winter Gardens Conservatory, Gloucestershire

PHONE: +44(0)1276 41 42 43 WWW.MERO-SCHMIDLIN.COM

453 pieces of steelwork totalling 995 linear metres & weighing approx 23 tonnes were used

*Planning Policy Statement 7: Office of the Deputy Prime MinisterSustainable Development in Rural Areas

Very occasionally the exceptional quality and innovative nature of the design of a proposed, isolated new house may provide this special justification for granting planning permission. Such a design should be truly outstanding and ground-breaking, for example

Project Details

Scope of Works: 46m x 22m (max) toroidal glazed roof and façade to wintergarden including four sets of doors, integral canopy extension to kitchen area, integrated electronic façade blinds and automatic roof vents

Cladding Details: Roof Glazing - 498m² triple glazed units comprising: 10mm clear heat soak treated tempered float glass outer pane, 16mm air filled outer cavity, 8mm clear heat soak tested tempered float glass middle pane, 16mm krypton gas filled inner cavity, 8mm clear heat strengthened float glass + 1.52mm clear pvb interlayer + 8mm clear heat strengthened float glass inner laminated pane.

Façade Glazing – 190m² triple glazed units comprising: 10mm clear heat soak tested tempered float glass outer pane, 32mm air filled outer cavity including silver DLS Ecklite louver electric blind, 6mm clear heat soak tested tempered float glass middle pane, 10mm krypton gas filled inner cavity, 8mm clear float glass inner pane.

Frit pattern to selected panels & areas.

Insulated aluminium panels and flashings.

Steelwork Details: 453 members, total 995m, approx 23tonnes:All columns 150x100x10 RHSAll roof and transom members 150x100x6 RHSAll hollow sections grade S355 J2H, all other sections and fittings grade S275.

MERO-SCHMIDLIN (UK) PLC‘Marlin’, 459 London RoadCamberley, Surrey GU15 3JAUnited Kingdom

Phone: +44(0)1276 41 42 43 Fax: +44(0)1276 41 42 41 Email: [email protected] Web: www.mero-schmidlin.com

PHONE: +44(0)1276 41 42 43 WWW.MERO-SCHMIDLIN.COM

Architects View

Aaron Terry, Director - Roberts Limbrick Architects www.robertslimbrick.com

The building works incredibly well as apart from the build itself, the biggest challenge was keeping the interior temperature within the parameters needed for the Winter Gardens. With the mix of opening vents at the summit of the roof and the electronic blinds within the glazing, this has been achieved. The same glazing specification has been used throughout the whole building, and the success of the glazing specification became apparent to me when I ventured up to the Panorama Room in July. The Panorama Room as its name suggests is a high level viewing room with 360 degrees of glazing, and on this day the inside temperature was in the low 20’s whilst the outside temperature was over 30 degrees.

The fears from the UK manufacturers included a sagging roof, due to lack of internal support, and wholesale water ingress were completely unfounded. Of course with any bespoke project there are bound to be complications and this project had its fair share along its course but the ‘can-do’ attitude of the whole MERO team enabled a very exacting client to be completely happy with his project and it certainly meets the ‘Significant Architectural Interest’ remit.

Images Courtesy of Roberts Limbrick Architects www.robertslimbrick.com and MERO-SCHMIDLIN (UK) PLC