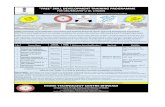

CASE STUDY ENERGY CONSERVATION OPPORTUNITIES at A Foundry at Bhiwadi (Rajasthan)

-

Upload

oliver-long -

Category

Documents

-

view

212 -

download

0

Transcript of CASE STUDY ENERGY CONSERVATION OPPORTUNITIES at A Foundry at Bhiwadi (Rajasthan)

CASE STUDYENERGY CONSERVATION

OPPORTUNITIES

at

A Foundry

at

Bhiwadi (Rajasthan)

COMPANY INTRODUCTIONCOMPANY INTRODUCTIONMANUFACTURING : GATE , GLOBE AND FLAP VALVES OF SIZES 1.5” TO 20” AND TURBINE PARTS SUCH AS CASING TOP / BOTTOM, HORSE SHOE, ETC.

MOC : CAST STEEL / SS

ANNUAL PRODUCTION: 600 TONNE

ANNUAL ENERGY CONSUMPTION :FUEL 48 KL ( LDO HSD AND FO)ELECTRICITY : 9.65 LAKH UINTSSPECIFIC POWER CONSUMPTION (TONNES / LAKH KWH) : 62.17

STUDIES CARRIED OUT DURING AUDITSTUDIES CARRIED OUT DURING AUDIT

ELECTRICAL:

INDUCTION FURNACE : 500 KG (I NO)

HEAT TREATMENT FURNACE : 250 KG (1 NO)

MOTORS : 10HP AND ABOVE (6 NOS)

AIR COMPRESSOR : 120 CFM (2 NOS)

ELECTRICITY BILL REVIEW

THERMAL:

HEAT TREATMENT FURNACE : 3.5 TONNE (1 NO)

LADDLE PRE HEATING

SUGGESTIONS FOR IMPROVEMENTSUGGESTIONS FOR IMPROVEMENTELECTRICAL:INDUCTION FURNACE : • MOLTEN METAL THAT REMAINS IN THE LADDLE, AFTER CASTING,

SHOULD BE RE-POURED BACK INTO THE FURNACE WHENEVER POSSIBLE

• THE ABOVE PRACTICE CAN SAVE RE-MELTING OF AT LEAST 80 KG OF IRON PER DAY THIS AMOUNTS TO ANNUAL SAVING OF RS.49,000/-

• INSTALL ENERGY METER EXCLUSIVELY FOR THE FURNACE AND THE DATA SHALL BE RECORDED IN THE LOG BOOK FOR EVERY HEAT. BY DOING SO THE ELECTRICAL ENERGY CONSUMED PER HEAT CAN BE MONITORED FOR REDUCING IDLE TIME

• SEPARATE POWER FACTOR INDICATOR TO BE INSTALLED, FOR MONITORING OF POWER FACTOR OF THE FURNACE,. THIS WILL ENABLE TO IMPROVE THE POWER FACTOR

• AVERAGE ELECTRICITY CONSUMED PER HEAT IS 240 UNITS (KWH) FOR MELTING 500 KG OF METAL i.e. 0.48 UNITS PER KG

SUGGESTION FOR IMPROVEMENTSUGGESTION FOR IMPROVEMENTELECTRICAL:• THE LOADING OF FURNACE TAKES ABOUT 1 HR AS THE RAW

MATERIAL IS PRIMARILY SCRAP OF UNEVEN SIZES.THIS TIME CAN BE REDUCED IF IT CAN BE FED IN FORM OF BUNDLES , ESTIMATED SAVING IN TIME WILL BE ABOUT 10% RESULTING IN SAVING OF RS 2.45 LAKHS PER ANNUM (BASED ON 8 HEATS A DAY AND 300 WORKING DAYS)

HEAT TREATMENT FURNACE :

• THE TEMPERATURE OF THE MATERIAL AFTER QUENCHING AND NORMALIZATION SHOULD NOT BE ALLOWED TO GO BELOW 150°C SO AS TO MINIMIZE HEATING TIME DURING TEMPERING IN THE NEXT CYCLE. THIS WILL REDUCE THE CYCLE TIME AND POWER CONSUMPTION BY 16 KWH PER DAY RESULTING IN ANNUAL SAVING OF Rs.20,000/-

SUGGESTION FOR IMPROVEMENTSUGGESTION FOR IMPROVEMENTELECTRICAL

• ONLY HALF CAPACITY OF THE FURNACE IS USED DUE TO LESS QUANTITY OF OIL IN THE QUENCHING TANK. BY INCREASING THE OIL QTY IN THE QUENCHING TANK FULL CAPACITY OF THE FURNACE CAN BE UTILIZED THIS WILL SAVE 45 KWH PER DAY RESULTING IN SAVING OF Rs 57,500/- P.A.

• IT WAS FOUND THAT MATERIAL BEING NORMALIZED BY NATURAL COOLING IS ALSO BEING TEMPERED AT 520°C. AFTER DISCUSSIONS WITH THE TECHNICAL PERSONNEL IT WAS DECIDED TO DISCONTINUE THIS PRACTICE AS IN THEIR VIEW TEMPERING IS NOT REQUIRED FOR A NORMALISED PRODUCT. (THIS PRACTICE WAS WRONGLY STARTED WITHOUT THE KNOWLEDGE OF HIGHER MANAGEMENT). THIS WILL SAVE 17 KWH PER BATCH OF 400 KG MATERIAL.

SUGGESTION FOR IMPROVEMENTSUGGESTION FOR IMPROVEMENT

ELECTRICALMOTORS : • THE PERCENTAGE LOADING OF SHOT BLASTING MOTORS (2

NOS) IS AROUND 17%. THE EXISTING 10 HP MOTORS CAN BE REPLACED BY AVAILABLE 5 HP MOTORS. THIS WILL IMPROVE EFFICIENCY AND POWER FACTOR OF THE MOTORS. NOT ONLY SAVING OF AROUND RS 11500 PER ANNUM CAN BE ACHIEVED BUT ALSO THE MOTORS OF 10 HP AND ITS STAR-DELTA STARTER SWITCH GEAR CAN BE UTILIZED ELSEWHERE

• ALL THE 5 BELTS SHOULD BE PROVIDED ON THE COUPLING BETWEEN MOTOR AND COMPRESSOR. THE BELTS USED AS THE POWER TRANSMISSION MECHANISM SHOULD BE TIGHT.

• THE WORKING ENVIRONMENT BEING DUSTY, MOTOR SHOULD BE CLEANED IN EVERY SHIFT TO INCREASE THEIR EFFICIENCY

SUGGESTION FOR IMPROVEMENTSUGGESTION FOR IMPROVEMENTELECTRICALAIR COMPRESSOR :• THE CFM OF C-2 WAS FOUND TO BE 74 CFM WHERE AS THE RATED CFM

IS 120(61%). OVER HAULING OF THE COMPRESSOR AND REGULAR SUCTION AIR FILER CLEANING SHALL IMPROVE IT

• THE LEAKAGE IN THE SYSTEM WAS EXTREMELY HIGH. AS A RESULT OF WHICH THE COMPRESSORS IS NOT GETTING UNLOADED DURING LEAKAGE TEST FOR 30 MINUTES. THIS INDICATES 100% LEAKAGE IN THE AIR SYSTEM. DUE TO LEAKAGE, THE PRESSURE AT THE UTILITY IS NOT SUFFICIENT AND IT IS REQUIRED TO RUN THE 2ND COMPRESSOR. HENCE THERE IS A LEAKAGE OF ABOUT 74 CFM AND A POTENTIAL OF SAVING RS 2 LAKH PER ANNUM

• WHENEVER COMPRESSOR IS RUN ON NO LOAD, SAVING OF 17 KW IS ACHIEVED. IF LEAKAGES ARE ATTENDED, RUNNING OF 2ND COMPRESSOR CAN ALSO BE AVOIDED

• PREFERABLY FLAT BELTS TO BE USED IN PLACE OF V-BELTS

SUGGESTION FOR IMPROVEMENTSUGGESTION FOR IMPROVEMENTELECTRICALELECTRICITY BILL REVIEW

• THE AVERAGE POWER FACTOR OF THE INSTALLATION IS 0.93. THE REBATE STARTS FROM 0.95 AND ABOVE. THERE IS A POTENTIAL SAVING OF Rs 2 LAKH PER ANNUM BY MONITORING P.F. OF FURNACE AND ACCORDINGLY INSTALLING SUFFICIENT CAPACITOR BANK

• IMPROVEMENT IN POWER FACTOR SHALL REDUCE CURRENT REQUIREMENT AND CONSEQUENTLY THE MAXIMUM DEMAND SHALL REDUCE WHICH WILL REDUCE THE FIXED CHARGES (@ 90/KVA) AND THERE IS POTENTIAL OF SAVING RS 26,000 P.A

SUGGESTION FOR IMPROVEMENTSUGGESTION FOR IMPROVEMENTTHERMALHEAT TREATMENT FURNACE• FURNACE OIL TEMP AT MAIN STORAGE, PREHEATING TANK AND

BURNER WERE FOUND 38, 45 AND 35°C RESPECTIVELY. THIS WILL RESULTS IN POOR FUEL AUTOMISATION AND FORMATION OF EXCESS CO IN FLUE GAS. THIS IS DUE TO ABSENCE OF SERVICE TANK AND INSUFFICIENT FUEL TEMPERATURE. BY INSTALLING SERVICE TANK WITH HEATER BETWEEN MAIN STORAGE TANK AND PREHEATING TANK. TEMPERATURE CAN BE MAINTAINED AT 45, 80 AND 110 °C AT MAIN STORAGE, SERVICE TANK AND PRE-HEATER TANK RESPECTIVELY AND ALSO THE ABOVE LINE AND FUEL TANK TO BE PROPERLY INSULATED

• HIGH EXCESS AIR OF 140% WAS MEASURED IN FLUE GASES DUE TO ABSENCE OF ANY AIR CONTROL MECHANISM FOR AIR SUPPLY

SUGGESTION FOR IMPROVEMENTSUGGESTION FOR IMPROVEMENTTHERMAL• BY REDUCING EXCESS AIR LEVEL FROM 140% TO 30 % SAVINGS

OF 5 KL OF FURNACE OIL PER ANNUM CAN BE ACHIEVED.

LADDLE PREHEATING • PRESENTLY COMPRESSED AIR IS BEING USED AS COMBUSTIBLE

AIR SINCE THE BLOWER IS OF SMALLER CAPACITY. SO, REPLACEMENT OF EXISTING BLOWER OF 2 HP WITH 5 HP OF 400 CFM AND 40” OF WG WILL RESULT IN SAVING OF 1.2 KL P.A.