CARRYING OUT STEEL STOPPLE OPERATIONS Safeguard Safe Work ... out Steel Stopple... · CARRYING OUT...

Transcript of CARRYING OUT STEEL STOPPLE OPERATIONS Safeguard Safe Work ... out Steel Stopple... · CARRYING OUT...

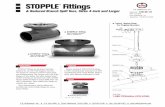

CARRYING OUT STEEL STOPPLE OPERATIONS Safeguard Safe Work Method Statement

Document: APAND00015 Version: 0.01 Date: 27/03/2013 Review by: 31/03/2014 Page 1 of 14 pages

SAFE WORK METHOD STATEMENT - CARRYING OUT STEEL STOPPLE OPERATIONS

HSE NET NAT SWMS APAND00015

Principal Contractor (PC)

APT AM Holdings Pty. Ltd.

[ABN] 95124754383

APA Group Level 19, HSBC Building 580 George Street Sydney NSW 2000

State Representative :

Subcontractor

Person responsible for reviewing &

approving the SWMS

John Ferguson Group Executive Networks Phone 02 9693 0057

Signature and Date Sign: Refer to Approval Sign off Sheet APADN00020 Date: 28/3/2013

Date SWMS provided to PC

27/3/2013 Provided to: Robin Gray Manager Systems Operations Phone 08 8159 1656

Work Description

SAFE WORK METHOD STATEMENT ACTIVITY

Connecting onto live gas mains Carrying out Steel Stopple Operations

Project Reference

Steel Hot Tap And Stopple Activities

Work Location /Address

Not applicable

Person Responsible for ensuring

compliance with SWMS on site

As identified on the APA JHEA (APA NAT-00026)

The following personnel who have

consulted and assisted in the

development of this

Billy McNeil, Ross Darrigan, Anthony Cronin. Jason Riddell Review date for this

SWMS March 2014

CARRYING OUT STEEL STOPPLE OPERATIONS Safeguard Safe Work Method Statement

Document: APAND00015 Version: 0.01 Date: 27/03/2013 Review by: 31/03/2014 Page 2 of 14 pages

PERSONNEL SITE CONTENT

Required Supervision As identified on the APA JHEA(APA NAT-00026)

Permit to Work & other Approval Requirements

Required Qualifications

TDW Competency

Plant, Equipment, Materials

Required Training

APA induction Card or Short term induction

Construction Industry General Induction

Workplace Specific Induction (if required)

Induction in to this SWMS

Induction to APA Pre Start HSE Check/Plan

Hazardous Substances

Ref MSDS Register on Crew Truck

Personal Protective Equipment (PPE)

High Visibility Clothing – Day and Night MANDATORY

Safety Gloves (as required)

Safety Glasses Clear and Sunglasses(as required)

Hearing Protection – Earmuffs / Earplugs (as required)

Safety Boots - Steel Cap MANDATORY

Protective Clothing – Must meet and be used as

Emergency Procedures and

Equipment

Seat Belts

Flashing lights

Reversing warning

First Aid Kit (on site)

SWMS

CARRYING OUT STEEL STOPPLE OPERATIONS Safeguard Safe Work Method Statement

Document: APAND00015 Version: 0.01 Date: 27/03/2013 Review by: 31/03/2014 Page 3 of 14 pages

per APA Operations Field Book Procedure 5206

Safety Helmet (as required)

Sun Lotion (as required)

Sun Hat (as required)

REFERENCES ASSOCIATED DOCUMENTS

[List as required. May include Legislation, Australian Standards, MSDS, Codes of Practice, etc.]

Work Health & Safety Act 2011

Work Health & Safety Regulations 2011

Work Health & Safety Act 2012 SA

Work Health & Safety Regulations 2012 SA

Work Health & Safety Plant Code of Practice

Work Health & Safety Risk Management Code of Practice

Work Health & Safety Noise Code of Practice

AS 1742.3:2009

[List as required. May include work instructions, APA Operating Manuals, inspection procedures, maintenance instructions]

APA Pre Start HSE Check/Plan

APA traffic management check/plan Book

APA Operations Field Book

Safeguard

CARRYING OUT STEEL STOPPLE OPERATIONS Safeguard Safe Work Method Statement

Document: APAND00015 Version: 0.01 Date: 27/03/2013 Review by: 31/03/2014 Page 4 of 14 pages

Step No.

What are the tasks involved?

in order of job sequence

Hazards/risks What can happen and how can it happen?

Raw Risk Controls to be implemented to reduce risks What will be done to ensure zero harm?

Residual Risk

Person responsible Who will make sure

it happens?

Break the job down into steps. Each step should accomplish some major task and be in a logical sequence

Specify the potential hazards associated with each step and risks to health, safety and the environment. Examine each to find possibilities that could lead to an incident.

Assess the raw risk without controls

Describe the measures to be implemented to eliminate or control the risks. Describe how these measures are to be implemented, monitored and reviewed.

Assess the residual risk with controls

Specify Person(s) Responsible

1. Check Design

Fitting failure due to incorrect fittings ordered and non-compliance to Australian Standard

Possible injuries from site selection due to deep excavation, wet areas.

Failure to have design checked and approved

Incomplete job packs

High

Design checklist to be approved by the Delegation of Authority (DOA)

Completed work pack signed by Delegation of Authority (DOA) prior to issue

Check location design for suitability.

All selected fittings to comply with Australian Standards

Moderate

Project Manager

Engineer

Site responsible supervisor

2.

Check Materials / Fittings

Failure of fittings due to incorrect pressure class.

Injuries from uncontrolled release of gas due to faulty fittings.

Inability to plug fittings due to damage caused prior to or during fitment.

Maximum Allowable Operating Pressure (MAOP) resulting in possible down rating of pipeline

Incorrect carbon content in

High

Confirm Maximum Allowable Operating Pressure (MAOP) of main / service

All materials to comply with Australian Standards

Visual inspection of fittings to ensure compliance to engineering design

Check all supplied materials for mechanical operation fit for task

Identification check of fitting number

Moderate

Project Manager

Engineer

Site responsible supervisor

CARRYING OUT STEEL STOPPLE OPERATIONS Safeguard Safe Work Method Statement

Document: APAND00015 Version: 0.01 Date: 27/03/2013 Review by: 31/03/2014 Page 5 of 14 pages

fittings

Incorrect quantity of fittings for task

Incorrect stopple cups range selection

Missing fitting certification

against supplied certification and APA requirements

Check fitting certification meets engineering design specification

Check quantity supplied meets order requirements

3. Site Set Up

Trips and falls during site walk due to uneven ground or items lying around.

Traffic Incident. Injuries to pedestrians / others.

Environmental impact – failure or leak while setting down equipment and or product.

Stopple plant set down areas not suitable for task

Inadequate area footprint to complete stopple task

High

Ensure a complete work pack is signed off and issued prior to site mobilization

Tool Box Meeting. (Identify site specific risks).

Pre-start and JHA completed

Ensure the fittings supplied are as specified

Keep site tidy and maintain good housekeeping.

Traffic management plan comply with Manual Uniform Traffic Control Device (MUTCD)

Implement sediments controls measures as per APA procedures.

Set down area to be pre-identified and managed by Traffic Controllers (TCs) / site foreman.

Ensure spill kits are available on site.

Moderate

Site responsible supervisor

All Team members

CARRYING OUT STEEL STOPPLE OPERATIONS Safeguard Safe Work Method Statement

Document: APAND00015 Version: 0.01 Date: 27/03/2013 Review by: 31/03/2014 Page 6 of 14 pages

Ensure adherence to approved applicable APA SWMS

4. Excavate site.

Trench collapsing

Damage to pipe or coating

High

Refer SWMS for Excavating and working in a trench greater than 1.5m

Refer to SWMS for Steel Main Laying

Ensure compliance with APA permitting procedures

Ensure adherence to approved applicable APA SWMS

Moderate

Site responsible supervisor

All Team members

5. Weld Fittings on to Main

Possible eye injuries due to weld flash.

Possible injuries from grinding slag.

Burns from welding.

Burn through of pipe during welding causing uncontrolled gas escape / fire.

Failure of welds causing uncontrolled gas escape / fire

Fire caused by grinding / pre heat.

Injuries from mechanical failure of equipment.

Hearing damage from excessive noise.

Heat stress.

Electrocution from contact with metal pipe during electrical storm

High

Use welding screens to protect public and other workers from flash.

Ensure adherence to approved applicable APA SWMS

Provision and use of Personal Protective Equipment - Ref Protective Clothing – Must meet and be used as per APA Operations Field Book Procedure 5206.

Use qualified welders and procedures.

Carry out lamination and thickness checks on main as specified by project engineer.

Use qualified welders and procedures. Carry out non-destructive testing of welds as per engineering specification.

Ensure compliance with APA permitting procedures

Have frequent breaks. Drink plenty of water. Provide shade (tarps).

Moderate

Site responsible supervisor

All Team members

Weld supervisor

CARRYING OUT STEEL STOPPLE OPERATIONS Safeguard Safe Work Method Statement

Document: APAND00015 Version: 0.01 Date: 27/03/2013 Review by: 31/03/2014 Page 7 of 14 pages

/stray currents.

Damage to exposed pipe during lifting operation.

Do not carry out welding operations during storms. Check weather reports.

Ensure Earthing leads attached to main. Use neon detector to check for stray current.

Have suitable repair fittings on site to suit Maximum Allowable Operating Pressure (MAOP) and size of pipe if specified.

6.

Test Fittings / Valves / By -passes

Injuries from sudden escape of pressure due to fitting failure.

Incorrect testing pressures.

Failure to comply with testing procedures/specifications.

Failure of test equipment.

Failure of pipe or fittings during test operations.

High

Visual inspection of fittings. Ensure all equipment and fittings to be used are suitable for test pressure.

Pressure test fittings and equipment prior to drilling. Refer to AS2885.2 Welding Standard; Section 13.14. Test Pressure must be minimum of 100kPa less than the pipeline operating pressure.

Use hydro test in preference to air test where possible or as specified by the project engineer.

Dewatering or depressurizing air/gas from tested section of mains should be undertaken with extreme caution refer to AS2885.5 Field Pressure Testing

Consider use of whip checks on flexible test equipment to prevent injury.

Use appropriate signage to warn others of pressure test.

Moderate

Site responsible supervisor

All Team members

Weld supervisor

CARRYING OUT STEEL STOPPLE OPERATIONS Safeguard Safe Work Method Statement

Document: APAND00015 Version: 0.01 Date: 27/03/2013 Review by: 31/03/2014 Page 8 of 14 pages

7. Drill Fittings

Injuries from uncontrolled escape of gas that may cause fire or explosion.

Fitting / valve failure due to incorrect drill size resulting in pipe damage/ leak that may cause fire or explosion.

Commissioning prior to pre-commission checklist being approved.

Loss of coupon could damage downstream equipment.

Injuries due to failure of mechanical or hydraulic/pneumatic equipment.

Environmental spills.

Hearing damage due to excessive noise.

Injuries from lifting equipment. (craning loads)

Possible fall during drilling operation.

High

Pressure test fittings and equipment prior to drilling. Refer to AS2885.2 Welding Standard; Section 13.14. Test Pressure must be minimum of 100kPa less than the pipeline operating pressure.

Check and confirm correct drill and pilot size selected. Use measurement cards. (Refer T.D.W. training manuals)

Ensure coupon catcher operating correctly.

Visual inspection of drilling equipment.

Check / maintain equipment.

Visual inspection of hydraulic / pneumatic hoses and couplings.

Provision and use of Personal Protective Equipment - Ref Protective Clothing – Must meet and be used as per APA Operations Field Book Procedure 5206.

Ensure adherence to approved applicable APA SWMS

Ensure spill kit on site.

Visual inspection of lifting equipment for damage.

Use drill platform or other appropriate controls.

Moderate

Site responsible supervisor

All Team members

Weld supervisor

CARRYING OUT STEEL STOPPLE OPERATIONS Safeguard Safe Work Method Statement

Document: APAND00015 Version: 0.01 Date: 27/03/2013 Review by: 31/03/2014 Page 9 of 14 pages

8. Stopple Main, Tie in /

Cut and cap

Injuries due to sealing element / mechanical equipment failure causing uncontrolled escape of gas that may cause fire or explosion.

Injuries from hydraulic / pneumatic hose failure.

Environmental spills

Hearing damage.

Supply loss

Injuries from cutting pipe. Sharp metal edges.

Burn from flaring gas

High

Ensure correct sealing elements are used, and that they are in good condition. Check elements are within use by date. (Refer to T.D.W. Training manuals.)

Ensure the second block between cut end and stopple sealing element is in place or as specified by the project engineer.

Have fire extinguishers located in an appropriate location.

Ensure all plant and equipment is well maintained/ calibrated and is fit for purpose.

Provision and use of Personal Protective Equipment - Ref Protective Clothing – Must meet and be used as per APA Operations Field Book Procedure 5206.

Ensure adherence to approved applicable APA SWMS

Support pipe with stands, jacks, slings. Discuss with staff and make them aware of possible movement.

Ensure non routine is followed to prevent loss of supply.

Moderate

Site responsible supervisor

All Team members

Weld supervisor

9. Purge main / by pass Failure on high pressure bypass

Burn while purging gas High

Refer to SWMS on Direct and Indirect Purging

Adherence to procedures as specified by the project engineer.

Moderate

Site responsible supervisor

All Team members

CARRYING OUT STEEL STOPPLE OPERATIONS Safeguard Safe Work Method Statement

Document: APAND00015 Version: 0.01 Date: 27/03/2013 Review by: 31/03/2014 Page 10 of 14 pages

Prior preparation of by-pass hoses (test)

Provision and use of Personal Protective Equipment - Ref Protective Clothing – Must meet and be used as per APA Operations Field Book Procedure 5206

Adherence to Emergency Services fire danger rating (FDR) and if required get permits.

10. Commissioning

Failure and gas escape, failure of golden weld

Failure of equalization of mains pressure

Failure to bring the main back to operating pressure

Loss of supply

Failure during decommissioning of by-pass hoses / fittings

High

Pre-commissioning checklist is to be approved, signed and sighted and on site prior to commissioning.

Adherence to general procedures as specified by the project engineer.

Provision and use of Personal Protective Equipment - Ref Protective Clothing – Must meet and be used as per APA Operations Field Book Procedure 5206

Moderate

Project manager

Site responsible supervisor

All Team members

11. Install completion plugs

/ fittings

Injuries from uncontrolled release of gas due to failure of plug to seat / seal correctly.

Injuries from mechanical failure of plug or plugging equipment.

Damage to existing infrastructure

Incorrect installation / failure of fitting

Loss of plug off the plugging

High

Visual inspection of plug, ensure all mechanical components of plug are operating correctly. Check seal for damage. Refer to T.D.W. procedure manuals

Ensure correct pressure rating of stopple plugging equipment.

Ensure adherence to approved applicable APA SWMS

Adherence to general procedures as specified by the project engineer.

Moderate

Site responsible supervisor

All Team members

CARRYING OUT STEEL STOPPLE OPERATIONS Safeguard Safe Work Method Statement

Document: APAND00015 Version: 0.01 Date: 27/03/2013 Review by: 31/03/2014 Page 11 of 14 pages

equipment

Failure to follow pre-determine measurements recorded on measurement card

Stopple measurement card to be located in a safe accessible place.

12. Mummify fittings / pipe /

valves

Possible future failure of asset due to corrosion, causing uncontrolled escape of gas.

Possible fires from use of gas torch to heat shrink sleeves where applicable.

Moderate

Use approved wrapping materials.

Follow A.P.A. procedures. Use Holiday detector to confirm wrapping done correctly.

Remove all flammable materials from site.

Check gas torch and gas bottle for leaks. Confirm bottle is in test.

Minor

Site responsible supervisor

All Team members

13. Backfill of Excavation

Non-compliance to SWMS for Excavating and Working in a Trench Greater than 1.5m

High Ensure adherence to approved

applicable APA SWMS Moderate

Site responsible supervisor

All Team members

14.

Deviation from this Safe Work Method Statement

Miscommunication by all parties onsite.

High

STOP all work activities

Ensure task and equipment is made safe

Hold a tool box meeting and record and adjust

Complete JSA for variations from work method – obtain approval from site representative.

Authorised by competent person, supervisor or HSE Advisor

Sign off on changes prior to the recommencement of work.

Adequately trained to complete JSA.

Moderate

Site responsible supervisor

All Team members

CARRYING OUT STEEL STOPPLE OPERATIONS Safeguard Safe Work Method Statement

Document: APAND00015 Version: 0.01 Date: 27/03/2013 Review by: 31/03/2014 Page 12 of 14 pages

CARRYING OUT STEEL STOPPLE OPERATIONS Safeguard Safe Work Method Statement

Document: APAND00015 Version: 0.01 Date: 27/03/2013 Review by: 31/03/2014 Page 13 of 14 pages

Declaration by contractors and workers - I have been given the opportunity to comment on the content of this SWMS. - I have read and understand how I am to carry out the activities listed in this SWMS. - I have been supplied with the personal protective equipment identified on this SWMS and I have been given training in the safe use of this equipment. - I have read and understand the requirements set out in the material safety data sheets for the hazardous substances identified in this SWMS

Consultation & Review Sign Off Analysis of Training / Skills or Competencies Required

Training / Skill / Competency Required to Complete the Work Safely

Gen

eral

Ind

ust

ry

Ind

uct

ion

Pro

ject

Sp

ecif

ic

Ind

uct

ion

[ Li

st o

ther

s]

A = All employees are required to hold. % of personnel required to hold

A A

Number of personnel required to hold

Name Position Signature Date Training / Skill / Competency held by employee – tick () – evidence must

be available

CARRYING OUT STEEL STOPPLE OPERATIONS Safeguard Safe Work Method Statement

Document: APAND00015 Version: 0.01 Date: 27/03/2013 Review by: 31/03/2014 Page 14 of 14 pages

Risk Assessment CONSEQUENCE

RISK RANKING ACTION REQUIRED

Negligible Work can proceed once risk controls identified and implemented

Minor Work can proceed once risk controls

identified and implemented

Moderate Work can proceed once supervisor has confirmed process has been

adequately followed and risk controls identified and implemented

High Reduce risk to at least moderate or to ALARP through additional controls.

Activity must not commence without Management approval

Extreme Activity must not commence.

Reduce risk to at least moderate or to ALARP through additional controls.

HSE First aid treatment only with the ability to return to work immediately

External medical treatment but excluding hospitalisation with the ability to return to work the next work day

Injury or illness requiring hospitalisation and resulting in the inability to return to work the next day (LTI

Permanent partial disability

Fatality OR permanent total disability

Multiple fatalities

Environment Limited impairment to minimal area of low significance

Short-term (<12 months) temporary impairment to the biological or physical environment of a very localised area (<0.1ha)

Prolonged (<5 years) reversible impairment to the biological or physical environment of a localised area (<1ha) which is easily rectified and which does not affect ecosystem function

Uncontrolled off-site release or event. Reversible prolonged impairment to the environment but which does not affect ecosystem function

An uncontrolled off-site release or event in wide area resulting in reversible long-term environmental impairment of ecosystem function

Uncontained, long-term serious environmental degradation OR permanent impairment to ecosystem function or habitat

LIK

ELIH

OO

D

Probability Historical Descriptor LEVEL 1 LEVEL 2 LEVEL 3 LEVEL 4 LEVEL 5 LEVEL 6 At least once per

year Is expected to occur in

most circumstances Frequent Minor Moderate High Extreme Extreme Extreme

At least once every 1 to 5 years

Expected to occur infrequently

Likely Minor Moderate High High Extreme Extreme

At least once every 5 to 10 years

May occur occasionally

Occasional Minor Minor Moderate High High Extreme

At least once every 10 to 50 years

Might occur at some time

Possible Negligible Minor Moderate High High High

At least once every 50 to 100 years

Could occur at some time but not

considered likely Unlikely Negligible

Minor

Moderate Moderate High High

Less than once every 100 years

Conceivable but only in exceptional circumstances

Improbable Negligible Negligible Minor Moderate Moderate High