CARBON FOOTPRINT: CEMEX METHODOLOGY · CEMEX decided to measure the full impact of its emissions...

Transcript of CARBON FOOTPRINT: CEMEX METHODOLOGY · CEMEX decided to measure the full impact of its emissions...

CARBON FOOTPRINT:

CEMEX METHODOLOGY

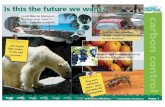

OUR COMMITMENTSustainable development is an important part of CEMEX’s strategy, as evidenced by our commitment to controlling and reducing our impact on the environment.

Conscious of the effect that greenhouse gas emissions from our production processes have on the environment, CEMEX decided in 2000 to be one of the founding members of the “Cement Sustainability Initiative” (CSI) of the World Business Council for Sustainable Development (WBCSD). Further strengthening its commitment, in 2010 CEMEX decided to measure the full impact of its emissions through an innovative carbon footprint measurement tool.

As aggregates, cement, and concrete are key materials to the development of society, we considered it essential to make an effort to measure the carbon footprint of each of these three products. The result of this analysis will allow us to prioritize our carbon reduction strategy at each of our facilities.

Thanks to these efforts, CEMEX is the first building materials company in the world to provide the carbon footprint of each of its core products on a global scale.

OUR OBJECTIVESCEMEX developed the carbon footprint methodology with the following objectives:

Quantify emissions of CO2 equivalent gas from the production of our products to assist in reducing emissions.

Perform a benchmark of facilities within the company with the goal of continually reducing our CO2 footprint.

Communicate to our stakeholders quantitative data on the carbon footprint of our products. This footprint will also allow our customers to obtain the footprint of CEMEX products to be used on their specific projects.

WHAT IS THE CARBON FOOTPRINT?Carbon Footprint measures the amount of CO2 and equivalent emissions directly or indirectly generated during the entire production process up to the door of CEMEX plants (“cradle to gate“ approach); i.e. taking into account all phases of production from the extraction of raw materials from natural resources (“cradle”) and their transporting, processing and packaging (if necessary) until the moment the product leaves the premises of CEMEX (“gate”).

WHY IS IT IMPORTANT TO KNOW IT?Knowing the carbon footprint of our products reveal the extent to which we are contributing to climate change and is the first step in reducing our emissions of CO2 to the atmosphere. As an additional benefit, it allows us to inform our customers about the greenhouse gases environmental impact of the products they use, and helps them calculate the carbon footprint of their projects. This knowledge is becoming increasingly important in today’s carbon-conscious society.

HOW HAS CEMEX CALCULATED ITS CARBON FOOTPRINT?The methodology is based on the ISO 14040:2006 standard for products “Life Cycle Assessment” and the PAS 2050:2008 standard “Specification for the Assessment of the Life Cycle Greenhouse Gas Emissions of Goods and Services” as well as in “draft” versions of the ISO 14067 “Carbon Footprint of products” and WBCSD / GHG protocol “Product Life Cycle Accounting and Reporting Standard.”

The methodology has been tested in 9 CEMEX plants across several continents by the certification company Det Norske Veritas (DNV). The tool has been implemented in 629 centers of production of cement, aggregates and concrete in the world, corresponding to 58% of total production for CEMEX. The implementation plan considers 100% coverage in the short term.

1. Does not include clinker purchased from third parties. Emissions from clinker purchased from third parties has been divided into the 4 areas in the following proportions: 90% direct emissions, 5% energy and other, 3% transport, 2% raw material

WHAT FACTORS ARE CONSIDERED IN THE CALCULATION OF THE CARBON FOOTPRINT?

TRANSPORT RAW MATERIALS ENERGY, FUEL AND OTHER DIRECT EMISSIONS FROM CLINKER

DEFINITION CO2 emissions from transportation of raw materials, fuels, energy and other production inputs

Embedded CO2 footprint of all raw materials, owned or acquired from third parties

Embedded CO2 footprint of all energy / fuel sources and other production inputs

CO2 emissions from the production process

CEMENT Limestone, gypsum, clay, slag, fly ash, etc.1

Energy, fossil fuels, alternative fuels, refractories, grinding media, etc.

Emissions from clinker production (de-carbonization and combustion)

CONCRETE Cement, aggregates, additives, additions (fly ash, slag), and process water

Energy, diesel, non-process water, etc.

AGGREGATES Aggregates purchased from third parties

Energy, explosives, diesel, spare parts, conv. belts, etc.

CEMEX IS A GLOBAL BUILDING MATERIALS COMPANY THAT

PROVIDES HIGH-QUALITY PRODUCTS AND RELIABLE SERVICE

TO CUSTOMERS AND COMMUNITIES IN MORE THAN 50

COUNTRIES THROUGHOUT THE WORLD. CEMEX HAS A

RICH HISTORY OF IMPROVING THE WELL-BEING OF THOSE

IT SERVES THROUGH ITS EFFORTS TO PURSUE INNOVATIVE

INDUSTRY SOLUTIONS AND EFFICIENCY ADVANCEMENTS

AND TO PROMOTE A SUSTAINABLE FUTURE.