CamPulse - Gas Turbine Inlet Air Filtration | Campulse Cambrane Hemipleat / 1 The CamBrane is a...

Transcript of CamPulse - Gas Turbine Inlet Air Filtration | Campulse Cambrane Hemipleat / 1 The CamBrane is a...

CAMFIL | Campulse Cambrane Hemipleat / 1

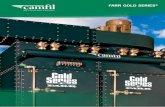

The CamBrane is a composite media which is extremely efficient on small particles and airborne salt. The membrane layer acts as a barrier to submicron particles and is impermeable to water, stopping salt from penetrating the filter.

Filter Media

The pre-filter synthetic media has a high dust loading capacity along with excellent performance in both dry and humid conditions. The supporting base of the membrane is a robust synthetic substrate that gives strength to the filter and allows it to meet the high burst strength requirement of gas turbine applications. The combination of these five media layers provides the Cambrane with excellent properties for use in gas turbines applications. The E12 EPA grade filtration, with 99.5% efficiency at the Most Penetrating Particle Size, offers considerable improvements in engine protection resulting in lower engine degradation and prolonged service intervals without need of shutdowns for compressor cleaning.

HemiPleatTM

The wider spacing of the HemiPleat™ design exposes more media to the air stream and results in lower pressure drop, stable performance in high humidity and improved dust release during pulse cleaning. Overall, the HemiPleatTM lowers energy cost through fuel savings and the high efficiency lowers engine power degradation.

Key features

• CamBrane media has 99.5%

MPPS pure mechanical effi-

ciency - Certified E12 according

to EN1822

• New multi-layer membrane

media with non-discharging fiber

shell.

• Proven HemiPleat technology

• Water & salt resistant

CamPulse Cambrane Hemipleat™

w w w.camfi l .com/ps

Water repellant

Submicron size fine fibre media (fiber)

Durable core layer

Submicron size membrane (transparent)

Strong synthetic substrate (solid gray)