Calibracion de Valvulas

-

Upload

steve-da-rivia -

Category

Documents

-

view

56 -

download

6

description

Transcript of Calibracion de Valvulas

Valve Lash Setting

Valve lash is measured between the rocker arm and the bridge for the inlet valves. Valve lash is measured between the rocker arm and the valve stem for the exhaust valve. All of the clearance measurements and the adjustments must be made with the engine stopped. The valves must be FULLY CLOSED.

Valve Lash Check: Engine Stopped

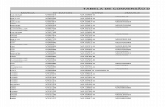

Table 3

Check for Valve Lash: Engine Stopped

Valves Acceptable Range for Valve Lash

Inlet 0.38 0.08 mm (0.015 0.003 inch)

Outlet 0.76 0.08 mm (0.030 0.003 inch)

An adjustment is NOT NECESSARY if the measurement of the valve lash is in the acceptable range. The range is given in Table 3.

Illustration 5

g00363480

Valve lash

Valve Lash Setting: Engine Stopped

Table 4

Valve Lash Setting: Engine Stopped

Valves Gauge Dimension

Inlet 0.38 mm (0.015 inch)

Outlet 0.76 mm (0.030 inch)

To make an adjustment to the valve lash, turn the adjustment screw in the rocker arm. Valve lash adjustments can be made by using the following procedure:

Illustration 6

g00363481

Valve adjustment (typical example)

Illustration 7

g01246025

Cylinder and valve location(A) Inlet. (B) Exhaust. (C) Fuel injection pumps1. Put No. 1 piston at the top center position.

Note: See Testing and Adjusting, "Finding Top Center Position for No. 1 Piston" for further details.

2. Make an adjustment to the valve lash on the inlet valves for cylinders 1, 3, 4, 6, 7, and 12. Make an adjustment to the valve lash on the exhaust valves for cylinders 1, 4, 5, 8, 9, and 12.

3. After each adjustment, tighten the nut for the valve adjustment screw to a torque of 30 4 Nm (22 3 lb ft). Then, check the adjustment again.

4. Remove the timing bolt and turn the flywheel by 360 degrees in the direction of the engine's rotation. This will position the No. 1 piston at the top center on the exhaust stroke. Install the timing bolt in the flywheel.

5. Make an adjustment to the valve lash on the inlet valves for cylinders 2, 5, 8, 9, 10, and 11. Make an adjustment to the valve lash on the exhaust valves for cylinders 2, 3, 6, 7, 10, and 11.

6. After each adjustment, tighten the nut for the valve adjustment screw to a torque of 30 4 Nm (22 3 lb ft). Then, check the adjustment again.

7. Remove the timing bolt from the flywheel after all valve lash adjustments have been made.

8. Recheck the valve lash on all twelve cylinders after the initial setting.

RENR1388-05Finding the Top Center Position for No. 1 Piston

Note: The starting position for all timing procedures is with the No. 1 piston at the top center position on the compression stroke.

Illustration 2

g00361852Locating the top center position (typical example)1) The storage location for the timing bolt

(2) Plug

(3) Bolt

(4) Cover

1. Remove the timing bolt (1), the bolt (3), and the cover (4) .

2. Remove the plug (2) .

Illustration 3

g00361853

The 9S-9082 Engine Turning Tool is installed(1) The installed timing bolt

(5) 9S-9082 Engine Turning Tool3. Install 9S-9082 Engine Turning Tool (5) in the housing.

4. Once plug (2) has been removed, insert the timing bolt (1) through the hole. Hold the timing bolt (1) against the flywheel.

5. Turn the flywheel in the direction of normal engine rotation until the timing bolt engages with the threaded hole. The No. 1 piston is at the top center position on the engine.

Note: If the flywheel is turned beyond the point of engagement, the flywheel must be turned in the direction that is opposite of normal engine rotation. Turn the flywheel by approximately 30 degrees. Then turn the flywheel in the direction of normal engine rotation until the timing bolt engages with the threaded hole. When the No. 1 piston is at the top center position, this procedure will remove the play from the gears.

Illustration 4

g01246025

Cylinder and valve location(A) Inlet. (B) Exhaust. (C) Fuel injection pumps6. Remove the left front valve cover. Look at the valves of No. 1 cylinder. The valves will be closed if the No. 1 piston is on the compression stroke. You can move rocker arms up and down with your hand. If the No. 1 piston is not on the compression stroke, perform the following steps.

7. Remove the timing bolt from the flywheel.

8. Rotate the crankshaft counterclockwise by 360 degrees. Install the timing bolt.

Note: If the flywheel is turned beyond the point of engagement, the flywheel must be turned in the direction that is opposite of normal engine rotation. Turn the flywheel by approximately 30 degrees. Then turn the flywheel in the direction of normal engine rotation until the timing bolt engages with the threaded hole. When the No. 1 piston is at the top center position, this procedure will remove the play from the gears.

RENR1388-05