C4 Derivatives

description

Transcript of C4 Derivatives

Derivatives of C4 Hydrocarbons

Derivatives of C4 Hydrocarbons

raw materials to be considered are butadiene, n-butylenes and isobutylene

butylenes produced from refinery catalytic crackers

butadiene prod. fr. butylenes dehydrogenation

demand for isobutylene : production of butyl rubber and polybutenes

industrial development of C4 prodts dominated by butadiene used in synthetic rubber industry

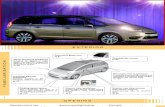

Separation of C4 Hydrocarbons straight fractional distillation will not meet the requirement of separating the C4 HC components

precise nature of C4 separation differ according to individual requirements

common practice to first remove butadiene present in stream

traditional method of extraction and recovery involves selective absorption of butadiene in ammoniacal cuprous acetate

achieved in multistage extractor/settler system with the HC stream flowing countercurrent to the copper ammonium acetate solution

butadiene desorbed fr. the solution by an increase in temp. and reduction in press & purified by distillation

popular technique by extractive distillation using external component that affect the relative volatilities of C4 HCs

furfural as external component then changed to acetonitrile

using acetonitrile, C4 mixt. distilled in presence of aqueous solvent, butadiene dissolves preferentially and butadiene/solvent mixt. Withdrawn fr. bottom of column

2nd column, butadiene separated fr. acetonitrile

3rd column, final purification achieved

* aspect of butadiene recovery is purity of final prodt. in particular effective removal of traces of acetylenes and unwanted dienes

butadiene free C4 stream treated for isobutylene removal

in refinery catalytic cracker C4 streams becomes the 1st operation

achieved by selective absorption in 65% sulphuric acid @ 10-20oC as absorption medium

isobutylene recovered by diluting acid to 40-50% concentration and heating or to warm fat acid containing absorbed isobutylene to 80-100oC for a period after which isobutylene polymers abt. 80% of total as diisobutylene, separate out as an upper HC layer

separation of isobutylene fr. n-butylenes usg. the versatile molecular sieve method

molecular sieve prodt. designed to adsorb n-butylenes and to exclude the isobutylene

n-butylenes are purged fr. molecular sieve bed by higher boiling material which may be separated fr. n-butylenes by distillation

after butadiene and isobutylene removal the remaining C4 stream, comprising 3 n-butylene isomers with n-butane and isobutane does not require further separation