by dArcy nybo A Modern dAyHobbit to stand the ... - Dome Diva · 32 JULY / AUGUST 2011 A Modern...

Transcript of by dArcy nybo A Modern dAyHobbit to stand the ... - Dome Diva · 32 JULY / AUGUST 2011 A Modern...

WWW.COTTAGEMAGAZINE.COM JULY / AUGUST 201132

A Modern dAyHobbit

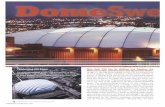

HoMeCindy Johnson’s monolithic dome is energy efficient, inexpensive and built to stand the test of time

by dArcy nybo

indy JoHnson wAn-ted a place where she could relax. A home on her own piece of land; one she could use as a

cottage away from the city and eventually move to full-time. She wanted a place where she could retire that wasn’t outrageously expen-sive to build or maintain. She knew she wanted something that was strong in case of natural disaster, fireproof and energy efficient.

She found all this in an egg-like structure called a monolithic dome. The word monolithic comes from the Latin word, monolithus, which roughly translated means one stone. Domes are the strongest structure in the world because every inch supports itself. There are no stress points in a dome and they are micro-energy users, averaging one fourth of that

used by other types of structures.Armed with this information, Johnson set

out to build her home-away-from-home in the alpine terrain below Mount Baldy outside of Oliver, BC. She explains how the project first began: “I was originally going to build a mono-lithic dome by using a classic air form, which is an inflatable bladder, but I went even further than that.”

As a scenic artist in the motion picture indus-try, Johnson worked with a wide variety of peo-ple, one of them a sculptor. He advised her that a sculptured monolithic dome would be even stronger, and more flexible from a design point of view. Intrigued by a concept that made the strongest structure in the world even stronger, she looked at a design he had created. She con-tacted the engineer who created the blueprints

for it and together they worked on customizing it to suit her lifestyle and property.

“We decided on a 38-foot diameter, which when finished, translates into an 1,850-square foot hobbit house in the woods,” she says. “A very strong, very twenty-first century hobbit house nonetheless.”

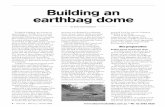

Blueprints in hand she set about making her dome. First the foundation was poured. Unlike most domes, which only pour a flat, 4–6-inch slab, she decided to pour 4x4x4 footing with a flat slab and 3-foot high footing walls reinforced with rebar. The rebar was inserted so that some was left sticking out to tie onto the metal fram-ing for the dome.

Once the base was in place, the sculpting began. The initial form consisted of rebar. On top of that was placed 6-inch road mesh.

c

JULY / AUGUST 2011 WWW.COTTAGEMAGAZINE.COM 33

[ 1 ] Johnson inserted rebar in the 3-foot footing walls in order to connect it to the metal framing of the dome. [ 2 ] The dome’s form grid consisted of rebar, 6-inch road mesh and metal lathe, which was then topped with rebar “U”s to create a 3-inch spacing before another grid of rebar was tied on.

[ 3&4 ] The dome was covered with shotcrete, which can just be shot onto a building without being formed. [ 5 ] Johnson added a special powder, which originated at NASA, to the exterior paint to add some extra insulation.

5

1 2

3 4

WWW.COTTAGEMAGAZINE.COM JULY / AUGUST 201134

Once that was in place metal lathe was added. The three layers formed the dome’s form grid. Once the form grid was in place they attached 3-inch rebar “U”s to create a 3-inch spacing upon which was tied another grid of rebar cre-ating the completed structural grid.

“We found we could only build the metal grid so high before it started leaning in because of the weight,” says Johnson. “The builder was convinced we needed to have a complex and expensive wooden scaffolding system around the interior, but we chose to rent a three tier scaffold instead. We experimented with tying 60 feet of rebar together, using the scaffold to hoist it up with rope, and started securing hoops. Once we had eight hoops up we used the bender bars to create circles of bar that we tied to our hoops. It was a marvelous bowl-shaped web. In essence we created a self supporting structure.”

Johnson and a friend decided they could do the rest of the metal framing and detail work themselves. “You can get really inventive when you have to,” she says. “The possibility of sav-ing thousands of dollars gets the creative juices flowing. In one instance the only sun-tunnel skylights I could find to go through 6 inches of cement cost $630 each. I looked around and got them fabricated from 18 gauge steel and paid $480for all five.”

When it came time to enclose the three small round portholes, Johnson had another idea. “I went to a local marine store and got three origi-nal porthole windows for under $200. They look and work great.”

Once the form was created they built out from the rebar and created arches where the windows and doors would eventually be placed. Everything had to be perfect and in place before they poured the shotcrete. Sun-tunnel skylights, piping for the fireplace, portholes, in and out air vents, piping for water, gas and electrical lines all had to be perfect because once the cement came nothing was going to be moved.

“In researching monolithic dome building I learned about shotcrete,” says Johnson, abso-lutely delighted with her find. “The beauty of shotcrete is that it doesn’t need to be formed. When you pour cement it is sloppy and needs a form. Shotcrete is like a thick mud. When you shoot it onto a building it just clings to the rebar and mesh. The strength is amazing at 90 psi.”

Now it was time for the engineer to come down to approve the metal structure. “He was almost in tears when he saw the skeleton,” she laughs. “He was thrilled to see his blueprint come to life and passed our metal form with-out a single modification. A short time later a Kelowna-based company came down with their trucks and blew the shotcrete on in two days. The first day they blew on 10 yards to create

Call 1-800-263-0379

INCINOLET Products1141968 Ontario Inc.

2022 7th Ave. E. Owen Sound, ON N4K 6R9(519) 938-9108 Fax (519) 938-9214

[email protected] www.incinolet.ca

For year round use in home, cottage, houseboat, shop, stable or motorhome.

Where other disposal sys-tems are not practical INCINOLET electrically incinerates waste to clean ash.

• Waterless• Compact • Convenient• Non-polluting

hELP PROTECT OuR LAKES & RIvERS

Power for yourCottage Life.

Renewable EnergySolutions & Products:• Sealed&Maintenance-freeBatteries• DeepCycleBatteriesandAccessories• Inverter&InverterChargers• ChargeControllers• Solar/PVPanels• Qualityindustryleadingproducts

Call: 604.420.7737 Email: [email protected]

JULY / AUGUST 2011 WWW.COTTAGEMAGAZINE.COM 35

an eggshell. The next day, once it was dry, they poured another 32 yards, which brought the thickness up to a total of 6 inches.”

Prior to the shotcrete pour, Johnson went out and purchased vinyl widows and punched holes into the vinyl to tie them directly to the metal grid. She decided to add mini-windows, or port-holes, so she could easily see who was coming down the driveway, and placed one upstairs and two on either side of her front door. “They also make a perfect cat door,” she chuckles.

Tarps were placed over the windows, door area and portholes to protect them against the shotcrete. The building didn’t end there. Once the shotcrete was complete, Johnson covered the dome with 4 inches of polyurethane foam, which in turn was covered by a coating of elas-tomeric paint.

In order to give the dome the energy effi-ciency she wanted, Johnson set about berm-ing up the dome; burying approximately 1,000 square feet of surface. The back of the structure closest to the hills was bermed up 12 feet. The middle sections of the building were bermed to 8 feet and near the front door area it was bermed to a 3-foot height.

Then it was time to paint. “I learned about this insulating powder that originated at NASA that can be added to paint,” explains Johnson. “The powder, Insuladd, is safe and non-toxic, and can transform any colour of paint into an environmentally friendly insulation barrier that saves energy and cost. The paint then creates

below The upper fl oor of the dome is lit with fi ve sun-tunnel skylights, and solar lights at the bottom of the Pyrex glass tubes provide ambient lighting during the evening.

2544 Aberdeen Road,

Lower Nicola, BC V0K 1Y0

250.315.0113

Cell 250.378.1984

www.bloomsfloorswithflair.com

Western Canadian distributors for

Waterlox tung oil and pure tung oil

from The Real Milk Paint Co.

The RedisCoVeRed

Wood FLooR

CompANY LTd.

Quality Reclaimed Flooring,

Furniture, & Accessories

Reclaimed hand hewn hickorydoor for a bathroom. Timbers door for a bathroom. Timbers door

came from structures built during the late 1700's thru to the late 1800's. Pure tung oil & Waterlox tung oil are perfect for this applica-tion, to pro-tect the door for another 100 years.

FOR SEPTIC WASTEWATER TREATMENT SYSTEMS

• Time-provenforover25years• Nomaintenancerequired• Loweroverallcost• Fitsanylotshape• Bestchoicefor

sensitivelakesideproperties• Passivesystem—nopowerrequired

eljen.com

Authorized Representative:BWD Engineering Inc.15822 – 106A106A106A AvenueSurrey, B.C., V4N 1K7Phone: (604) 789-2204Fax: (604) 582-8231Web: www.bwdeng.ca

properties

CORPORATION

WWW.COTTAGEMAGAZINE.COM JULY / AUGUST 201136

a barrier that deflects the sun’s heat away from the dome, plus it helps keep the building tem-perature where it should be; warm in the winter and cool in the summer.”

Once completed the insulating paint added an additional R15 to her already energy effi-cient home. As an added bonus, the Insuladd in the paint renders the surface of the dome non-flammable.

Johnson’s dome has three windows and a glass fire door that leads into a vestibule with a regular door. The vestibule contains two ther-mal pane windows, which bring plenty of light into the dome.

Shelf space in the round interior was impor-tant so the windows were set near the middle of the structure, allowing for a 4-inch shelf on the inside of the dome. Over that, Johnson installed 8-inch white fir planks to create the window-sills. On the outside of the dome, the overhang was used to insert ornamental security bars for the times she is away.

The inside of the dome has been designed for living in the round. The only walls on the lower floor create the master bedroom and the bath-room. The bedroom is to the left of the entry door and is approximately 400 square feet with a walk-in closet. It has one of the three windows and looks out onto the yard and forest beyond.

Above The dome has an R50 rating due to its design and placement in the earth.

Left A ceiling fan circulates air, and cheap marine porthole windows saved Johnson money.

renewable energy from sun, wind &

water

Leaders in renewable energy for homes and

cottages25 years of valued service throughout

western Canadaspecializing in off grid & grid tie systems– pecializing in off grid & grid tie systems–

installation optional

1-800-661-8484 Kelowna, bC

Phone: 250-763-8484 fax: 250-763-7620email: [email protected]

www.renewables.net

Sun-Mar EXCEL NEComposting Composting Toilet$1,295

While stock While stock lasts

• Grid Tie Systems • PV Modules• Mounting Structures • Inverters• Mounting Structures • Inverters• Charge Controllers • Batteries• Charge Controllers • Batteries• Charge Controllers • Batteries

• Wind Generators • Micro Hydropower

• Refrigeration • Water Pumps• Refrigeration • Water Pumps• Composting Toilets • Generator Sets • Composting Toilets • Generator Sets

• System Design

JULY / AUGUST 2011 WWW.COTTAGEMAGAZINE.COM 37

The bathroom is pentagon-shaped and sits in the middle of the dome with one door lead-ing into it from the bedroom and another from the dining area. The bathroom is spacious and houses the washer and dryer, as well as sink, large bathtub and a toilet.

The kitchen also has one of the three large windows, along with 18 feet of curved kitchen countertops. It is large enough to hold a full-sized fridge and stove. Johnson placed an island in the middle to give her more counter space.

Next to the kitchen is a dining area, sepa-rated from the living area by an airtight wood-stove. As the building is in the round you hear, but cannot see the kitchen area as you relax in the living area.

In order to keep a more rustic look, the inte-rior walls are parget with cement to create a rough texture, and then smoothed over with a liquid limestone marble.

For hot water, Johnson recommends a Rin-nai hot water on demand system heated by propane. The stove is also propane.

The upper floor of the dome has 750 square feet of living space that is lit with five sun-tunnel skylights. Johnson got creative again and placed solar lights at the bottom of the Pyrex glass tubes to provide ambient light-

In an energy efficient building like this, it only makes sense to use an energy efficient woodstove. Johnson chose a Quadra-Fire air-tight stove. “It burns so proficiently there is very little smoke or ash left,” she says, and notes that, “many of my neighbours use five to eight chords of wood throughout the winter. I use about two-and-a-half chords when I stay the whole year.”

Johnson is proud of what she has created. “My whole focus with building this was to have a sustainable, earth-friendly, energy efficient home. I’m from Nova Scotia where you never tear down a house, so I wanted something that was going to last. This should still be standing multiple generations from now.”

Johnson has chronicled her experience so that others can learn how to build their own sculptured monolithic dome. She sums up her experience this way: “The only thing better than building a dome is living in one.”

ing during the evening. There is also a single light at the top of the dome and a ceiling fan to circulate air.

The floor itself is made of freestanding post and beam. Johnson explains why: “We had to leave a 2-inch gap between the walls and the upper floor for air circulation. It makes heat-ing and cooling the dome more efficient. Also, just in case an earthquake occurs, the upper floor has room to move.”

Johnson says the total time from start to fin-ish for building the shell, installing windows, doors and framing the upper floor was about three months. Her total cost? Under $100 per square foot.

“The beauty of this dome is how energy effi-cient it is,” she says, relaxing in the living area. “The total R factor is around R50 whereas a normal building would have an R28. In the summer the heat does not penetrate through the roof. When it is 40° C outside it is a cool 20° C inside without using a fan or air con-ditioning. This winter I was gone for several months. When I left it was 22° C inside. When I returned it was 15° C. The place was kept warm with two small baseboard heaters set on low. When I got here I fired up the woodstove and the temperature quickly rose to a comfort-able 20° C within the hour.”

INFO

To learn more about this amazing home and to fi nd information on why you may want to build one visit www.domediva.com.

• Specialty Lumber• Custom Log Homes• Structural Insulated

Panel Homes• Custom Timbers• Log Cabin Siding

• 1x6 & 2x6 Tongue & Groove

• 1x8 Channel Siding• Wide Plank Flooring & Custom Mouldings

265 CN Junction Road, Kamloops250-314-1172 or Toll Free 1-877-312-1172

www.troutcreekenterprises.com • www.troutcreekhomes.com

Pre-Manufactured Homes, Cottages & Specialty Millwork

Locally Manufactured

Homes, Cottages & Specialty Millwork

Locally Owned and Operated265 CN Junction Road, Kamloops

250-314-1172 or Toll Free 1-877-312-1172www.troutcreekenterprises.com • www.troutcreekhomes.com

• Specialty Lumber• Custom Log Homes• Structural Insulated

Panel Homes• Custom Timbers

• Log Cabin Siding• 1x6 & 2x6 Tongue & Groove• 1x8 Channel Siding• Wide Plank Flooring &

Custom Mouldings

VISIT OUR RETAIL LOCATION JUST OFF THE YELLOWHEAD HWY. 1 MILE NORTH OF HALSTON CONNECTOR

PROUD TO BE

PART OF THE 2011

Y DREAM HOME!

sip sip sip panelpanelpanelpanelpanelpanel

supplier supplier supplier supplier supplier supplier supplier supplier supplier for the 2011for the 2011for the 2011for the 2011for the 2011for the 2011for the 2011for the 2011for the 2011

Y dreamY dreamY dreamY dreamY dreamY dreamY dreamY dreamY dreamY dreamY dreamY dreamY dreamY dreamY dreamY dreamY dreamY dreamhomehomehomehomehomehome

CUSTOM HOMES AND COTTAGE KITS Structural Insulated Panels | Pre-Built | Pre-Insulated | Pre-Packaged | Ready for Delivery | Easy Assembly