By CAROL MAXWELL & E.S. GURDJIAN, F76350

Transcript of By CAROL MAXWELL & E.S. GURDJIAN, F76350

ALTERNATIVE ENERGY SYSTEMSP A R T I I

Understanding solar panel structureand performance,

By CAROL MAXWELL & E.S. GURDJIAN, F76350

The following article is part II of athree-part series about alternativeenergy systems. In Part 1 (Novem-ber 1997, page 98), the authorsdiscussed their quest for energyindependence and their early expe-riences with solar power. Part III,which focuses on wind power, willappear in the January 1998 issue.

olar panels are becoming morepopular among motorhomers.Having a better understanding of

the different types of solar panels andhow they work will help coach ownersto make purchasing decisions and toobtain the maximum efficiency from asolar electric system.Solar cell composition. Solar cells arePN junction photodiodes. To understand the term PN junction, one mustfirst understand some aspects of semiconductors. Under certain conditions,semiconductors can act like conductorsor insulators. Semiconductors are madefrom crystals. Silicon, the main com-ponent of sand, makes up about 28 percent of the Earth’s crust and is the mostwidely used crystal for semiconductors.Because of intrinsic positive and nega-

tive attributes, cadmium telluride orgallium arsenide can be used as alter-native crystals in the manufacture ofsolar panels. Gallium arsenide panelsare employed for satellite and otherspace applications.

Silicon crystals are created byheating silicon to the melting point.Pure silicon, although inexpensive, isinert and not very useful. To createpositive and negative crystals, a smallamount of either boron or phosphorousis added to the liquid silicon. This pro-cess is called “doping.” From this liq-uid, crystals are grown and cut intowafers. Those wafers with boron areP-type (positive) silicon, and thosewith phosphorus are N-type (negative)silicon.

The silicon atom has four electronsin its outer shell. In the crystallineform, adjacent silicon atoms sharethese four electrons. Boron has onlythree electrons in its outer shell. Hav-ing one less electron creates a hole inthe P-type silicon crystal. A neigh-boring electron can jump into thishole. This creates a hole elsewhere, sothe hole appears to move. Phospho-rous has five electrons in its outer

shell. This extra electron can movefreely in the silicon crystal. Both holesand electrons can conduct electricalcurrent.

When a P-type crystal and an N-type crystal are layered together, a PNjunction is created. All PN junctionsare light sensitive to varying degrees.When illuminated, a PN junctionphotodiode (solar cell) may be eitherphotovoltaic, meaning it is the sourceof current, or photoconductive,meaning it carries the current.

Solar panels are photovoltaic. Aphotovoltaic cell is capable of pro-ducing a voltage when exposed toradiant energy especially light. As arenewable power source, solar panelshave no moving parts and no chemicalreactions that could create undesirableend products.

One way to understand how a solarpanel works is to think of it as a pump.A particle of light, the photon, is thefuel for the pump. The photon strikesthe photovoltaic material, exciting theouter electrons on the silicon atoms.As the electrons jump the PN junction,a voltage potential is created and cur-rent flows. Continued

S

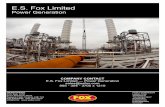

Solar panel station at the U.S.Army at Yuma Proving Grounds

64 December 1997 FMC

The electrons flow from the negativeterminal of the solar panel, through thebatteries and then back to the positiveterminal of the panel.

Types and performance. There aretwo main types of solar cells: rigid crys-talline cells and thin film flexible amor-phous cells. Rigid crystalline cells maybe a single crystal thick, and are used insolar panels manufactured by Siemens.Another version of the rigid crystallinecell is the polycrystalline type used insolar panels produced by companies suchas Kyocera and Solarex.

As mentioned, the second type of so-lar cell is the thin film flexible amor-phous type. Generally, the amorphoustype is less expensive, because lessphotovoltaic material is required. Onesource stated that the amorphous typeuses only 1 percent of the photovoltaicmaterial as a similarly sized crystalline-type panel does. Amorphous panels aresubject to a 15 to 30 percent degradationof output, which usually occurs withinthe first three to six months of use. Therate of degradation is dependent on theamount of exposure to sunlight. Therigid crystalline panels have an effi-ciency of approximately 13 per-cent andthe amorphous type approximately 6

percent. The life expectancy of the crys-talline type ranges anywhere from 10 to30 years. The life expectancy of theamorphous type has not yet been deter-mined.

Some solar panel sales literature im-plies that the panels have an almost in-definite life. However, even though thephotovoltaic material itself does not de-grade or deplete, the packaging compo-nents are subject to degradation, whichaffects the panel’s output. The packagingrefers to all other components, includinggrid wires, electrical collectors, otherelectrical connections, and the glasscover. Solar panels are heated by sun-light during the day and then becomecooler at night. The resulting expansionand contraction of the various compo-nents leads to a gradual deterioration anddiminished output over the years. Also,blowing sand can scratch the glass cover,and that can impede the light and de-crease energy output.

So, although the photovoltaic mate-rial may last forever, the solar panel it-self has a definite life expectancy. It’snot unusual for a solar panel to be underwarranty for 10 years. Siemens recentlyextended the warranty on its panels to 25years. The warranty applies to panels of

45 watts or more (SM or SP models)purchased after March 1, 1997. The war-ranty, which is transferable to subse-quent owners, guarantees that the panelwill retain 80 percent of its rated capac-ity for the warranty period.

Light and temperature factors.Various sales claims are made for solarpanel performance in low light condi-tions. Figure 1 shows the typical powerresponse to various light levels, ex-pressed as watts per meter squared(W/M2).The consumer should be aware thatpanel performance is most dependentupon engineering design. Panels can beengineered for optimal performance inlow light, direct light, or ranges in be-tween. Panels used in space can achievegreater efficiency ratings, because theyare designed for bright light conditionsand use a light-focusing cover. Suchpanels require a two-axis positioner toremain perpendicular to the sun at alltimes. Low light performance is not afactor.

Solar panel output voltage is relatedto operating temperature. Manufacturers’specifications are often shown for indus-try standard conditions at a cell tem-perature of 25 degrees Celsius, but amore common condition in practice is acell temperature of 47 degrees Celsius.It is important that the panel(s) be ableto provide more than 14.6 volts at oper-ating temperatures. Don’t forget to allowfor line losses between the solar panelsand the batteries.

Solar panel cells are wired in series,each producing approximately 0.5 volt.The size of each cell determines the am-perage. Panels described as self-regulating have 30 cells. Unregulatedtypes have 33 or 36 cells. To work prop-erly, the self-regulated panel(s) must besized to an appropriate battery bank.Manufacturers usually provide the sizingspecifications. Note that the maximumoutput voltage for a self-regulating panelis 14.5 to 14.6 volts at 25 degrees Cel-sius. At operating temperatures, thevoltage will be less. As the battery ap-proaches a full charge, the amperagesupplied by the panel approaches zero,because of the decreasing differentialbetween the solar panel voltage and thebattery voltage.

Figure 1. The IV Curve (current versus voltage) demonstrates typicalpower response to various light levels, measured in watts per square me-ter, at 25 degrees Celsius cell temperature and 47 degrees Celsius celltemperature. With lower light conditions, the effects of temperature areminimized.

64 December 1997 FMC

Regulators. Many experts prefer notto use self-regulated panels for seriousbattery charging, because too many vari-ables exist. The preferred method is touse high-voltage panels with a seriesrelay controller or a shunt-type regulator.A shunt-type regulator uses a blockingdiode to direct a one-way flow of currentfrom the solar array to the batteries.When the battery charge set-point volt-age has been reached, an internal shuntin the regulator conducts the output ofthe array back to itself. A series relayregulator simply turns off the flow of current when the battery reaches its chargeset-point voltage. When a load is appliedand the battery voltage drops, the relaycloses and current is allowed to flow.The relay can be internal or external tothe regulator.

The regulator capacity is determinedby the relay capacity, Relays of 20, 30,and 70 amps are available. Either type ofregulator may function by turning off ata certain high voltage set point andturning on at some lower voltage setpoint. Some regulators are capable ofthree-stage charging, while others areable to charge with partial output, keep-ing the battery voltage at some interme-diate point, or “floating” the batteries.

Shunt regulators tend to run hot as aresult of having to dissipate the output ofthe solar panels. This heat creates somereliability problems. Mechanical relaysused in the series relay regulator aresubject to failures, because of the repeti-tive opening and closing of the relaycontact points. Our high-output systemhas a series relay controller with a 70-amp relay, but we have not experiencedfailures, because we rarely achieve a fullcharge status; therefore, the relay cyclesinfrequently. However, if the relayshould fail, it is easy and inexpensive toreplace.

A phenomenon of reverse current canoccur when solar panels are not charg-ing. Reverse current can be caused bynightfall or shade. If caused by shade,this decreases output and also increasesheat, which leads to a further decrease inoutput. To prevent this reverse current,some manufacturers of high-voltagepanels incorporate a bypass diode in

each panel. One of three methods canprevent reverse flow at night. The first isto use diodes on each panel, as previ-ously mentioned. The second is to use aproperly heat-sinked line diode of suit-able capacity. The third method is to usea regulator that turns off when the solarpanel voltage drops. The regulator mayuse an internal diode or a relay.

Solar panels equipped with diodescan be wired for 24-volt operation with-out adding any extra diodes. To accom-plish this, create individual series stringsof two panels and then parallel thesestrings to obtain the required current.

Positioning factors. The U.S. Army

at Yuma (Arizona) Proving Grounds hasinstalled a 450-kw solar power stationequipped with 8,148 Siemens M55 pan-els, which can supply 7 percent of thefacility’s existing peak power demandrequirements. In case of a complete gridfailure, the solar power station can sup-ply 100 percent of the water plant con-sumption and emergency power forcommunications.

Yuma’s solar panel array is not tiltedtoward the sun, but it does have east to-west, single-axis tracking. According toJack Nixon of the Proving Grounds, sin-gle-axis tracking increases output byapproximately 15 percent, while addinga second axis increases efficiency byonly 2 to 4 percent. For Yuma, the costof two-axis positioning was not worththe small increase in efficiency. Trackingeast to west utilizes early morning andlate afternoon sun light, which is notavailable in a stationary array.

For motorhome applications, a two-axis tracking system has been manufac-tured to position a small array (two tofour panels). We have also seen a track-ing system fashioned from a manual CBand satellite antenna positioner. How-ever, it is usually more practical andmuch less expensive to tilt panels per-pendicular to the seasonal inclination ofthe sun and not worry about daily track-ing.

Sun spots. The tropic of Cancer andthe Tropic of Capricorn are imaginarylines that trace the boundaries of theearth’s tropical zone. The lines mark thefarthest limits north (Cancer) or south(Capricorn) of the equator where the suncan appear directly overhead. On March21 and September 21, the sun is directlyover the equator. On June 21, the sun isover the Tropic of Cancer in the North-ern Hemisphere. On December 21, it isover the Tropic of Capricorn in theSouthern Hemisphere.

The tropics lie 23 degrees, 27 minutesnorth and south, respectively, from theequator. With this in mind, you can usethe date and the latitude of your locationto position solar panels perpendicular tothe sun for optimal energy output. Usethe following for-

This graphic depicts the processwherein light is transformed intousable energy. Sunlight (top verti-cal lines) lands on the solar panel.The three cubes (from top to bot-tom) depict the solar panel regu-lator/controller, the storage battery,and the inverter. The end result isan electrical device powered bysolar energy — in this case, a lightbulb.

68 DECEMBER 1997 • FMC

mulas as a guide. (Any atlas willindicate the latitude of your posi-tion.)

Date FormulaMarch 21

&September 21

Your latitude+ 0 degrees

June 21 Your latitude - 23 ½ degrees

December 21 Your latitude+ 23 ½ degrees

Consider the following examples:In Minot, North Dakota, on July

4, solar panels should be tilted atlittle more than 24 degrees (48 - 231/2). On Labor Day, the panelsshould be tilted at a little less than48 degrees (48 + 0).

In Yuma, Arizona, on December21,the panels should be tilted at 55degrees (32 + 23 1/2) and onMarch 21, at 32 degrees (32 + 0).

In Key West, Florida, on June21, the panels should be nearly flat(24 23 1/2) On December 21, theyshould be tilted at 47 degrees (24 +23 1/2).

The earth is tilted 23 ½ degreeson its axis. In the summer, days be-come longer the farther north youtravel, and shorter the farther southyou travel. Conversely, in the win-ter, days become shorter the farthernorth you travel and longer the far-ther south you travel. For example,on December 21 in Austin, Texas (at30 degrees latitude, slightly south ofYuma), there are approximately 10hours of daylight. In Denver (at 40degrees latitude), there is approxi-mately 9 hours and 20 minutes ofdaylight. In Minot (at 48 degreeslatitude) there are approximatelyeight hours of daylight. On June 21,there are approximately 14 hours ofdaylight in Austin, 15 hours in Den-ver, and a little more than 16 hoursin Minot. Without a solar trackingdevice, effective solar power pro-duction time will be three to fourhours less than the total number ofdaylight hours.

Solar panels are a valuable ad-junct to an electrical system and arebecoming increasingly popular inthe motor-home market. To be ef-fective, the solar array must be sizedto the individual application. Sea-

sonal factors will affect the effi-ciency of any system. Because of thelength of daylight hours duringwinter, it may be difficult to obtainsufficient charging; therefore, an ACgenerator is still an important part ofthe charging system.

For more information about solarpower, you may want to refer to thefollowing sources:• Wiring 12 Volts for AmplePower by David Smead and RuthIshihara, $20. This book is availablefrom PowerTap Inc., 6315 NWSeaview Ave., Seattle, WA 98107;(800) 541-7789 (phone orders withVISA, MasterCard, Discover), (206)789-1138.• A revised edition of Living on 12

Volts with Ample Power by Smeadand Ishihara will be available in thespring of 1998, also from PoweTapInc.• RV Electrical Systems by Billand Jan Moeller, $19.95, plus ap-proximately $4 shipping and han-dling. This book is available fromTAB Books, a Division of McGraw-Hill, P.O. Box 548, Black Lick, OH43004; (800) 262-4729.• Getting Started In Electronicsby Forrest Mims III, $4.99. RadioShack catalog No. 62-5003; (800)843-7422.