Butterfly

Click here to load reader

-

Upload

sergio-de-manuel-galvez -

Category

Documents

-

view

217 -

download

2

Transcript of Butterfly

From the publishers of

IN THIS ISSUE

PLAN OFTHE MONTH

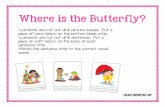

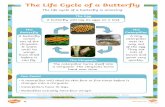

1 Butterfly A true indoor flyerby Dave Robelen

2 On the Flyby Debra Cleghorn

MODEL REVIEW

4 WattAge Micro Flyer World’s smallest RTFby Bob Aberle

MODEL REVIEW

6 Matchless Aero Micro Edgling by Roger Carignan

PRODUCTREVIEW

9 Hobby Lobby Intl.Axi 2204/54 Brushless Outrunner Motorby Bob Aberle

PRODUCTREVIEW

10 Bob Selman Designs LiPC2080Li-poly Chargerby Matt Keennon

12 Cloud 9RTF World Expandsby John Worth

16 SOURCE GUIDE

ON THE WEBSITErcmicroflight.com/jan05

With the winter flying season upon us, I’vebeen thinking in terms of a “true” indoor RC

model. What do I mean by “true”? In this case, the modelshould have a very light wing loading and be capable of maneuvering in tight quarters.To keep the cost down, I chose the popular RFFS-100 receiver and actuators for control.This allows me to create a design that uses a single Li-poly cell for power. Meanwhile,the well-known Mabuchi M20 (KP-00) drive develops good power on a single Li-poly cell.

MIC

RO FLYER

P

THP

LA

N

OF THE M

ON

TH

JANUARY 2005

RCMICROFLIGHT.COM

A true indoor flyerby Dave Robelen • [email protected]

2 RC MICROFLIGHT

CONCEPT ENGINEERINGFrom the beginning, I decided to treat this projectmore like an RC indoor free-flight model and use thematerials and techniques typical of the constructionof these models. In certain areas, I went outside ofthe hobby to find parts and materials that wouldyield the best result. For example, I found an excel-lent gear set in a broken battery-operated alarmclock (the sort that works on one AA cell). This gaveme the desired 6:1 ratio to drive a larger, more efficient propeller with the same motor. In othercases, I selected materials from free-flight specialtybusinesses to get the lightest model.

My “role model” for this project was the SkyHooks & Rigging Mosquito. Its handling qualities aresuperb and well worth imitating. My first effort was toduplicate much of the Mosquito with thinner, lightermaterials, along with changing to a V-tail. The V-tailworks well and keeps the delicate tail farther fromthe surface when landing and taking off.

I built the first version fairly quickly. The weatherwas unusually calm, so I headed out for a test flight.Big surprise! The Butterfly went about 5 feet from ahand-launch and proceeded to dive steeply to theground. Not believing these results, I tried again,holding up-elevator—no change. I had built an

unflyable airplane! Reviewing the problem, I realizedthat the wings were twisting a lot under load andwere losing lift. Armed with this information, I builtanother, stiffer set of wings and headed out again.Problem solved! The Butterfly cruised at 30- to 40-percent throttle and turned in a 6-foot circle.Meanwhile, it could fly really slowly and was aboutas gentle as they come.

CONSTRUCTION HINTSWood selection. There is nothing especially trickyabout the basic structure, but some of my materialschoices and techniques are worth discussing. Balsais a marvelous material, but it can be mighty rustrating to find the “magic” piece for the job. Thosewho follow my articles are used to my specifying“light” balsa for a project. To be specific, wood forthis application should weigh no more than 6 gramsfor each 1⁄32 inch of thickness in a 3x36-inch sheet.The problem goes deeper, though. This light woodcan be cut in a variety of ways, dramatically affecting its stiffness and quality.

Probably the best way to get just the rightamount of suitable wood is to purchase it from oneof the indoor specialty supply houses that servicesthe free-flight community. I recommend IndoorModel Supply (indoormodelsupply.com) as a sourceof excellent wood, and they also carry Polymicro, aspecial lightweight covering. Dave Lewis(homefly.com) is a very good source for the smallcarbon-fiber rods and ball bearings as well as a lotof other great indoor supplies. Dynamics Unlimited(slowfly.com) also carries carbon-fiber rods as wellas a line of light RC equipment. Bob Selman (bsdmicrorc.com) has some great stuff, too. Checkout all of these folks, and you will find all the “goodies” needed to build a Butterfly.

Covering tips. Because I was going to use a clearcovering on my Butterfly, I chose to paint the wood-work before covering it. I used Krylon spray paint, andit added a total of 0.5 gram to the model. I am veryfond of CA in my work, but it is incredibly easy toapply too much to these light structures. By the way,I am talking about medium-thickness CA. I either usea nozzle with a very small hole for application, or I put

BUTTERFLYLeft: the fuselage parts, readyto be assembled. Be sure touse the light wood specifiedin the “Construction Hints.”Below: the covering materials.Krylon spray paint and light-weight Polymicro yieldedexcellent results for myButterfly. I used a hot solder-ing iron to trim the edges ofthe film.

Welcome to our first newsletterof 2005! We look forward tobringing you the latest news onsmall RC as micro flyers con-tinue to push the envelope.

This month’s featured plan is yet anotherwinner from the workshop of master modelerDave Robelen. A true indoor flier, Dave’sButterfly features built-up construction andmagnetic actuator controls. Dave’s articlehighlights construction tips and tricks forbuilding lightweight models and, if you buildthis plane, he notes, “you may get ‘hooked’”on this peppy, ultralight style of flying!

The smallest ready-to-fly plane available,the WattAge Micro Flyer flies incredibly welland is destined to attract many first-timepilots to RC. But don’t discount its appeal toexperienced modelers: this great little designjust begs to be tinkered with! We’ve alreadyseen biplane Micro Flyers, and other varia-tions are surely underway as I write. Why notuse its power and control systems in yourown design? The possibilities are only limitedby your imagination.

Roger Carignan test-flies the MatchlessAero Micro Edgling 3D, a built-up aerobaticplane powered by a KP-00 motor on 2,170mAh Li-poly cells. This lightweight show-stopper has just a 16-inch wingspan and isquite possibly the smallest model ever to perform 3D maneuvers! Check out Roger’sassessment on page 6.

Brushless outrunner motors are rapidlygaining in popularity for larger electrics, andnow Axi has added a micro version to itslineup. Distributed by Hobby Lobby Intl., the2204/54 weighs just 0.8 ounce and isdesigned to be powered by 2 Li-poly cells.Read more about this little powerhouse inBob Aberle’s review this issue.

In another product review, Matt Keennontests the latest Li-poly charger from BobSelman Designs, the LiPC2080. This $25 unitis ideal for charging small-capacity cells likethe popular Kokam 20mAh as well as Li-polycells up to 145mAh. Matt’s writeup starts onpage 4 this month.

In “Cloud 9,” founding editor John Worthshares news of some interesting new ready-to-fly planes, insight on differential-thrust control,the latest magnetic-actuator design, a 3.5-gram outrunner motor from India and more.

Here’s to 2005! Safe landings.

Debra [email protected]

FLYTHEON

Wingspan: 25 in.

Length: 17 in.

Wing area: 138 sq. in.

Weight: 23g

Wing loading: 0.85 oz./sq. ft.

Power system: Mabuchi M20 LV motor geared 6:1

Propeller: 5x4

Battery: 170mAh Li-poly

No. of channels: 3

Radio system: RFFS-100 receiver and actuators

Flight duration: 15 to 20 min.

Comments: the Butterfly is a true indoormodel with a minimum speed that’s lowenough for flights in very tight quarters. Its con-struction is not complicated but makes use ofspecial lightweight materials and techniques.The model has superb handling qualities with a3-foot turning radius and a rapid rate of climb.Cruising at 30- to 40-percent power, flights lastbetween 15 and 20 minutes on a full charge.The minimum flying area is a large recreationroom or small social hall.

SP

EC

IFIC

ATIO

NS

a puddle on a scrap of wax paper and then transferdrops to the joints with a toothpick.

Working with really light covering such asPolymicro is another area that requires a variety ofmethods. For one thing, forget about cutting thisstuff with a blade; it will tear, and you will get reallyfrustrated. A hot tool such as a soldering iron doesa super job of slicing as needed. I use 3M Super77 spray cement to attach the film to the frame-work, but there are special techniques involved toget the best result.

Start by laying a clean, flat sheet of paper onthe work surface that is larger than the part to becovered. Unroll a length of plastic film onto this, andslice it off the roll with the soldering iron. Workslowly, and smooth away any wrinkles. Spreadsheets of newspaper over about 6 feet of floor inyour work area. Begin by laying a wing panel right-side up in the center of the newspaper. Holding thecan of contact cement about 3 feet above thestructure, lightly dust the frame with a mist of glue.Carry this sticky frame to the plastic, and lay it glue-side down on the plastic. Rock it back and forth toattach it completely. I found that I could also get atail half on the same sheet before I began trimming

the parts. Next, run the hot soldering iron aroundthe edges, and the job will be half done. There isstill some time to work around the edges andsmooth out small wrinkles while the glue is damp.Please be sure to clean up all the messy newspaper before someone walks on it! One morething: avoid the temptation to heat-shrink the covering because this will surely warp the structure.

Miscellaneous hints. I am fond of using Hutchisoncontrol horns for these models, and a few strips offrosted mending tape cut1⁄4-inch wide make finehinges attached to theuncovered side of thecontrols. You can makepushrods out of 0.5mmcarbon-fiber rod withbrass wire ends andsmall lengths of heat-shrink tubing to holdthem together.

Along with specialbuilding methods for areally light model, you will

need a safe method to store and transport them. Acardboard box of suitable size works great. It keepsthe dust off in the shop, and you can walk from thecar to the gym in a strong wind with no problem.

You will notice that I marked the dimensions onthe plan sheet in decimal format. You will be slicingyour own strips of wood to the various sizes, andthis system of measurement is more precise. One ofmy favorite tools is a 6-inch-long steel ruler withdecimal graduations. These can be found in toolcatalogs and in stores such as Sears.

The Butterfly is anexample of a peppy,ultralight indoor flyer,and you may get“hooked” on this styleof model. I certainlyhope so; I have! �

MFP0105A ButterflyDesigned by DaveRobelen, this indoor modeluses typical free-flightconstruction methods andmaterials. WS: 25 in.; L: 17 in.; power: gearedMabuchi M20; 1 Li-polycell; 1 sheet; $12.95

FREE! Download this plan from rcmicroflight.com.

January 2005 3

The Hutchison micro plastic horns work great. The lightweight drive has plenty of pep. The control installation.

The actuators areready to beinstalled in theplane. They provideexcellent responsefor indoor flying.