BURNDY...Copper compression connectors are manu-factured from high-conductivity electrolytic copper....

Transcript of BURNDY...Copper compression connectors are manu-factured from high-conductivity electrolytic copper....

BURNDYCompression

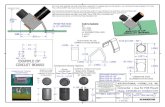

ONE HOLE HYLUG™CODE CONDUCTORSTANDARD BARRELNARROW TONGUE

TYPES YA-L-NT

COPPER COMPRESSIONNARROW TONGUETERMINAL

UL LISTED 90°C, 600VOLT TO 35 KV «•

DIE AND COLORCODE INFORMATION

ELECTRO-TINPLATED CABLE

ACCOMMODATION

<gFig. 2 Fig. 3

Catalog NumberYA8CLNT6YA6CLNT6YA4CLNT10

YA3CLNT516

YA2CLNT10YA2CLNT14YA2CLNT516YA1CLNT10YA1CLNT14YA25LNT10YA25LNT516YA26LNT10YA26LNT516YA26LNT516UYA26LNT38YA27LNT38YA28LNT38YA29LNT38VA29LENT38VA30LNT38YA31LNT38YA32LNT38YA34LNT38YA36LNT38YA39LNT38

Fig#111

1

111111111111111111111

Conductor

AWG#8 AWG#6 AWG#4 AWG#3 AWG#2 SOL

#2 AWG

#1 AWG

1/0 AWG

2/0 AWG

3/0 AWG4/0 AWG

250 kcmil

300 kcmil350 kcmil400 kcmil500 kcmil600 kcmil750 kcmil

MM:

---

25

-

50

70

-

120

150--

240300

Stud HoleSize66

#10

5/16"

# 101/4"

5/16"#101/4"#105/16"# 105/16"

3/8"3/8"3/8"

3/8"

3/8"3/8"3/8"3/8"3/8"3/8"

TongueWidth.29".29".40"

.49"

.48"

.50"

.49"

.50"

.50"

.62"

.62"

.62"

.62"

.62"

.72"

.76"

.76"

.96"

.76"

.96"

.96"

.96"

.96"1.12"1.12"

Length(L)

1.08"1.45"1.73"

1.80"

1.80"1.80"1.82"2.23"2.23"2.28"2.28"2.62"2.62"2.62"2.48"2.73"2.67"2.96"2.96"2.97"3.31"3.21"3.65"4.09"4.24"

TongueAngle

StraightStraightStraight

Straight

StraightStraightStraightStraightStraightStraightStraightStraightStraightStraightStraightStraightStraightStraightStraightStraightStraightStraightStraightStraightStraight

Installation ToolingMechanical

MD7-34RW8CVT(1)W5CVT(1)W4CVT(1)

W3CVT(1)

W2CVT(1)

W1CVT(1)

W25VT (2)

W26VT (2)

W27VT (2)W28VT (2)W29VT (2)W29VT (2)W30VT (4)W31VT(4)W32VT (4)W34VT (4)

--

HydraulicBCT500Y500CT

X8CRT(1)X5CRT(1)X4CRT(1)

W3CVT(1)

X2CRT(1)

X1CRT(1)

X25RT (2)

X26RT (2)

X27RT (3)X28RT (3)X29RT (4)X29RT (4)

--

Y750-2/Y46C'BAT-750CU8CRT(1)U5CRT(1)U4CRT(1)

U3CRT(1)

U2CRT(1)

U1CRT(1)

U25RT(1)

U26RT(1)

U27RT(1)U28RT(1)U29RT(1)U29RT(1)U30RT (2)U31RT(2)U32RT (2)U34RT (2)U36RT (2)U39RT (2)

COLORCODERedBlueGray

White

Brown

Green

Pink

Black

OrangePurpleYellowYellowWhiteRedBlue

BrownGreenBlack

DIEINDEX

4978

9

10

11

12

13

14151616171819202224

WIRESTRIP

LENGTH1/2"7/8"7/8"

15/16"

15/16"

15/16"

15/16"

1"

1-1/16"1-1/8"1-1/8"1-1/8"1-1/8"1-3/16"1-1/4"

1-7/16"1-3/4"

1-15/16"

' Use P-UADP-1 adapter with "U" dies in Y46 HYPRESS™A See tooling section of this, catalog for complete tool and die listings. Use ONLY color-coded die recommendations for "-FX"

connectors. For nest/indentor system contact factory.* For applications greater than 2000 Volts consult cable manufacturer for voltage stress relief instructions. r>

BURNDYCompression

INTRODUCTIONMEDIUM AND LARGE HYDENT™

Copper and aluminum compression terminalsand splices for terminating conductors from#8 AWG through 2000 kcmil.

The medium and large HYDENT™ line isdesigned for terminating and splicing mediumand large conductors in electrical powerapplications.

HYLUG™

UNINSULATED COPPERCOMPRESSION TERMINALS

UL LISTED 90°C,600 VOLT TO 35kV »

BURNDY's HYLUG™ terminals, types YA,YA-TC, YA-L, YA-L-TC, YA-2N, YA-2TC, YA-L-TC-FX, YA-L-2TC and YA-2LN are designedfor terminating copper conductors in a widevariety of electrical connections, includingheavy-duty industrial, utility, commercial andtelecommunications applications.

The HYLUG™ terminals require simple cablepreparation for an easily installed permanentand inspectable cable termination. The termi-nals are listed by UL (UL STD.486A) and CSAcertified to 600 volt, when applied with theproper tool and die combination. The termi-nals may be used in applications to 35KV.See each catalog page for UL 35kV listings.

Features and Benefits• Manufactured from seamless high

conductivity electrolytic copper tubingwith heavy duty wall thickness.0 Provides maximum conductivity, low

resistance and ductility for an excellentcombination of electrical and crimpforming properties.

• Barrel diameter closely matchescommercial (code) cable and navycable diameters.0 Provides an excellent relationship

of the conductor/connector combinationto produce a high quality electrical con-nection with the recommended tooling.

• Electro-tin plated. Electro-lead plated.Burndy's proprietary brite finish.0 Provides durable long-lasting

corrosion resistance.• Internally beveled barrel end.

0 Provides easy cable insertion.• Each connector is clearly marked with

the wire size and type, die index, andcolor coding.0 Provides easy identification and proper

tooling recommendation.

Marked with the proper number andlocation of crimps.0 Lowers installed costs. Provides for

proper installations.Proper compression systems forms ahomogeneous mass.0 The result is an excellent electrical

connection.Use up to 35KV as indicated.0 Suitable for high voltage applications.Expanded wire ranges when usingY644 HYPRESS™ Dieless "1" Crimp.0 Provides ability to complete emergency

repairs when connector and wire sizedo not match.

Crimp areas clearly marked.0 Provides correct number and location

of crimps for proper installation.• Hydraulic and Battery tooling crimpembossment.0 Provides permanent die index number

embossment on completed crimp forinspection purposes.

IBURNDYCompression

I

r

STRANDED"CODE"

CLASS "B"CABLE

STD. LENGTH

LUGS

LONGBARREL LUGS

COPPERSPLICES

REDUCERADAPTER

COPPERTAPS

ONE HOLE

NARROW TONGUE

NARROW TONGUE TWO HOLE

TWO HOLE

YA-L. YA-L-TC

YA-L-NT

YA-L-2NT

YA-2L. YA-2LN.YA-L-2TC

C - 6 - C 1 1

C12

C47

C40 - C46

ONE HOLE

TWO HOLE

FOUR HOLE

YA. YA-TC, YAZ

YA-2N, YA-2TC, YAZ

YA-4N.YAB-4N

C13-C21

C48 - C60

C8t

STANDARD LENGTH

LONG BARREL

YS-L

YS, YS-T, YSP-T

C90

C91.C95

REDUCER ADAPTER Y-R C92

TEE

C-TAP

LIGHT DUTY C TAP

YST NYT

YC-C

YC-L

C105-C106

C98

C97

ONE HOLE

ONE HOLE-WIDE BELLED ENTRY

ONE HOLE-LEAD PLATED

TWO HOLE

TWO HOLE-LEAD PLATED

YA-L, YA-L-FX, YAV, YAV-L-FX

YA-LB

YAG-L-TC-LD

YA-L-2TC-FX, YAV-L-2TC-FX

YAG-L-2TC-LD

C22 - C27

C2B

C29 - C34

C61 - C67

C68 - C74

r^

ALUMINUM

t

LUGS

TRANSFORM.LUG KIT

STACKINGADAPTER

PINADAPTER

SPLICES

REDUCERS

TAPS

——

ONE HOLE

TWO HOLE

YA-A, YA-A-TN

YA-A

C110-C111

Ct12

YA-A-KIT C114

ASA-U cm

STRAIGHT

OFFSET

AYP

AYPO

C115.C116

C115.C116

STANDARD

TAPERED FOR HIGH VOLTAGE

YS-A

YS-AT

C117.C118

C119

YRB C120

H-TAPS YFD. YFN, YFO, YFR C121

BURNDYCompression

COMPRESSIONCONNECTORSBurndy's compression connectors aredesigned for reliable and controllable electri-cal connections. The complete installation isfully inspectable. They are high conductivitycopper and operate cooler than the wire onwhich they are installed. The connectors with-stand a wide range of electrical and environ-mental conditions, including current surges,temperatures, corrosion and vibrations, for awide variety of applications. These featuresmean a consistently high quality connectionat a low installed cost.

Copper compression connectors are manu-factured from high-conductivity electrolyticcopper. The connectors are normally tin-plated, lead-plated, or plated with proprietaryBurndy brite finish to provide durable long-lasting corrosion resistance. The connectordesign has been matched to the cable size toprovide the necessary physical strengthrequirements for reliable electrical perfor-mance.

Aluminum compression connectors are man-ufactured from high conductivity, high puritywrought aluminum. They are designed withsufficient mass and are electro-tin plated tominimize corrosion due to galvanic actionbetween dissimilar metals. The connectorbarrels are pre-filled with PENETROX,Burndy's oxide inhibiting compound.

PENETROX contains homogeneously sus-pended metallic particles which penetrate thewire's oxides to establish excellent continuitybetween the individual strands and the con-nector barrel for a low-resistance connection.PENETROX maintains'an air-tight connec-tion. Each barrel end is covered with a color-coded plastic dust cap which prevents foreignmatter from entering the connector before it isused. The connector design has been engi-neered to match the cable size to provide thenecessary physical strength requirements forreliable electrical performance.

SELECTION AND USECopper compression connectors are recom-mended for use on copper conductors.Aluminum compression connectors are rec-ommended for use on aluminum conductors.Dual-rated aluminum compression connec-tors may be used on both copper andaluminum conductors.

Two basic compression designs are available:Circumferential and indent.

Circumferential//::>. compression is solid\|t̂ and symmetrical.

No sharp "Flash".

fa, Indent compression•~ The connector is swaged

to trie conductor.

After compression, virtually all the air isremoved leaving a tight homogeneous massof connector and conductor.

The circumferential crimp design is recom-mended for color coded connectors in lowand high voltage applications. Die index num-ber embossment provides an easy inspectionwhere required to verify the use of the properconnector/die combination. It is also recom-mended for insulated connectors and for ter-minating flexible and welding cables.

The circumferential crimp design dies com-press cable strands into polygonal shapesforming intimate contact with each other andthe connector barrel. This compression formsa tight homogeneous mass with virtually noair pockets. The circumferential crimp pro-vides an excellent electrical connection withhigh pull-out values. The circumferential crimpis ideal for high voltage applications leavingthe connector barrel symmetrical, which iseasier to insulate.

The indent type crimp can be used in virtuallyany application except polyvinylchloride(PVC) insulated terminals and splices. It is anexcellent means of terminating flexible, extraflexible and welding cables. The indentorcompresses the cable strands to form inti-mate contact with each other and the con-nector barrel. The result is an excellent elec-trical connection with high pull-out strength.Laboratory work testing curves establishedthe proper depth and shape of indent for eachtype of connector and wire combination.

"HDOLINCTooling systems are essential for properinstallation of a compression connector.Since connectors and dies are designed as aunit for specific wire sizes, only the recom-mended tools and dies should be used. Mostaluminum and copper HYLUG terminals andHYLINK splices are marked with a die indexnumber and are color-coded to identify thecorrect installation die. Dies marked with thematching die index number and color can beused to install the connector.

Burndy tooling installs a wide range of con-nectors, is reliable, cost effective, and preci-sion engineered for durable, long-lasting ser-vice and quality connections. The toolsinclude small plier types, full cycle ratchetdesigns and hydraulically-poweredHYPRESS heads and new Battery ActuatedTools. Some have permanent die grooves oradjustable dies, while others require achange of die sets or nest die for each con-nector size. Burndy's recommended toolsachieve crimp performance consistent withUL and other industry standards. Since sev-eral tools are suitable for most connectors,the most economical and practical tool can bechosen for each application.

NDUSTRY STANDARDSBurndy's compression terminals, splices andtap connectors requiring third party testingand approval are listed by Underwriters'Laboratories, Inc. Many have also receivedCSA approval and are approved under MIL-T-7928 and other military standards. All con-form to applicable sections of the NationalElectrical Code.

Burndy also offers connectors and spliceswhich meet the (LOCA Seismec and Aging)requirements of IEEE standards 323, 383and 344 for class 1E critical circuits for use inNuclear Utility Applications. Certification to10CFR50 and 10CFR21 available.

Detail catalog listings should be consulted toobtain the appropriate standards for eachconnector and splice.