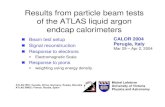

Broad Argon Beam Tools for SEM Prep -...

Transcript of Broad Argon Beam Tools for SEM Prep -...

CONFIDENTIAL (presentation title here)

Broad Argon Ion Beam Tools for SEM Prep

Mike Hassel Shearer1 & Vikstrom Hakan2

1 Gatan

2 Oxford Instruments

CONFIDENTIAL (presentation title here)

Commercial Slide

Ilion II- Argon Prep Tool

Murano in-situ EBSD Heating Stage

Oxford Instr. Nordlys EBSD System

MonoCL4- Cathodoluminescence

CONFIDENTIAL (presentation title here)

Why Is Sample Prep Important & Requires Intuitive Skill ?

FIB + 300 V Argon Polish

Argon Polish 8Kev + 1 KeV

Argon Polish 6 KeV

Titan TEM Image of Transistor Gate

SEM Image FOV 500 micron in diameter ready for EBSD

SEM Image FOV 1mm x 600 microns voids as small as 4nm visible . Key analysis in Fracking

CONFIDENTIAL (presentation title here)

Work Flow: From Bumper to Microstructure --- How ?

6

Argon Polish 6Kev + 1 KeV

CONFIDENTIAL (presentation title here)

WorkFlow for Steel and Hard Materials

Outcome:

Large Polished/Undamaged surface to use for grain size and grain orientation analysis in test samples or structural components.

This means using a SEM ( Back-Scattered Image) and EBSD.

Often this work to be done at elevated temperature (Murano).

Issues:

Large Area >500 micron x 500 microns restricts the use of FIB

Mechanical Polish requires skill and every material may require a special process. Additionally the process may require the use of chemicals (acids) to remove final damage layer.

Solution:

Broad Argon Beam Tool (Ilion II) in both cross section or planar mode.

Murano for in-Situ EBSD at Temperature

7

CONFIDENTIAL (presentation title here)

Mechanical Polishing Steps for a Specific Hardened Steel

8

STEP PG FG DP1 DP 1B DP2 DP3 OP

Surface SiC Paper 320 MD-Largo MD-Dur MD-Dur MD- Nap MD-Nap MD_Chem

Suspension

DiaPro Allegro

9 micron

DiaPro Dur 3

micron

DiaPro Dur 3

micron

DiaPro Nap B 1

micron

DP-Susp.P 1/4

micron OP-AA

Lubricant Water Blue Lub

rpm 300 150 150 150 150 150 150

Force (N) 30 30 30 15 10 10 10

Time (min) 1 5 to 10 5 5 5 5 5

Hardened Steel

Source : www.ebsd.com ( very useful Website)

Hardened steels The distorted lattice of martensite makes it difficult to get a good quality EBSD. Good results are obtained on hardened plain carbon and low alloy steels containing various amounts of martensite using a long fine diamond polishing process. Alumina (OP-AA) is preferred for final polishing to obtain a proper final result with a minimum amount of relief. The result obtained for a tool steel (9CrWmn)

CONFIDENTIAL (presentation title here)

Mechanical Polish Workflow

9

Saw Grind & Polish Acids & Cleans

Experience and Luck

CONFIDENTIAL (presentation title here)

Ilion II Workflow

10

Cut to correct size Polish to 9 microns

Ilion II

Advantages of Ilion II vs. Mechanical/Chemical Polish: • Material Neutral • No Experience Base required • No Acid/Chemicals used

CONFIDENTIAL (presentation title here)

Ilion II Cross Section Process ( 8keV 2hr. + 1keV 30 min.)

11

Ilion II Blade

9 micron diamond polish then Ilion II . No chemical etch to bring on the grain structure

CONFIDENTIAL (presentation title here)

EBSD analysis

IPF

Phases map

Martensite retained Austenite (9%)

IPF map

CONFIDENTIAL (presentation title here)

Affect of Argon Polishing Voltage on EBSD Results

see www.srim.org for details of the effect of Noble Ion Species on Sputtering ( yields, implant, damage) at LOW Voltage

CONFIDENTIAL (presentation title here)

Ilion 8keV, 122μA, 5 min

Tungsten Carbide NO Phase transformation of the Co Phase to Hex unlike prep with FIB

WC WC Co (fcc)

Ilion II Polishing of W-Carbide with Cobalt Phase

CONFIDENTIAL (presentation title here)

Argon Milling W-Carbide Compare to 8 KeV

MC4: Improved EBSD indexing

Gallium Ion beam milling damage degrades the EBSD patterns leading to poor indexing. By milling using broad Ar ion beam (Ilion) we can obtain better EBSD quality so that the patterns can be indexed automatically.

Illion 1keV, 28µA, 120 min

WC WC Co (fcc)

CONFIDENTIAL (presentation title here)

Sample 1

Cross section

AZtec user interface showing data as acquired i.e. raw data; both EDS and EBSD were acquired simultaneously.

Sample 1 Cross Section Al2O3/TiCN/WCarbide

Aztec guides the user through the set up and acquisition process, and is extremely intuitive and easy to use.

• EBSD allows a wide raft of measures, plots and maps to be obtained, and is highly complementary with EDS, a combined system provides a full analysis of the microstructure, texture, phases and chemistry amongst other advanced measures

CONFIDENTIAL (presentation title here)

Band contrast map showing a greyscale image derived from the quality of the Electron Backscatter Patterns (EBSPs); lighter shades are indicative or higher quality patterns and vice versa. This type of map can reveal fine structures and detail not visible in the electron image(s)

Sample 1 Polished at 6KeV 90 minutes + 1 KeV 60 minutes

CONFIDENTIAL (presentation title here)

Inverse Pole Figure (IPF) colour coded map for all phases

IPF colour keys for WC, TiCN, Al2O3, left to right, showing the orientation relationship with respect to colour for each of the phases.

Sample 1

CONFIDENTIAL (presentation title here)

Showing strong alignment of Al2O3 crystals (note position of cursor (cross) in each image) resulting from and indicative of the growth dynamic

Sample 1

CONFIDENTIAL (presentation title here)

Model 525 – Murano Heating Stage

Temperature range up to 950 °C , accuracy <0.5 °C , stability <0.5 °C per hour. Makes it ideal for controlled experiments.

Detachable consumable heating plate so multiple specimens can be prepared , studied and stored.

Offers ease of handling and sample preparation away from SEM.

Versatile, takes specimens up 4.5 x 9 x 1.5 mm.

CONFIDENTIAL (presentation title here)

300 µm

In-situ phase transformation observed in low carbon steel

945 °C

Specimen heated to 945 °C full transformation to Austenite phase Austenite FCC Ferrite BCC

Data courtesy – Oxford Instruments (Dr. Singh Uhbi)

CONFIDENTIAL (presentation title here)

Ferrite BCC

300 µm

In-situ phase transformation observed in low carbon steel

945 °C 0 mins 895 °C 5 mins

Murano temperature control allows transformation to Ferrite phase to be mapped.

Austenite FCC

Data courtesy – Oxford Instruments (Dr. Singh Uhbi)

CONFIDENTIAL (presentation title here)

Austenite FCC Ferrite BCC

300 µm

In-situ phase transformation observed in low carbon steel

945 °C 0 mins 895 °C 5 mins 895 °C 10 mins

Murano stable temperature control allows transformation to Ferrite phase to be mapped.

Data courtesy – Oxford Instruments (Dr. Singh Uhbi)

CONFIDENTIAL (presentation title here)

Austenite FCC

300 µm

In-situ phase transformation observed in low carbon steel

945 °C 0 mins 895 °C 5 mins 895 °C 10 mins 880 °C 15 mins

Additional controlled cooling to 880°C observe nearly full transformation to Ferrite phase Ferrite BCC

Data courtesy – Oxford Instruments (Dr. Singh Uhbi)

CONFIDENTIAL (presentation title here)

In-situ phase transformation observed in low carbon steel

Data courtesy – Oxford Instruments (Dr. Singh Uhbi)

CONFIDENTIAL (presentation title here)

LEDs and solar materials – ‘exotic’ semiconductors Although these are semiconductor materials they are not ‘Semi’

Silicon for Semi is the most perfect material ever created

Zero dislocations or grain boundaries in 300mm diameter wafer

1 in 1 Billion atoms ‘incorrect’

Why the need for this ‘perfection’? Defects kill devices

Why don’t we use silicon for LEDs?

It is fundamentally inefficient at emitting light (and absorbing sun rays)

o World record LED efficiency for silicon = 0.00005%

o Maximum PV efficiency for silicon = 33.7%

So we look for other materials that are ‘right’

LEDs: GaN, GaP, InP, ZnO, CdZnTe, …..

PV: CIGS, CdTe/CdS, Ge, triple junction, ……..

But these are all difficult to grow and contain many defects

CONFIDENTIAL (presentation title here)

‘Exotic’ compound semiconductors Doesn’t matter what the latest trendy material is, we (almost) always

need to understand the same things:

Composition SEM/TEM, EDS, PIPS II, EELS, CL

Interfaces SEM/TEM/FIB, Ilion II, EELS

Electronic band gap SEM/TEM/FIB, PIPS II, Ilion II, EELS, CL

Grain structure SEM/TEM, PIPS II, Ilion II, EBSD

Electrical activity of defects PIPS II, Ilion II

o Grain boundaries SEM/TEM, CL, EBIC

o Dislocations SEM/TEM, CL, EBIC, C100X

o Point defects CL, CF302

Doping SEM/TEM, PIPS II, Ilion II, EELS

Conversion efficiency: light-to-current or current-to-light (LED) Ilion II CL, EBIC

Physics Ilion II CL, EBIC, CF302, C100X

Electric fields Ilion II EBIC

Stress TEM, CL, PIPS II 34

CONFIDENTIAL (presentation title here)

How white LEDs work Convert electrical energy into white light

36

LED Chip

A

Phosphor converter

UV/Blue photon (electroluminescence)

White light (photoluminescence)

LED chip Determines raw brightness and efficacy

Phosphor Determines color

Packaging

CONFIDENTIAL (presentation title here)

Commercially Purchased HB LED – Ilion-milled

1mm Cut Width

4hr cut time

Materials from: Plastic, Sapphire, Phosphor, Gold, Silicone Gel, Silicate

Great for CL as well

I count about 20 interface of interest in this one sample

CONFIDENTIAL (presentation title here)

Ultra High Resolution Image of the Active region of the Device

CONFIDENTIAL (presentation title here)

Rock 石头 (shitou)

ぐう (jan)

위 (bawi)

Sten

Stein

Kivi

Paper 布 (bu)

ぱー) (pon)

보 (bo).

Papper

Papir

Paperi

Scissors 剪刀 (jiandao)

ちょき (ken)

가위 (gawi),

Sax

Saks

Sakset

Broad Argon Beam Tools Can Cross Section Almost Anything

Shale Paper Plate W-Carbide