Briggs & Stratton Operating & Maintenance Instructions Model 80200 to 82200

description

Transcript of Briggs & Stratton Operating & Maintenance Instructions Model 80200 to 82200

Operating andMaintenance I nstructions

Model Series 80200 to 82200

Briggs & Stratton CorporationMilwaukee. Wisconsin 53201

FORM NO. 27996-4/86PRINTED IN U.S-A-

w { R l J ! [ G : D O N O T R U N T H E E N G I N E l N A NENCLOSED AREA. Exhaust gases conta in carbonmonoxide, an odor less and deadly poison.

A F IRE OR EXPLOSION CAN OCCUR RESULTING INPERSONAL INJURY IF THE FOLLOWING INSTRUC-TIONS ARE NOT FOLLOWED:

1. DO NOT FILL GASOLINE TANK whi le engine isrunning. Al low engine to cool for two minutesbefore refueling.

2. Do not operate the engine when an odor ofgasol ine is present or other explos ive condi t ionsEXISI ,

3. l t gasol ine is sp i l led, move machine away f rom thearea of the spil l and avoid creating a4y source ofigni t ion unt i l the gasol ine has evaporated.

4. DO NOT STORE, SPILL OR USE GASOLINENEAR AN OPEN FLAME, or devices such as astove, furnace, water heater which uti l ize a pilotl ight, or devices which can create a spark.

5 . Re fue l ou tdoo rs p re fe rab l y , o r on l y i n we l lventi lated areas.

6 . D O N O T O P E R A T E E N G I N E W I T H O U T AMUFFLER. Inspect muf f ler per iodical ly and re-place, if necessary.

7. Periodically clean the muffler area to preventgrass, d i r t and combust ib le mater ia l f rom ac-cumulat ing.

8. DO NOT use this engine on any forest covered,brush covered or grass covered unimproved landunless a soark arrester is attached to the muffler.

9. DO NOT operate the engine i f a i r c leaner or coverdirectly over the carburetor air intake is removed.

10. DO NOT choke carburetor to stop the engine.

,:, i jJl l ir i{. DO NOT RUN ENGINE AT EXCESSIVESPEEDS. Operat ing an engine at excessive speedsincreases the danger of personal injury.

1. DO NOT TAMPER WITH GOVERNOR SPRINGS,GOVERNOR LINKS OR OTHER PARTS WHICHM A Y I N C R E A S E T H E G O V E R N E D E N G I N ESPEED.

2. A.N.S.l. Standard Safety Specifications for rotarypower lawn rnowers specify a maximum blade tipspeed of 19,000 feet per minute (96.5 meters persecond), pr imar i ly to reduce the danger l romthrown objects.

3. Do not tamper wi th the engine speed selected bythe or ig inal equipment manufacturer .

4. DO NOT TOUCH hot muf f lers, cy l inders or f ins ascontact may cause burns.

5. Di r t and grass c l ipp ings or other debr is , in cool ingfins or governor parts can affect engine speed.See c lean ing i ns t ruc t i ons i n MAINTENANCEsection.

6. TO PREVENT HAND OB ARM INJURY, a lwayspul l s tar ter cord rapid ly to avoid k ickback; s tar t ingengine wi th a loose b lade or wi thout a b lade maycause a severe kickback.

7. ALWAYS KEEP HANDS AND FEET CLEAR OFMOVING OR ROTATING PARTS.

8. TO PREVENT ACCIDENTAL STARTING wlJse rv i c i ng t he eng ine o r equ ipmen t , a lwaysremove the spark p lug or wi re f rom the spark p lugand inser t in hold ing tab shown on page 3.

WHEN WORKING ON EQUIPMENT

DO NOT STRIKE FLYWHEEL wi th a hard oblect ormetal tool as this may cause flywheel to shatter inope ra t i on , caus ing pe rsona l i n j u r y o r p rope r t ydamage. To remove flywheel, use Briggs & Strattonapproved tools only.

IN THE INTEREST OF ENVIRONMENT

A muff ler which leaks because of rust or damage canpermi t an increased exhaust noise level . Therefore,examine the mul f ler per iodical ly to be sure i t isf unctioning effectively. To purchase a new muffler, seeSERVICE AND REPAIR INFORMATION.

r : r i -UTlQNi l f th is engine is not equipped wi th a sparkarrester and is to be used on any forest covered, brushcovered, or grass covered unimproved land, beforeusing on such land a spark arrester must be added tothe mu f f l e r . The a r res te r mus t be ma in ta ined i neffective working order by the operator. In the State ofCalifornia the above is required by law (Section 4442 otthe California Public Resources Code). Other statesmay have s imi lar laws. Federal laws apply on federallands. See your Authorized Briggs & Stratton ServiceCenter for spark arrester muffler options.

*h TH|S SYMBOL MEANS v!. 'Alit i i irt, q1 CA{.trlQN, PERSONAL INJURY.: {s . AND/oR PRoPERTY DAMAGE MAY OCCUR UNLESS INSTRUCTIONS

ARE FOLLOWED CAREFULLY.

l f service or repair is needed, contact an AuthorizedBr iggs & Strat ton Serv ice Center . To serve youpromptly and efficiently, the Service Center wil l needthe model , type and code number on your engine.

Each Authorized Service Center carries a stock ofo r i g i n a l B r i g g s & S t r a t t o n r e p a i r p a r t s a n d i se q u i p p e d w i t h s p e c i a l s e r v i c e t o o l s . T r a i n e dmechanics assure expert repai r serv ice on a l l Br iggs &Stratton engines.

Major engine repairs should not be attempted unlessyou have the proper tools and a thorough knowledgeof internal combustion engine repair procedure.

Your nearest service center is l isted in the"Yel low Pages" under "Engines, Gasol ine"or "Gasol ine Engines" . He is one o l over25,000 authorized dealers available to serveyou.

This i l lust rated book inc ludes"Theories of Operation", com-mon specifications and detailedinformat ion cover ing the ad-j us tmen t , t une -up and repa i rprocedures for 2 through 16H.P . s i ng le cy l i nde r , 4 cyc lemodels. l t is avai lable f rom anyAuthorized Briggs & StrattonService Center. Order as PartNumber 270962.

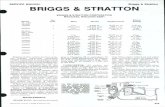

- * i s eng ine is a s ing le -cy l inder L -head, a i r -coo ledL7e

MODEL SERIES 80200 and 82200

B o r e . . . . . 2 - 3 / 8 " ( 6 0 . 3 3 m m )Stroke . . . 1-3/ 4" (44.45 mm)D i s p l a c e m e n t . . . . . . . . 7 . 7 5 c u . i n . ( 1 2 7 . 0 c c )Horsepower Max. . . 3 .0 @ 3600 RPMTorque (F t . - t bs . )Max . . . . . . 4 .6 @ 3100 RPM

The horsepower rat ing l is ted is establ ished in ac-cordance wi th the Society of Automot ive EngineersTest Code-J607. For pract ica l operat ion, the horse-power loading should not exceed 850/o of th is rat ing.Engine power wi l l decrease 3-1 /20/o for each 1,000feet (304.8 m) above sea level and 10lo for each 10oabove 60 " F (16 'C ) .

' fome areas, local law requires the use of a resistorVark p lug so as to suppress igni t ion s ignals. l f anengine was or ig inal ly equipped wi th a res is tor sparkplug, be sure to use the same type of spark p lug forreplacement .

TUNE-UP SPECIFICATIONS

Spark Plug TypeShort PlugLong PlugResistor Short PlugResistor Long Plug

Spark P lug Gap . . . . . . 030 " ( . 76 mm)Intake Valve

C l e a r a n c e . . . . . . . 0 0 5 " - . 0 0 7 " ( . 1 3 - . 1 8 m m )Exhaust Valve

C l e a r a n c e . . . . . . . 0 0 9 " - . 0 1 1 " ( . 2 3 - . 2 8 m m )

STORAGE INSTRUCTIONS

Engines to be stored over 30 days should be com-pletely drained of f uel to prevent gum deposits formingon essential carburetor parts, fuel f i l ter and tank.

NOTE: The use of a f uel addi t ive, such as STA-BlLo, oran equivalent , wi l l min imize the format ion of fuel gumdeposits during storage. Such an additive may beadded to the gasol ine in the fuel tank of the engine, orto the gasoline in a storage container.

a. Al l fue l should be removed l rom the tank. Run theengine unt i l i t s tops t rom lack of fuel .

b. Whi le engine is s t i l lwarm, dra in o i l f rom crankcase.Ref i l l wi th f resh o i l .

Remove spark plug, pour approximately 1 / 2 ounce(15 cc) of engine o i l in to cy l inder and crank s lowlyto distribute oil. Replace spark plug.

Clean d i r t and chaf f f rom cy l inder , cy l inder headf ins, b lower housing, rotat ing screen and muf f lerareas.

e. Store in a clean and drv area.

d .ChampioncJ -8

J -8CRCJ-8

RJ-BC

Autol i te235295245J U O

BRIGGS & STRATTON ENGINES ARE MADE UNDER ONE OR MORE OF THE FOLLOWING PATENTS2,999,491 3,30s,223 3,526,1 46 3,625,492 3,745,393 3,971,353 4,233,0433.194.224 3,457.804 3,57?,218 3,650.354 3,961,724 4,168,288 4,270,5093,276.439 3,465,740 3,625,071 3.738,345 3,968,854 4,1 89,040

DESIGND-247,177

OTHER PATENTS PENOING

tt EA D TH F, {} p E R AT i f\, G I hl S I P l.i {': t t'lr i'.'''''T|f E EQUIPIJIENT 1l-'t iS L.t;Gii lS {'{:;r ' . : i ' . .:

OIL RECOMMENDATIONS

Note: Engine is shipped \lV!_Il_9!lT oil.

Use a h igh qual i ty detergent o i l c lass i f ied "For Serv iceSF, SE, SD or SC." Detergent oils keep the enginecleaner and retard the formation of gum and varnishdeposits. No special additives should be used withrecommended o i ls .

RECOMMENDED SAE VISCOSITY GRADES

* l f not avai lable, a synthet ic o i l may be used having 5W-20, 5W-30 or5W-40 v iscosi ty.

NOTE: 10W-40 o i l mav be used i f 10W-30 is notavai lable.

TO FILL CRANKCASE WITH OILPlace engine level. Clean area around oil f i l l beforeremoving o i l f i l l p lug or o i l -minder.

OIL FILL PLUG. Remove o i l f i l l p lug or (opt ional ) o i l -minder. F i l l crankcase to point of over f lowing. POURSLOWLY. Capacity approximately 1-1 /4 pints (0.6l i ters) . Replace o i l f i l l p lug or o i l -minder.

l r \ \ ' , ,LOOK FOR \ \O I L H E R E d

OIL FILL PLUG OIL.MINDER

EXTENDED OIL FILL (Opt ional ) . Remove cap anddipst ick. FILL TO FULL MARK on d ipst ick, POURSLOWLY. Capacity approximately 1-1 /4 pints (0.6l i ters) . When checking o i l level , screw dipst ick as-sembly firmly but slowly unti l cap bottoms on tube. DONOT OVERFILL. Dipstick assembly must be securelyassembled to tube at all t imes when enqine is ooer-at ino.

EXTENDED OIL FILL

FUEL RECOMMENDATIONSOur engines wi l l operate sat is factor i ly on any gasol ineintended for automotive use. DO NOT MIX OIL WITHGASOLINE.FORM NO. 27996-4/86PRINTED IN U.S.A.

We recommend the use of clean, fresh, iead-freegasol ine. Leaded gasol ine may be used i f lead". f ree isnot available. A minimum of 77 octane is recom-mended. The use of lead-free gasoline results in fewercombustion deposits and longer valve l ife.NOTE: We DO NOT recommend the use of gasolinewhich contains alcohol, such as gasohol. However, ifgasol ine wi th a lcohol is used, i t MUST NOT conta inmore than 10 percent Ethanol and MUST be removedfrom the engine during storage. DO NOT use gasolinecontaining Methanol. See STORAGE INSTRUCTIONS.

a. DO NOT t i l l fue l tank to point of over f lowing.$. ,& Provide approximately 1/4" of tank space for

fuel expansion.

H O L D I N G T A B F O RSPARK PLUG WIRE v ,

STOPSWITCH

AIR CLEANEF]

F U E L T A N K

O I L D R A I N P L U G

N,It U F FLEH

C Y L I N D E RHEAD

FU ELF I L L

(

)

F -20 20 40 60 80 100

c -30 -20 '10 0 1 0 20 30 40TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

C R A N K S H A F T

O I L F I L L P L U G

, ",.1, ",-'i,:,';: Frt;,i;r"iiir' . .; -l':'..'t.t,:". .

CHOKE-A-MATIC COI ' , ]TRCLS:as oossib le toward "CHOKE" or

Move controls as far. 'START".

Start, store and fuel engine in a level position.

DO NOT use a pressurized starting fluid as severeinternal engine damage may occur due to loss oflubr icat ion.

CHOKE ENGINE:

Engine may be equipped wi th e i ther manual , remote orchoke-a-mat ic contro ls ,

MANUAL CHOKE: Move lever as i l lust rated.

TO START ENGINE,. ALWAYS KEEP HANDS AND FEET CLEAR OF

.6 # , MOWER BLADE OR OTHER ROTATTNGMACHINERY.

Rewind Slarter. Grasp starter grip as i l lustrated andpul l s lowly unt i l s tar ter engages. Then pul l cord rapid lyto overcome compression, prevent kickback and startengine. Repeat i f necessary wi th choke openedslightly. When engine starts, open choke gradually.

Rope Starter. Wind the starter rope around the pulleyin d i rect ion shown by arrow. Pul l the rope wi th a quickfull arm stroke to overcome compression and preventkickback. Repeat if necessary with choke openedslightly. When engine starts open choke gradually.

.! a r. .,- T;' ') l i When using rope starter to crank;.1.*. engine, use caution so knotted end of rope

does not strike persons standing nearby.

TO STOP ENGINE

Move control to slow, then "STOP" or "OFF" position.Do not choke the carburetor to stop engine.

STOP SWITCH: Move STOP swi tch awalr f rom sparkplug or to "ON" posi t ion as i l iust rated, i f so equipped.

NOTE: A warmco id eng ine .

NOTE: Eng ineequ ipmen t doMENT sect ion.

SPEED CONTROL LEVER: Move speed control leverto "RUN," "FAST" or "START" position if so equipped.

engine requi res less choking than a

nlay not start if controls on powerednot c lose choke fu l ly . See ADJUST-

O U T R O Du h t r A 5 t r J r t r t r u

T O C H O K E

*'6t

,,,,%lb!{>-?

TYPICAL SPEED CONTROLS"<tu%

CAU rlOli: TO PREVENTACCIDENTAL START-ING when serv ic ing the engine or equipment ,always remove the spark plug or wire from thespark p lug and inser t in hold ing tab shown orrpage 3.

CHECK OIL LEVEL regularly - after each five hours oJoperat ion. BE SURE OIL LEVEL lS MAINTAINED.

CHANGE OIL after f irst f ive hours of operation. There-after change engine oil every 50 hours of operation,under normal operat ing condi t ions. Change engine o i levery 25 hours of operation if the engine is operatedunder heavy load, or in h igh ambient temperatures.Remove o i l dra in p lug and dra in o i l whi le engine iswarm. Replace dra in p lug. Remove o i l f i l l p lug, o i l -minder, or cap and d ipst ick and ref i l l wi th new oi l o fproper grade. Replace o i l f i l l p lug, o i l -minder or capand d iost ick.

CHANGE OIL (GEAR REDUCTION optional). Removeoi l level p lug and o i l l i l l p lug. Drain o i l every t0O hoursof operat ion. To ref i l l , pour 10W-30 o i l in to f i l ler holeunt i l i t runs out level check hole. Replace both p lugs.Oi l f i l l p lug has a vent hole and must be insta l led on topof gear case cover.

OIL F ILLER PLUG(WITH VENT

HOLE}

O IL LEVELPLUG --- -

TO SERVICE AIR CLEANERS

CARTRIOGE AIR CLEANER

Clean cartridge at three month intervals or every 25hours, whichever occurs first.

NOTE: Service more often-if necessary.

1. Remove knob and cover .

2. Remove cartridge by pull ing if off of the screw.

3. Clean by tapping gently on a ftat surface. lt verydirty, replace cartridge or clean as follows:

a. Wash in a low or non-sudsing detergent andwarm water solution.

' Do not use

petroleum solvents such as kerosene, to cleancartridge.

b. Rinse thoroughly wi th l lowing water f rom ins ideout unti l water is clear.

c . Al low car t r idge to s tand and a i r dry thoroughlybefore us ing. DO NOT OIL CARTRIDGE. DONOT USE PRESSURIZED AIR TO CLEAN ORDRY CARTRIDGE

4. Install cartridge, then cover and screw knob downsecurely.

DUAL ELEMENT AIR CLEANER(oPTroNAL ON SOME MODELS)

Clean and re-o i l foam ore-c leaner at three monthintervals or every 25 hours, whichever occurs first.

NOTE: Serv ice a i r c leaner more of ten under dustvconditions.

1. Remove knob and cover. J

2. Remove foam pre-c leaner by s l id ing i t o f f the papercartridge.

3. a. Wash foam pre-c leaner in kerosene or l iqu iddetergent and water.

b. Wrap loam pre-cleaner in cloth and squeezeqry.

c . S a t u r a t e f o a m p r e - c l e a n e r i n e n g i n e o i l .Seueeze to remove excess oil.

4. Install foam pre-cleaner over paper cartridge. Re-assemble cover and screw down securelv.

NOTE: Replace or c lean car t r idge inc luded wi th DUALELEMENT AIR CLEANER year ly or every 100 hours asdescr ibed in CARTRIDGE AIR CLEANER. Serv icemore often if necessary.

CARIR IDGE

BASE PLATE

"o lL FoAM" AtR CLEANER (OPTtONAL)

Clean and re-o i l foam element at three month in tervalsor every 25 hours, whichever occurs first.

NOTE: Serv ice a i r c leaner more of ten under dustvcondi t ions.

1. Remove screw.

2. Remove air cleaner carefullv to crevent dirt {romentering carburetor.

3. Take a i r c leaner apar t and c lean.a. WASH foam element in kerosene or l iou id deter-

gent and water to remove dirt.b. Wrap foam in cloth and squeeze dry.c . Saturate foam wi th enoine o i l . Soueeze to re-

move excess o i l .

4. Reassemble parts and fasten to carburetor securelywi th screw.

REMOVE COMBUSTION DEPOSITS every 100-300hours of operation. Remove cylinder head and cylinderhead shie ld. Scrape and wire brush the combust iondeposits from cylinder, cylinder head, top of piston andaround valves. Use a soft brush to remove deoosits.Re-assemble Easket , cy l inder head and cy l inder headshie ld. Turn screws down f inger t ight , wi th the threelonger screws around the exhaust va lve, i f so equip-ped. Torque cylinder head screws in a staggeredsequence lo 140 inch pounds (15.82 Nm).CLEAN ENGINE - Remove dirt and debris with a clothor brush. Cleaning wi th a forcefu l spray of water is notrecommended as water could contaminate the fuel

tem.

CARBURETOB ADJUSTMENTS

Minor carburetor adjustment may be required to com-pensate for differences in fuel, temperature, alt itude orload.

NOTE: The air cleaner must be assembled to carbu-retor when running engine.

TO AD, jUST CARBURETOR - Gent ly turn valveclockwise unti l i t iust cioses. Valve may be damaged byturn ing i t in too far .

Novr oDen needle vaN,e I - 1 /2 turns counterclockwise.T h i s i n i t i a l a d j u s t m e n t w i l l p e r m i t t h e e n g i n eto be started and warmed up (approximately 5 minutes)pr ior to l ina l adjustment

CLEAN OUTCHAFF ANO

OIRT

CLEAN COOLING SYSTEM - Grass, chafl or dirt mayclog the rotating screen and the air cooling system,especially after prolonged service cutting dry grass.Yearly or every 100 hours, whichever occurs first,remove the blower housing and clean the areas shownto avoid overspeeding, overheating and engine dam-age. Clean more often if necessary.

, WA:rr., i i l . isr: Periodically clean muffler area to#fu remove all grass, dirt and combustible debris.

SPARK ARRESTER EQUIPPED MUFFLER - l l enginemuffler is equipped with spark arrester screen as-sembly, remove every 50 hours for cleaning andinspection. Replace if damaged.

SPARK PLUG - Clean and reset gap at .030" every100 hours of operation.

030" ( 76 mm)FEELER GAUGE

S P A R X P L U G

NOTE: Do not b last c lean spark p lug. Spark p lugshould be c leaned by scraping or wi re brushing andwashing with a commercial solvent.

j r * i ;A i , ) i { ) ! ' i : Spark ing can occur i f wi reterminal#& does not f it f irmly on spark plug, or if stop

switch vibrates against spark plug. Reformterminal or reoair switch if necessarv.

-,r.iff.::'i..ii"

t L t t t r T _

SCREW

FINAL ADJUSTMENT

Place speed contro l lever in "FAST" posi t ion. Turnneedle valve in unt i l engine s lows (c lockwise - leanmixture) . Then turn i t out past smooth operat ing pointunt i l engine runs unevenly ( r ich mixture) . Now turnneedle valve to the midooint between r ich and lean sothe engine runs smoothly . Next , adjust id le RPM.Rotate throttle counterclockwise and hold against stopwhi le adjust ing id le speed adjust ing screw to obta in1750 RPM. Release throt t le - engine should accel -erate wi thout hesi tat ion or sput ter ing. l f engine doesnot accelerate proper ly , the carburetor should be re-adjusted, usual ly to a s l ight ly r icher mixture.

CONTROL ADJUSTMENTS

The speed control must be properly adlusted to stop,star t and operate the engine at maximum speed.

TO CHECK OPERATION OF CHOKE CONTROLS:

Move speed control lever to "choke" position. Thecarburetor choke should be c losed.

To Adiust:Place speed contro l lever on equipment in "FAST"(h igh speed) posi t ion. Loosen contro l casing c lampscrew (B) on control plate. Move control casing (A) andwire forward or backward unt i l washer (C) just touchesthe choke operat ing bel l crank (D). T ighten casingclamp screw (B) on control plate. Recheck operation ofcontro ls af ter adjustment . Move contro l lever to"STOP" position. Lever must make good contact withstop swi tch i f So equipped. Replace a i r c leaner.

SPEED CONTROL ADJUSTMENT

The acceptable operat ing speed range is 1800 to 3600RPM. ld le soeed is 1 750 RPM. The manufacturer of theequipment of l which the engine is used, speci f ies thetop governed no load speed at which the engine maybe operated. DO NOT EXCEED th is speed.

Standard Control - Fixed SpeedThe governor speed lever has been adjusted to permitthe top no load speed speci f ied by the equipmentmanufacturer. DO NOT bend governor speed lever.

Manual Friction ControlTo increase or decrease engine speed, move contro lrod as shown below.

Speed ControlContro ls on powered equipment should move gov-ernor speed lever in a direction that wil l elongdtBgovernor spring to increase speed.

MECHANICAL GOVERNOR

To Adjusl:Loosen clamo screw on carburetor or f uel tank bracketand move casing in or out to obta in proper speed. DONOT EXCEED maximum speed recommended bymanufacturer of your equipment . Ret ighten c lampscrew.