Briggs And Stratton Engine Service Manual BS-S-TUNEUPALL · Briggs And Stratton Engine Service...

Transcript of Briggs And Stratton Engine Service Manual BS-S-TUNEUPALL · Briggs And Stratton Engine Service...

THIS IS A MANUAL PRODUCED BY JENSALES INC. WITHOUT THE AUTHORIZATION OF BRIGGS & STRATTON OR IT’S SUCCESSORS. BRIGGS & STRATTON AND IT’S SUCCESSORS

ARE NOT RESPONSIBLE FOR THE QUALITY OR ACCURACY OF THIS MANUAL.

TRADE MARKS AND TRADE NAMES CONTAINED AND USED HEREIN ARE THOSE OF OTHERS, AND ARE USED HERE IN A DESCRIPTIVE SENSE TO REFER TO THE PRODUCTS OF OTHERS.

Service Manual

Serv

ice

Man

ual

Tune-Up

BS-S-TUNEUPALL

TUNE-UP AND SERVICE MANUAL, COVERING MODELS (A THRU Z)

:============.================== BRIGGS & STRA nON CORP.

MILWAUKEE, WIS., U. S. A.

NATION-WIDE SERVICE ORGANIZATION

FACILITIES To provIde prompt and efficient service on Briggs 6 Stratton Gasoline Motors we have established Authorized Central Service Distributors and Motor Service Stations i~ principal cities of the United States and Canada. The station nearest to you is listed on the cover of this book.

These organizations cony a complete stock of Briggs 6 Stratton Motor Parts and sell at published factory prices. All Authorized Service organizations are equipped with special factory tools and factory-trained mechanics. assuring expert repair service on Briggs 6r Stratton Motors. They operate under factory policies and are authorized to provide free service and parts on defective material according to the conditions of our quarantee.

RECOMMENDATIONS When a motor is not performing as it shOUld. and you need outside help to correct the trouble. the unit should be turned over to our nearest Central Service Distributor. or Motor Service Station. Do not wait until the original trouble' causes other parts to become inoperative. Pfompt attention .oves costly repairs.

When sending the m9torfor repairs be sure to include all parts such as gas line. gas tank. etc .• so that the complete unit can be checked carefully.

When ordering parts. always give model Jetter, serial and type numbers 01 motor ..

Worn parts of the motor should be replaced only by Original Briggl & Stratton Parts. Our motors are precision built and. the replacement parts we furnish follow the exacting speCifications of original equipment. There is no economy in using cheap substitute parts which may affect the efficiency and service life of the motor. For best results insist on Original Briggs & Stratton Replacement Parts.

For service other than the motor. write to the manufacturer of the complete unit. the dealer or distributor from whom purchased.

GUARANTEE For one year from date of purchase on motors used for washing machine application (90 days from date of purchase on motors used for all other applications) Briggs 6r Stratton Corp. will replace for the original purchaser. FREE OF CHARGE. any parts found upon examination at our factory at Milwaukee. Wisconsin. to l?e defective 'under normal use and service. on account of defects in material or workmanship. All Iransportation charges on motors or parts thereof submitted for replacement under this guarantee must be borne by the owner.

This GUARANTEE shall not be effective if the motor has been subjected to misuse. negligence. or accident. or if it has been repaired outside our factory or Authorized Service Station in any respect which. in our judgment. affects its condition or operation.

IMPORTANT Motors cannot be considered as defective and qualified for free service if repair. or part replacements are necessary as the result of abuse. misuse. negligence. accident or normal wear. or the result of using improper fuels and lubricants. or of failure to follow operating instructions.

No credit or refund will be allowed on labor charges to replace defective parts during the guarantee period if service is performed outside our tactory or Authorized Service Stations.

When a motor owner feels entitled to tree aervice and the Authorized Service organization doea nol agree. all charges should be paid by the owner, and a motor Service Request Form listing all facts should be forwarded with the materia! in 'question to the tactory tor final decision. It our examination sustains the customer's claim. proper adjustment will cheerfully be made.

IIDiX

CONDENSED TUNE-UP TABLES SUBJECT

CARBURATOR ADJ ••••.•••••••••••••.••••• 5-1 0 CONDENSERS. • • • • • • • • . • • • • • • • • • • • • • . • . • • 25 GENERAL TUNE~UP CHART................. 5 MODEL LETTERS EXPLAINED............... 4 MOTOR SPEED SETTINGS-SPECIAL TyPES.... 6

" " " -STANDARD TYPES ••• 7-11 SARK PLUG GAP ADJ ••••••••••••••••.•••• 5-19 VALVE CLEARANCES •••••••••••••••••••••• 5-30

INSTRUCTIONS FOR ADJUSTMENTS AND REPAIRS SUBJECT .f!g! SUBJECT ~

AIR CLEANERS ••..•...•.•••.•.••••• 44 IGNITION TESTS ••••••.•..• 19 ARMATURES AND MAGNETOS ••••• 26 to 29 MAGNETOS •••...••••• 26 to 29 BREATHERS •......•.........•••• 42-43 MAGNETO TIMING •••••••.••• 24 CARBURETORS AND GOVERNORS ... 8 to 18 MOTOR TUNE-UP ••.•.......•• 1 CONDENSERS •...........•....••.••. 25 MOTOR TUNE-UP PROCEDURE ••• 3 CONTACT POINTS ... .- .....•.••••• 23-24 OIL - PROPER GRADE •••..••• 2 CRANKSHAFT END PLAy .......•....•• 40 OIL RETURN VALVES •.....•• 40 FLyWHEELS •••.•........•.••• 19 to 22 OIL RETAINER RINGS ••••••• 41 FUEL SYSTEM ••••••••.••••.•.•••.••• 8 SPARK PLUGS ••••••.••.•••• 19 GASOLINE AND GUM •..•••••.•••••. · ••• 2 STARTERS ••••••••••• 36 to 39 GOVERNORS •••.•....•..•....• 11 to 18 VALVES •••..•....••• 30 to 35

NECESSITY OF MOTOR TUNE-UP TO OPERATE EFFICIENTLY A MOTOR MUST HAVE GOOD CARBURETION, ••

IGNITION AND COMPRESSION, AND THE OIL AND GASOLINE USED MUST BE •.•• FRESH,CLEAN AND OF THE RECOMMENDED GRADE. .

A MOTOR THAT IS NOT FUNCTIONING PROPERLY CAN, IN MOST CASES J

BE PUT BACK INTO SATISFACTORY OPERATING CONDITION BY A TUNE-UP •••••• AN OCCASIONAL TUNE-UP IS RECOMMENDED FOR EVERY MOTOR AS IT IMPROVES PERFORMANCE AND EXTENDS SERVICE LIFE.

A BRIGGS & STRATTON MOTOR TUNE-UP CONSISTS OF RESTORING ALL ESSENTIAL ADJUSTMENTS TO FACTORY LIMITS. IT IS SIMPLE AND WILL ••...• CORRECT PRACTICALLY ALL THE CONDITIONS WHICH IMPAIR THE EFFICIENCY •• OF BRIGGS & STRATTON MOTORS. .

IN ORDER TO PERFORM A CORRECT TUNE-UP YOU MUST HAVE: 1 • KNOWLEDGE OF ADJUSTMENTS, PROCEDURES AND THE

FACTORY TOLERANCES AND STANDARDS. 2. PROPER TOOLS. (SEE PAGE 45) 3. ORIGINAL HOTOR·PARTS.

1

2

GENERAL INFORMATION AND RECOMMENDATIONS·

How A 4-Cycle Motor Operates. On the intake stroke the piston goes down, producing a vacuum in the cylinder, thereby drawing fuel up through the carburetor 80 that the space above the piston becomes filled with combustible gas. During this stroke the intake valve is open. Next, the pis~on comes up on the compression stroke with both valves closed. At the top of the compression stroke a spark occurs at the spark plug, firing the highly compressed gas. This produces an explosion above the piston which forces it down on the power stroke. Both vlaves are closed. On the next upstroke of the piston, called the exhaust stroke, the exhaust valve i8 open, and the burned gasses driven out. See Plate" No. 1.

Plato No. 1 Tho 4-Stroke Cyole

COMPAI UIOH IIAOKI POWIA SlROKl (A"A-Usr su.o""

Use Clean Gasoline. A good clean, fresh, third-grade gasoline is recommended. A gasoline of too high test" may form vaporlock in gas line when motor gets hot. This interrupts the flow of gasoline and causes the motor to stop.

Gummy Gasoline. If a gum deposit is found in the gas tank, carburetor or other parts of the fuel system, instruct motor owner to change to another brand of gasoline. Gum content can be determined by evaporating a half pint of gasoline in an open dish.

Correct Lubrl cat ion i B Important. We recolll(Tlend the use of MOBILOLL "ARCTIC" or other high grade oil having a low carbon residue and a body not heavier than S.A.E. No. 20. all shoulu bo added to the top of the filler plug opening after oa~h 5 hours of motor operation.

Oil should be changed after every 25 hours of motor operation. In the normal running of any motor, small particles of metal from the cylinder walls, pistons and bearings will gradually work into the oil. Dust particles from the air also get into the oil, Sludge, a gummy mass, forms which clogs up the oil passages. If the oil 1s not changed regularly, these foreign particles causes lnc~eased friction and a grinding action which shortens the life of the motor. Fresh oil also assists in cooling, for ~ld oil gradually becomes thich and loses its cooling as well as its lubricating properties.

---~---I a;) rmti~li i;t' i (']~I ~

GENERAL MOTOR TUNE-UP PROCEDURE

The following procedure should be followed in every instance to be sure that the motor is functioning properly. The customer may report trouble that is aggravated by causes which can only be detected and remedied by a complete Tune-Up.

All the adjustments, repairs and roplacements covered by the following procedure are illustrated and described in the following pages.

NOTE: All motors that have a model letter suffixed to the basic model letter such as AH - AHL - AP etc., use the same parts and method of repair as the basic model except where special instructions or parts are mentioned. ·See page 4 for list of basic model motors and their adaptations.

Fuel System. and Carburetor Clean the gasoline line, gas filter and petcock. Clean the gss pipe, check valve and· screen. Clean the gasoline tank and cap. Clean the carburetor and parts. See that governor works freely. Clean and check air cleaner.

Ignition System Check spark plug: Clean points and set gap to .025" •

. Check cable. Clean and adjust contact points to .020". Check condenser connections. Cheok armature connections and terminals.

Compression

Starter

Check for leaky or stioky valve. Check and adjust valve clearances when cold. (See chart on page 5)

Check and alig~ starter. lever. sector and gears.

'inal Test Check crankcase, drain, flush and reflll with MOBILOIL "ARTIC"

or other.good grade of S.A.E. 20 011 of low carbon residue.

Fill gas tank·with a good, clean, tresh, third-grade gasoline

Start Motor. Adjust carburetor 8o~that motor runs smoothly. Adjust governor to the correct motor speed.

~

3

4

MODEL DATA

Tabl. No. I

NOTE: Each Briggs & Stratton motor carries a basic model letter, such as A, B, I., etc. This will be found stamped on the metal nameplate. Motors having special features are Identified by additional letters or numenals affixed to the basic model letter such as AP, AR-6, etc. For example: Model AR-6 motor Is a Model A -with a 6-to-l gear reduction.

Use the same parts and method of repair as the basic model; except where special Instructions. or parts are ment ioned. The following table explains the letter symbols used:

EXPLANATION OF LETTERS SUFFIXING BASIC MODEL LETTERS

DESIGNATION EXAMPLE G - Generator WMG is Model WM with Generator H - High Speed AH is Model A with High Speed L - Aluminum AHL 15 Model A with High Speed and ...

A I um I num ~arts P - Olrect Crankcase AHLP Is Mode I A with .Hlgh Speed, Aluminum

Mount I no .parts and 01 rect Mount Ing R - Reduct Ion Drive AR Is Mode I A with Reduction Gear

R" - Reduction Drive (4 to II AR or ARIl Is Mode I A with Reduction Gear(4 to R6 - Reduction Drive (6 to I I AR6 is Model A with Reduction Gear(6 to

H - Marl ne Conversion AM Is Model A with Marine Conversion

II I)

T - Marine Transmission AMT is Mode I A with Marine Conversion and Transmission

COMPLETE LIST OF BASIC AND SPECIAL MOTOR MODELS

BASIC CORRESPONDING BAS IC CORRESPOND I NO MODELS SPECiAl HOD~LS HODELS SPEC I Al MODELS

A AGR-4,AH,AHL,AHLP,AHP,AHM,

" NP NR-2 NR-6 AHMT,AHR-4,AHR-6,AL,ALP, PB ALR-4,ALR-6,AP,AM,AMT, AR-4 AR-6 Q

R RC • BH,BHL,BHLP,BHP,BHM,BHR-4, S SC BHR-6,BHLR-4,BHLR~6,BL, T TA BLP,BLR-4,BLR-6,BM,BMG, BP BR-4 BR-6. .. -

U UR-2..LUR- 6 .

" WA FH FHI WI WI BP WR-6. F I WH WMG FJ I FJ2 WMB WBG H HM. WHI WMIP I IB,IBHP,IBLP,IBP,IL,ILR-6, Y

IMT IP IR-6 IS. K KL,KLP,KLR-4,KLR-6,KM,KP,

KR-4 KR-6. L LA H MC,MB,MF,MH

Z ZH,ZHL,ZHLP,ZHP,ZHLR-4, ZHLR-6,ZHM,ZHR-4,ZHR-6, ZL,ZLP,ZLR-4,ZLR-6,ZM,ZP, ZR-4 ZR-6.

ZZ ZZL,ZZLP,ZZP,ZZR

AUTO-CHAMPION LITE

PLUG PLUG HODEL HOTOR NO. HO.

A-AGR-AH-AHL-AHLP AHP-AHR'I-AHIt6-AL ALP-ALRIf -ALR 6-AP UII-U6 6M

AHH-AHHT-AM-AHT 7

B-BH-BHL-BHLP-BHLRI4-BHLR6-BHP-BHRII-BHR6-BL-BLP-BLRII-BLR6-BP-BR'I-BR6 6M BHH-BH-BHG 7 FH-FHI 6M F I 7 FJI-FJ2 6M H 6M HH 7 I -I S J8 AN7 IB-IBHP-18lP-18P-I L'-I LRIi-IHT-1 P- J8 AN7 IRe K- KL- KLP-KLR'I-KLR6-KP-KRIJ-KR6 6M KH 7 L-LA 6M "'-He-HH 6M HB-HF 6M H - N P -~ R 2 - N R 6 J8 AN7 PB 6M Q 6M R-Re 1 s-se _6M T -TA 6M' U-UR2-UR6 J8 AN7 W-WA 6M WBG-WI-WIBP-WH-WHB-WHG-WHI-WHIP- J8 AN1 WII6 Y 6M l-lH-ZRL-lHLP-ZHLR'l-IHlR6-IHP-

6M ZHR'I·ZHR6-ZL-lLP-ZLR'I~ZLR6-ZP-ZR'l-ZRS ZHH-ZH 7 ZZ-ZZl-ZZlP-ZZP· HR6 6M

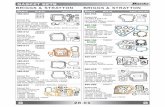

GENERAL TUNE UP CHART

Table No 2

SPARK VALVE CLEARANCE PLUG

INTAKE EXHAUST GAP

MAX. HI H. HAX. 1 HIH.

MOTORS WITH 6 DIG IT TY PE NUM8lRS OR WiTH EXHAUST VALVES HARKED - sil. XCR

.013 .011 .025 .001 .005 HOT OR S wiT H 5 DIG IT

TYPE NUM8ERS AND WITH EXHAUST VALVES MARKED - S i lch.ll

.030 .001 .005 .009 I .007 MOTORS WITH 6 DIGIT TYPE NUMBERS OR WITH EXHAUST·VALVES HARKED - sll. XCR

.014 .012 HOTORS WITH 5 DIGIT TYPE NUMBERS AND WITH EXHAUST VALVES MARKED -Sll.-i-EX.

.025 .001 .005 .009 .001

.030 .007 .005 .009 .007

.025 1/16 1/32 .013 .011

.030 .007 .005 .007 .005

.025 .011 .009 .021 .019

.025 .011 .009 .021 .019

.030 .011 .009 .021 .019

.025 .007 .005 .009 .007

.025 . .007 .005 .009 .007

.025 .007 .005 .015 .013

.030 .001 .005 .015 · 013 .025 · all .009 .021, · 019 .025 · 001 .005 .009 .007 .025 .007 .Q05 .009 · 007 '.025 · 007 .005 .012 · 010 • 025 3/32 1116 .021 .019 .025 .001 .005 .009 .OOT .030 .007 .005 .009 .007 .025 _,007 005 009 .007 .025 .007 .005 .009 007 .025 • 007 .005 .012 .010 .025 .007 .005 .009 .007

.025 .007 ' .005 .009 .007

.025 .011 .009 .021 .019

.025 .001 .005 .015 .013

.030 .001 .005 .015 .013

.025 .021 .019 .021 .019

. POlj~T GAP-ALL MODELS .020" ~ ~cvru~

~~RBUREIOR ADJUSTHEHT TURNS OPEH

IDLE NEEDLE -SCREW VALVE

None I to Ie

None ,I to I~

, to i1 I to I h , to ii I to If.

None I to I, None 11 to I None I to I fl None I to I~ None I to Iii

; to ~ ; to It

None ~ to t

, to ii I to It: ~ to ~ I to 1_4.

None I to I, None I to I~

~ ton I to It , to u J to ~

None tt to I None ~ to .1-

11 to II I to Ie None I to I ~ None I to It. None l.ato I~

I; to i1 I to I~

None I to I ~

None I to I ~

-~ to ~ I to Iii

~ to ~. I to In

I ~ ton I to 1:

5

MOTOR SPEED SETTINGS FOR SPECIAL TYPE NUMBERS

Tabl. No.3

NOTE: To find the correct speed at which motor ~hould be set: First, check to see if type nwnber (atamped on nameplate) 1& liated In this tablo. The speeds of these motors are established to meet special operating requirements and differ from stana-ard models. If the type number i8 not listed, refer to Table No.4. "

All 8pe~1s listed in Tables No. 3 and 4 are to he Bet when unit is operated under load. When speeq 1s set without load, add 200 H.P.M. to listed speed settings.

[TYPE" I RPH Y PEl R PH TY PEl r::-:-:-=-=---::--,r-:;:-::-.,.--. ITYPE I RPH TYPE' RPM TYPE' RPH

20005 1650 25456 2000 95403 2025 300312 3600 30422& 2200 :20018 2500 25451~ 1800 95461 2300 30031<\ ;-:;:00 304234 2.200 20e25 1750 25460 2000 95462 2300 30032) 2800 304236 26(,0 20058 1725 20080 1800

25461 1800 25403 2000

95467 1900 95466 2025

206372 3400 300105 2000 206375 2600 300166 1800

302087 ~~ 302083 2100

304237 2'JGQ 304238 2400

20081 2000 26465 1800 g5466 2025 206376 2700 300193 1600 302104 2440 304239 2300 20082 1800 203011 1725

25567 1800 25604 2000

95526 2400 95526 2400

206376 1600 300104 2400 206362 3500 300100 2300

302107 1800 302106 1t800

304241 2500 304242 2300

20375 1750 25005 2000 95561 2400 206363 2600 300201 2300 302113 1750 304246 2300 20381 1700 ~0387 1600

25606 1650 26607 1bOO

~§~ ~~ 05561 2025

206464 2300 300203 2300 206055 2000 300205 1000

302127 1600 302136 2000

304251 <:200 304252 2000

20410 2300 26008 1800 95563 2025 206057 1000 300207 1600 30213t; 1800 304260 1800 20423 1725 266011 1800 05834 2300 208056 2000 300208 2300 302142 2300 304203 180G 20424 1800 25012 2100 95853 2720 206059 2000 300209 "2300 304054 1800 304271 2200

20.ZS 1800 26013 1600 g5910 3100 2011064 2000 300210 2300 304089 2200 30~272 1800

20464 1800 20515 2400

26614 2000 25622 2000

~919 2200 95925 1400

206065 2000 300211 2300 300213 2000

304106 2500 304114 2660

304273 18GO 304274 1800

207115 2000 26623 2000 95936 2300 20600 300216 1000 304124 2000 304283 1800 1207117 1600 26027 2000 95\139 2100 206009 300217 1000 304131 1800 304285 2400 20810 le60 ::Otlll 2100 20813 2100

25629 2000 ~663" 2000 25649 2200

95946 2300 0:';065 2500 95067 3100

206070 300210 2:~00

200071 1000 :;'2Q;~20 1000 206072 3000 30tl223 1600

304132 16_QQ. ~--:~04 134 '18-00

t-304135 ItlOO

304287 220(; 3042tl9 I b CJ()

304298 <:cG0

20814 2100 25869 1876 95970 3100 208077 2000 300224 1700 304140 1800 304290 220') Z0815 1600 60150 2000 95071 2500 2060110 2000 300225 1600 304147 1800 30<\303 lflV,

20818 2000 80316 2500 95g75 1200 206062 1800 3002G6 2300 304151 2100 ~O4304 11::00 208111 1600 00321 1600 2040611 2300 206064 2000 300227 2300 304160 2100 304310 2300

--" 20820 1750 208411 1750 G06115

205063 3600 205070 3500

206106 2700 300226 2300 206114 1725 300229 1700

1~00 304186 304192 2200

304311 2300 304312 2775

208eO 1000 205065 3000 1600 300231l 1600 3041 113 2200 304560 1600 20801 1000 2050111 3500 1600 300246 2800 304194 1800 304572 2300 20808 3200 1205099 3000 2200 300246 2300 304195 2200 304570 2.3G()

20870 4000 60711 1600 205113 2200 1700 300249 2300 304 106 2200 304578 1800 20665 4000 60826 3000 205114 300(i 1700 300250 2300 304107 2200 3<J4560 22C" £01/10 £700 201/14 3200

60861 1800 60906 1725

205!!!L 3000 205141 4300

:'>00261 1600 206151 1800

._------ - _.-~W0253 2300

3041011 2200 304200 1000

304584 1 bCG~-

301585 -if;-Ch 201133 11150 601/40 1726 205142 3500 206167 1600 300264 380 304202 2200 304591 lElCO

26030 3600 601175 2000 206166 3300 20tll66 1600 300250 2300 304203 2100 3045(lCl 21C..; 26048 3800 95011 3400 206180 2600 206169 1600 300265 2500 304204 1800 304597 2100 25048 2300 06065 1926 206177 2700 206160 2000 300266 2100 304205 2200 3045g8 3CG~ 25177 2600 115090 1600 206160 3100 300065 1600 300276 2600 304207 2200 304602 180G 26228 2860 25258 3000

g5170 2600 951n 1700

~t:190 2600 206327 "3c500

300065 1600 300260 2600

300096 2000 300202 2100 304208 1800 304209 2200

301604 1600 ~04t.oe 24vJ

25282 3600 96204 1800 206330 4000 3000119 1600 300265 2300 304210 2200 304607 2~00 25300 3800 g5261 2600 206340 2700 300106 1600 300267 2200 304211 2200 304614 2300 25305 2440 95285 1600 206341 2600 300119 1725 300202 2500 304212 1800 253~ 2880 95293 1800 206351 3100 300136 1600 300296 2800 304214 2200 25314 2500 11621/4 1600 206352 4000 2000 300297 2600 304215 ItlOO 25381 1800 25421 1600 25,,21/ 2000 25453 2000

95302 2400 96303 2025 95305 2400 115308 2300.

206369 4000 2063150 4000 206381 2600 206362 3600

300300 2500 304210 1700 304220 2200 3042~ 2200 304226 2600

~~U, lOOO Q~~2~ 2400 ,20a!a! 2800 ~227 2200

SEE PAGE 7 MODELS

~ 6

""

MOTOR SPEED SETTINGS FOR STANDARD MODELS Table No.4

IMPORTANT: Check motor type number (stamped on metal nameplate) against Table No. 3 before using this chart. If type number of motor being adjusted is not listed, thell use this chart for setting motor speed. Full load speed setting normally is the middle of the speed runRe shown.

SPEED RANGE SPEED RANGE SPEED RANGE SPEED RAHGE --HODEl R. P. M. R. P. M.

FIVE DIGIT SIX DIGIT HODEl R. P. H. R. P. M. FIVE DIGIT SIX DIGIT

TYPE NUMOERS TYPE NUMBERS TYPE HUMOER:; TYPE NUHOERS A 2200-3200 2200-3200 IS 2600-4200 2600-4200 AOR-" 500-600" K-KL- KLP-KP 2300-2700 2300-2700 AH-AHL 2200-3200 KLR-" 575-675· AH LP-AH P 2200-3200 K LR-6 390-450· AHH-AHHT 2200-3200 KM 2300-2700 2300-2700 AHR-IJ 550-800·-- KR-" 575-675" 575-675· AHR-6 370-530'" KR-6 390-450· 390-450· A L-A LP 2000-2400 2200-3200 L- LA 1700- 1900 ALR-IJ 500-600· M-HC-HB-HF 1800-2400 ALR-6 330-400'" MH 3000-4000 AP 2000-2400 2200-3200 H -H P 2600-4000 AH-AMT 2000-2400 HR-2 1300-2000"

U-" 500-600" HR-6 435-670·

U-6 330-400· 365-530· PB 2100-2300

B 2300-2700 2200-3200 Q 1700-1900

BH-BHL 3000-3600 3000-3600 R-RC 1800-2400

BHLP-BHP 3000-3600 3000-3600 S-SC 1700-1900

BHH 2200-3200 T-TA 1700-1900 -.---- ----BHR-" 750-900· 750-900· U 2200-3200

BHR-6 500-600" 500-600· UR-2 1100-1600·

BH LR-" 750-900· 750-900· UR-6 365-530·

BH LR-6 500-600· 500-600· \i-WA 1800-2400 BL-BLP 2300-2700 2200-3200 WBG 2300 2300

BLR-" 575-625* WI-WIBP 2200-3200 BLR-6 380-450· WM-WMB 2250-3000 2250-3000

BH 2300-2700 2200-3200 WMG 2300 BHG 2300-2700 2200-3200 WMI-WMIP 2100-2500 ------BP 2300-2700 2200-3200 WR"-6 365-530"

BR-" 575-625· y 1700-1900 BR-6 380-450· 365-530· Z 2200-2600 2200-3J~

FH-FHI 1750-1800 ZH-ZH L 2200-3200 2200-3200 F I 1750-1900 ZHLP-ZHP 2200-3200 2200-3200 FJ1 3000-4000 ZHLR-q 550-800· FJ2 1800-2400 ZH LR-6 370-530· H 1750-2100 ZHM 2200-3200 HH 1750-2100 ZHR-q 550-800" 550-800· I 2100-4000 2600-4000 ZHR-6 370-530· 370-530· I BH P 2100-4000 ZL-ZLP-ZP-ZH 2200-2600 2200-3200

IB-IBLP 2600-3200 ZLR-LJ 550-650·

IBP 2600-3200 2600-3200 ZLR-6 360-430· 365-530·

I L 2600-3200 2600-3200 ZR-q 550-650" I LR-6 435-535'" 430-670'" ZR-6 360-430· 365-530·

IIH-IP 2600-3200 2600-32illL- zz 2200-3200

IR-2 1300-1600* 1300-2000* IR_S _43S-S3S* 430-670*

Z ZL - Z ZL P -Z Z P 220C-3200 ZZR-6 }65-530·

.On Bear reductlon mOdels the speed is the same as standard when checked tram the ~7.neto side. The speed or crankstarter motors can only be checked at thc power takc-ofr shart. The speed on the powe take-orr s1de 1s reduced oy reduction gears to approximately 1/2. -1/4 or 1/6 or mo~or apoe~ as 1ndlcated by numeral followlng model lctters~

CY lE

7

8

FUEL SYSTEM======================~= Briggs & Stratton motors have two types of fuel systems -- suction

feed and ~ravity feed. The suction feed type has the gas tank below carburetor level with a gas pipe to it. The gravity feed type has the tank above carburetor level and a float in the carburetor, as in an automobile.

Gas Line. Remove and blow. through to olear. When replaCing, be sure that all conneotions are tisht.

Gas Filter. To olean, first close the shut-off valve, then loosen thumb screw at bottom of glaoo bowl. Remove and clean glaoo bowl, gasket and ocreen. Open shut-off valve to see if gaBoline flowo freely from the tank. If you find a gummy varnish-like substanoe, it should be removed with alcohol or acetone.

Gas. Tank Cap. Remove dirt in vent hole. Blow through to clear. The gas t~k ca~ on the Model "U" motor has no vent hole and must seal tank air tight. '

Gas Feed Pipe. Models WI-WM-WM5-WMI-Y-L. Remove from tank. Brush dirt from screen but do not remove or damage. Blow through pipe from Bcreen end to Bee if check ball is free. Blow through opposite end to determine if ball seats and closes passage. If ologged, olean with alcohol or aoetone. Be sure to replace gasket when replaoin~ pipe in tank. See Plate No.2.

Model "U" - The gaB feed pipe is the same as the respects, except it has a disc valve and valve retainer. must 'be assembled with the convex side down or towe,rd the Plate No. 2A.

"WI" above in all' The valve retainer disc, valve. See

Models "FH"-"S" - Gas feed pipe IJl located below carburetor. See Plate No.6. Remove carburetor from bas8and unscrew pipe. Clean a6 explained above. The end of sas pipe must oleat' Inslde bottom of baBe by 1/16".

Gas Tank. Flush tank with olean gas to remove dirt and water. Use alcohol or acetone to dissolve gum. The hole in thevacuuml1ne cOMecting of the Model "U" motor DlUst be open trom .025" to .028".

Gummy Gas. It the above parts show deposits of a gummy, sticky substance with a peculiar obnoxious smell, they should be thoroughly cleaned with alcohol or aoetone.This sum comes from the ,gasoline and frequently clogs the parts ot the tuel system.

The oustomer should be instruotea to ohange to another brand of gasoline. To cheok for gum oontent, evaporate a half pint of gasoline in an op'en dish. Gum trouble can be avoided it owner will keep tank full when motor is not in use. If used oniy oooasionally, drain tank completely and refill when used. This is neoessary beoause the continued evaporation of stale ga8011ne aauses most gum deposits.

Plat.e No.2 Plat.e No. 2A

Types of Carburetors. Gravity and suction feed. See chart on page· lOfor type of feed on each model.

To Clean Carburetor. Carburetor openings must be clean. If clogged, blowout. But do not attempt to clear by usirig wire or tool. Clean carburetor and parts in alcoho or acetone - do not scrape. The gravity feed type carburetors sometimes leak at th~ inlet valve. When this occurs you will find that the inlet valve and seat are dirty or worn, or both.

Check for Wear. If carburetor throttle, throttle shaft, or body is worn it will C8U

motor to run erratically. Replace worn parts. If needle valve head is broken, dril small hole in needle valve and use end of .file to turn it out.

Idle Adjustment. Set the carburetor throttle lever adjustment screw so that motor will idle dt about 1600 R.P.M.

Float Level. The carburetor float level on gr~vity feed carburetors can be .adjusted in all cases except those marked "F" in the chart on page 10. The exceptions have a float with fixed position and need not be adjusted. All others can be adjusted by either bending the tang or float lever.

Model-U Speciai Adjustment. To adjust the carburetor, hold throttle at idling position unti you complete the following adjustments:- Turn needle valve unti~ motor runs evenly. Then open needle valve until motor starts to run unevenly. Now close needle valve just a little until motor starts to.run evenly. This adjustment will be a little rich, but you will find it correot for full throttle range.

TO REMOVE AND REPLACE CARBURETORS For all models, except those marked with an asterisk (.) on pagelO, (which

are explained below) removal and replacement of carburetors will be easy by referrin to the chart on page 10 and to. the plates or illustrat ions indicated.

Mod.l I Disconnect gas line at gas filter, then remove blower case with gas tank

attached. Unhook throttle spring at lower end and remove carburetor mounting screws and throttle link carefull~ so as not to bend link. See Plate No. 10.

Model-N

The same as for Model "I" exoept see Plate No. laC. Model. WI-WM-WMB-WMI

Disconnect gas line at carburetor and remove blower case, valve cover plat and carburetor mounting bolts. Remov.e carburetor carefully and, without stretching, unhook goveroor spring at lower end. Do not remove governor spring or link from throttle arm. See Plate No. 16.

To remove the throttle with a steel throttle lever, loosen set screws that hold the choke valve and throttle in place. The throttle is easily removed with the fingers. To reasse~ble, replace choke valve and insert throttle in the carburetor body as far as it will go. Line up hole in sleeve with locating hole in body and throttle stop between forked points of throttle lever. Insert a small tool between throttle lever and sleeve, and, push sleeve in place SO that locating hole lines up with set screws. See Plate No. 17.

The later throttle and ohoke valve set sorew now has a special tip, and a 3/32" locating hole in the throttle sleeve. For the earlier type with large hole us screw. No. 90211, and for the new type with small hole use scr~w No. 63854.

To rem~ve throttle with a die cast throttle l.ever, remove cotter pin and washer and slip throttle from body. See Plate No. 17.

9

CARBURETORS (Cont'd.) =================== CARBURETOR ADJUSTMENT CHART

See Plate No.

Model Motor Type Idle Adj, Screw Needle Valve Adj. Hook Float Feed Turns Open Turns Open -Up Level

A-AGR4-AH-AHL-AHLP- 5 and 6 5 Digit early modele AHP-AJiM-Amll'-AHR4- Digit have none-later 5 and 6 5 Digit F AHR6-~ALP-ALR4- Type models t to -i Digit Type 3 ALR6-AP-AM-AMT-AR4- Nos. 6 Digit t to ~ Nos, 1 to 1t 6 Digit 18E AR6 G 18B B-BH-BHL-BHLP-BHP-BHW-BHR4-BHR6-BHLR4 G 1/2 to 3/4 1 to 1-1/4 5 leE BHLR6-BL-BLP-BLR4-BLR6-BW-B~BR4-BR6-

FH S none 1 to 1-1/2 6 nontl FI-FlU G none 3/4 to 1 7 18F

F11-F12 G none 1 to 1-114 3 F H-HW G 1/2 to 3/4 1 to 1-1/4 9 F

·I-I8-IBHP-IBLP-IBP 5 ana 6 5 and 6

5 Digit F ·IL-ILR6-IMT-IP-IR6 Digit ~ Digit have none 10

.IS Type Nos 6 Digit t to i Digit Type 6 Digit G Noe, 1 to li 18A 18E

K~KL-~KLR4-KLR6-G 1/2 to 3/4 1 to 1-1/4 5 l8E KW-KP-KR4-KR6

L-LA S none 1 to 1-1/2 4- none

M-MC G none 1 to 1-1/4 3 F M8-MF G 1/2 to 3/4 1 to 1-1/4 8 18G WH G none 1 to 1-114 3 F • N-NP-NR2-NR6 G 1/2 to 3/4 1/2 to 3/4 lec leE PB G none 3/4 to 1 12 18F Q G none 3/4 to 1 15 18F R-RC G 1/2 to 3/4 1 to 1-1/4 14 18G S-SC S none 1 to 1-1/2 11 none T-TA G none 1 to l-1L4 3 F • U-UR2-UR6 $ none 3/4 to 1· 18D none -W-WA G 1/2 to 3/4 1 to 1-1/4 14 18G ·WBG-WI-WIBP-WM-WMB-·WG-WMI -WMIP-WR4- S none 1 to 1-1/4 16 none -WR6 y S none 1 to 1-1/2 13

--none

Z-ZH-ZHL-ZHLP-ZHLR4-ZHLR6-mw-ZH~ZHR4- G 1/2 to 3/4 1 to 1-1/4 5 18E ZHR6-~ZLP-ZY-ZP-ZLR4-ZLR6-ZR4-ZR6

ZZ-ZZL-ZZLP-ZZP-ZZR G 112 ~o 3/4 1 to 1-1/4 5 leE S - Suction Feed G - Gravity Feed

• - See special adjustment Page 9 ~ F - Float level not adjustable.

10 • a ;ntmif~'i i .13 i '0:. ~

GOVERNOR SPEED ADJUSTMENT CHART

Peak Output R.P.H Plate NO. Decrease~------~------~

Speed X5 Digit X6 Digil Type TYPE Increase Oov. 16 DlgH. X6 Digit Adjuster Speed

Hodel Hotor

-.!-U-ALP-AP • 2200 3200 ClIp Raise Lower 3 18B AOR • "!fi60 :11P Rai se Lowe r ;} AH-AHL-AHLP-AIIP • 3100 Cllp Raise Lower 3

~A~HH~-~A~H~H~T~~~----~~N~,o-n-e~~~~100---+· ______ -r~L4e~vrie~r~;_,r.u~IP~--_+_TD~Ow~'~~--;_--3~--~-------~ ~~AH~R4--------------~-~.--_+~1~7+7~S---;_------1-~C:~lTI~p_+-;F_R;a7·1~sle __ -;~L~o~w~e~r __ _+--~;}r---_+------__ I JliJi6hno.--___________ t--..:=.'::-=--+..L,; f*51,5 __ --1_--...n=c---l,illl> 1\8 se Low-=.e.!..r __ --1 ___ 3;r-__ _+---.--,.;...,---1 ~AHT ~N~o~n~O-;_7E~EOIO~~~-+73~2~10~40~~-~we~vTer~_+~~uTP~--_+-~Dlo~w~n=---r-~~r----t---r.l8~IH~_4

ALR4-AR4 • -f 560 f BO I> I\a se Lower 3 81' A .R6-AR6 • 1 360 1 533 D Ra.1se .Lower 3 88 II-BL-BLP-SP ,,2500 3200 Nut Rlp;ht Le rt 5 5 BH-BHL-BHLP-BHP ,,3200 Nut Right Lert 5 5 BHH None 3200 Lever RIght Left BHR4-BHLR4 • 870 Nut Right e rt 5 5 BHR -BHLR6 ,,540 Nut Right ert 5 5 IlLK -8K4 • 66 ., H7U NU "gnt e ~

BLR -SR6 • 410 -f 640 Nut RlRht e t 5 5 ~S~H~-*IH~C~----------1-~N~<o~ne-+~2'::~5~'0~~--~3~j2~O~CO~-+'L7e~v~er~-+~R71~Rlh~t---;·-fL~e~C~t----r-~5~--~--~5~--i

F"H • 1751 .P"8 se lower 6 F"H 1 Non e 1750 None None Non e 18 F"I .. .900 Clip Right Lert 7 fJl ,,~uoo Clip Raise lower 3 X~ • e200 Cll p RB1se Lower 3 H-HI1 •• l750 l:llP Lert " ;nt ~

- - r ". --.40( NU R lP;n e . t IB-IBLP-IBP-IP •• ZO( Nut RIRht Le t 10

BHP •• 4 Nut "lgnt .Le t .R6- 1\6 •• -f ., 67 Nut RIght Lert 10 18A IT- ~if 2' 40e RO<l ,p own l" •• -f -fEOe Nut RIAh~ LeCt 1 .SA ~ •• 420< Nut Right Lert

K-KL-KLP-KP • 2600 260 Nut Right e t 5 IBA

5 KLR4-KR4 • 1 660 -I 66' Nut Right Le Ct 6 K_R6-KR6 • 141 141 Nut RIRht ert I)

5

KH None ~50~O __ +-~2~5~O~O __ ~L~e~vne~r~4-~R~I~h~t~-1~Lre~r~t~--+---.----+--____ -; L-LA • --r-75Q _~ ______ -1~r.~·H·I~p~4-_R~a~B~e~~~¥Lo~w~c~r~-+ __ ~4 ____ +-______ ~

1-7.11;-_';:;H~C-------------1----".'---+-- 2200 C .1 P Ra se Lowe r ~ ~B-I1~ • Z2~~O~ __ }-______ +-~C.~IP __ +-;Rr.18~8~e __ -f-;Lr.0~w~e~r~-+ __ ~8~ __ -+ ______ -;

HH"..,H.,.,..,.. _____________ 1---:-.. 31)00 l:.1 P Ra se Lowe r 3 N-NP ". 4000 Nut RIRht e t . tlC NR2 ..~~OOO Nut RIght LeCt 18C tiRO •• -I 670 Nut RIllht Lert lee PH None ~~O!,; None None None :Z

1-..9..*-".,.----------~ •• --~~R90 Cllp Lert RIEht 15 K-H I ~.~~~_+-------~-~(:+1~I.p~~-~Rl~lg~thult~___I~~r~t~--~-1~i1~--1_ ______ ~

r.:S;--....,. S C ______________ +_--'''L---!----1e.QO Clip R I Rh t Le r til T ,.. tHOO CllD Raise LoweI'. 3 TA • 1800 CIID Raise l.ower e

.. 2800 Nut RIAht Le r t 180 llR2 •• -#l40( Nut RIRht .e t eo 'R6 •• -# 466 Nut Right La rt

W-WA • 1600 CIID RIRht Lert 14 WBC -WMB •• 2300 2300 Nut Rlp;ht Lert 16 16 WI-WISP •• 2700 Nut Right Le rt 16

•• 2300 SHde I.ower RaIse 16 •• 1 425 Nu\. Right Lert 16

'1 if'" 1750 Nut. Right e t 1~

Z-ZL-ZLP-ZP • 2400 2900 Nut Rlp;ht Le Ct 5 ZH-ZHL-ZH LP-ZH P • 2900 2900 Nut Rlp;ht Left 5 5 ZHH None 21)00 2900 Lever Right Left

• 765 766 Nut Right Lert 5 5 ZHLR6-ZHR6 • 480 480 Nut Right Left 5 5 ZLR4-ZR4 • 635 725 Nu t Rhh t Le r t 5 5 ZLR6-ZR6 • 395 48 1 Nut RIg~t Left 5 ZH-ZHO • ZZ-ZZL-ZZLP-ZZP ... ~201 Nut RIs t Lert 5 ZZRe ... 1 63 Nut Rlg~t Left b

• CentrlCusal •• Pneumatic 1 Repeat as or • note on oottom oC Page 6

1 6 Dl< and 6 dl,lt Indicate. the numoer'or 41g1t8 In the motor type numoer.

1 1

12

CORRECT MOTOR SPEED

Gasoline motor speed directly reflects the power output. The best efficiency will be obtained at the peak output speed shown in the Governor Speed Adjus tment Chart on page 11. The cooling and lubrica tion, crankshaft counterweights, valve timing, governing and spark advance have each been designed to function best at this speed. For best general results the operating speed should be held closely to "peak output speed". Lower speeds than those recommended are permissible. although at the sacrifice of efficiency and, eventually, motor life.

Rpes of Governors. Pneumatic and centrifugal. See chart on page 1'1 for ype of governor on each model motor. The pneumatic type governor is opera

ted by air blown from the flywheel fins. The centrifugal or fly-ball type is operated by weights either in the governor housing or on the governor gear.

To Adiust Centrifural Governor. If the lever of this type governor has beenoosened or removed from the shaft, it is easily reset. With the carburetor attached to motor and hooked up to governor lever with throttle link, loosen screw holding governor lever on the shaft. Push the governor lever toward the left as far as it will go. Hold it 1n this position and turn the governor shaft to the right with pliers until it strikes a stop in the crankcase. Tighten screw that holds governor lever to shaft until the lever 1s snug. Push governor lever to the right as far as it will go and t1ghten screw securely.

Model FH

~~~~~~~~~~~~~e~G~o~v~eTr~n~o~r~. If proper speed cannot be obtained, governor arm t er rection so that throttle plate moves freely

from one throttle stop to other. When throttle plate 1s against either stop there should be no· play in the link. See Plate No.6.

Remote Throttle and Governor Controls. To secure full speed range of motor on models using remote throttle and governor controls, it is necessary to adj\1st the position of the control lever on the control wire. This adjustment should be made while the motor is running.

Move control lever ~1ther against the front or rear stop of control lever base, as the case maybe, 80 that motor will run with the throttle lever against the idling stop of ·the·carburetor and still have enough tension on the throttle spring not to unhook. To change position of control lever loosen swivel screw on control lever assembly and move lever against the stop. Then tighten swivel screw and cut off surplus wire.

A short control wire that does not permit the carburetor throttle to close enough so that motor will idle at proper speed, or one that will not permit full travel of remote control lever. should be replaced by a longer one. See various lllustratlonson pages 13 to 17.