BRACING MEMBERS - Faculdade de Engenharia da … · Understand that the design requirements for...

Transcript of BRACING MEMBERS - Faculdade de Engenharia da … · Understand that the design requirements for...

BRACING MEMBERS

SUMMARY.

Introduce the bracing member design concepts. Identify column bracing members requirements in terms of strength and stiffness. The assumptions and limitations of lateral bracing for unrestrained beams analysis are given Diaphragms design, limitations and applications are introduced.

OBJECTIVES.

Understand that the design requirements for column and portal frame bracing. Understand that the design requirements for unrestrained beams lateral bracing. Understand that the design requirements for diaphragms action use and its main approaches.

REFERENCES. [1] ENV 1993-1-3 Eurocode 3 Part 1-3 General rules - Supplementary rules for cold formed thin gauge

members and sheeting. [2] The Steel Construction Institute, Steel Designers Manual, 5th Edt., Blackwell, 1992. [3] Winter, G. Transactions of ASCE, 125, pp.807, 1960. [4] Kennedy, J. B., Neville, A. M., Basic statistical Methods for engineers and Scientists, 3rd., Harper

and Row, New York, pp. 114, 1986. [5] Canadian Sheet Steel Building Institute, Diaphragm Action of Cellular Steel floor and Roof Deck

Construction, CSSBI Suite 305, 201 Consumers Road, Willowdale, On, M2J 4GB, 1972. [6] McGuire, W., Steel Structures, Prentice-Hall, 1968.

1. INTRODUCTION. The bracing system:

Must provide both force and stiffness. Is used for beams, columns and frames. Reduces effective length of columns. Reduces effective length of beams. Provides overall stability to frames. May be discrete or continuous.

Consider:

If is equal to zero then Q is also equal to zero, but in a system that is less than ideal, 0, and the situation portrayed in (c) occurs:

Q = k for equilibrium:

L

PQQLPM A 0 or: LPk

L

Pk

Note if: kL > P there is no sideway kL < P there is sideway

The critical case occurs when kL = P

[1] k0 = Pcr /L; The maximum load in the member is: 2

2

02

2

L

EILk

L

EIPcr

-For kL/k0L > 1, the system is braced and can reach Pcr -Any k > kc, gives no benefit -For k < kc, the system is only partially braced and P/Pcr < 1

2. COLUMN BRACING. Consider a two-storey column braced at mid-height. The bracing member forces the column to buckle into two half waves, i.e.:

Free body diagram of the top half.

22

LkQLPcr

L

Pk cr2

0 [2]

For a three-storey column braced at each storey height:

Buckling Mode 1

330 LkQL

Pcr

L

Pk cr3

0 [3]

Buckling Mode 2

LkQLPcr 0

Not critical when compared to first mode

For a four-storey column buckling in a zigzag manner the deflection at mid-height is not necessarily :

Free body diagram of top quarter

12

1 2

PL

QQ and

12

1 2

PLk

22

1

1Pk [A]

Free body diagram of next quarter 0BM

02 211

21

PLQL

212 2 PLQ

2

212

L

Pk [B]

Equating [A] and [B]:

2

21

21

1 2

2

2

; 2

22121212121 22 ; 21414.1

LPk cr41.30 [4]

For a large number of storeys the deflections in opposite directions at interior points, remote from the ends, must be equal and the net shear on a panel height will be Q/2. Therefore from the free body diagram:

222 0 LkQL

P

l

Pk

40 [5]

Hence:

In general L

Pk

0

Thus the bracing stiffness k0, corresponding to zero initial deflection at the bracing points, can be determined. The bracing force required is Q = k0 .

In a real structure, however columns have initial crookedness. Forces in the bracing only occurs when the force in the column causes the brace to deform.

0BM

00 crPQL

00 1

L

PkPLk cr

cr

00 1kk [6]

There is still the need to know both 0 and

000

0 1

kkkQ [7]

For compression members, normal tolerances are 1/500 to 1/1000 of the length for plumbness

Say 0 = L/500 = 0.002L; let = 0 k = k0(1+1) = 2k0

Required stiffness l

Pk cr2 and Q = k = crcr

cr PPxl

P 004.0002.02

2k Q [8]

Note: Assumed 0 = L/500 and =0

The selection of braces based on equation [8] implies:

-Assume equation [8] applies to both columns and beams. -For beams deal with compressive force only. -Does not apply to plastically designed structures. -Pcr can be interpreted as the elastic or inelastic load. -Does not apply to locations where brace forces are included in the analysis i.e. P- effects.

Steps: 1- Establish brace locations. 2- Calculated Pcr = Compressive resistance for a column and Ac y for a beam. 3- Calculate or estimate .

4- Calculate L

Pk cr

0 for n equal spaces L

5- Select Ab i.e. the area of brace such that: L

P

L

EA cr

b

b 2 (units in

mm

N

mmmm

Nmm

12

2 )

6- Check that crP004.0 Q

First Example Provide braces at 1/3 points for a WWF 600x152, 250MPa yield stress, carrying a uniformly distributed load on a span of 18 metres. Only one beam is to be braced. The beam is designed to reach its capacity for an unbraced length of 6 metres. The brace length is 4.5 metres.

Evaluate the 6m unbraced length beam capacity. First the beam class has to be determined.

-Flange 7.8250

2359

235996

252

300

yfxt

c i.e.: Class 1

-Web 8.69250

23572

23572728.68

8

550

yft

c i.e.: Class 1

It can reach: Mpl = Z fy = 920 x 103 x 250 x 10-6 = 1230 kNm

Mcr = 5,0

2

2

2

2

z

t

z

wz

EI

GIL

I

I

L

EI

=

= kNmxxxx

xxxx

x

xxxx2167

1011310200

10322010776000

10113

109300

6000

10113102005,0

632

332

6

9

2

632

LT =cr

yy

M

fW= 75.0

2167

1230

2167

10250920000 6

xx

2)2.0(15,0 LTLTLTLT a = 92.075.0)2.075.0(49.015,0 2

LT

LT = 5,022

1

LTLTLT = 69.0

75.092.092.0

15,022

Mb.Rd = LT w Wpl.y fy/m1 = 0.69x 920 x 103 x 250 x 10-6 / 1.1 =771.5kNm

The unfactored compressive force is

1475.9kN25600

105.7711.1 3

xx

td

MF

f

rmc

For braces at 1/3 points: 3

mmNxx

L

Pk cr /738

6000

109.14753 3

0

20 2.33200000

450073822mm

xx

E

LkA b

b

As a compression member mmrrL 5.22200

4500200 min

Try L 150x150x10: rmin = 29.7mm; A = 2930mm2

17.71kN9.14753004.0 004.0 Q xxPcr

9.88250200000

1 yf

E 71.19.887.29

4500

1

xr

L

i

cr

2)2.0(15,0 a = 44.471.1)2.071.1(34.015,0 2

= 5,022

1

= 12.0

71.144.444.4

15,022

Nb.Rd = A fy/m1 = 0.12 x 2930 x 250 x 10-3 / 1.1 =78 kN >> Q = 17.71 kN

Notes:

1. mmx

xx

AE

PL14.0

2000002930

10450071.17 3

; assumed = 0.002L = 0.002x6000 = 12 mm.

The force of 17.71kN is generated in 0.14 mm not 12 mm

2. kNL

PkQ cr 914.012

1000

7380002

This is considerably less than the 17.71 kN assumed and in turn generates less .

3- If mm61000

10 was used rather than 1/500 then Q < 738 (6.14)/1000 =4.5 kN

mmx

xx

AE

PL03.0

2000002930

1045005.4 3

5.4 then Q3 < 738 (6.03)/1000 =4.45 kN

ok.

4. The brace have to designed for:

0.01 force in the compression flange if in an elastic design or 0.025 force in the compression flange if in a plastic design

0.001 kN4.1325600

105.77101.001.0 3

xx

td

MF

f

rc

This is 0.75 Q1 and 3Q3

5- What if braces can be provided in 2 directions so that brace can be assumed to act in tension?

Then as Ab = 47mm2 with a slenderness limit of 300, as a tension member:

mmrrL 15300

4500300 min

Try L 90x90x7: rmin = 17.7mm; A = 1220mm2 Npl.Rd = A fy/m1 = 1220 x 250 x 10-3 / 1.1 =272.3 kN O.K

17.71kN9.14753004.0 004.0 Q xxPcr

mmx

xx

AE

PL33.0

2000001220

10450071.17 3' << 12mm assumed.

kNQ 1.933.0121000

738'

mmx

xx

AE

PL16.0

2000001220

1045001.9 3'' kNQ 916.012

1000

738''

mmx

xx

AE

PL16.0

2000001220

1045009 3''' kNQ 914.012

1000

738'''

This is approximately 2/3 of the required by the design standard.

-Examination of Equations [6] and [7]

000 11

L

Pkk cr

[6]

000 L

PkQ cr

[7]

0

0

1k

k [6a]

0

00

1k

Q [7a]

If 10k

k

Select 210

andk

k

- As stiffness of brace, k/k0, decreases the deflections increase. - As stiffness of brace decreases the force Q that must be developed increases. - If the brace is too soft it will need a large force therefore the design should be based on both

strength and stiffness requirements.

3. BRACING OF PARALLELL MEMBERS. - Assume that bracing is of constant size.

- The extreme value of out-of-straightness for m members is mi , [5]. This states that the

extreme value for m members is less than for one: - Members are equally spaced. - Example m =3.

0

3 c

M

300303

2 k

L

PQ cr

2002032

2 k

L

PQQ cr

1001021

2 k

L

PQQ cr

Also: k

Q

EA

LQ

E

b 111

k

k

Q

k

Q

EA

LQ

E

b 2121212

k

QQQ

EA

LQ

E

b 321323

3210321

0003 QQQQQQQ

k

kkQ

Where: k00 =Q0 and 10 k

k

01 0321 QQQQ 210210

0012 QQQQQk

kkQQ

01 0321 QQQQ

And: 1010

0021 QQQk

kkQQ 01 021 QQQ

The three simultaneous equations are;

01 0321 QQQQ [A]

01 0321 QQQQ [B]

01 021 QQQ [C]

Where: k

k0 ; L

PkQ 0

000

and

mi0

The previous conclusions induce a selection of: 210 k

k

Second Example Will the L 150 x 150 x 10 mm selected for the first example provide adequate bracing for three parallel WWF 600x152, 250MPa yield stress, when spanning of 18 metres. The brace length is 4.5 metres.

1- The unfactored compressive force is equal to 1475.9 kN. 2- The braces at the 1/3 points i.e.: = 3

3- Therefore mmNxx

L

Pk cr /738

6000

109.14753 3

0

4- mmx

mi 93.6

3

60000020.00

Q0 = k00 = 6.93 x 738 = 5114.3 N

5- mmNx

L

EAk

B

B /2.1302224500

2000002930

6- 25.176738

2.130222

0

K

K ; 0057.00

k

k

7- The simultaneous equations are:

0 5114.310057.00057.00057.0 321 QQQ [A]

0 5114.310057.00057.0 321 QQQ [B]

0 5114.310057.0 21 QQ [C]

kN 15.7N 15763 1 Q ; kN 10.6N 10559 2 Q ; kN .35N 5295 3 Q

121.02.130

7.1511

k

Q; 202.0

2.130

6.10121.02

12 k

Q; 243.0

2.130

3.5202.03

23 k

Q

The capacity of L 150 x 150 x 10 mm, calculated in the first example, was: Nb.Rd = 78 kN >> Q = 15.7 kN

Summary 243.03

202.02

121.01

mmmi 9.60

Note: (i) One brace is in tension (ii) It is tacitly assumed that the braces area installed to limit imax to 0.002 of 6000mm. (iii) If braces are installed with imax = 36 mm there is a change in the forces previously calculated. (iv) If braces are installed with initial forces present, these forces should be considered. Third Example

Part floor framing plan

Column C1extends 3700 mm above and below this level. It is prevented from buckling about its weak axis at this level only by the flexural stiffness about the weak axis of beams AC-1 and CE-1. The diaphragm action of the floor prevents relative movement of A1, B1, D1 and E1. Column loads above and below are 1560 kN and 1780 kN. Assume 0 is L/1000 = 2x3700/1000 = 7.4 mm. Question: Do beams provide adequate support so that column can be designed for kL = 3700mm?

1- Take kNPc 16702

17801560

; 903.0

3700

167020

x

L

Pk c

kNQ )4.7(903.0 ; mmkNQ

k /4.7

1903.0

EI

aLPa

3

2 ; aLa

EIPk

2

3

kNmmNxxxxxx

aLa

EI

aLa

EIktotal 05.1/1051273778

73502750

103.252000003

73001500

103.212000003332

6

2

6

22

221

1

16.1903.0

051.1

0k

kno good,

too large, see previous graph, a stiffer system is needed, greater than double of the initially adopted.

2- Try a WWF 300x95.3 & WWF 300x115 i.e.: comparable W and Z (Iz = 72x106 mm4, 85.5x106 mm4) ktotal = 2.629 + 0.922 = 3.55 kN/mm

Q = 3.55 3.55 = 0.903 ( + 7.4) = 2.52mm Q = 8.96kN

3- An alternative solution takes into account that most of the restraint comes from AC-1 beam. Therefore as good solution will be to increase its size and leave CE-1 as it is i.e.:

ktotal = 2.629 + 0.273 = 2.902 kN/mm 2.902 = 0.903 ( + 7.4) = 3.34mm Q = 9.7kN

4- the bending moments developed in the members should also be checked, i.e. for AC-1:

kNmM dy 1.135.1902.2

629.2x7.9

Mb.Rd = Wpl.y fy/m1 =726x103 x 250x10-6 / 1.1 =165kNm

..108.0165

1.130

,,

KOM

M

M

M

ryb

dy

rdzb

dz

4. DIAGONAL BRACING FOR COLUMNS. The general procedure is composed of four steps:

1- Select bracing, 2- Compute deflections; 3- Determine the P- effects; 4- Iterate till the desired solution convergence.

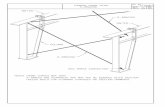

Fourth Example The specified (1/50) win forces acting on a braced bay and the resulting forces are show in the illustration below. Select diagonal bracing to resist the imposed loads including the P- effects.

Additional information 1- Dead plus wind load combination case has been established to be critical. Dead loads

contributing to P- effects are: Level 2: 6248kN, Level3: 6248kN, and Level4: 2384kN.

2- Storey drifts due to: bracing force B aAE

BlB

2

in the storey;

Compressive force C aAE

ChC

2

in the leeward column;

Tensile force T aAE

TChT

2

in all the storeys above.

3- Area of column is equal to 9280mm2 in all the levels

Select bracing

Level 1-2 kNxQT qf 5870.3915.1

mmLr 1.333009931300min

Try 2 150x90x10 long legs back to back with a 10mm gusset plate: Ag= 4640mm2 and ry= 35.8mm

Adopting one bolt hole for 22mm diameter bolt the net area can be evaluated: An = 4640 – 2(10x26) = 4120 mm2

kNxxAf

NM

yRdpl 5.1054

1.1

102504640 3

0.

; kN

xxfAN

M

unetRdu 6.1186

25.1

1040041209.09.0

3

2.

kNNkNN duRd 5875.1054 O.K. Levels 2-3 and 3-4 Use 2 150x90x10 long legs back to back with a 10mm gusset plate, i.e.: Ag= 4640mm2 and ry= 35.8mm to provide minimum slenderness ratio. Lateral deflections (specified wind) Level 1-2

Bracing mmxx

xx

aAE

BlB 62.4

20000046409000

993110391 232

Column mmxx

xx

aAE

ChC 31.0

20000092809000

420010293 232

=4.93mm Level 2-3

Bracing mmxx

xx

aAE

BlB 70.2

20000046409000

980910234 232

Column Level 1-2 mmx

C 29.04200

390031.0

Level 2-3 mmxx

xxC 12.0

20000092809000

390010127 23

2

Level 2-3 mmxx

xxT 13.0

20000092809000

420010127 23

1

=3.24mm Level 3-4

Bracing mmxx

xx

aAE

BlB 00.1

20000046409000

9809106.86 232

Column Level 1-2 mmx

C 29.04200

390031.0

Level 2-3 mmC 12.0

Level 3-4 mmC 12.0

Level 2-3 mmT 13.0

Level 3-4 mmx

T 12.04200

390013.0

=1.784mm

P- effects (D + Q)

In any storey

Non-iterative method

QV

V

VV '

''

max

1

The deflected shape and factored P- effects are:

Equivalent Equivalent Shears, V’ Lateral Force, H ― ― → ――→

1.09 D Q 1.09 D Q

← ― ―

― ― → ――→

7.17 D Q 6.08 D Q

← ― ―

― ― → ――→

17.47 D Q 11.39 D Q

← ― ― ←――

17.47 D Q

For Level 3-4 (2384 D x 1.78 Q)/3900 = 1.09 D Q

For Level 2-3 ((2384 + 6248) D x 3.24 Q)/3900 = 7.17 D Q

For Level 3-4 ((2384 + 6248 + 6248) D x 4.93 Q)/3900 = 17.47 D Q

For level 1-2 kNxx

V

V

VV

Q

4.36

531

07.341

07.345.13.147.17

1'

''

max

The force in the bracing including the P- effects;

kNNkNa

LN uRdPd 5.10541.626

9000

99314.5674.36531, O.K.

For Levels 2-3 and 3-4 the diagonals selected for maximum slenderness ratio will also be ok.

2384 D

6248 D

1.78 Q

3.24 Q

4.93 Q

6248 D

5. DIAPHRAGMS.

The diaphragm action:

- Transfer in-plane lateral loads applied at roof and floor levels to stiffer members; - Need strength and stiffness;

- Must look at flow of forces (how forces are carried from point to point) intersheet connections and connections at boundaries are important.

Consider:

The shear strength of diaphragm depends on: - Seam capacity. - Edge capacity.

- Purlin capacity (a controlled by fasteners). overall buckling strength.

Stiffness of diaphragm depends on: -Panel warping;

- Movement at seams; - Edge panel slip.

The shear stiffness

G and a

;

a

bt

FG

bt

F or

b

FaGtG '

“spring stiffness” is equal to a

bGF '

Wall Cladding

Can cladding take horizontal force (in-plane) from girts to reduce effective length of columns? Must establish force in girt as a function of . Cladding must provide this force and stiffness. Roof Diaphragm

The diaphragm acts as a deep beam to carry the shear to the ends where it must be transferred to the ground.

The force in the flanges is equal to D

wL

D

M

8

2

6

4

102384

5

x

vLF

EI

wLVft

Where F is the flexibility factor equal to a function of: -Deck span/average length supplied; -Deck gauge;

- -Side lap connection; - -Transverse welds.

And I is the moment of inertia of the flanges (which must be connected to the web).