Boron Fibres

-

Upload

kishore-kumar-rajendiran -

Category

Documents

-

view

238 -

download

0

Transcript of Boron Fibres

-

7/31/2019 Boron Fibres

1/21

Boron FibresBoron Fibres

-

7/31/2019 Boron Fibres

2/21

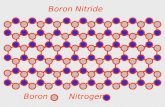

IntroductionIntroduction

Inherently brittle materialInherently brittle material

Produced by chemical vapour depositionProduced by chemical vapour deposition High temperature processHigh temperature processLimited substrate materialsLimited substrate materials Tungsten or Carbon fibre is usedTungsten or Carbon fibre is usedItself a composite fibreItself a composite fibre

First boron fibre obtained byFirst boron fibre obtained by WeintraubWeintraub in 1911in 1911Commercial production started during 1960Commercial production started during 1960At present, usage is very much limitedAt present, usage is very much limited

-

7/31/2019 Boron Fibres

3/21

FabricationFabrication

Thermal decomposition of a boron hydrideThermal decomposition of a boron hydride

Involves low temperaturesInvolves low temperatures

CarbonCarbon--coated glass fibres can be usedcoated glass fibres can be used

Weak due to lack of adherenceWeak due to lack of adherence

Much less dense owing to the trapped gasesMuch less dense owing to the trapped gases

Reduction of boron halideReduction of boron halide

2BX2BX33

+ 3H+ 3H22

2B + 6HX2B + 6HX

XX ClCl, Br, I, Br, I High temperature processHigh temperature process Refractory material substrateRefractory material substrate

heavyheavy

High & uniform quality fibresHigh & uniform quality fibres

-

7/31/2019 Boron Fibres

4/21

Schematic of boron

filament production by the CVD technique

-

7/31/2019 Boron Fibres

5/21

-

7/31/2019 Boron Fibres

6/21

Formation TemperatureFormation Temperature

Below critical temperature (CT)Below critical temperature (CT)

AmorphousAmorphousAbove CTAbove CT

CrystallineCrystalline

Stationary wireStationary wire

CT is 1000CT is 1000CCMoving wireMoving wire CT is higherCT is higherCT increases with speedCT increases with speed

-

7/31/2019 Boron Fibres

7/21

-

7/31/2019 Boron Fibres

8/21

Structure & MorphologyStructure & Morphology

Structural defects & morphological irregularitiesStructural defects & morphological irregularitiesdeteriorate the mechanical propertiesdeteriorate the mechanical properties

Depend on the conditions of depositionDepend on the conditions of depositionComposition of gases, gas dynamics, temperature,Composition of gases, gas dynamics, temperature,

etc.etc.

Temperature gradients & trace impurities areTemperature gradients & trace impurities areprocess irregularitiesprocess irregularities

Greater irregularities caused byGreater irregularities caused by

Fluctuations in electric powerFluctuations in electric powerInstability in gas flowInstability in gas flowOther operator induced variablesOther operator induced variables

-

7/31/2019 Boron Fibres

9/21

StructureStructure

Depends on deposition conditionsDepends on deposition conditions

Melt/CVD above 1300Melt/CVD above 1300CC

--rhombohedralrhombohedralLower temperature (

-

7/31/2019 Boron Fibres

10/21

-

7/31/2019 Boron Fibres

11/21

-

7/31/2019 Boron Fibres

12/21

Barrier coatingBarrier coating

SiC barrier coating prevents adverseSiC barrier coating prevents adverse

reactionreactionegeg. between Al & B. between Al & B

SiC is vapour deposited using a mixture ofSiC is vapour deposited using a mixture ofHH22

& methyl& methyl dichlorosilanedichlorosilane

-

7/31/2019 Boron Fibres

13/21

Corn-cob structure of boron fibre

Consisting of nodules separated by boundaries

Nodule size varies during the course of fabrication

-

7/31/2019 Boron Fibres

14/21

Residual stressesResidual stresses

Boron fibres have inherent residualBoron fibres have inherent residual

stressesstressesGrowth stresses in the nodules of boronGrowth stresses in the nodules of boron

Stresses induced by diffusion of boron into WStresses induced by diffusion of boron into Wcorecore

Stresses generated by difference in TECStresses generated by difference in TEC

Compressive stresses on surface due toCompressive stresses on surface due toquenching actionquenching action

-

7/31/2019 Boron Fibres

15/21

Residual stress pattern in boron fibre

-

7/31/2019 Boron Fibres

16/21

Fracture characteristicsFracture characteristics

Brittle materialBrittle material

distribution of strengthsdistribution of strengthsnot capable of deforming plasticallynot capable of deforming plastically

Imperfections lead to stress concentrationsImperfections lead to stress concentrations

Cracks originate at preexisting defectsCracks originate at preexisting defects

located at boronlocated at boron--core interface/ surfacecore interface/ surface

Surface defects are due to nodularSurface defects are due to nodular

structurestructure

-

7/31/2019 Boron Fibres

17/21

Radial cracks due to internal stresses

Cracks run from within the core to just inside

Characteristic brittlefracture of B fibre

-

7/31/2019 Boron Fibres

18/21

PropertiesProperties

YoungYoungs modulus is 380s modulus is 380--400 GPa400 GPa

Does not show intrinsic strength under tensileDoes not show intrinsic strength under tensileloadingloading

Average tensile strength is 3Average tensile strength is 3--4 GPa4 GPa

Intrinsic strength of B obtained in flexure testIntrinsic strength of B obtained in flexure test

Strength of 14 GPa observedStrength of 14 GPa observedDensity of 100Density of 100 mm B/W fibre is 2.6 g/ccB/W fibre is 2.6 g/ccMelting point is 2040Melting point is 2040CC

Thermal expansion coefficient is 8.3 X 10Thermal expansion coefficient is 8.3 X 10--66

CC--11

-

7/31/2019 Boron Fibres

19/21

-

7/31/2019 Boron Fibres

20/21

ApplicationsApplications

Used in a number of military aircraftsUsed in a number of military aircrafts

FF--14, F14, F--15 and US space shuttle15 and US space shuttleUsed for stiffening golf shafts, tennisUsed for stiffening golf shafts, tennis

rackets and bicycle framesrackets and bicycle framesOne big obstacle is high costOne big obstacle is high cost

Higher cost is due to the costly W substrateHigher cost is due to the costly W substrate

-

7/31/2019 Boron Fibres

21/21

Find out the final density of B fibre of diameter 100 m deposited on

a W fibre of diameter 12.5 m. Density values of B & W are 2.34 & 19.3 g/cm3

respectively.