Boost 1d3d Coupling

-

Upload

adrian-ferrer -

Category

Documents

-

view

219 -

download

0

Transcript of Boost 1d3d Coupling

-

8/13/2019 Boost 1d3d Coupling

1/42

-

8/13/2019 Boost 1d3d Coupling

2/42

-

8/13/2019 Boost 1d3d Coupling

3/42

-

8/13/2019 Boost 1d3d Coupling

4/42

-

8/13/2019 Boost 1d3d Coupling

5/42

1D - 3D Coupling BOOST v5.1

AST.01.0108.0510 31-Jan-2008 i

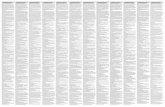

Table of Contents

1. Introduction _____________________________________________________1-1

1.1. Scope _______________________________________________________________________1-1

1.2. User Qualifications ___________________________________________________________ 1-1

1.3. Symbols_____________________________________________________________________1-1

1.4. Configurations _______________________________________________________________ 1-2

1.5. Documentation ______________________________________________________________1-2

2. General Overview________________________________________________2-1

3. Theoretical Background _________________________________________3-1

3.1. FIRE-BOOST Interaction _____________________________________________________3-3

3.2. 1D-Coupling Software Implementation _________________________________________3-5

4. BOOST Input Data_______________________________________________4-1

4.1. Global Data__________________________________________________________________4-2

4.2. FIRE Link___________________________________________________________________4-3

5. FIRE Input Data _________________________________________________5-1

5.1. Mesh Generation_____________________________________________________________ 5-1

5.2. BOOST Link Data____________________________________________________________5-3

5.3. Setup Calculation ____________________________________________________________5-5

5.3.1. Boundary Conditions______________________________________________________5-5

5.3.2. Initialization ____________________________________________________________5-10

5.4. Simulation _________________________________________________________________5-12

5.4.1. Check List for Calculation ________________________________________________5-12

5.4.2. Start Calculation ________________________________________________________5-13

5.4.3. Starting from Command Line _____________________________________________5-14

5.4.4. 1D-Coupling under MPI __________________________________________________5-15

6. Result Analysis __________________________________________________6-1

7. Model-1D Variables ______________________________________________7-1

-

8/13/2019 Boost 1d3d Coupling

6/42

BOOST v5.1 1D - 3D Coupling

ii AST.01.0108.0510 31-Jan-2008

List of Figures

Figure 3-1: Classic Species in BOOST Compared to Standard Species in FIRE................................................3-2

Figure 3-2: Start of Hybrid Calculation ...............................................................................................................3-3Figure 3-3: Data Transfer FIRE to BOOST.........................................................................................................3-3

Figure 3-4: Data Transfer BOOST to FIRE .........................................................................................................3-4

Figure 3-5: Flow Patterns at 1D - 3D Interfaces .................................................................................................3-5

Figure 3-6: 1D-Coupling Software Implementation ............................................................................................3-5

Figure 4-1: FIRE Link Elements in a BOOST Model..........................................................................................4-1

Figure 4-2: Simulation Control FIRE Link Control Window...........................................................................4-2

Figure 4-3: FIRE Link Dialog ...............................................................................................................................4-3

Figure 4-4: Convergence Control in BOOST........................................................................................................4-4

Figure 5-1: Mesh Generation FIRE Domain .....................................................................................................5-1

Figure 5-2: Mesh Generation CAD Surface.......................................................................................................5-2

Figure 5-3: Mesh Generation Enlarge FIRE Domain.......................................................................................5-2

Figure 5-4: Mesh Generation Connecting Edge Topology ................................................................................5-3

Figure 5-5: FIRE Link Correct Connectivity Boundary...................................................................................5-3

Figure 5-6: FIRE Link Example of Incorrect Connectivity Boundary.............................................................5-4

Figure 5-8: Data Transfer FIRE to BOOST.........................................................................................................5-4

Figure 5-9: Data Transfer BOOST to FIRE .........................................................................................................5-5

Figure 5-10: Boundary Conditions Window .........................................................................................................5-5

Figure 5-11: Boundary Type Recommendation for Intake Manifold..................................................................5-7

Figure 5-12: Convergence Problems Caused by Boundary Type ........................................................................5-8

Figure 5-13: Boundary Type Recommendation for Intake Manifold with Change in Cross-Section................5-8

Figure 5-14: BOOST: Fluid Link ID.....................................................................................................................5-9Figure 5-15: Initialization in FIRE Domain.......................................................................................................5-10

Figure 5-16: Initialization for Intake Manifold..................................................................................................5-11

Figure 5-17: Pressure Trace at FIRE - BOOST Connectivity (1stcycle, FIRE only) .......................................5-11

Figure 5-18: Calculation Wizard 1D-Coupling Server-host Selection............................................................5-13

Figure 5-19: 1D Model Selection Window ..........................................................................................................5-14

Figure 6-1: Structure of 1D-Coupling Monitoring File using FIRE Species ......................................................6-1

Figure 6-2: Structure of 1D-Coupling Monitoring File using BOOST Species ..................................................6-2

Figure 6-3: BOOST result .....................................................................................................................................6-3

-

8/13/2019 Boost 1d3d Coupling

7/42

1D - 3D Coupling BOOST v5.1

1. INTRODUCTIONThis manual describes how to use the FIRE-BOOST Interface (FBI).

1.1. Scope

This document is for users of 1D 3D Coupling and anyone interested in theory and

modeling. It does not attempt to discuss all the concepts of gas dynamics required to obtain

successful solutions. It is the users responsibility to determine if he/she has sufficient

knowledge and understanding of fluid dynamics to apply this software appropriately.

1.2. User Qualifications

This document is a basic qualification for using BOOST and users are recommended to

continue with basic and advanced training courses.

1.3. Symbols

The following symbols are used throughout this manual. Safety warnings must be strictly

observed during operation and service of the system or its components.

!

Caution: Cautions describe conditions, practices or procedures which

could result in damage to, or destruction of data if not strictly observed or

remedied.

Note: Notes provide important supplementary information.

Convention Meaning

Italics For emphasis, to introduce a new term or for manual

titles.

monospace To indicate a command, a program or a file name,

messages, input / output on a screen, file contents or

object names.

31-Jan-2008 1-1

-

8/13/2019 Boost 1d3d Coupling

8/42

BOOST v5.1 1D - 3D Coupling

1-2 31-Jan-2008

SCREEN-KEYS A SCREENfont is used for the names of windows and

keyboard keys, e.g. to indicate that you should type a

command and press the ENTERkey.

MenuOpt A MenuOptfont is used for the names of menu options,

submenus and screen buttons.

1.4. Configurations

Software configurations described in this manual were in effect on the publication date.

It is the users responsibility to verify the configuration of the equipment before applying

procedures.

1.5. DocumentationBOOSTdocumentation is available in PDF format and consists of the following:

Release Notes

Users Guide

Theory

Primer

Examples

Aftertreatment

Aftertreatment Primer

Linear Acoustics

1D-3D Coupling

Interfaces

Validation

GUI Users Guide

Installation Guide (Windows & UNIX)

Licensing Users Guide

Python Scripting

Optimization of Multi-body System using AVL Workspace & iSIGHTTM

Thermal Network Generator (TNG) Users Guide

Thermal Network Generator (TNG) Primer

-

8/13/2019 Boost 1d3d Coupling

9/42

1D - 3D Coupling BOOST v5.1

31-Jan-2008 2-1

2. GENERAL OVERVIEWThis manual describes how to perform coupled 1D-3D gas dynamics calculations with the

FIRE v8 - BOOST interface (FBI). The concept of coupling allows BOOST and FIRE to be

run as independent executables. The data exchange is performed via UNIX sockets usingnetwork communication (TCP/PP).

Note: FIRE v8.6 and BOOST v5.1 are required for the 1D/3D Interface.

-

8/13/2019 Boost 1d3d Coupling

10/42

-

8/13/2019 Boost 1d3d Coupling

11/42

1D - 3D Coupling BOOST v5.1

31-Jan-2008 3-1

3. THEORETICAL BACKGROUNDThe numerical solution of the governing transport equations in the 3D domain is

performed by the fully implicit finite volume method of FIRE and, in the 1D domain, by

the explicit finite difference method of BOOST. In each sub-domain the unsteadyconservation equations of mass, momentum and thermal energy will be solved by each

program separately using the results of the attached program as boundary conditions. The

boundary conditions are derived from space/time averaging of flow variables in selected

regions of the domain surfaces. These regions are calledfluid links.The exchange of

physical quantities takes place at the beginning of each time step, whereby the geometrical

definition of fluid links must be performed prior to the calculation in the CFD Workflow

Manager pre-processing, using the method of SELECTIONS.

Due to the mixture of fully implicit and explicit discretization schemes the flow solvers

must agree upon the time step size. Since the step size of FIRE can be very large, the

stability criterion for explicit schemes (Courant no. < 1) could be violated significantly,which would end up with unstable solutions in the BOOST calculation. To prevent such

instabilities, BOOST is able to perform a number of sub-cycle steps until the above

stability criterion becomes satisfied. There are three conditions to initiate a sub-cycle

process:

The FIRE crank angle (CA) increment is larger than the CA increment

resulting from the CFL stability criterion.

The CA increments of FIRE and BOOST do not coincide exactly.

The accumulated FIRE and BOOST crank angles do not fit exactly at

characteristic (pre-scribed) values, e.g. BDC or TDC.

At the end the sub-cycling process BOOST v4 provides FIRE v8 with the time integral

mean values over the sub-cycles as boundary conditions.

BOOST computes the one-dimensional flow of a gas mixture. Separate mass balances are

solved for the individual species that make up the mixture, but only one momentum

balance is solved. The BOOST species are automatically mapped to active scalars in FIRE,

so that the treatment (one momentum balance for the entire mixture, separate mass

balances for the species) conforms to that in BOOST. The local values (i.e. FIRE cell

values) of the gas constant and the specific heat depend on the local species concentrations.

FIRE does not know the species properties. It sends the species concentrations and

temperatures of all cells to BOOST, BOOST computes the gas constants and specific heats

and sends it back to FIRE. This is done once for each time step. In FIRE the Standardspecies model has to be activated to allow for species-dependent values of the gas constant

and specific heat. But the FIRE species do not correspond to the BOOST species. Instead,

active scalars are generated automatically in FIRE and these correspond to the BOOST

species.

Note: The FIRE species do NOT correspond to the BOOST species

(unless the feature described below is active). Instead, separate active

scalars are generated automatically in FIRE which correspond to the

BOOST species.

-

8/13/2019 Boost 1d3d Coupling

12/42

BOOST v5.1 1D - 3D Coupling

The BOOST species transport model Classicconforms to the FIRE species model

Standard. If this model is activated in BOOST, FIRE will directly map the BOOST species

to its standard species, without creating active scalars. In this case, the gas constants and

specific heats for all cells are directly computed in FIRE. Combustion or other processes

working on the standard species concentrations will affect also the BOOST species. The old

species-coupling-mechanism with separate active scalars can still be enforced also in thiscase by setting the environment variable FORCE_1D_PROPSto 1 (i.e. with the additional

solver argument-env=FORCE_1D_PROPS=1in the Calculation Wizard or cfdwm_solver

script).

A comparison of the species mechanism is shown in Figure 3-1.

Figure 3-1: Classic Species in BOOST Compared to Standard Species in FIRE

mfFb mass fraction fuel burned

mfFv mass fraction fuel vapor

mfCP mass fraction combustion products

mfm mass fraction fuel mixture

mfEGR mass fraction Exhaust gas return

When the old species coupling mechanism is used (using BOOST species) in FIRE the fluid

properties are taken also from the BOOST database. The update of the properties is done

at the beginning of each time-step (see message in .fla file:

%fire-I-CPL1D_UPDATE_RGAS_CP, cp, Rgas updated from 1D code).

With the species coupling mechanism FIRE uses it's own standard species. The update of

the properties is done for each iteration.

3-2 31-Jan-2008

-

8/13/2019 Boost 1d3d Coupling

13/42

1D - 3D Coupling BOOST v5.1

Note: Small differences may result from the frequency of the update

between the two coupling mechanisms. Differences are expected only in

cases with high temperature or species gradient.

3.1. FIRE-BOOST Interaction

When the BOOST model is initialized, an additional pipe containing one cell is created

automatically. The overlapping length of the pipe in the following figure is input in the

BOOST pre-processor. In the FIRE preprocessor a cell selection (with a specific name) has

to be created for each overlapping region, corresponding to the shaded cells in the figure

below. (If no selection is defined, only the first cell layer at the interface is used as

overlapping region in FIRE).

Figure 3-2: Start of Hybrid Calculation

At the start of the calculation of a time step, the density, momentum and temperature are

averaged over the part of 3D domain in the corresponding cell selection. This data is

transferred to the additional BOOSTpipe as shown in the following figure.

Figure 3-3: Data Transfer FIRE to BOOST

31-Jan-2008 3-3

-

8/13/2019 Boost 1d3d Coupling

14/42

BOOST v5.1 1D - 3D Coupling

As BOOSTuses an explicit scheme for solving the pipe flow, the time step can then be

calculated. As a result, the average mass flow and the flows of momentum and energy over

the interface between BOOST and FIRE are obtained. These flow rates are specified as

boundary conditions for FIRE at the interface and the calculation of the conditions at the

end of the time step are done by FIRE as shown in the following figure:

Figure 3-4: Data Transfer BOOST to FIRE

The FIRE 3D code uses an implicit scheme for the solution of the governing equations. It

therefore allows Courant numbers larger than 1. BOOST uses an explicit scheme and

therefore requires Courant numbers smaller than 1. This is usually not a severe

restriction as the modeling of critical parts in the engine with the 3D code requires a fine

mesh, whereas the 1D code is able to resolve pressure waves with satisfactory quality using

a coarser grid. This gives the desired ratio of the Courant numbers in the two calculation

domains with the same absolute value for the time step.

The user must ensure that the transition between the BOOST and FIRE calculation

domains is located in a straight pipe section where a one dimensional flow field can be

assumed. The length of the pipe section should be sufficient to avoid recirculation zonescrossing the boundary, shown in the following figure.

3-4 31-Jan-2008

-

8/13/2019 Boost 1d3d Coupling

15/42

-

8/13/2019 Boost 1d3d Coupling

16/42

BOOST v5.1 1D - 3D Coupling

3-6 31-Jan-2008

The hostname for the coupling server (i.e. the name of the computer running the server),

the input-dataset name for BOOST and a port number for the network connection has to

be specified when starting FIRE from the GUI or from command line. The coupling server

is started automatically together with FIRE.

The FIRE solver operates according to the procedure below (given in pseudo code).

Start :I ni t 1D coupl i ngf or al l t i me st eps {

f or al l 1D- i nt er f aces {set i nt er f ace f l ow val ues f or 1D code

}advance 1D si mul at i on one FI RE- t i mest epf or al l i nt erf aces {

get i nt er f ace f l ow val ues f r om 1D code}advance FI RE 3D si mul at i on one t i me st ep

}exi t 1D si mul at i onend

Algorithm 1: Basic Solver Algorithm for 1D-Coupled Simulations

-

8/13/2019 Boost 1d3d Coupling

17/42

1D - 3D Coupling BOOST v5.1

4. BOOST INPUT DATAPlease refer to Chapter 5 of the BOOST Examples manual for a description of FIRE

BOOST examples (pipe and intake manifold).

For a time and cost effective simulation of three dimensional (3D) flow patterns, BOOST

enables a 1D/3D hybrid calculation using FIRE. In this calculation mode, BOOST is used

as a subroutine of FIRE.

The user must design a one dimensional (1D) BOOST model using the BOOST pre-

processor and a 3D FIRE model using the FIRE pre-processor for the engine geometry

between the 3D-sides of the FIRELink elements. The user must ensure that the interface

between the 1D and 3D domains is located in a pipe section, where essentially one

dimensional flow occurs.

The FIRE Link elements located in the BOOSTmodel represent interfaces between the 1D

BOOST domain and the 3D FIRE domain. The FIRELink element is similar to a flowrestriction with two attached pipes, but with one explicit 1D-side and one explicit 3D-side.

The BOOST sub-model between the 3D-sides (shadow network) should be a 1D-

approximation of the 3D FIRE domain. Pipes are attached to the FIRE Link element in a

similar way as is done for a restriction.

PIPE 2 = Shadow Network

Figure 4-1: FIRE Link Elements in a BOOST Model

31-Jan-2008 4-1

-

8/13/2019 Boost 1d3d Coupling

18/42

BOOST v5.1 1D - 3D Coupling

4.1. Global Data

When performing a BOOST-FIRE simulation specify the required data in the Simulation

Globals section as shown in the following figure:

Figure 4-2: Simulation Control FIRE Link Control Window

Number of BOOST-only cycles

The BOOST simulation is performed using the shadow network as 1D-approximation of the 3D FIRE domain.

Number of FIRE/CFD-only cycles

The FIRE simulation is performed applying fixed boundary conditions generated

during the last cycle of the BOOST-only simulation.

This allows the coupled BOOST-FIRE simulation to be performed in three steps:

1. Simulation of BOOST only

During the Number of BOOST-only cycles the BOOST simulation is performed

using the shadow network as 1D-approximation of the 3D FIRE domain. During the

last of these cycles the conditions at the 3D-side of all FIRE-link elements are stored

for use as boundary conditions during the FIRE-only simulation.

2. Simulation of FIRE only

During the Number of FIRE-only cycles the FIRE simulation is performed until the

end of the FIRE-only cycles is reached using the boundary conditions generated

during the last BOOST-only cycle.

4-2 31-Jan-2008

-

8/13/2019 Boost 1d3d Coupling

19/42

1D - 3D Coupling BOOST v5.1

3. Coupled BOOST-FIRE simulation

The third step is the coupled simulation, where the BOOST and FIRE calculations are

performed simultaneously and full data exchange FIRE BOOST and BOOST FIRE

appears. The calculation in the BOOST shadow network also is performed. A data

exchange from the coupled BOOST-FIRE-simulation to the shadow network appears,

but does not appear in the other direction.

Splitting the simulation procedure into three steps will yield a better convergence of the

results and therefore a decrease of calculation time.

4.2. FIRE Link

This improved link allows to perform BOOST only calculations until it is converged, after

this a single cycle with the existing BOOSTresults is calculated to initialize the FIRE

domain and the last few cycles are calculated as a combined FIREBOOST calculation.

Figure 4-3: FIRE Link Dialog

Note: When restarting a co-simulation run, all data written for time levels

bigger than the actual restart time will be automatically deleted from the

monitoring file.

A convergence control can be performed with FIRE, where the calculation stops if aprescribed convergence criterion is fulfilled. The convergence criterion is that the variation

of the cycle-averaged values ("transients") of some parameters in BOOST elements over the

last three consecutive cycles is less than a prescribed threshold.

When the convergence criterion has been fulfilled, FIRE stops the coupling calculation. A

message will be found in the .fla file.

%f i r e-I - cpl 1d_advance, 1d pr ogr ami ndi cat es cycl e- conver gence

% st oppi ng

31-Jan-2008 4-3

-

8/13/2019 Boost 1d3d Coupling

20/42

-

8/13/2019 Boost 1d3d Coupling

21/42

-

8/13/2019 Boost 1d3d Coupling

22/42

BOOST v5.1 1D - 3D Coupling

Connectivity at inlet not perpendicular to pipe,inlet too close to separation plate

Connectivity at inlet almost perpendicular topipe, cylindrical pipe at inlet considered

NOYES

Figure 5-2: Mesh Generation CAD Surface

If possible a pipe section with the length of at least 1x the diameter of the corresponding

pipe should be considered at the transition between BOOST and FIRE.

As it is not always possible to provide the perfect pipe shape at the inlet and outlet it is

recommended to add at least a small cylindrical pipe to the FIRE domain (refer to Figure

5-3). The best way to do this is to enlarge the connectivity areas in the direction of the

pipes for at least few cell layers (i.e. 5mm to 10mm).

Figure 5-3: Mesh Generation Enlarge FIRE Domain

Note: The position of the 1D 3D interface must match between FIRE

and BOOST and the pipe length has to be consistent.

At all inlet/outlet boundaries it is strongly recommended to use a connecting edge topology

as the solver may have problems in terms of convergence behavior. In the automatic

meshing process (FAME Advanced Hybrid) the connecting edge will be created on the

boundary of a face selection.

5-2 31-Jan-2008

-

8/13/2019 Boost 1d3d Coupling

23/42

1D - 3D Coupling BOOST v5.1

Without connecting edge,

cut through volume mesh

With connecting edge,

cut through volume mesh

Figure 5-4: Mesh Generation Connecting Edge Topology

Note: A connecting edge has to be created always, when fluid is entering

or leaving the simulation domain.

5.2. BOOST Link Data

Selections have to be defined to specify boundary conditions (inlet/outlet and wall)

and to set up the connectivity between FIRE and BOOST.

1D 3D Link: Boundary faces 1D 3D Link: Integration volume

Cylinder 1

Cylinder 2

Cylinder 3

Cylinder 4

Figure 5-5: FIRE Link Correct Connectivity Boundary

1D 3D Link: Boundary faces 1D 3D Link: Boundary faces

C 2C 2C 1 C 1

C 3C 3

31-Jan-2008 5-3

-

8/13/2019 Boost 1d3d Coupling

24/42

-

8/13/2019 Boost 1d3d Coupling

25/42

1D - 3D Coupling BOOST v5.1

Figure 5-8: Data Transfer BOOST to FIRE

Note: For the data exchange between BOOST and FIRE at each pipe

attachment, the overlapping length must be defined in the BOOST pre-

processor. The length must be according to the length of the integration

volume in FIRE.

5.3. Setup Calculation

5.3.1. Boundary Conditions

In the Solver Steering File(SSF) parameter tree, select Module activationand activate

the Species Transportmodel. In the Species Transport menu, activate the Standard

option.

Select Boundary conditionsin the parameter tree to open the following window:

Figure 5-9: Boundary Conditions Window

31-Jan-2008 5-5

-

8/13/2019 Boost 1d3d Coupling

26/42

-

8/13/2019 Boost 1d3d Coupling

27/42

1D - 3D Coupling BOOST v5.1

Integration

volume

Select the cell selection containing the cells of the

overlapping region.

If no selection is defined as the integration volume at

the interface, the (single) cell layer adjacent to the

interface is used automatically. It is stronglyrecommended to define the first 2-3 layers as the

integration volume to avoid solver problems in terms

of convergence behavior.

NoSelection

Turbulence

velocity and

length scale

The turbulent length scale can be prescribed either

directly (Turb. length scale) or as a fraction of the

hydraulic diameter of the boundary surface (% of

hydraulic diameter). In the latter case, the absolute

value in meters is computed and displayed in the

GUI immediately. The solver only receives the value

displayed under Turb. length scale. The defaultvalues should be used as long as more precise data is

not available (i.e. experience).

After the FIRE BOOST connectivity has been set

up then the wall temperature has to be defined. The

temperature must be specified according to the value

used in BOOST.

% of mean

velocity

Enter the turbulence velocity at the boundary in %

of the mean flow velocity.

10

% of hydraulic

diameter

Enter the turbulent length scale at the boundary in

% of the hydraulic diameter of the boundary-

condition-face-selection.

10

Turb. length

scale

Enter the turbulent length scale in meters. 0.001

RED:Massflow boundary

GREEN:Pressure boundary

Figure 5-10: Boundary Type Recommendation for Intake Manifold

31-Jan-2008 5-7

-

8/13/2019 Boost 1d3d Coupling

28/42

-

8/13/2019 Boost 1d3d Coupling

29/42

1D - 3D Coupling BOOST v5.1

FIRE Link

Figure 5-13: BOOST: Fluid Link ID

31-Jan-2008 5-9

-

8/13/2019 Boost 1d3d Coupling

30/42

BOOST v5.1 1D - 3D Coupling

5.3.2. Initialization

The whole domain is initialized according to the BOOST data. When pressure and

temperature values are specified the density is recalculated in the solver automatically.

The whole domain should be smooth using 100 iterations for the pressure as well as for the

temperature value (refer to Figure 5-14).

Figure 5-14: Initialization in FIRE Domain

A key point for stability at calculation start is the correct initialization. Insufficient or even

wrong initialization will have a negative effect on the convergence behavior and in the

worst case it will cause divergence of the calculation.

It is recommended to initialize the BOOST values of pressure and temperature in the

integration volumes. The data has to be taken from measurement points connected to the

1D/3D interfaces. The data according to the coupling calculation start should be used (in

BOOST activate the data readeroption in the curve properties). Figure 5-14shows an

example for initialization of an intake manifold.

5-10 31-Jan-2008

-

8/13/2019 Boost 1d3d Coupling

31/42

1D - 3D Coupling BOOST v5.1

Figure 5-15: Initialization for Intake Manifold

Since several 1D 3D coupling cycles are calculated the initialization at calculation start

will not affect the final result. But due to a more precise initialization less coupling cycles

might be necessary and calculation time could be decreased.

70000

75000

80000

85000

90000

95000

100000

105000

110000

115000

120000

0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 170 180

Crank angle

Press

ure

[Pa]

C 3, w/o Initialisation in IV

C 3, w Initialisation in IV

C 5, w/o Initialisation in IV

C 5, w Initialisation in IV

Figure 5-16: Pressure Trace at FIRE - BOOST Connectivity (1stcycle, FIRE only)

Note: Boundary and initial conditions in FIRE must be defined according

to the BOOST data.

31-Jan-2008 5-11

-

8/13/2019 Boost 1d3d Coupling

32/42

BOOST v5.1 1D - 3D Coupling

5-12 31-Jan-2008

5.4. Simulation

5.4.1. Check List for Calculation

Before starting the calculation the following checks should be made to reduce user errors.BOOST:

FIRE Link positions correlate with FIRE model (i.e. air cleaner position is

inside/outside FIRE domain, pipe length is correct, ...)

Check FIRE Link for correct set up of connection direction (1D and 3D side)

BOOST only and FIRE only cycle are defined (30 BOOST only and 1 FIRE only cycle

are recommended values)

The BOOST input file (.bst file) has been generated and includes the latest corrections

made in the BOOST model.

Network connection to FIRE is available and online.

Classic species transport is activated.

FIRE:

FIRE model correlates with the BOOST model (connectivity location is defined

correct).

All relevant details are considered in the 3D model and correct placed (i.e. flap

position,...).

The FIRE model contains no negative volumes or negative normal distances. The

solver cannot accept those cells.

All selections for the 1D 3D connectivity have been set up (boundary faces and

integration volume).

No selections are overlapping or mismatched (i.e. no boundary faces are connected to

the wrong integration volume).

The Fluid ID is defined correctly (check with BOOST).

The correct engine speed is defined (check with BOOST).

The crank-angle range covers the required range (FIRE only cycle + coupling cycles).

The selected port number for TCP/IP connection is not in use (further 1D 3D

coupling calculation, license server, ...).

Check if the correct 1D-coupling server version is available.

Standard species transport is activated.

If the check list has been passed successfully the calculation can be started.

-

8/13/2019 Boost 1d3d Coupling

33/42

1D - 3D Coupling BOOST v5.1

5.4.2. Start Calculation

The 1D-program always runs its own process separately from FIRE. This program is called

the 1D-server (i.e. fire_boost_server.ia32-unknown-winnt for WINDOWS platform

or fire_boost_server.ia32-unknown-linux for Linux 32 bit system). It is started

automatically with FIRE. The 1D-server-executable must be installed parallel to the AST-bin-directory.

The 1D-server-host selection is shown in Figure 5-17. The 1D-server may be local (i.e. the

same host running FIRE and the server) or remote, in which case the machine name and a

user name must be specified. The port-number is necessary for the interprocess-connection

and must be in the range 1025-65000.

Note: The same port-number must NOT be used for running 1D-coupling

simulations simultaneously on the same computer.

Figure 5-17: Calculation Wizard 1D-Coupling Server-host Selection

The 1D model selection is shown in Figure 5-18. Select BOOSTas the required 1D-

program to couple with. The calculation wizard checks which 1D-servers are installed and

only these are selectable. Additionally, the BOOST.bst-file input file must be specified.

The input file must be accessible under the specified path from the server-host.

31-Jan-2008 5-13

-

8/13/2019 Boost 1d3d Coupling

34/42

BOOST v5.1 1D - 3D Coupling

Figure 5-18: 1D Model Selection Window

If more than one FIRE BOOST coupling calculation is started different BOOST input

files have to be used.

The time-out for the TCP-connection (see 3.2) between FIRE and the 1D-program is 3600

seconds by default. This means, FIRE will keep on running and try to re-establish a

connection to the 1D-program for one hour if the connection was lost. A shorter or longer

time-out can be defined by specifying the additional solver argument-

env=ASTPNT_RECONNECTION_TRIES=n , where nis the number of reconnection-tries.

FIRE waits three seconds after each try, so the resulting time-out is 3nseconds.

5.4.3. Starting from Command Line

Starting a 1D-coupled FIRE -simulation from command line is possible using the

cfdwm_solver-script. Basically the same parameters for the 1D-coupling have to be

specified as for starting from the GUI. The corresponding options are:

- 1dcpl _cmd BOOST

- 1dcpl _pr oj ect Location of the input file for BOOST,

including path

- 1dcpl _host Name of host to start coupling server

- 1dcpl _user Name of user on

- 1dcpl _por t Port number under which to run coupling

server,

1024 < port-number < 65000

5-14 31-Jan-2008

-

8/13/2019 Boost 1d3d Coupling

35/42

1D - 3D Coupling BOOST v5.1

31-Jan-2008 5-15

5.4.4. 1D-Coupling under MPI

1D-coupling is supported also under MPI. In this case only one coupling server will be

started. Only the first MPI-sub-process will communicate with the server and distribute

the data accordingly among the other sub-processes.

-

8/13/2019 Boost 1d3d Coupling

36/42

-

8/13/2019 Boost 1d3d Coupling

37/42

1D - 3D Coupling BOOST v5.1

31-Jan-2008 6-1

6. RESULT ANALYSISResult analysis of volume data must be performed with the build-in post-processing tools

of each program. For transient analysis of locally exchanged data 2D plot-files containing

the most important flow variables will be written by FIRE.

In order to distinguish the bi-directional data exchanges FIRE 1D-model and 1D-model

FIRE two sets of 2D-plotting files are created for each fluid link. The corresponding

data is written in ASCII format. The filenames and extensions are derived from the

exchange directions and the fluid link IDs, e.g. FIRE-2-1D-program.00001 represents data

transferred from FIRE to the 1D-program at fluid link number 1. 1D-program-2-

FIRE.00001 represents data transferred from the 1D-program to FIRE at the same fluid

link. Each 2D file consists of a header and a data section (refer to Figure 6-1). The header

section displays information about general interface settings and certain single-valued

model parameter. In the data section the space/time averaged values of momentum,

pressure, density, temperature and species concentrations, which are exchanged at thebeginning of each co-simulation step, are recorded. To visualize the 2D data standard

plotting tools, like XMgrace (http://plasma-gate.weizmann.ac.il/Grace) or MS-Excel, can be

used.

########################################################################## FI RE- M1D I nter f ace: Data Exchange Hi st ory########################################################################## Fl ui dLi nk I D 1# Fl ui dLi nk I ndex 1# BoundaryRegi on I ndex 0# Sel ect i on Name BOOST_Li nk_1# Speci es Type FI RE st andard speci es# I nt er f ace Type 1D- gener al# Dat a Exchange Di r ect i on FI RE - - > 1D- gener al# Boundary Type MASSFLOW# I ni t i al FI RE Cr ank Angl e 1. 00000 [ deg]# I ni t i al FI RE Ti me St ep 4. 166667E- 05 [ sec]# Overl ap Length 6. 000000E- 03 [ m]# Uni t Normal Vector x 0. 00000 [ m]# Uni t Normal Vector y 0. 00000 [ m]# Uni t Normal Vector z 1. 00000 [ m]# At t achment Ar ea 1. 648350E- 03 [ m 2]###################################################################################################### TS CA VEL PRE DEN MASSFLOW TEM EGR Mi xt ureFr acFuel# - [ deg] [m/ s] [ Pa] [ kg/ m 3] [kg/s] [ K] [kg/kg] [kg/kg][ kg/ kg]#######################################################################################################################1 1. 00 0. 0000E+00 9. 4106E+04 1. 0797 0. 0000E+00 302. 4114 0. 0000E+00 0. 0000E+00 0. 0000E+002 2. 00 - 3. 1872 9. 3263E+04 1. 0728 - 5. 6363E- 03 301. 6216 0. 0000E+00 4. 1821E- 05 4. 1821E- 053 3. 00 - 37. 0375 8. 0162E+04 0. 9615 - 0. 0587 289. 3098 0. 0000E+00 2. 2460E- 05 2. 2460E- 054 4. 00 - 45. 7185 7. 8677E+04 0. 9491 - 0. 0715 287. 6481 0. 0000E+00 1. 1481E- 05 1. 1481E- 055 5. 00 - 49. 6092 7. 7770E+04 0. 9417 - 0. 0770 286. 5586 0. 0000E+00 5. 6442E- 06 5. 6442E- 066 6. 00 - 50. 6968 7. 7629E+04 0. 9409 - 0. 0786 286. 2711 0. 0000E+00 2. 7570E- 06 2. 7570E- 067 7. 00 - 50. 5994 7. 7749E+04 0. 9423 - 0. 0786 286. 2666 0. 0000E+00 1. 3522E- 06 1. 3522E- 068 8. 00 - 49. 8662 7. 8022E+04 0. 9451 - 0. 0777 286. 4371 0. 0000E+00 6. 6974E- 07 6. 6974E- 079 9. 00 - 48. 8307 7. 8374E+04 0. 9484 - 0. 0763 286. 7051 0. 0000E+00 3. 3591E- 07 3. 3591E- 07

Figure 6-1: Structure of 1D-Coupling Monitoring File using FIRE Species

http://plasma-gate.weizmann.ac.il/Gracehttp://plasma-gate.weizmann.ac.il/Grace -

8/13/2019 Boost 1d3d Coupling

38/42

BOOST v5.1 1D - 3D Coupling

6-2 31-Jan-2008

########################################################################## FI RE- M1D I nter f ace: Data Exchange Hi st ory########################################################################## Fl ui dLi nk I D 1# Fl ui dLi nk I ndex 1# BoundaryRegi on I ndex 0

# Sel ect i on Name BOOST_Li nk_1# Speci es Type 1D- code speci es# I nt er f ace Type 1D- gener al# Dat a Exchange Di r ect i on FI RE - - > 1D- gener al# Boundary Type MASSFLOW# I ni t i al FI RE Cr ank Angl e 1. 00000 [ deg]# I ni t i al FI RE Ti me St ep 4. 166667E- 05 [ sec]# Overl ap Length 6. 000000E- 03 [ m]# Uni t Normal Vector x 0. 00000 [ m]# Uni t Normal Vector y 0. 00000 [ m]# Uni t Normal Vector z 1. 00000 [ m]# At t achment Ar ea 1. 648350E- 03 [ m 2]####################################################################################################################### TS CA VEL PRE DEN MASSFLOW TEM BurnedFuel Combust i onPFuel Vapour# - [ deg] [m/ s] [ Pa] [ kg/ m 3] [kg/s] [ K] [kg/kg] [kg/kg][ kg/ kg]#

###################################################################################################################### 1 1. 00 0. 0000E+00 9. 4106E+04 1. 0839 0. 0000E+00 302. 4114 0. 0000E+00 0. 0000E+000. 0000E+00

2 2. 00 - 3. 1611 9. 2265E+04 1. 0771 - 5. 6124E- 03 298. 3848 0. 0000E+00 0. 0000E+004. 1840E- 05

3 3. 00 - 34. 9840 8. 0021E+04 0. 9711 - 0. 0560 287. 0853 0. 0000E+00 0. 0000E+002. 3000E- 05

4 4. 00 - 43. 2405 7. 8681E+04 0. 9584 - 0. 0683 285. 9963 0. 0000E+00 0. 0000E+001. 2063E- 05

5 5. 00 - 47. 1203 7. 7772E+04 0. 9507 - 0. 0738 284. 9616 0. 0000E+00 0. 0000E+006. 0818E- 06

6 6. 00 - 48. 2060 7. 7640E+04 0. 9499 - 0. 0755 284. 7308 0. 0000E+00 0. 0000E+003. 0467E- 06

7 7. 00 - 48. 1333 7. 7757E+04 0. 9512 - 0. 0755 284. 7376 0. 0000E+00 0. 0000E+001. 5323E- 06

8 8. 00 - 47. 4218 7. 8026E+04 0. 9540 - 0. 0746 284. 9082 0. 0000E+00 0. 0000E+007. 7835E- 07

9 9. 00 - 46. 4027 7. 8374E+04 0. 9573 - 0. 0732 285. 1674 0. 0000E+00 0. 0000E+004. 0043E- 07

Figure 6-2: Structure of 1D-Coupling Monitoring File using BOOST Species

Note: When restarting a co-simulation run, all data written for time levels

bigger than the actual restart time will be automatically deleted from the

monitoring file.

CYLINDERS: Average Values

-------------------------

Total

Engine Cyl. 1 Cyl. 2 Cyl. 3 Cyl. 4 Cyl. 5 Cyl. 6

Firing TDC [deg] 0.00 120.00 240.00 360.00 480.00 600.00

Bore [mm] 87.00 87.00 87.00 87.00 87.00 87.00

Stroke [mm] 90.00 90.00 90.00 90.00 90.00 90.00

Conrodl. [mm] 149.00 149.00 149.00 149.00 149.00 149.00

..

..

IMEP Exh. [bar] -1.1938 -1.2262 -1.1622 -1.2071 -1.1159 -1.2530 -1.1987

IMEP Int. [bar] 0.5240 0.8252 0.2124 0.8392 0.2180 0.8264 0.2229

IMEP Gasex. [bar] -0.6698 -0.4009 -0.9498 -0.3678 -0.8979 -0.4266 -0.9758

IMEP HP [bar] 4.3559 9.4861 1.9576 6.2764 1.1272 6.1235 1.1649

FMEP [bar] 0.9300 0.9300 0.9300 0.9300 0.9300 0.9300 0.9300BMEP [bar] 2.7262 8.1351 0.0479 4.9000 -0.7007 4.7370 -0.7000

-

8/13/2019 Boost 1d3d Coupling

39/42

-

8/13/2019 Boost 1d3d Coupling

40/42

-

8/13/2019 Boost 1d3d Coupling

41/42

-

8/13/2019 Boost 1d3d Coupling

42/42

BOOST v5.1 1D - 3D Coupling

AVG_PS Mass averaged passive scalars.

AVG_XN1 Averaged x-component of unit normal vector.

AVG_XN2 Averaged y-component of unit normal vector.

AVG_XN3 Averaged z-component of unit normal vector.

ATT_AREA Attachment area.

XM1D_LEN Overlap length.