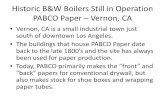

Boiler 2

Transcript of Boiler 2

Boiler Boiler

RefresherRefresher

What will we cover..?What will we cover..?

Basic Concept of Steam BoilerBasic Concept of Steam BoilerBoiler Pressure PartsBoiler Pressure PartsBoiler Operation PrinciplesBoiler Operation Principles

Basic Concept Basic Concept of Steam Boilerof Steam Boiler

Boiler System

What is Boiler..?What is Boiler..?

A closed vessel that safely, A closed vessel that safely, reliably and efficiently transfers reliably and efficiently transfers heat released during combustion heat released during combustion of fuel in which water and steam of fuel in which water and steam are heated under pressure.are heated under pressure.

The steam or hot fluid is then The steam or hot fluid is then circulated out of the boiler for use circulated out of the boiler for use in various processes and heating.in various processes and heating.

Boiler FunctionBoiler Function To release the energy in To release the energy in

the fuel as efficiently as the fuel as efficiently as possible.possible.

To transfer the released To transfer the released energy to the water and energy to the water and to generate steam as to generate steam as efficiently as possible.efficiently as possible.

To separate steam from To separate steam from the water where the the water where the energy can be energy can be transferred to the transferred to the process as efficiently as process as efficiently as possible.possible.

Boiler FunctionBoiler FunctionChanges of Water Phase inside a Boiler

Types of BoilerTypes of Boiler

Fire-Tube BoilerFire-Tube BoilerWater-Tube Boiler, including Water-Tube Boiler, including

HRSGHRSGTubeless BoilerTubeless BoilerElectric BoilerElectric Boiler

Fire Tube BoilerFire Tube Boiler

A cylindrical vessel with the flame in the A cylindrical vessel with the flame in the furnace and the combustion gas inside furnace and the combustion gas inside the tubes.the tubes.

The furnace and tubes are within a The furnace and tubes are within a larger vessel, which contains the water larger vessel, which contains the water and steam.and steam.

Also known as Shell Boiler and Package Also known as Shell Boiler and Package Boiler in modern timeBoiler in modern time

Lancashire Boiler, Scotch Marine, CornishLancashire Boiler, Scotch Marine, Cornish

Fire Tube BoilerFire Tube Boiler

Stoker Boiler

Modern Fire Tube BoilerModern Fire Tube BoilerSafety Valve

Chimney

Control Panel

Burner

Combustion Air

Steam Outlet

Blowdown

Fire Tube BoilerFire Tube Boiler

Fire Tube BoilerFire Tube Boiler

Water Tube BoilerWater Tube Boiler Water and steam are Water and steam are

inside the tube, and inside the tube, and the hot gas is in the hot gas is in contact with the outer contact with the outer tube surfaces.tube surfaces.

Normally operates on a Normally operates on a principle of natural principle of natural circulation.circulation.

Babcock & Wilcox Babcock & Wilcox BoilerBoiler

Water Tube BoilerWater Tube Boiler

ComparisonComparison

Water-TubeWater-Tube Fire-TubeFire-TubePressure can be as high Pressure can be as high as 350 baras 350 bar

Pressure limited to 27 Pressure limited to 27 bar & 27 t/h of flow.bar & 27 t/h of flow.

Fast response timeFast response time Low response timeLow response time

Requires on-site Requires on-site fabricationfabrication

Everything is factory Everything is factory packed, ready for usepacked, ready for use

High capital cost due to High capital cost due to its complexityits complexity

Relatively cheaper and Relatively cheaper and uses less spaceuses less space

High maintenance cost & High maintenance cost & requires sophisticated requires sophisticated DCSDCS

Simple maintenance and Simple maintenance and controlcontrol

Other TypesOther Types

Fulton Boiler

Modern Power Generation Modern Power Generation BoilerBoiler

Can be classified into sub-critical and Can be classified into sub-critical and super-critical boiler.super-critical boiler.

Capacity as high as 1,300MWCapacity as high as 1,300MW Triple fuel capabilityTriple fuel capability Double ReheatDouble Reheat Demand high quality waterDemand high quality water Higher efficiencyHigher efficiency Opposed-fired design is more Opposed-fired design is more

preferable with efficient burner preferable with efficient burner designdesign

Boiler for Power GenerationBoiler for Power Generation

Boiler Heat Transfer ZonesBoiler Heat Transfer Zones

Furnace ZoneFurnace Zone – – high temperature gases high temperature gases of combustion can be used for heating of combustion can be used for heating water and steam with low to medium water and steam with low to medium superheat.superheat.

Convection ZoneConvection Zone – – medium temperature medium temperature gases can be used for heating steam with gases can be used for heating steam with medium to high superheat.medium to high superheat.

HRA ZoneHRA Zone – – with cool gases, heat can with cool gases, heat can only be extracted effectively by cool liquid.only be extracted effectively by cool liquid.

Firing ConfigurationFiring Configuration

Firing ConfigurationFiring Configuration(Opposed-Fired)(Opposed-Fired)

Firing ConfigurationFiring Configuration(Tangential-Fired)(Tangential-Fired)

Firing ConfigurationFiring Configuration(U-Flame)(U-Flame)

Boiler Essential FittingsBoiler Essential Fittings

1.1. Safety ValvesSafety Valves2.2. Two Water GaugesTwo Water Gauges3.3. Steam Pressure GaugeSteam Pressure Gauge4.4. Blow-down ValveBlow-down Valve5.5. Feed PumpsFeed Pumps6.6. Boiler Stop ValveBoiler Stop Valve7.7. Feedwater Check ValveFeedwater Check Valve8.8. Inspector’s test pressure gauge attachmentInspector’s test pressure gauge attachment9.9. Fusible PlugFusible Plug

Boiler Essential FittingsBoiler Essential Fittings

10.10. Low water alarmLow water alarm

11.11. Low water fuel cut outLow water fuel cut out

12.12. Manufacturer’s or maker plateManufacturer’s or maker plate

13.13. A registration plateA registration plate

Boiler Essential FittingsBoiler Essential Fittings

Water Gauge Glass Blowdown

Boiler Essential FittingsBoiler Essential Fittings

Boiler Stop Valve Feedwater Check Valve

Manufacturer’s Plate Pressure Gauge Safety Valve

xx 700MW Boilerxx 700MW Boiler

IHI natural circulation with single IHI natural circulation with single reheat and single drum design.reheat and single drum design.

Coal as Main Fuel with LFO as back-upCoal as Main Fuel with LFO as back-up Boiler outlet pressure of 171.9 barBoiler outlet pressure of 171.9 bar Boiler outlet temperature – 541 CBoiler outlet temperature – 541 C Reheat Pressure – 39 bar @ 566 CReheat Pressure – 39 bar @ 566 C Balanced Draught DesignBalanced Draught Design

Feedwater Flow in Feedwater Flow in BoilerBoiler

Furnace Rear Wall

Furnace Front Wall

Furnace Side Wall (L)

Furnace Side Wall (R)

Furnace Roof

HRA RoofHRA Rear Wall

HRA Partition Wall

HRA Sidewalls

Steam Drum

Boiler Sections Arrangement

T=301 CP=185 b

Economizer

T=283 CP=190 b

T=301 CP=185 b

T=301 CP=188 b

T=365 CP=182 b

T=360 CP=185 b

PrimarySuperheater

T=386 CP=181 b

T=379 CP=180 b

SecondarySuperheater

T=450 CP=178 b

T=429 CP=177 b

FinalSuperheater

T=538 CP=166 b

T=541 CP=171 b

Reheater

T=338 CP=42.5 b

T=338 CP=41.9 b

T=566 CP=39 b

Flow=2259t/h

Feedwater & Steam P-T Feedwater & Steam P-T DiagramDiagram

0.00

50.00

100.00

150.00

200.00

250.00

BFP Disc

harg

e

After H

P hea

ter 5

After H

P hea

ter 6

After H

P hea

ter 7

/Boil

er F

eedw

ater

HP Ste

am a

fter b

oiler

HP Ste

am b

efor

e tu

rbine

HP Extr

actio

n (to

HP h

eate

r 7)

HP Tur

bine

exit (

to H

P hea

ter 6

)

Cold R

H bef

ore

Boiler

Hot R

H afte

r Boil

er

Hot R

H bef

ore

IP T

urbin

e

IPT E

xtrac

tion

(to H

P hea

ter 5

)

IPT e

xit (t

o Fee

dwat

er T

ank)

LPT e

ntry

LPT E

xtrac

tion

1 (to

LP h

eate

r 3)

LPT E

xtrac

tion

2 (to

LP h

eate

r 2)

LPT E

xtrac

tion

3(to

LP h

eate

r 1)

LPT e

xit/C

onde

nser

Conde

nsat

e af

ter C

EP

Conde

nsat

e af

ter L

P hea

ter 1

Conde

nsat

e af

ter L

P hea

ter 2

Conde

nsat

e af

ter L

P hea

ter 3

Feedw

ater

afte

r Fee

dwat

er T

ank

Location

Pre

ssu

re (

bar

)

0.0

100.0

200.0

300.0

400.0

500.0

600.0

Tem

per

atu

re (

C)

Pressure

Temperature

Boiler Heat AbsorptionBoiler Heat Absorption

Furnace -Furnace -48%.48%. Boiler bank – (convection section) Boiler bank – (convection section)

20%.20%. Superheaters – Superheaters – 15%.15%. Air Heaters -Air Heaters -10%.10%. Economiser -Economiser -7%7%

Boiler Pressure PartsBoiler Pressure Parts1.Economiser2.Steam Drum3.Furnace Wall4.HRA5.Superheater6.Reheater

Radiant SuperheaterRadiant Superheater

Feedwater Flow in BoilerFeedwater Flow in Boiler

SecondarySuperheater

FinalSuperheater

PrimarySuperheater

From HPTexhaust

To IPT

Reheater

Water wall

EconomizerFrom HPHeater 7

To HPT

EconomiserEconomiser Absorb low quality heat from the flue Absorb low quality heat from the flue

gases in the form of sensible heat, to gases in the form of sensible heat, to the boiler feedwater before entering the boiler feedwater before entering steam drum.steam drum.

Located after primary superheater Located after primary superheater and reheater but before the RAPHand reheater but before the RAPH

Reduce flue gas temperature to a Reduce flue gas temperature to a satisfactory level for the RAPHsatisfactory level for the RAPH

Can be Plain Tube type or Welded Fin Can be Plain Tube type or Welded Fin TubeTube

EconomiserEconomiser

1. 368 tubes2. Inlet temperature – 283 degree C @ 190.6 bar3. Outlet temperature – 301 degree C @ 188.6 bar

Steam DrumSteam Drum Receives feedwater from the Receives feedwater from the

economisereconomiser Contain saturated steam and water Contain saturated steam and water

which act as a buffer during sudden which act as a buffer during sudden load changeload change

Steam is separated and dried from Steam is separated and dried from entrained water before further heating entrained water before further heating in the superheaters.in the superheaters.

Blow-down of dissolved solid from Blow-down of dissolved solid from boiler water takes placeboiler water takes place

Location of some statutory safety Location of some statutory safety equipmentequipment

Steam DrumSteam Drum

Steam DrumSteam Drum

Steam DrumSteam Drum First Stage Drying Relies on principle of centrifugal action to separate substance of different density Eliminates steam content in steam/water mixture so that only water will pass to downcomers 234 units

Horizontal Separator

Steam DrumSteam Drum 2nd. Stage Drying Plating out moisture in steam onto metallic surface. The film of water adhering to the dryer surface drain by gravity to the bottom of the dryer and falls back into the water. 76 units

Chevron Dryer

Steam Drum FittingsSteam Drum Fittings

Furnace WallFurnace Wall Panels of welded fin tubes form walls Panels of welded fin tubes form walls

of rectangular furnace of steam of rectangular furnace of steam generator.generator.

Place where steam is generated in the Place where steam is generated in the boilerboiler

Bottom of furnace hopper connected Bottom of furnace hopper connected to ash receiving hopper via a water to ash receiving hopper via a water seal.seal.

Rear wall of furnace has a nose Rear wall of furnace has a nose section to assist distribution of gas section to assist distribution of gas flow to SH section located above the flow to SH section located above the nose.nose.

FurnaceFurnace Large water-cooled chamber in Large water-cooled chamber in

which fuel and air are mixed and which fuel and air are mixed and burned in suspension.burned in suspension.

Houses the firing equipment and Houses the firing equipment and confines the combustion process confines the combustion process by having a gas tight enclosure.by having a gas tight enclosure.

Furnace WallFurnace Wall

Furnace WallFurnace Wall

Furnace WallFurnace Wall

SuperheatersSuperheaters

Superheats the dry steam out of the drum Superheats the dry steam out of the drum to few hundred degrees as to eliminate to few hundred degrees as to eliminate high moisture content after LP turbines high moisture content after LP turbines expansion.expansion.

Design can be 2 types:Design can be 2 types: Radiant SuperheaterRadiant Superheater – consists of division – consists of division

wall and Platen Superheaterwall and Platen Superheater Convection SuperheaterConvection Superheater – consists of – consists of

Primary and Secondary Superheater either Primary and Secondary Superheater either pendant or horizontal type.pendant or horizontal type.

Radiant SuperheaterRadiant Superheater

Platen SuperheaterPlaten Superheater utilises the radiant heat left in the flue utilises the radiant heat left in the flue

gas before they enter the convection gas before they enter the convection zone. zone.

Consists of closed pitched tubes welded Consists of closed pitched tubes welded together to form a platen section.together to form a platen section.

Surface parallel to the gas flow and with Surface parallel to the gas flow and with spaces at least 600mm between platen spaces at least 600mm between platen elements.elements.

Convection SuperheaterConvection Superheater Primary SuperheaterPrimary Superheater

Consists of horizontal & vertical loop Consists of horizontal & vertical loop tubes located in the HRA gas path tubes located in the HRA gas path parallel to reheater.parallel to reheater.

Flue gas flowing at right angles to the Flue gas flowing at right angles to the tubes, creating turbulence and thus tubes, creating turbulence and thus maximise heat transfer rate.maximise heat transfer rate.

Outlet steam temperature is controlled Outlet steam temperature is controlled by primary attemperator before by primary attemperator before entering the Secondary Superheaterentering the Secondary Superheater

Convection SuperheaterConvection Superheater Secondary SuperheaterSecondary Superheater** (can be radiant)(can be radiant)

Located close to the furnace outlet and Located close to the furnace outlet and protected from the intense radiation by protected from the intense radiation by water wall nose.water wall nose.

Consists of vertical elements (pendant Consists of vertical elements (pendant type) arranged across the furnace type) arranged across the furnace width.width.

The outlet steam temperature is The outlet steam temperature is controlled by second stage controlled by second stage attemperator before entering the Final attemperator before entering the Final SuperheaterSuperheater

Convection SuperheaterConvection Superheater Final SuperheaterFinal Superheater

Located at furnace exit above the nose Located at furnace exit above the nose section of the furnace rear wall.section of the furnace rear wall.

Consists of vertical elements, arranged Consists of vertical elements, arranged across the furnace width.across the furnace width.

Final part of the boiler where final Final part of the boiler where final superheated steam leaves the boiler superheated steam leaves the boiler before entering the HP Turbine.before entering the HP Turbine.

ReheaterReheater Receives exhausted steam from HP Receives exhausted steam from HP

turbine through Cold Reheat Pipeturbine through Cold Reheat Pipe Consists of 4 sectionsConsists of 4 sections

Lower, intermediate, upper & vertical Lower, intermediate, upper & vertical sectionssections

Steam flows upward through the Steam flows upward through the horizontal banks by counter flow to flue horizontal banks by counter flow to flue gas flow.gas flow.

Outlet steam leaves the reheater to IP Outlet steam leaves the reheater to IP turbine inlet through Hot Reheat Pipe.turbine inlet through Hot Reheat Pipe.

Other tubes in HRAOther tubes in HRA

1.1. Furnace RoofFurnace Roof

2.2. HRA Rear WallHRA Rear Wall

3.3. HRA Front WallHRA Front Wall

4.4. HRA Side WallHRA Side Wall

5.5. Partition WallPartition Wall