Biocoup : Co-processing of upgraded bio-liquids in standard refinery units

-

Upload

audrey-poget -

Category

Documents

-

view

296 -

download

4

description

Transcript of Biocoup : Co-processing of upgraded bio-liquids in standard refinery units

A European Integrated Project supported through the Sixth Framework Programme for Research and Technological Development

Co-processing of upgraded bio-liquids in standard refinery units

Photo : Shell

Energy plays a crucial role in modern life. Its consumption grew by around 2% a year in the decade 1990-2000, and it is expected to

grow even more in 2000-2020.

Whilst fossil fuels remain by far the main source of energy, the development of

renewable energies is an investment for a clean and sustainable energy future.

Indeed, the use of renewable energy sources in place of fossil fuels reduces emission

pollutants, including greenhouse gases and it improves the security of supply by

promoting the diversification of energy production. They are clearly favoured by the

Europeans.

In the EU renewable energy sources provided about 6% of the total energy

requirements and the objective is for that share to reach 12% in 2010. This target

was first set in 1997 by the European Commission in its White Paper “Energy for

the future renewable sources of energy”. Reaching this target would lead to a CO2

reduction of 320 million tonnes per year (compared to about 130 million tonnes

currently). The important role of renewable energies in sustainable development

and climate change was acknowledged in the United National World Summit on

Sustainable Development that was held in Johannesburg in 2002. The development

of renewable energies will also contribute towards a weaker reliance on energy

imports and the fulfilling of international obligations such as the Kyoto protocol.

The main sources of renewable energy include wind, photovoltaics, solar thermal heating and cooling, geothermal heat, and biomass.

Biomass represents today nearly two-thirds of all the renewable energy sources, and it is it only renewable source that can be used

to produce competitively-priced liquid fuels for transport. It will therefore play a significant role in the growing production and use of

renewable energies.

One key challenge is to optimise reliable, efficient and cost effective technologies for the

conversion of biomass.

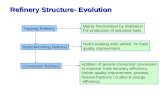

The BIOCOUP Integrated Project coordinated by VTT in Finland is aimed at developing a

chain of process steps to allow a range of different biomass feedstocks to be co-fed to a

conventional oil refinery to produce energy and oxygenated chemicals.

The overall objective is to respond to the increasing demand of biofuels with a new

innovative processing route.

The overall innovation derives from integration of bio-feedstock procurement with existing non-food industries (energy, pulp and paper)

and processing of the upgraded biomass in existing mineral oil refineries. This will allow a seamless integration of bio-refinery co-

processing products to the end-consumers for products such as transport fuels and chemicals, and thus provide an important stimulus

to biomass acceptance and further technological development of biomass production routes.

Conventionalfuelsand

chemicals

Oxygenatedproducts

Primary liquefactionBiomass

residuesDe-oxygenation

Scenario analysis

Coordination

Co-processingin petroleum

refinery

Conversion

Shell Global Solutions InternationalUT

TU/e

SP1 Fractionation and liquefaction of the biomass

In order to reduce the costs of primary bio-oils, an innovative

integrated bio-oil concept will be developed from a number of

viable biomass feedstocks. These oils will be used in subsequent

de-oxygenation processes.

SP2 De-oxygenation of bio-oils

Primary bio-liquids typically have oxygen contents of about 50%

and cannot be processed in standard refinery units. Current de-

oxygenation processes are not mature and are expensive due to

high hydrogen consumption and costs. The BIOCOUP consortium

aims to develop new integrated approaches to decrease this

oxygen content.

SP3 Evaluation of upgraded bio-oils in standard refinery units

The opportunities for biomass co-processing in standard refinery

units will be assessed, regarding the technical and economical

feasibility. The parameters of the refinery units most viable for

bio-liquid co-processing will be defined, as well as their change

depending on the bio-liquid specifications.

SP4 Production of chemicals from biomass

One of the characteristics of the produced bio-liquids over crude

oil is their high content of oxygenates.

This sub-project will therefore also aim at developing technologies

for the conversion of these bio-intermediates to valuable

products by chemical processes, for developing processes for the

transformation of intermediates and the production of industrial

oxygenated chemicals. It will also include the synthesis of bio-

liquid derived thermosetting adhesives .

SP5 Scenario and life cycle analysis

The most promising optimised biomass-refinery chains (biomass

feedstocks → final products) will be assessed both technically and

economically.

SP6 Transversal activities

Dissemination of the knowledge generated with BIOCOUP will

be an important activity organised in this sub-project. It will also

support the management of the project so that the objectives are

achieved with allocated resources.

The project is organised as 6 Sub-Projects with the following objectives :

SPE Manifold SPE Eluates

GC-MS/FIDSPE Chromatograms

Solid phased Extraction Fractionation :

Project Coordinator:VTT, Yrjö Solantausta, + 358 20 72 25 517 - [email protected] Project Officer: European Commission, Dr Maria GEORGIADOU, +32-2-29 59 846 - [email protected] the support of:ALMA Consulting Group, Christine Robertson, +33 4 72 35 80 30 - [email protected]

Supported by the European commission through the Sixth Framework

Programme for Research and Development with a grant up to 7.6 M€,

the BIOCOUP project addresses the T6 thematic priority : “Sustainable

development, global change and ecosystems”. The project is running since

May 2006 and will last 60 months. Cr

éati

on ::

Com

ète

:: w

ww

.com

ete.

com

An international consortium has been established to explore this innovative route calling for cogeneration of

biofuels and chemicals.

www.biocoup.eu

vTi

BTGUT

Shell Global SolutionsRUG

ALBEMARLETUE

CNRS-IRC ARKEMA

METEXALMA

NIC

INNVENTIA BIC

CHIMAR

VTTAalto

Photo : Shell