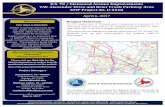

U.S. 70 Glenwood Avenue Improvements T.W. Drive and Brier ...

BIBLIOGRAPHY - Shodhgangashodhganga.inflibnet.ac.in/bitstream/10603/2065/18/18_bibliography.pdfof...

Transcript of BIBLIOGRAPHY - Shodhgangashodhganga.inflibnet.ac.in/bitstream/10603/2065/18/18_bibliography.pdfof...

188

BIBLIOGRAPHY

Abilio, M., Pinho. D.J., Alfredo, S.R. and Antonio, A.F. (2007) Influence of

the submerged arc welding in the mechanical behaviour of the

P355NL1 steel-Part II: analysis of the low/high cycle fatigue

behaviours. Journal of Material Science, 42: 5973–5981.

Aggarwal, A. and Singh, H. (2005) Optimization of Machining Techniques-

A Retrospective and Literature Review. Sadhana, 30(6): 699-711.

Aksoy, M., Ero, M. and Orhan, N. (1999) Effect of coarse initial grain size

on microstructure and mechanical properties of weld metal and HAZ of

a low carbon steel. Material Science and Engineering, 269 (1): 1-9.

Aksoy, M., Ero, M., and Orhan, N. (1999) Effect of coarse initial grain size

on microstructure and mechanical properties of weld metal and HAZ of

a low carbon steel. Material Science and Engineering, 269 (1): 1-9.

Al-Aomar, R. (2002) Robust Simulation based Multi criteria Optimization

Methodology”, Proceedings of the 34th conference on Winter

simulation: exploring new frontiers, San Diego, California, 2(8-

11):1931-1939.

Ana, M., Paniagua, M., Victor, M. Lopez, H., Hector, J., Dorantes, R.,

Paulino, E., Diazb., E. and Diaz, V. (2009) Effect of TiO2-containing

fluxes on the mechanical properties and microstructure in submerged-

arc weld steels. Material Characterization, 60(1):36-39.

189

Ana, M., Paniagua, M., Victor, M., Lopez, H., Maribel, L. and Saucedo,

M. (2005) Influence of the Chemical Composition of Flux on the

Microstructure and Tensile Properties of Submerged-Arc Welds.

Journal of Materials Processing Technology, 169: 346-351.

Ana, M., Paniagua. M., Paulino, E.D., Victor, M. and Lopez, H. (2003)

Chemical and structural Characterization of the crystalline phases in

agglomerated fluxes for submerged arc welding. Journal of Materials

Processing Technology, 141: 93-100.

Antony, J. and Antony, F (2001) Teaching the Taguchi Method to Industrial

Engineers. Work Study, 50(4): 141-149.

Antony, J. and Kaye, M. (1996) An application of Taguchi's parameter

design methodology for process improvement. Journal of Quality

World Technical Suppl. 350-41.

Asiabanpour, B., Palmer, K. and Khoshnevis, B. (2004) An Experimental

Study of Surface Quality and Dimensional Accuracy for Selective

Inhibition of Sintering. Rapid Prototyping Journal, 10(3), 181-192.

Avner, H. (2000) Introduction to Physical Metallurgical. Second Edition,

Tata Mcgraw-Hill, New-Delhi.

Baach, H., Nadkarni, S.V. and Vishvanasth, P.S. (1981) Submerged arc

welding: Combined increased deposition rates with improved

mechanical properties. Proceedings of the National Conference, Trichi,

India.

190

Babu, S.P.K. and Natarajan, S. (2008) Influence of heat input on high

temperature weldment corrosion in submerged arc welded power plant

carbon steel. Materials & Design, 29(5): 1036–1042.

Basu, B. and Raman, R. (2002) Micro structural Variations in a High-

Strength Structural Steel Weld under Isoheat Input Conditions.

Welding Journal, 81(11): 239s-248s.

Baune, C. Bonnet. and Lieu, S. (2000) Reconsidering the basicity of FCAW

consumables- Part1: Solidified slag composition of FCAW

consumable as a basicity indicator. Welding Journal, 79 (3): 57s- 65s.

Baune, E., Bonnet, C. and Liu, S. (2000b) Reconsidering the basicity of

FCAW consumables-Part2: Solidified slag composition of FCAW

consumable as a basicity indicator, Welding Journal Suppl , 79 (3):

66s - 75s.

Baune, E., Bonnet, C., and Liu, S. (2000a) Reconsidering the Basicity of a

FCAW Consumable-Part 1: Solidified Slag Composition of a FCAW

Consumable as a Basicity Indicator. Welding Research Suppl. 3:57s-

65s.

Bebis, G. and Georgiopoulus, M. (1994) Feed Forward Networks, Why

Network Size is so important, IEEE Potential, 27-31.

Beck, H.P. and Jackson, A.R. (1996) Recycling of SAW Slag Proves

Reliable and Repeatable. Welding Journal, 75(66): 51-54.

191

Behçet, G. and Nizamettin, K. (2003) Wear behavior of bulldozer rollers

welded using a submerged arc welding process, Materials and Design,

24: 537-542.

Belton, G. R., Moore, T. J. and Takings, E.S. (1963) Slag Metal Reactions

in Submerged Arc Welding, Welding Journal, 42(7): 289s- 297s.

Bennet, A. P. and Stanley, P. J. (1966) Fluxes for the SAW of QT 35 Steel.

British Welding Journal, 13: 59-66.

Bennett, A.P. (1970) Using basic fluxes. Metal Construction, December: 523-

527.

Besseris, George. J. (2008) Multi-response optimization using Taguchi

method and super ranking concept. Journal of Manufacturing

Technology Management, 19(8):1015-1029.

Bhadeshia, H. (1997) Mathematical Modeling of Weld Phenomena III,

London: Institute of Materials, 229-284.

Bhole, S.D., Nemade, J.B., Collins, L. and Cheng, Liu. (2006) Effect of

nickel and molybdenum additions on weld metal toughness in a

submerged arc welded HSLA line-pipe steel. Journal of Materials

Processing Technology, 173: 92–100

Bobrikov, Yu. V., Potapov, N.N. and Volauev, Yu. S. (1983) The

metallurgical properties of silicon fluxes containing halides and

alkaline metal oxides. Automatic Welding, 36(6): 41-43.

192

Box G.E.P, Hunter W.G. and Hunter J.S. (1976) Statistics for

experimenters: An introduction to design, data analysis, and model

building, New York: John Wiley & Sons.

Box, G.E.P. and Behnken, D.W. (1960) Some new three level designs for the

study of quantitative variables. Techno metrics, 2: 455-475.

Brien, R.L. (1978). Welding Handbook, Vol. 2, 8th Edition, Miami. U.S.A:

American Welding Society.

Butler, C.A. and Jackson, C.E. (1967) Submerged arc welding

characteristics of CaO-TiO2-SiO2 system. Welding Journal, 46(11):

448s - 445s.

Eijk, C. Vander., Grong, O. and Hjelen, J. (1999) Quantification of

inclusions stimulated ferrite nucleation in wrought steel using the

SEMEBSD technique, Proceedings of the International Conference on

Solid–Solid Phase Transformations’99 (JIMIC-3), Kyoto, Japan.

Caddle, R.M. (1967) The influence of physical properties in on penetration in

arc welding. Transactions of ASME, Journal of Engineering for

Industry, May: 328-332.

Chai, C. S. and Eagar, T. W. (1982) Slag-Metal Reactions in Binary CaF2-

Metal Oxide Welding Fluxes. Welding Research Supplement, July:

229s-232s.

193

Chai, C.S. and Eagar, T.W. (1981) Slag-Metal Equilibrium During

Submerged Arc Welding. Metallurgical Transactions B, 12(B),

September: 539- 547.

Chandel, R.S. (1987) Mathematical modeling of melting rates for submerged

arc welding. Welding Journal, 65 (5): 32s -39s.

Chandel, R.S., Bala, S.R. and Malik, L. (1987) Effect of submerged arc

welding process variables. Welding & Metal Fabrication, August: 302-

30.

Chandel, R.S., Chan, B., Yang, L.J. and Bibby, M.J. (1994) A software

system for anticipating the size and shape of submerged arc welds.

Journal of Materials Processing Technology, 40: 249-262.

Chandel, R.S.and Cheng, H. P. (1997) Effect of increasing deposition rate on

the bead geometry of submerged arc welds. Journal of Materials

Processing and Technology, 72: 124 – 128.

Charles, H. and Entrekin. J.R. (1979) The Influence of Flux Basicity on

Weld-Metal Microstructure. Metallography, 12: 295-312.

Chester, D. (1990) Why Two Hidden Layers Are Better Than One?

Proceedings of IEEE International Joint Conference on Neural

Networks, Washington, DC, 265-268.

Chew B. (1976) Moisture loss and regain by some basic flux covered

electrodes. Welding Journal, 55 (7): 127s - 131s.

194

Christopher, Bayley., Gregory, Glinka. and John, Porter.(2000), Fatigue

crack initiation and growth in A517 submerged arc welds under

variable amplitude loading. International Journal of Fatigue, 22: 799–

808.

Cornu, J. (1988) Advanced Welding Systems, Vol.2, London: IFS Publication.

Dallam, C.B., Liu, S. and Olson, D.L. (1985) Flux composition dependence

of microstructure and toughness of submerged arc HSLA weldments.

Welding Journal, 64 (5): 140s -149s.

Datta S, Bandyopadhyay, A. and Pal P.K. (2006a) Quadratic response

surface modeling for prediction of bead geometry in submerged arc

welding. Indian Weld Journal 39(1):33–43.

Datta, G.L. and Nagesh, D.S. (2002) Prediction of weld bead geometry and

penetration in shielded metal arc welding using artificial neural

networks. Journal of Material Processing Technology, 123(2): 303-

312.

Datta, S., Bandyopadhyay, A. and Pal P.K. (2006) Desirability Function

Approach for solving Multi-Objective optimization problem in

Submerged Arc Welding. International Journal of Manufacturing

Science and Production, 7(2): 127-135.

Datta, S., Bandyopadhyay, A. and Pal P.K.(2008) Modeling and

Optimization of features of bead geometry including percentage

Dilution in Submerged Arc Welding Consuming Mixture of Fresh Flux

195

and Fused Slag. International Journal of Advanced Manufacturing

Technology, 36: 1080-1090.

Datta, S., Bandyopadhyay, A. and Pal, P.K. (2008), Application of Taguchi

philosophy for parametric optimization of bead geometry and HAZ

width in submerged arc welding using a mixture of fresh flux and fused

flux. International Journal of Advanced Manufacturing Technology,

36: 689-698.

Datta, S., Bandyopadhyay, A. and Pal, P.K. (2008), Solving multi-criteria

optimization problem in submerged arc welding consuming a mixture

of fresh flux and fused slag. International Journal of Advanced

Manufacturing Technology, 35(9-10): 935-942.

Datta, S., Bandyopadhyay, A., Pal P. K, Nandi, G. and Roy, S. C. (2007)

Controlled Random Search Algorithm for Parametric Optimization of

Bead Geometry in Submerged Arc Double Pass Butt Welding.

Proceedings of the Global Conference on Production and Industrial

Engineering, March 22-24, Dr. B. R. Ambedkar National Institute of

Technology, Jalandhar, India.

Datta, S., Sundar, M., Bandyopadhyay, A., Pal, P.K., Nandi, G. and Roy,

S.C. (2006b) Statistical modeling for predicting bead volume of

submerged arc butt welds. Australasian Welding Journal, 51(2):39–47

Davies, O.L. (1978) The Design and Analysis of Industrial Experiments, New

York: Longman.

196

Davis, M. L. E. and Bailey, N. (1982) Properties of Submerged Arc Fluxes-

Fundamental Studies. Metal Construction, 65(6): 202-209.

Davis, M. L. E. and Bailey, N. (1991) Evidence from Inclusion Chemistry of

Element Transfer during Submerged Arc Welding. Welding Journal,

70(2): 57s-65s.

Davis, M.L. and Bailey, N. (1991) Evidence from inclusion chemistry of

element transfer during submerged arc welding, Weld. J. Suppl. Res. 70

(2):57–61.

Dowling, J.M., Corbett, J.M. and Kerr, H.W. (1986) Inclusion phases and

the nucleation of acicular ferrite in submerged-arc welds in high-

strength low alloy steels, Metall. Trans. A, 17 (9): 1613–1618.

Eagar, T.W. (1980) Oxygen and Nitrogen Contamination during Submerged

Arc Welding of Titanium. Proceedings of the International Conference

of Welding Research, Osaka University, Osaka, Japan.

Eager, T.W. (1978) Sources of weld metal oxygen contamination during

submerged arc welding, Welding Journal, 57(3): 76s - 80s.

Easterling, K.E. (1992) Introduction to the Physical Metallurgy of Welding,

Butterworth-Heinemann, London.

Eroglu, M. and Aksoy, M. (2000) Effect of initial grain size on

microstructure and toughness of intercritical heat-affected zone of a

low carbon steel, Materials Science and Engineering, 286(A): 289–

297.

197

Eroglu, M., Aksoy, M. and Orhan, N. (1999) Effect of coarse initial grain

size on microstructure and mechanical properties of weld metal and

HAZ of a low carbon steel, Materials Science and Engineering,

269(A): 59-66.

Evans, G.M. (1989) The effect of chromium on the microstructure and

properties of C–Mn all-weld metal deposits. Weld Met Fabr, 57(7):

346– 58.

Farias, J.P., Scotti, A., Balsamo, P.S. and Surian, E. (2004) The Effect of

Wollastonite on Operational Characteristics of AWS E6013 Electrodes,

Journal of Brazilian Society of Mechanical Sciences and Engineering,

26(3): 317-322.

Farias, J.P., Quites, A.M. and Surian, E.S. (1997) The effect of magnesium

content on the arc stability of SMAW E7016-C2L / 8016-C2 covered

electrodes. Welding journal, 78(1): 1s - 8s.

Ferrera, K. P. and Olson, D. L. (1975) Performance of the MnO-SiO2-CaO

Systems as Welding Fluxes, Welding Journal, 54: 211s-215s.

Fleck, N.A., Grong, O., Edwards, G. R. and Matlock, D. K. (1986) The

Role of Filler Metal Wire and Flux Composition in the SAW Metal

Transformation Kinetics, Welding Journal, 65(5): 113s-121s.

Flick, N.A. (1986) The role of filler metal wire and flux composition in

submerged arc weld metal transformation kinetics. Welding Journal, 66

(5): 113s- 120s.

198

Ful-Chiang, Wu. (2005) Optimization of Correlated Multiple Quality

Characteristics Using Desirability Function. Quality Engineering,

17(1): 119-126.

George, F. (1986) Applied Metallography. Van Nastrand Reinhold Company,

New-York.

Ghosh, P.K. and Ahmed, M. (1999) Characterization of Mechanical

Properties of Multipass Submerged Arc Weld by Model Analysis of its

Microstructure Facilitated by Aid of Computer. Indian Welding

Journal, 32(4): 32-42.

Ghosh, P.K. and Khanna, A. (1991) The influence of electrode polarity and

welding current on mechanical properties of submerged arc welding.

Indian Welding Journal, 24(3): 145-150.

Goloshubov,V.I. (1972), The viscosity and surface tension of the certain

fluxes. Automatic Welding, 25 (2): 61-62.

Gretoft, B., Bhadeshia, H. and Svensson, L.E. (1986) Development of

Microstructure in the Fusion Zone of Steel Weld Deposits. Acta

Stereol, 5(2): 365-371.

Gulenç, B. and Kahraman, N. (2003) Wear behavior of bulldozer rollers

welded using a submerged arc welding process. Materials and Design,

24: 537-542.

199

Gunaraj V, Murugan N. (2000) Prediction and optimization of weld bead

volume for the submerged arc process-part-2. Weld Res. Suppl.79(11):

331–338

Gunaraj, V. and Murgun, N. (1999) Application of response surface

methodology for predicting weld bead quality in submerged arc

welding of pipes. Journal of Materials Processing Technology, 88:

266-275.

Gunaraj, V. and Murugan, N. (2000) Prediction and Optimization of Weld

Bead Volume for the Submerged Arc Process- Part-1. Welding

Research Suppl. 79(10): 286s-294s.

Gunaraj, V. and Murugan, N. (1999) Prediction and Comparison of the Area

of the Heat Affected Zone for the Bead-no-Plate and Bead-on-Joint in

Submerged Arc Welding of Pipes. Journal of Materials Processing

Technology, 95(1-3): 246-261.

Gupta, S.R. and Arora, N. (1993) Influence of Flux Basicity on Weld Bead

Geometry and HAZ in Submerged Arc Welding. Journal of Material

Processing Technology, 39(1-2): 33-42.

Gupta, S.R. and Gupta, P.C. (1988) Investigation into flux consumption in

submerged arc welding. Indian Welding Journal, 21 (3): 365-369.

Gupta, S.R. and Arora,N.(1991) Influence of flux basicity index on weld

bead geometry and HAZ submerged arc welding. Indian Welding

Journal, 24 (3):127-133

200

Hazlett, T.H. (1957) Coating ingredients influences on surface tension arc

stability and bead shape. Welding Journal, 38 (1): 18s - 22s.

Heuschkel, J. (1969) Weld metal composition control. Welding Journal,

48(8): 323s -347s.

Heuschkel, J. (1973) Weld metal property control. Welding Journal, 52(1): 1s

-20s.

Hould croft P.T. (1989), Submerged Arc Welding, 2nd ed., England:

Abington Publishing, Cambridge.

Indacochea, J.E. and Olson, D.L. (1983) Relationship of weld–metal

microstructure and penetration to weld-metal oxygen control. Materials

for energy systems, 5 (3): 139- 145.

Irvine, K.J. (1969) A comparison of the bainite transformation with other

strengthening mechanisms in high strength structural steels. Symp. on

Steel Strengthening Mechanisms, Climax Molybdenum. MI, USA. 55–

65.

Jackson, C.E. and Shrubsall, A. E. (1953) Control of penetration and

melting ratio with welding technique. Welding Journal, 32(4): 172s-

178s.

Janez, Tueck. (2000) Mathematical modeling of melting rate in twin-wire

welding. Journal of Material Processing, 100(4): 250-256.

Jang, J. and Indacochea, J.E. (1987) Inclusion effects on submerged-arc

weld microstructure. Journal of Materials Science, 2(2): 689-700.

201

Jeffus, Larry. (2000) Welding: Principles and Applications. Florence, KY:

Thomson Delmar Learning.

Jerzy, Nowacki. and Paweł, Rybicki. (2005) The influence of welding heat

input on submerged arc welded duplex steel joints imperfections.

Journal of Materials Processing Technology, 164(165): 1082–1088.

Jeyapaul, R., Shahabudeen, P. and Krishnaiah, K. (2005) Quality

Management Research by Considering Multi-Response Problems in the

Taguchi Method-A Review. International Journal of Advanced

Manufacturing Technology, 26: 1331-1337.

Joarder, A., Saha, S. C. and Ghosh, A. K. (1991) Study of Submerged Arc

Weld Metal and Heat Affected Zone Microstructure of Plain Carbon

Steel. Welding Journal, 151-157.

Joarder, A., Saha, S.C. and Ghose, A.K. (1991) Study of submerged arc

weld metal and heat-affected zone microstructures of plain carbon

steel, Weld. J. Suppl. Res. 70 (6): 141–146.

Jorge, J.C.F., Rebello J.M.A. and Evans, G.M. (1993) Microstructure and

toughness relationship in C–Mn – Cr all weld metal deposits. IIW

DOC. II-A-880-93.

Jorge, J.C.F., Souza, L.F.G., and Rebello, J.M.A. (2001) The effect of

chromium on the microstructure/toughness relationship of C–Mn weld

metal deposits. Materials Characterization, 47:195– 205.

202

Kaae,J.L. (1968) Mechanical Properties, Microstructure and Susceptibility to

Cracking in the HAZ of Controlled Rolled Niobium Treated Low

Carbon Manganese Steels. British Welding Journal, 12(7): 395-398.

Kalpakjian, Serope, and Steven Schmid. (2006) Manufacturing Engineering

and Technology, 5th ed. Upper Saddle river, NJ: Pearson Prentice Hall.

Kane,S.F.(1999) Welding consumable Development for a cryogenic

application. Welding Journal.78 (8):292s-300s.

Kang, B. Y. (2005), Fuzzy Regression Method for Prediction and Control the

Bead Width in the Robotic Arc-Welding Process. Journal of Materials

Processing Technology, 164(165): 1134-1139.

Kanjilal, P., Mazumder, S. K., Pal, T.K.(2004) Prediction of Submerged Arc

Weld-Metal Composition from Flux Ingredients with the help of

Statistical Design of Mixture Experiment. Scandinavian Journal of

Metallurgy, 33: 146-149.

Kanjilal, P., Pal, T.K. and Majumdar, S.K. (2006) Combined effect of flux

and welding parameters on chemical composition and mechanical

properties of submerged arc weld metal. Journal of Materials

Processing Technology, 171: 223-231.

Karaoglu, S. and Secgin, A. (2008), Sensitivity analysis of submerged arc

welding process parameters. Journal of Material Processing

Technology, 202(3): 500-507.

203

Khallaf, M.E., Ibrahim, M.A., EI-Mahallawy N.A. Taha, M.A. (1997) On

crack susceptibility in the submerged arc welding of medium-carbon

steel plates. Journal of Materials Processing Technology, 68: 43-49.

Khuri A.I. and Cornell, J.A. (1996) Response Surfaces; Design and Analysis,

New York: Marcel Dekker.

Kim, D. and Rhee, S. (2001) Optimization of arc welding process parameters

using genetic algorithm. Welding Journal, 80(7): 184s -190s.

Kim, D. and Rhee, S. (2004). Optimization of Gas Meal Arc Welding Process

using the Desirability Function and the Genetic Algorithm.

Proceedings of the Institution of Mechanical Engineers, Part B: Journal

of Engineering Manufacture, 218(1): 35-41.

Kim, D., Kang, M. and Rhee, S. (2005) Determination of Optimal Welding

Conditions with a Controlled Random Search Procedure. Welding

Journal, 84:125s-129s.

Kim. I. S., Jeong, Y.J., Lee, C.W. and Yarlagadda, P.K.D.V. (2003)

Prediction of Welding Parameters for Pipeline. Welding using an

Intelligent System, 22(9-10): 713-719.

Kohno, R., Takami, N., Mori,N. and Nagane, K.(1982) New fluxes of

improved weld metal toughness for HSLA steels. Welding Journal,

61(12): 173s – 180s.

Kolhe, K.P.and Datta,C. K. (2005) Prediction of Microstructure and

mechanical properties of multipass Submerged Arc Welding.

204

Proceedings of International Conference on Mechanical Engineering

in Knowledge Age, December 12-14, Delhi College of Engineering,

Delhi, India.

Kolhe, Kishor. P. and Data, C.K. (2008), Prediction of microstructure and

mechanical properties of multipass SAW. Journal of Materials

Processing Technology, 197: 241–249.

Komapov, A.I., Khodakov, V.D. and Volobuev, Yu. (1983) Effects of the

surface tension of steels and fluxes on the shape of deposited metal.

Automatic Welding, 36 (3): 27-29.

Kostrivas, A. and Lippold, J. C. (2000) A Method for Studying Weld Fusion

Boundary Microstructure Evolution in Aluminium Alloys. Welding

Research Suppl. 79: 1s-8s.

Kubli, R.A. and Sharav, W.B. (1961) Advancements in submerged arc

welding of high impact steels. Welding Journal, 40 (11): 497s - 502s.

Kuzmenko, V.G. (1985) Effects of slag on formation of the surface of a weld.

Automatic Welding, 38 (2): 32-35.

Lancaster, J.F. (1980) Metallurgy of Welding, London: Alden Press Ltd. 25–

50.

Lancaster. J.F (1993) Metallurgy of Welding, 5th Edition, London: Publisher.

Chapman and Hall, 171-175.

205

Lau, T., Weatherly, G.C. and Mc Lean, A. (1980) Gas/metal/slag reactions

in submerged arc welding using CaO-Al2O3 based fluxes. Welding

Journal, 69(2): 31s -39s.

Lekthi, Y. (1998) Engineering Physical Metallurgy, Moscow: Mir

Publication.

Lightfoot, M.P., Bruce, G.J., McPherson, N.A. and Woods, K. (2005) The

Application of Artificial Neural Networks to Weld-Induced

Deformation in Ship Plate. Welding Journal, 84:23s-31s.

Little, R.L. (1976) Welding and Welding Technology, New Delhi: Tata-

Mcgraw-Hill publishing Company.

Liu, S. and Olson, D.L. (1986) The role of inclusions in controlling HSLA

steel weld microstructures, Weld. J. Suppl. Res. 65 (6): 139–141.

Livshit, L.G. and Shiryaev, A.I. (1960) A New Ceramic Flux for Hard

Facing. Welding Production, 1: 25-29.

Louise, D. (1981) An introduction to welding fluxes for mild and alloy steels.

Cambridge: The Welding institute, 1-10.

M.Y. Li and Kannatey Asibu, E., Jr. (2002) Monte Carlo Simulation of Heat

–Affected Zone Microstructure in Laser-Beam-Welded Nickel Sheet.

Welding Journal, 81: 37s-44s.

Maghsoodloo, S., Ozdemir, G., Jordan,V. and Huang,C.H. (2004)

Strengths and Limitations of Taguchi‟s Contributions to Quality,

206

Manufacturing, and Process Engineering. Journal of Manufacturing

Systems, 23(2): 73-126.

Maheshwari, Sachin. (1998) Elements transfer behaviour in submerged arc

welding. Ph.D. thesis, IIT, Delhi.

Malin, V. (2001) Root Weld Formation in Modified Refractory Flux One-

Sided Welding: Part 1-Effect of Welding Variables. Welding Research

Suppl. 217s-226s.

Malin, V. (2001) Root Weld Formation in Modified Refractory Flux One-

Sided Welding: Part 2- Effect of Joint Geometry. Welding Journal

Research Suppl. 227s-237s.

Mandatov, N.M. (1969) Shape relationships for under water welding.

Welding Production, 16(3): 18-23.

McGlone, J.C. (1982) Weld bead geometry prediction-A review. Metal

Construction, 14(7): 378-384.

Mitra, U., Chai, C.S. and Eagar, T.W. (1984) Slag-Metal Reactions During

Submerged Arc Welding of Steel. Proceedings of International

Conference and Reliability in Welding, 2, Chinese Mechanical

Engineering Society, Harbin, PRC, B.24.1, 1984.

Mohan, N. and Pandey, S. (2005) Modeling for Element Transfer in

Submerged Arc Welding. Proceedings of International Conference on

Mechanical Engineering in Knowledge Age, December 12-14, Delhi

College of Engineering, Delhi.

207

Mohan, N. and Pandey. S. (2002) Welding current and melting rate in

submerged arc welding. Proceedings of International Conference in

Mechanical Engineering, Dakha, Bangladesh.

Mohandas, T and Reddy, G.M. (2001) Solidification cracking studies on

steels. Indian Welding Journal, 34(3):13-19.

Moi, S. C., Bandyopadhyay, A. and Pal, P. K. (2001) Submerged Arc

Welding with a Mixture of Fresh Flux and Fused Slag. Proceedings of

National Seminar on Advances in Material and Processing, IIT,

Roorkee, India.

Montgomery, D.C. (1992) The use of statistical process control and design of

experiments in product and process improvement, IEE Transactions,

24(5): 4-17.

Montgomery, D.C., Peck, E. A. and Vining, G.G. (2006) Introduction to

Linear Regression Analysis, 3rd edition, New York: John Wiley &

Sons, Inc.

Montgomery, D.C. and Mayers R.H. (1995) Response surface Methodology:

Processes and product Optimization Using Designed Experiments,.

John Wiley & Sons: New York;

Murray, P.E. (2002) Selecting Parameters for GMAW using Dimensional

Analysis. Welding Journal, 125s-131s.

208

Murugan, N. and Gunaraj, V. (2005), Prediction and Control of Weld Bead

Geometry and Shape Relationships in Submerged Arc Welding of

Pipes. Journal of Materials Processing Technology, 168: 478-487.

Murugan, N., Parmer, R.S. and Sud, S.K.(1993) Effect of submerged arc

process variables on dilution and bead geometry in single wire

surfacing, Journal of Materials Processing Technology, 37: 767–780

Nadkarni, S.V. (1988) Modern Arc Welding Technology, New Delhi: IBH

publication.

Nalbant, M., Gokkaya, H. and Sur, G. (2007) Application of Taguchi

Method in the Optimization of Cutting Parameters for Surface

Roughness in Turning. Materials & Design, 28(40:1379-1385.

Nippes, E.S. (1993) Welding, brazing and soldering. Metals Handbook,

Volume-6, 9th Edition. Metal Park Ohio, American Society for Metals:

202-207.

Noordin, M.Y., Venkatesh, V.C, Sharif, S., Elting, S., Abdullah, A. (2004).

Applications of response surface methodology in describing the

performance of coated carbide tools when turning AISI 1045 steel.

Journal of Materials Processing Technology, 145: 46-58.

North, T.H., Bell, H.B. and Raig, C. (1978) Slag/ Metal interaction, oxygen

and toughness in submerged arc welding. Welding Journal, 56 (3): 63s-

73s.

209

Olson, D.L., Dixon, R. and Liby, A.L. (1990) Welding Theory and Practice,

Holland: North- Publication.

Pal, P.K., Bandyopadhyay, A. and Bala A.K. (2001) Some Aspects of

Submerged Arc Welding with Mixture of Fresh Flux and Fused Slag.

Proceedings of the International Conference on Mechanical

Engineering, BUET, Dhaka, Bangladesh.

Palani, P.K. and Murugan, N. (2005) Optimization of Weld Bead Geometry

of Stainless Steel Cladding by Flux Cored Arc Welding Using Excel

Solver. Indian Welding Society Journal, March: 15-19.

Palm, J.H. (1972) How fluxes determine the metallurgical properties of

submerged arc welds. Welding Journal, 51(7):358s -365s.

Pandey Sunil. (2004) Welding current and melting rates in submerged arc

welding: A new approach. Australian Welding Journal, 2: 34-42.

Pandey, N.D., Bharti, A. and Gupta, S.R. (1994) Effect of submerged arc

welding parameters and fluxes on element transfer behaviour and weld-

metal chemistry. Journal of Materials Processing Technology, 40: 195-

211.

Pandey, S. and Mohan, N. (2003) Investigation into flux consumption.

Proceedings of International Conference on CAD, CAM, Robotics and

Autonomous Factories, IIT, Delhi.

Parmar, R.S. and Srihari. T. (1991) Mathematical models for predicting

bead geometry and dimensions in automatic submerged arc welding.

210

Proceedings of International Conference on Computer and

Mathematical Modeling, Maryland, U.S.A.

Patchett, B.M. (1983) Some effects of physical properties on weld bead

formation, in SAW process. Materials for energy system, 5(3): 165 -

174.

Patchett, B.M. and Dancy, E.A. (1980) Discussion on the relationship of

weld penetration to the welding flux. Welding Journal, 59 (1):

Patchett, B.M. and Milner, D.R. (1972) Slag-metal reaction in electro-slag

process. Welding Journal, 51 (10): 491s -505s.

Patchett, B.M. (1974) Some influences of slag composition on heat transfer

and arc stability. Welding Journal, 53 (5): 203s - 210s.

Pathak, A. K. and Datta, G. L. (2004) Three-dimensional finite element

analysis to predict the different zones of microstructure in submerged

arc welding. Proceedings of Institution of Mechanical Engineers Part

B: Journal of Engineering Manufacture, 218: 269-280.

Peng, Y., Chen, W. and Xu, Z. (2001) Study of High Toughness Ferrite Wire

for Submerged Arc Welding of Pipeline Steel. Materials

Characterization, 47: 67-73.

Peng, Yun., Wuzhu, Chen. And Zuze, Xu. (2001) Study of high toughness

ferrite wire for submerged arc welding of pipeline steel. Materials

Characterization, 47: 67– 73.

211

Petropoulos, G.P., Vaxevanidis, N. M., Pandazaras, C. N. and Antoniadis,

A. (2006) Multi-Parameter Identification and Control of Turned

Surface Textures. International Journal of Advanced Manufacturing

Technology, 29: 118-128.

Ping, Li., Fang, M.T.C. and Lucas, J. (1997), Modelling of submerged arc

weld beads using self-adaptive offset neutral networks. Journal of

Materials Processing Technology, 71: 288-298.

Polar, A., Indacochea, J.E. and Blander, M. (1991) Fundamentals of the

Chemical Behavior of Selected Welding Fluxes. Welding Journal,

70(1): 15s-19s.

Potapov, N.N. (1978) A quantitative evaluation of basicity of fluxes. Welding

Production, 25 (9): 4-8.

Potapov, N.N., Kurlanov, S.A. and Lazerev, B.I. (1981) The metallurgical

properties of silicon fluxes containing halides salts and alkaline metal

oxides. Automatic Welding, 34 (6): 38-40.

Prasad, K and Dwivedi, D.K. (2008) Some investigations on microstructure

and mechanical properties of submerged arc welded HSLA steel joints.

International Journal of Advanced Manufacturing Technology, 36(5-

6): 475-483.

Price, W.L. (1977) A Controlled Random Search Procedure for Global

Optimization. The Computer Journal, 20(4): 367-370.

212

Quintana, R., Cruz, A., Perdomo, L. and Castellanos, G., Garcia, L.L.,

Formoso, A. and Cores A. (2003) Study of the transfer efficiency of

alloyed elements in fluxes during the submerged arc welding process.

Welding International, 17 (12): 958–965.

Ramakrishnan, R. and Karunamoorthy, L. (2006) Multi Response

Optimization of Wire EDM Operations Using Robust Design of

Experiments. International Journal of Advanced Manufacturing

Technology, 29: 105-112.

Ramasamy, S., Gould, J. and Workman, D. (2002) Design of Experiments

Study to Examine the Effect of Polarity on Stud Welding. Welding

Journal, 19s-26s.

Ramasawmy, H. and Blunt L. (2002) 3D Surface Characterization of Electro

polished EDMed Surface and Quantitative Assessment of Process

Variables using Taguchi Methodology. International Journal of

Machine Tools and Manufacture, 42: 1129-1133.

Reddy, G. M., Ghosh, P. K. and Khanna, A. (1991) The Influence of

Electrode Polarity and Welding Current on Mechanical Properties of

Submerged Arc Weld. Indian Welding Journal, 23(3): 145-150.

Reddy, N.S.K. and Rao, P.V. (2005) Selection of Optimum Tool Geometry

and Cutting Conditions Using a Surface Roughness Prediction Model

for End Milling. International Journal of Advanced Manufacturing

Technology, 26: 1202-1210.

213

Renwick, B.G. and Patchett, B.M. (1976) Operating characteristics of

submerged arc process. Welding Journal, 55 (3): 69s-79s.

Ridings, G.E., Thomson, R.C. and Thewlis, G. (2002) Prediction of

Multiwire Submerged Arc Weld Bead Shape Using Neural Network

Modeling. Science and Technology of Welding and Joining, 7(5): 265-

279.

Rissone, N.M., Farias, J.P., Surian, E.S. and Bott, S. (2002). ANSI / AWS

A5.1-91 E6013 rutile electrodes: the effect of calcite. Welding Journal,

81(12): 113s-120s.

Robinson M.H. (1961) Observation on Electrode Melting Rate During

Submerged Arc Welding. Welding Journal, 40: 503s-515s.

Robinson, M.H. (1983) Observation on electrode melting rates during

submerged arc welding. Welding Journal, 62 (11): 503s-509s.

Rowlands, H., Antony, J. and Knowles, G. (2000) An Application of

Experimental Design For Process Optimization. The TQM Magazine,

12(2): 78-83.

Roy, S. S. (2006) Design of Genetic-Fuzzy System for Predicting Surface

Finish in Ultra-Precision Diamond Turning of Metal Matrix

Composite. Journal of Materials Processing Technology, 173: 337-

344.

Samiti, Z. (1986) Automatic pulsed MIG welding. Metal Construction 1: 38R-

33R.

214

Sarkar, B.R., Doloi, B. and Bhattacharyya, B. (2006) Parametric analysis of

Discharge Machining of Silicon Nitride Ceramics. International

Journal of Advanced Manufacturing Technology, 28(9-10): 873-881.

Schwemmer, D.D. and Olson, D.L. (1979) Relationship of Weld Penetration

to Welding Fluxes. Welding Journal, 58 (5): 153s-160s.

Shan-Ping Lu., Oh-Yang, K., Tae-Bum, K.and Kwon-Hu, K. (2004)

Microstructure and wear property of Fe–Mn–Cr–Mo–V alloy cladding

by submerged arc welding. Journal of Materials Processing

Technology, 147: 191-196.

Sharma, A., Arora, N. and Mishra, B.K. (2008) A practical approach

towards mathematical modeling of deposition rate during twin-wire

submerged arc welding. International Journal of Advanced

Manufacturing Technology, 36: 463-474.

Shultz, B.L. and Jacson C.E. (1973) Influence of weld bead area on weld

metal mechanical properties. Welding Journal, 52(1):26s- 37s.

Singh, K., Pandey, S. and Arul M.R. (2005) Effect of Recycled Slag on Bead

Geometry in Submerged Arc Welding. Proceedings of International

Conference on Mechanical Engineering in Knowledge Age, December

12-14, Delhi College of Engineering, Delhi.

Singh, K., Pandey, S. and Mani, R.A. (2006) Recycling of Submerged

Welding Slag. Australasian Welding Journal, 51(2): 34-38.

215

Sirvanci. M. B. and Durmaz, M. (1993) Variation reduction by the use of

designed experiments. Quality Engineering, 5(4): 611-618.

Smith, N.J. (1989). Microstructure / Mechanical property relationships of

submerged arc welds in HSLA 80 steel. Welding Journal, 68(3): 112s-

120s.

Songbai, Xue. and Wang Donglin. (1994) The effect of Chemical

metallurgical factors on contents of phosphorus and sulfur in weld

metal during submerged arc welding. Proceedings of Hanjie Xuebao

Transactions of China, Welding Institute, 14 (4): 215- 220.

Srihari, T. (1992) Submerged arc welding of high Strength low alloy steels.

Ph.D. thesis, IIT, Delhi.

Stuck, S.S. and Stout, R.D. (1972) Heat treatment effects in multi-pass

weldments of high strength steel. Welding Journal, 52 (10): 508s -

514s.

Sui, S.H., Cai W., Liu Z.Q., Song T.G. and Zhang, A. (2006) Effect of

Submerged Arc Welding Flux Component on Softening Temperature.

Journal of iron and steel research, 13(2): 65-68.

Suresh, P.V.S., Rao, P. and Deshmukh, S. G. (2002) A Genetic Algorithm

approach for optimization of Surface Roughness prediction model.

International Journal of Machine Tools and Manufacture, 42: 675-

680.

216

Surian, E and Boniszewski, T. (1992) Effect of manganese and type of

current on the properties and microstructure of all- weld- metal

deposited with E7016-1 electrodes. Welding Journal, 72 (9): 348s-

360s.

Surian, E., Maranillo, E. and Boniszewski, F. (1995) The effect of carbon in

E7027 SMAW electrodes all weld metal. Welding Journal, 75 (8):

279s-280s.

Surian, E., Trotti, A. Cassanelli, A. and Devedia, L.A. (1994) Influence of

chromium on mechanical properties and microstructure of weld metal

from a high-strength SMA electrode. Welding Journal, 75 (8): 45s-54s.

Surian, E.S. and Vedia, L.A. (1999) All-Weld-Metal Design for AWS

E10018M, E11018M and E12018M Type Electrodes. Welding

Research Suppl. 217s-228s.

Svensson, L.E. (1994) Control of Microstructures and Properties in Steel Arc

Welding, CRC Press, Boca Raton, FL.

Synder, J.P. and Pense, A.W. (1982) The effects of Titanium on submerged

arc weld metal. Welding Journal, 61 (7): 201s –210 s.

Tanaka, J., Kitada, T., Nagarwa, Y., Kunisada, Y. and Nakagawa, H.

(1980) Element transfer behavior during submerged arc welding.

Proceedings of International Conference on Weld Pool Chemistry and

Metallurgy, Cambridge, England, The Welding Institute: 279-288.

217

Tandon, S., Kanshal, G.C. and Gupta, S.R. (1988) Effect of Flux

Characteristics on HAZ during Submerged Arc Welding. Proceedings

of the International Conference on Welding Technology, September,

University of Roorkee, 65-73.

Tarlinsku. (1980) The effect of viscosity of slag on the welding and

technological properties of electrodes. Svar. Proiz. 9: 21-22

Tarng, Y.S., Yang, W.H. and Juang, S.C. (2000) The Use of Fuzzy Logic in

the Taguchi Method for the Optimization of the Submerged Arc

Welding Process. International Journal of Advanced Manufacturing

Technology, 16:688–694.

Tarng, Y.S. and Chang, S.C. (2002) The use of grey- based Taguchi methods

to determine submerged arc welding process parameters in hard facing.

Journal of Materials Processing Technology, 128: 128-131.

Tarng, Y.S., Juang, S.C., Chang, C.H. (2002) The Use of Grey-Based

Taguchi Methods to determine Submerged Arc Welding Process

Parameters in Hardfacing. Journal of Materials Processing

Technology, 128: 1-6.

Thier. H. (1980) Metallurgical reactions in submerged arc welding. Weld Pool

Chemistry and Metallurgy, International Conference, Cambridge,

England, The Welding Institute: 271-278.

218

Tsai, H. L., Tarng Y. S. and Tseng C. M. (1996) Optimization of Submerged

Arc Welding Process Parameters in Hardfacing. International Journal

of Advanced Manufacturing Technology, 12: 402-406.

Tsai, J.T., Liu, T.K. and Chou, J.H. (2004) Hybrid Taguchi-Genetic

Algorithm for Global Numerical Optimization. Evolutionary

Computation, Proceedings of IEEE Transactions, 8(4): 365-377.

Tuliani, S.S., Boniszewski, T. and Eatan, N.F. (1972) Carbonate fluxes for

submerged arc welding of mild steel. Welding and Metal Fabrication,

40 (7): 247-250.

Tusek, J. (1999) A Mathematical Model for the Melting Rate in Welding with

a Multiple Wire Electrode. Journal of Physics D: Applied Physics, 32:

1739-1744.

Tusek, J. and Suban, M. (2003) High-productivity multiple-wire submerged-

arc welding and cladding with metal powder addition. Journals of

Materials Processing Technology, 133: 207-213.

Unal, R., and Dean, Edwin B. (1991) Taguchi Approach to Design

Optimization for Quality and Cost: An Overview. Proceedings of the

International Society of Parametric Analysts 13th Annual Conference,

May 21-24, 1991, New Orleans, LA.

Vishvanath, P.S. (1982) Submerged arc welding fluxes. Indian Welding

Journal, 15(1): 1-11.

219

Vitek, J.M., Iskander, Y.S. and Oblow, E.M. (2000a) Improved Ferrite

Number Prediction in Stainless Steel Arc Welds Using Artificial

Neural Networks-Part 1: Neural Network Development. Welding

Research Suppl. 33s-40s.

Vitek, J.M., Iskander, Y.S. and Oblow, E.M. (2000b) Improved Ferrite

Number Prediction in Stainless Steel Arc Welds Using Artificial

Neural Networks-Part 2: Neural Network Results. Welding Research

Suppl. 41s-50s.

Volobue, S. (1982) Metallurgical properties of fluxes with a varying silica

content used in the welding of 08 Kh19N 10B type corrosion resisting

steels. Svar. Proiz. (1):31-33.

Wang, Jen-Ting and Jean, Ming-Der. (2006) Optimization of Cobalt-Based

Hardfacing in Carbon Steel using the Fuzzy Analysis for the Robust

Design. International Journal of Advanced Manufacturing Technology,

28: 909-918.

Wang, S.H., Luu, W.C., Ho, K.F. and Wu, J.K. (2002) Hydrogen

permeation in a submerged arc weldment of TMCP steel, Materials

Chemistry and Physics, 77: 447–454.

Wanka, R. (1980) The influence of the physical properties of fluxes on

submerged arc welding. Proceedings of International Conference on

Weld Pool Chemistry and Metallurgy, Cambridge, England, The

Welding Institute. 93-95.

220

Ward, R.G. (1965) An introduction to the physical chemistry of iron and steel

making, London: Publisher English Book Society.

Weiman, C. (1981) Fundamentals of welding, Vol. 2, Florida: American

Welding Society Handbook.

Weymueller, C.R. (1981) Electrodes and fluxes-needed: speed, quality.

Welding Design & Fabrication, (6): 56-64.

Widrow, B. and Lehr, M.A. (1990) 30 Years of Adaptive Neural Networks,

Perception and Back propagation. Proceedings of IEE, 78: 1415-1442.

Wilson, E.M. (1966) SAW of 1% Titanium 18% Nickle-Co-Mo Maraging

Steel. British Welding Journal, 13 (2): 67-74.

Wiseman C. (1976) Welding Hand Book, Vol.1, 7th Edition, American

Welding Society: 137-138.

Witting, L. (1980) Some physical and chemical properties of welding slag and

their influence on slag detachability. Proceedings of International

Conference on Weld Pool Chemistry and Metallurgy, Cambridge,

England, The Welding Institute. 83-90.

Wojnowski, D., Oh, Y.K. and Indacochea, J.E. (2000) Metallurgical

assessment of the Softened HAZ region during multipass welding.

Journal of Manufacturing Science and Engineering, Transactions of

the ASME, 122: 310-315.

221

Wu, C.S. and Gao, J.Q. (2002) Analysis of the heat flux distribution at the

anode of a TIG welding arc. Computational Materials Science, 24:324-

327.

Xue, Y., Kim, I.S., Son, J.S., Park, C.E., Kim, H.H., Sung, B.S., Kim, I.J.,

Kim, H.J. and Kang, B.Y. (2005) Fuzzy Regression Method for

Prediction and Control the Bead Width in the Robotic Arc-Welding

Process. Journal of Materials Processing Technology, 164-165, 1134-

1139.

Yakobashvili, S.B. (1970) Inter-phase tension at the boundary. Armco iron

and ANF –IP flux. Automatic Welding, 23 (6): 20-23.

Yang, L.J. Chandel, R.S., and Bibby, M.J. (1993) The effects of process

variables on the weld deposit area of submerged arc weld. Welding

Journal, 72 (1): 11s-18s.

Yang, L.J., Bibby, M.J. and Chandel, R.S. (1993) Linear regression

equations for modeling the submerged-arc welding process. Journal of

Materials Processing Technology, 39: 33-42.

Yang, L.J., Chandel, R.S. and Bibby, M.J. (1992) The effects of process

variables on the bead width of submerged-arc weld deposits. Journal of

Materials Processing Technology, 29(1): 133-134.

Yang, W.H. and Tarng, Y.S. (1998) Design Optimization of Cutting

Parameters for Turing Operations Based on the Taguchi Method.

Journal of Material Processing Technology, 84: 122-129.

222

Zhang, X.P. and Dorn, L. (1999) Investigation on the possibility of using the

microshear test as a surveillance method to estimate the mechanical

properties and fracture toughness of nuclear pressure vessel steel,

A508CL3, and its joints welded by narrow-gap submerged-arc

welding. International Journal of Pressure Vessels and Piping, 76: 35–

41.