Lanfeust De Troy T08 _ La bete fabuleuse - Arleston,Taquin.pdf

BETE 207USA - XA Components & Options · 2018-05-17 · XW Air Cap XA 01/02 Body with E or F...

Transcript of BETE 207USA - XA Components & Options · 2018-05-17 · XW Air Cap XA 01/02 Body with E or F...

External Mix Set-upsThe air and liquid streams exit thenozzle independently and are com-bined and mixed outside of the nozzle.Because there is no connec-tionbetween the air and liquid lines withinthe nozzle, the air and liquid flow ratescan be controlled indepen-dently,allowing precise metering of the liquid.The atomization can be controlled byadjusting the air flow rate—more airproduces finer atomization. In mostcases these set-ups do not atomize asfinely as Internal Mix Set-ups.

XA

www.BETE.com

Low Flow Air Atomizing

74

The XA nozzle system uses the energy in compressed air to produce highlyatomized sprays at low flow rates. Thereare many interchangeable componentsthat can be assembled to achieve avariety of spraying objectives.

SPRAY SET-UPSXA nozzles produce eight distinctlydifferent types of sprays, dependingon which interchangeable air andfluid caps are selected. The spraytype and flow rate are determined bythe ”set-up”—a specific combinationof one air cap and one fluid cap.

Internal Mix Set-upsLiquid and air streams meet withinthe nozzle and are mixed togetherand expelled through the same ori-fice(s). This internal mixing meansthe streams are not independent; achange in air flow will affect the liq-uid flow. This makes precise meter-ing of the liquid more difficult thanwith an External Mix Set-up. InternalMix Set-ups are able to produce thefinest atomization of any of the XAset-ups, but they are generally notsuitable for use with liquids whichhave a viscosity that isabove 200 centipoise.

External Mix Set-ups may be usedwith liquids having a viscosity above200 centipoise and for abrasive sus-pensions. BETE ApplicationsEngineering can provide guidancefor spraying high viscosity liquids.

Siphon Set-upsInternal and External Mix Set-upsrequire the liquid to be supplied tothe nozzle under pressure from amunicipal water supply, pump, orpressure pot. Siphon Set-ups use theflow of compressed air within thenozzle to siphon liquid from a con-tainer. Siphon Set-ups are frequentlyused for spraying additives from acontainer without the use of a pump.They provide the lowest flow ratesavailable in the XA series (as low as

Cutaway View: Internal Mix Set-up

Cutaway View: External Mix Set-up

AIR

ATO

MIZ

ING

E. Air Operated Shut-off

A. End Plug

Bold letters (A, B, C, D, E, F) refer to hardware assembliesshown on p. 76.

D. Clean-out/Shut-offB. Shut-off

TO O

RD

ER:s

peci

fy p

ipe

size

, bod

y st

yle,

spr

ay s

et-u

p #,

hard

war

e an

d m

ount

ing

asse

mbl

ies,

and

mat

eria

l. S

ee p

age

76.

ANNULAR AREA AIR FEED

LIQUID FEED

AIR FEEDLIQUID FEEDAIR ORIFICES

LIQUID ORIFICES

XW Air Cap

XA 01/02 Bodywith E or FHardware

CA

LL 413-772-0846C

all for the name of your nearest B

ET

E representative.

75

A. Plug. The minimum optionhardware assembly required for XAoperation. Provides neither clean-outnor shut-off.B. Shut-off. Turning the knurledknob will stop the flow of liquid tothe nozzle. Should not be used tometer the flow of liquid.C. Clean-out. Pressing the spring-loaded plunger will force a smalldia-meter rod through the liquidorifice, cleaning any obstruction.Useful for intermittent spraying of aliquid that may dry in the orificewhen not in use.

D. Clean-out/Shut-off. Combinesfunctions of hardware assemblies Band C in one unit.For critical applications which re-

0.1 GPH). They are generally notsuitable for use with liquids having aviscosity above 200 centipoise.

By supplying the liquid underpressure, SR Set-ups may be usedwith liquids having a viscosity above200 centipoise. In this case, the liquidflow rate is regulated by the fluidcap, and can be determined by usingthe EF chart for the specific fluid cap.

The basic XA nozzle assemblyconsists of a body, a spray set-up,and a “hardware assembly” that canprovide shut-off and clean-outcapabilities.

The XA00 Square Body is the basiccomponent of a non-automatic XAnozzle. Air and liquid feeds arelocated at opposite ends, perpendi-cular to the spray.

The XA03 Body has air and liquidfeeds on one side, perpendicular tothe spray axis.

The XA05 Body has air and liquidinlets located in-line with the spray.Hardware assemblies cannot be usedwith the XA05 body.

PF Air Cap

AIR

ATOM

IZING

XA03 Body

XA00 Body

with C Hardware

Fluid Cap

FF Air Cap

PR Air Cap

BASIC OPERATION

Non-Automatic Operation

Hardware Assemblies for Non-Automatic Operation

XA Components & Options

EF Air Cap

SR Air Cap

www.BETE.com

XA05 Body

76

AIR

ATO

MIZ

ING

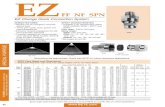

XA Components & OptionsSpray Set-upSpray Set-up Body Styles and SealsBody Styles and Seals Hardware AssembliesHardware Assemblies

SF

SR

PR

PF

AD

EF

FF

XW

Fluid Cap

Front Gasket

Air Caps

XA 00

Rear Gasket

Rear Gasket

Replaceable E orF Tip assembly

A End Plug

B Shut-off

C** Clean-out

D** Clean-out/Shut-off

E Air-operated Shut-off

F** Air-operated Clean-out/Shut-off

Adapter

ReplaceableE or F Tipassembly

Rear Gasket Seal Kit: 39572

Bushing

Large O-rings

MountingBracket

Thin Wall MountLock Nut

Thick & Thin WallMounting Adapter

Thin WallMounting Gasket

Replaceable Components and Gaskets

Seal KitFront GasketRear GasketBody SealCap NutAdapter

Thick & Thin Wall Mount AdapterThin Wall Lock NutThin Wall Mounting GasketMounting Bracket

E - Replacement TipF - Replacement Tip**

**Specify fluid cap

Spray Set-up Number

Sizes and Series1/8”B, 1/4”B, 1/2”B - BSP 1/8”, 1/4”, 1/2” - NPT

Body Styles00 01 02 03 05

Air Cap StylePR FF AD XW PF EF SR SF

Mounting Hardware01 02 03

Extension Size12”

Hardware AssembliesA B C D E F

Combination Number

1/4 XA 01 PR 250 E 01 12

TO ORDER

XA 08 Directional spray,2 nozzle spray setups

XA 06 (4-5 spray setups)Parallel inlets

XA 05 Spray parallel to parallel inlets

XA 03 spray perpendicular to parallel inlets

XA 07 Diminutive bodyspray perpendicular to1/8” parallel inlets

XA 01

XA 02

www.BETE.com

TO O

RD

ER:s

peci

fy p

ipe

size

, bod

y st

yle,

spr

ay s

et-u

p #,

hard

war

e an

d m

ount

ing

asse

mbl

ies,

and

mat

eria

l. S

ee p

age

76.

AIR

ATOM

IZING

CA

LL 413-772-0846C

all for the name of your nearest B

ET

E representative.

77

quire automatic, no-drip, or high-speed spray shut-off, the XA can besupplied with an air-cylinder-operated shut-off or clean-out/shut-off. These air cylinders provide virtu-ally instantaneous liquid shut-off atrates of up to 180 cycles per minute.The air cylinders require a minimum of 30 PSI.

The XA01 and XA02 Round Bodiesare rugged, highly reliable, and wellsuited to the rigors of high-cycleautomatic operation. They have beendesigned to simplify the feed pipingrequired for installing automatic noz-zles by providing a constant locationfor the air inlet piping. With theirneat, professional appearance, theyare particularly recommended forOEM applications.

The XA01 Round Body has oneinlet for air and one for liquid. Be-cause the air inlet supplies air forboth cylinder movement and liquidatomization, spraying during start-up and shut-off is not as crisp andprecise as with the XA02. The XA01body cannot be used with atomizing airpressure under 30 PSI.

The XA02 Round Body has twoinlets for air and one inlet for liquid.One of the air inlets supplies thecylinder and the other suppliesatomizing air. The XA02 bodymust be used when the air cylinder

operates at a different pressure fromthe atomizing air or where the atomi-zing air is supplied below 30 PSI.NOTE: The XA00 Square and XA03Bodies used for non-automatic operationcan also be used, with hardware assem-blies E or F, for automatic operation.Special design features allow fieldupgrading to automatic operation.

E. Air-Operated Shut-off. Removalof air pressure to the cylinder causesa spring-loaded poppet valve actua-tor to shut off liquid flow.F. Air-Operated Clean-out/Shut-off.Operation similar to E, but includesa clean-out needle.

Electrically operated solenoid valvescan be used to control the operationof any XA nozzle. BETE can supplysolenoid valves matched to yourspecific application.

A 3-way, quick-exhaust solenoidvalve is required to operate the E orF hardware assembly. The valve islocated in the line that supplies air tothe cylinder, as close to the nozzle as

possible. Independent control of theatomizing air of an XA02 or squarebody requires an additional 2-waysolenoid valve.

Two-way solenoid valves can beused to stop and start the flow of airand liquid to any non-automatic XA nozzle.

For optimum reliability, everypressure-fed XA nozzle should havea strainer and regulator in the liquidfeed line and a filter and regulator inthe air feed line. Every XA nozzlewith a Siphon Feed Set-up shouldhave a filter and regulator in the airline. The size and type of each ofthese components depends on theapplication, and can be determinedby your BETE sales representative.BETE maintains an inventory offilters, strainers, and regulators thatcan be supplied with your XA nozzleto ensure reliable operation. Thesecomponents can be purchasedindividually or in kit form.

XA Components & OptionsAUTOMATIC OPERATION

Bodies for Automatic Operation Hardware Assemblies for Automatic Operation

SOLENOID VALVES

Solenoids for Automatic XA Nozzles.

Solenoids for Non-Automatic XA Nozzles.

FILTERS, REGULATORS AND STRAINERS

www.BETE.com

Simple piping and robust design describe this multiple nozzle XA lance.

Corrosion-resistant XA in PVC

External mix cone cap

The XA06 manifold body can befitted with up to five nozzle

setups and is often used forhumidification of large areas.

78

The spray set-up can be moved awayfrom the nozzle body by usingoptional 6” or 12” extensions. Theseallow the spray to be moved closer tothe target while keeping the nozzlebody and associated piping at adistance.

In many XA installations the nozzleis supported by the rigid metal pipethat supplies air or liquid. There areseveral components which canprovide support for the XA Bodieswhen it isn’t appropriate to suspendthe nozzle from piping; for example,when the nozzle will spray throughthe wall of a tank or duct, or whenthe air and liquid will be suppliedthrough flexible tubing. All XAbodies except the XA03 can be usedwith any of the mounting hardwaredescribed here.

Three-piece adapter used to supportan XA nozzle with the body locatedoutside a tank or duct having arelatively thin (less than 3/8”) walland the spray directed into theinterior. To use this adapter, a 1-1/16”diameter hole must be drilledthrough the wall. This adapter bothsecures the air cap and attaches thenozzle body to the tank wall.

Similar in design and function to theThin Wall Adapter, but intended foruse with tanks or ducts with wallsthat are thick enough (3/8” or over)to be drilled and tapped for a 3/4”NPT thread.

This bracket is used in combinationwith a Thin Wall Adapter to supportan XA nozzle from a 1/2”-diametermetal rod. The bracket allowsflexibility in aiming the spray.

The standard materials for the XAseries are nickel-plated brass and 303and 316 stainless steels. Other metalsand plastics can be supplied onrequest. See page 13 for a completematerial list.

The air cylinders used for XAhardware assemblies E and F haverods and cylinders made of stainlesssteel and end caps made of anodizedaluminum. All metal parts in contactwith the spray liquid are 316 stainless steel.

The standard material for XA gasketsis compressed fiber with a neoprenebinder. For installations requiringFDA approval, SBR gaskets areavailable. Other elastomeric andmetallic gasket materials can besupplied on request.

The standard material for O-rings inXA automatics is Viton®. Othermaterials available on request.A

IR A

TOM

IZIN

GXA Components & Options

XA02 with Thin Wall 02 Adapter

XA02 with Thick Wall 01 Adapter

SPRAY EXTENSIONS

MOUNTING HARDWARE

Thin Wall 02 Adapter

Thick Wall 01 Adapter

Mounting Bracket 03 Adapter

MATERIALSBodies, Fluid Caps, Air Caps,Hardware Assemblies, MountingHardware

Air Cylinders

Seals

2XA9890Gasket

2XA9886B - 3/4” BSP2XA9886 - 3/4” NPT

2XA9889Locking nut

Minimum wall thickness

XA03 MountingBracket

BETE can fabricate XA nozzlesinto any number of lance

assembly variations

Automatic XA nozzles in amanifold configuration used forcoating a very wide product

Extensionsseparate the spray tip from the body

Spray lance (see page 107) with a right angle XA and quick-connect fittings

www.BETE.com

TO O

RD

ER:s

peci

fy p

ipe

size

, bod

y st

yle,

spr

ay s

et-u

p #,

hard

war

e an

d m

ount

ing

asse

mbl

ies,

and

mat

eria

l. S

ee p

age

76.

2 5/8”MAX.

Spray Set-up Numbers

PIPESPRAY SIZE SET-UP FLUID AIRSET-UP BSP or NPT NO. CAP CAP

EF

EF 050 FC7 AC1001EF 100 FC7 AC1003EF 150 FC4 AC1001

1/8

OR

1/4

EF 200 FC4 AC1003EF 250 FC3 AC1001EF 300 FC3 AC1003

FLATFAN

(EXTERNALMIX)

EF 350 FC6 AC1002EF 400 FC6 AC1004EF 450 FC2 AC1002EF 500 FC2 AC1004EF 550 FC1 AC1002EF 600 FC1 AC1004EF 650 FC8 AC1005EF 700 FC9 AC1005EF 800 FC5 AC1005

1/2 EF 5050 FC501 AC5001

SFSIPHON

FLATFAN

1/8OR1/4

SF 050 FC3 AC1101SF 100 FC6 AC1102SF 150 FC2 AC1103SF 200 FC2 AC1104

SR

SR 050 FC7 AC1201

1/8OR1/4

SR 150 FC4 AC1201

SIPHONROUND

SR 200 FC4 AC1202SR 250 FC3 AC1202SR 400 FC1 AC1204SR 450 FC5 AC1205

1/2 SR 5050 FC501 AC5201

PF

PF 050 FC4 AC1301PF 100 FC3 AC1303

1/8OR1/4

PF 150 FC3 AC1301

PRESSUREFLATFAN

PF 200 FC3 AC1302PF 250 FC2 AC1304PF 300 FC1 AC1304PF 350 FC1 AC1305PF 400 FC5 AC1306

1/2PF 5050 FC501 AC5301PF 5100 FC502 AC5302

XWEXTRA

WIDE-ANGLEROUND

1/8 OR 1/4 XW 050 FC8 AC1401

1/2 XW 5050 FC502 AC5401

PR

PR 050 FC4 AC15011/8OR1/4

PR 100 FC4 AC1502PR 150 FC3 AC1502

PRESSURE ROUND

PR 200 FC2 AC1503PR 250 FC1 AC1503PR 300 FC5 AC1504

1/2PR 5050 FC501 AC5501PR 5100 FC502 AC5502

AD

AD 050 FC4 AC1601AD 100 FC2 AC1603AD 150 FC2 AC1602

WIDEANGLEROUND

AD 200 FC1 AC1603AD 250 FC1 AC1604AD 300 FC5 AC1605

1/ 2

AD 5050 FC501 AC5601AD 5100 FC501 AC5602AD 5150 FC501 AC5603AD 5200 FC502 AC5604

FF DEFLECTEDFLAT FAN 1/8 OR 1/4 FF 050 FC10 AC1701

1/8OR1/4

CA

LL 413-772-0846C

all for the name of your nearest B

ET

E representative.

AIR

ATOM

IZING

XA Components & Options

Overall Dimensions of XA Assemblies with XA00 Body (Shown with E or F Hardware)

Overall Dimensions for Assemblies with XA01 or XA02 Bodies

Dimensions with Hardware Options for XA00 Body, BSP or NPT

Pipe

Size

Hardware

Option

W X Y Max. "Z"

A

7/8 1 11/16 1 15/16

9/16

1/8 B 1 5/8

OR C 2 5/8

1/4 D 3 3/16

E 4 1/16

F 4 1/16

1/2 A 1 1/4 2 1/2 2 11/16 1

Dimensions in inches

79

X

W

ZYMAX.

Ø 1 5/8”

4 1/16”1 15/16”MAX.

CENTERLINE FORAIR & LIQUID INLETS

Dimensions are approximate. Check with BETE for critical dimension applications.

www.BETE.com

2 1/8”MAX.

1 5/8”

Overall Dimensionsfor Assemblies with

XA03 Bodies

Overall Dimensions for Assemblies with

XA05 Bodies

Ø 1 5/8”

80

TO O

RD

ER:s

peci

fy p

ipe

size

, bod

y st

yle,

spr

ay s

et-u

p #,

hard

war

e an

d m

ount

ing

asse

mbl

ies,

and

mat

eria

l. S

ee p

age

76.

AIR

ATO

MIZ

ING

XA Components & Options

BETE carries a complete line ofcontrols and accessories requir-ed for setting up a system usingthe XA Series nozzles.

Contact your BETE represent-ative for details.

In a pressure-fed system, theliquid is supplied under pressureto either internal or external mixBETE XA Series nozzles.

Air and liquid regulatorscontrol the fluid delivery pres-sure, while the air filter and liquidstrainer ensure that the suppliedfluids are free of particulate.

Operational control is main-tained by manual orsolenoid valves used inconjunction with the varioushardware assemblies.

In a siphon-fed system, theliquid is supplied by either asiphon or gravity feed.

An air regulator controls the airdelivery pressure, while the airfilter ensures that the com-pressed air is of high quality.

Operational control is main-tained by manual or solenoidvalves used in conjunction withthe various hardware assemblies.

When used as a gravity feedset-up, a positive liquid shutoffcapability should be provided.

Filters, regulators, andstrainers matched to your XAapplication are available from stock.

SYSTEM SET-UPS ANDACCESSORIES

Pressure System Set-up

Siphon System Set-up

SIPHON SYSTEM

PRESSURE SYSTEM

www.BETE.com