BENTLY NEVADA Technical Training TM Technical Training ... · BHGE provides technical training on...

Transcript of BENTLY NEVADA Technical Training TM Technical Training ... · BHGE provides technical training on...

GE Oil & Gas

Digital Solutions

Technical Training Bently Nevada*

imagination at work

BENTLY NEVADATM

Technical Training

bhge.com

BENTLY NEVADA TRAINING CENTERS IN EUROPE

ROTTERDAM

FLORENCE

NANTES

MADRID

MOSCOW

BERGEN

MANCHESTER

FRANKFURT

VIENNA

ELBLAG

A single email address to contact

all European training centers:

NORWAY | Bergen

Ytrebygdveien 215

Blomsterdalen, 5258

+47 900 90 226

POLAND | Elblag

Stoczniowa 2

82-300 Elbląg

+48 55 239 19 11

NETHERLANDS | Rotterdam

Delftechpark 26

2628 XH Delft

+31 1615641325

SPAIN | Madrid

Josefa Valcarcel, 26

Madrid, 28027

+91 587 06 67

UK | Manchester

22 Grimrod Place

Skelmersdale, WN8 9UU

+44 1695 380 013

RUSSIA | Moscow

10, Presnenskaya nab., bld. A, fl. 10

Moscow 123112

+7 495 937 1111

FRANCE | Nantes

14 rue de la Haltinière

44 300 Nantes

+33 240 729 944

ITALY | Florence

Via Perfetti Ricasoli, 78

Firenze, 50127

+39 238 590 506

GERMANY | Frankfurt

Bleichstrasse 64-66

Frankfurt am Main 60313

+49 694 012 518 12

CONTENTS

8

Fundamentals of Vibration course

9

Systems and Instrumentation course

10-19

Machinery Diagnostics courses

20-22

ISO 18436 courses

A WORLDWIDE PARTNER FOR OPERATIONAL EXCELLENCE

BHGE, a GE and Baker Hughes joint venture, provides customers with

condition monitoring solutions and services, from design to operation and

expert diagnostics.

BHGE provides technical training on Bently Nevada solutions delivered by

our experienced Field Engineers. You and your team will benefit from

comprehensive hands-on courses, starting at fundamentals to in-depth

diagnostics on rotating machinery.

BHGE technical training programs provide you and your team the

knowledge and skills required to protect and control your machinery and

to optimize the performance of your equipment. BHGE works with you to

build a training plan that is best adapted to your needs. Overall, it will

maximize your return-on-investment by ensuring machinery availability

and reliability, by avoiding unplanned events and limiting disruption risks

and costs.

POWER UP YOUR KNOWLEDGE

BHGE training centers provide a full range of training in Bently Nevada solutions. These courses which, encompass

all aspects from fundamentals to in-depth solution and diagnostics knowledge, are based on value-added pillars.

TECHNICAL EXPERTISE with 22 experienced trainers. Our team combines pro-

duct installation, operation, maintenance or engineering experience with technical ex-

pertise, proven teaching skills and a commitment to knowledge transfer.

EXPERIENCE from our Bently Nevada field engineers and technical experts. With

more than 40 years of technical training experience, BHGE has pioneered the art of

long-term skill development.

HANDS-ON WORKSHOP to guarantee operational excellence and to ensure

trainings combine theory and practice. Workshops include practice with 'live' monitors

and racks. Class sizes are kept small ensuring students get the most out of training.

CUSTOMIZED TRAINING to fit with your needs and enhance your team’s perfor-

mance. With 15 modules in different languages, you will find the courses adapted to you

or your team’s role and experience (operators, managers, engineers…). A training curricu-

lum can be developed, including needs and gap analysis, objectives development and

skills based training solutions.

DIGITAL & UP-TO-DATE MATERIAL to optimize learning. Course content and

workshops are continually revised to reflect latest technologies, experience and local

regulatory standards.

COMPREHENSIVE OFFERS to match your specific needs and what works the

best for you and your team: modular training at one of BHGE training center or at your

site, coaching program or skills development program.

300

Attendees

8 800

Trainee Hours

98%

Net Promoter Score

94%

Customer Satisfaction

Excellence is an ART won by training and habituation.

We ARE what we repeatedly DO.

Excellence then is not an act, but a HABIT.

Aristotle

MODULAR TRAINING

Provide your team with the right skills and knowledge, according to their profile, to increase their motiva-tion, performance and productivity.

Our core curriculum includes 15 training modules with an emphasis on practice. The benefits of training on real

equipment is instantaneous. In small groups, trainees learn both theory and practice, the “why” and the “how-to”.

Courses are adapted to your profile.

INSTRUMENTATION

& MAINTENANCE OPERATORS

RELIABILITY &

DIAGNOSTIC EXPERTS

Fundamentals of Vibration

Fundamentals

of Vibration

Fundamentals of Vibration

3500 System Operation

& Maintenance

System 1 ADRE 408

Machinery

Diagnostics

System 1 ADRE 408

Applied Diagnostics Workshop

Advanced Electric Motors Workshop

Reciprocating Compressors

Advanced Machinery Dynamics

Advanced Field Balancing

COMPREHENSIVE TRAINING FOR YOUR NEEDS

BHGE works with you to develop a comprehensive Skills Development Program specifically designed to address your

needs. It will help you to build sustainable competencies and maximize your return on investment in condition moni-

toring technologies.

The first step in our Skills Development Program is establishing a role-based competency matrix. This will be

achieved by combining your organization’s job descriptions with condition monitoring best practices from BHGE. The

team will be assessed against a competency matrix specific to their role to identify skills and competency gaps.

Based on the skills gaps identified, condition technologies deployed at site and operational constraints, a roadmap

to build sustainable competencies will be developed.

By using customized training content, our certified instructors will conduct training sessions at a BHGE training cen-

ter or at your site. These power users equipped with plant-specific knowledge and advanced awareness of the sys-

tems will be able to extract maximum benefit from the systems deployed and improve the ROI.

SKILLS DEVELOPMENT PROGRAM

Bring your team to a higher confidence and competence level with our customer-specific program, based

on proven technical competency matrix.

ANALYZING

Needs Analysis

Assessment Test

PREPARING

Course Design

Planning

TEACHING

Technical Training

On-site Coaching

QUALIFYING

Knowledge Test

Validation

CERTIFICATION

To evaluate trainee’s

knowledge level

To optimize course

To acquire required

skills

To check knowledge acquisition

COACHED PROGRAM

Empower employees by combining standard training and personalized on-site coaching to improve their confidence, efficiency and operational excellence.

To get the most out of training, BHGE set up the coached pro-

gram. Based on their knowledge, trainees will be oriented to the

appropriate training program and once completed, will benefit

from onsite coaching to leverage what they have learned in

classroom on their day-to-day job at site. This program brings

incremental value and confidence to your engineers.

Technical Training

Online Test

On-site Coaching

Fundamentals of Vibration

VIBFU

Duration

Audience

• Technicians with a limited experience on vibration machinery

• Technicians working on vibration control with condition monitoring program

• Engineers involved in condition monitoring • Technicians in preventive maintenance

Program

Day 1

• Machinery Monitoring: history, benefits, and strategies. Ty-pically Monitored Machines and Considerations

• Basic Vibration Concepts: definition of vibration, understan-ding relationships of vibration displacement, velocity, acce-leration, units of amplitude and meaning of vibration ampli-tude in analysis

• Defining frequency, units of frequency, and meaning of fre-quency in analysis, defining phase and measuring relative and absolute phase, understanding natural frequencies

Day 2

• Vibration Transducers: theory of accelerometer operation, theory of Velomitor operation, theory of Proximity Trans-ducer System operation

• Workshops identifying amplitude, frequency and phase

from timebase and spectrum plots. Workshops for trans-ducer and monitoring systems for given machine scenarios

Objectives • Explain the reasons for vibration monitoring and maintenance strategies. • Identify key components and describe vibration motion in a measurement plane. • Define the parameters used to measure vibration motion and state the units used to express each parameter. • Describe the principles of vibration transducer operation, the benefits and disadvantages of each type, and typical scale

factor of output signal. Apply selection criteria to choose a useable vibration transducer for a specific machine vibration. • Read values of amplitude, frequency, phase and recognize sources of vibration indicated by waveform and spectrum plots.

Learning path

Next steps

• System & Instrumen-tation courses

• Machinery Diagnostic courses

VIBFU

Prerequisites

New in condition monito-ring and control of ma-chinery

BENEFITS

2 days (14 hours)

Basics on measurement, parameters, monitoring approach and use of trans-ducers

+

3500 Operation & Maintenance

3500OM

Duration

Audience

Objectives

• Explain the role of the 3500 Monitoring System in machinery monitoring and protection. • Identify installation conditions affecting the correct operation of proximity transducer systems. • Test monitor alarms and verify channel values in a radial vibration monitor. • Use BHGE propriety configuration software to configure and/or reconfigure the 3500 monitor system. • Troubleshoot the 3500 monitor system and associated transducers using software and hardware techniques.

• 3500 monitoring system users. • Engineers involved in maintenance and

troubleshooting of the 3500 Monitoring System. • Instrument technicians.

Program

Day 1

• Overview of 3500 Monitoring System

• 3300 Proximity Transducer System Operation

• 3500 Monitor System Support Components

• TDI/RIM Hardware Connections and Communications

• Power Supply, TDI/RIM and Keyphasor Configuration

Day 2

• Radial Vibration

• Thrust Position

• Relays

Day 3

• 3500 System Utilities

• Troubleshooting 3500 System

• 3500/92 Communications Gateway (Optional)

• Data Acquisition/DDE Server Software (Optional)

• Reciprocating Compressors (Optional)

Optional: The last day focus can vary depending on audience

needs.

Learning path

Next steps

• Specific courses

• Machinery

Diagnostics courses

3500OM

Prerequisites

• Fundamentals of vibrations (VIBFU)

• Review of data acquisi-tion CBT solution (Reference 168836-01-01)

BENEFITS

3 days (21 hours)

Practice workshops with 'live' monitors and racks .

+

10 | [email protected]

System 1 Fundamentals

S1FU

Duration

Audience

• System 1 Platform Users. • Reliability Engineers. • Condition Monitoring Engineers. • Engineers involved in Preventive Maintenance.

Program

Day 1

• System 1 Overview

• Viewing Information with System 1 Display

• Event Manager and Asset Active Alarm in System 1 Display

• Customizing Trend Plots

Day 2

• Vibration Signal Fundamentals

• Introduction to Plot Sessions and Plot Groups

• Working with Plot Session and Plot Groups

• Shaft Centerline Plots

• Plotting Dynamic Data and Using Collection Groups

Day 3

• Collecting Data in Transient Mode

• System 1 Asset Information Storage

• System 1 Administrative Tasks

Objectives

• Use various System 1 software tools and plots to detect subtle changes in asset condition. • Retrieve and display data in bar graphs and various plot formats. • View alarms and events in the event manager. • Enter observations and notes with the journal editor. Use DOCUVIEW* to create links to various reference documents. • Create reports on monitored plant assets. • Describe how our communication processors such as TDI or TDXnet™ collect transient data.

Learning path

Next steps

• Specific courses

• Machinery

Diagnostics courses

S1FU

Prerequisite

• Fundamentals of vibrations (VIBFU)

• Review of data acquisi-tion CBT solution (Reference 168836-01-01)

BENEFITS

3 days (21 hours)

Pratice workshops on efficient use of the platform to support decision making.

+

11 | [email protected]

System 1 for Portables

S1EVOP

Duration

Audience

Objectives

• Explain portable data measurement. • Use the Scout or Vb instrument to collect data and then send to System 1 Evolution. • Use the Status tab and Plots tab to analyze the collected data. • Analyze faults and alarms. • Manage access through the Security Manager.

• System 1 Platform Users. • Reliability Engineers. • Condition Monitoring Engineers. • Engineers involved in Preventive Maintenance.

Program

• Installation

• Licensing Proficy Historian and System 1 • Asset Building • Instrumentation

• Route Building

• SCOUT

• Data Collection – SCOUT 100/Vb Series

• Analyzing Collected Data

• Faults and Alarms

• 6 Pack and Individual Points (with optional Rack Buffered Outputs)

• Database Manager

• Creating Templates

• Data Analysis and Diagnostics (Demo Database)

• Remote Communication

Learning path

Next steps

• Specific courses

• Machinery

Diagnostics courses

S1EVOP

Prerequisite

• Fundamentals of vibrations (VIBFU)

• Review of data acquisi-tion CBT solution (Reference 168836-01-01)

BENEFITS

2,5 days (18 hours)

Pratice workshops at

each step of the course.

+

12 | [email protected]

S1EVOT

Duration

Audience

Objectives

• Connect to an Enterprise to view data. Check for alarms through event manager and create alarm plots of the latest events. • Use status screens to find bad actors and using alarm plots to look for trend and data correlations at train, machine and bea-

ring levels as well as point in alarm data. • Use Quick plots to further investigate reason for alarm. Create a base line from first sample and overlay in spectra and time

base. Generate waterfall plots on points and dynamic data of interest, Quick report of the findings in a word document on at least one machine problem.

• System 1 Platform Users. • Reliability Engineers. • Condition Monitoring Engineers. • Engineers involved in Preventive Maintenance.

Learning path

Next steps

• Specific courses

• Machinery

Diagnostics courses

S1EVOT

Prerequisite

• Fundamentals of

Vibration for Con-

tinuous Monitoring

(VIBFUCM)

BENEFITS

3 days (21 hours)

Pratice workshops at

each step of the course.

+

System 1 for TurboMachinery

Program

• Overview

• Introduction to on-line systems and data collection

• Machine Building

• Creating_Templates

• Database_Manager

• Data Analysis and Diagnostics

• Transient_Data

• Steady State Data

• Alarms and Condition Monitoring

• Create Enterprise & setting preferences

• Notes, Plot Sets, Case History & Audit_Files

• Notifications_Presentation

• Condition Monitoring Based Variables and Alarms

13 | [email protected]

ADRE 408 DSPi/Sxp

ADRE

Duration

Audience

Objectives

• Configure ADRE system to collect machinery data. • Acquire data effectively for real-time analysis. • Display vibration and other data types using various plot types for machine condition analysis. • Edit, document and store databases for future use.

• Adre 408 Users. • Condition Monitoring Engineers. • Engineers involved in Preventive Maintenance.

Program

Day 1

• Overview and Introduction

• Using the Front Panel

• Communication and Networking

• Vibration Fundamentals

• Planning Data Sampling

• Basic Sampling

Day 2

• Static Data Plotting

• Signal Processing

• Dynamic Data Plotting

• Advanced Sampling

Day 3

• Using the ADRE 408 Replay Card

• Collecting and replaying raw continuous data

• Sharing and Exporting Data

• Advanced Utilities

Learning path

Next steps

• Specific courses

• Machinery

Diagnostics courses

ADRE

Prerequisites

• Fundamentals of vibrations (VIBFU)

• Review of data acquisi-tion CBT solution (Reference 168836-01-01)

BENEFITS

3 days (21 hours)

Advanced database manipulation tools.

+

14 | [email protected]

Advanced Electric Motors Predictive

Maintenance Techniques Workshop

AEM

Duration

Audience

• AnomAlert and System 1 Platform Users. • Electrical Maintenance Engineers and Technicians • Reliability Engineers. • Condition Monitoring Engineers. • Engineers involved in Predictive Maintenance.

Objectives

• Explain the purpose of Motor Current Signature Analysis (MCSA) and Advanced Transient Current Signature Analyses (ATCSA).

• Describe how the motor and coupled machine design and behavior are reflected in Current and Vibration Spectrum. • Discuss the causes, effects and indicators of the typical machine malfunctions; including recognition of problems such as

unbalance, misalignment, soft foot, rotor broken bars, bearing damage, eccentricity, stator problems.

Program

Day 1

• Introduction to Motor Current Signature Analysis (MCSA) and Advanced Transient Current Signature Analyses (ATCSA)

• Winding Harmonics, Principal Slot Harmonics

• Motor Speed Calculation using Principal Slot Harmonics of Motor Current Spectrum

• Workshop

Day 2

• Introduction to AnomAlert Toolkit measuring current spectrums and Scout data collector measuring vibration spectrums

• Workshop on Demonstration and Diagnostics of Motor Malfunctions such as Unbalance, Soft Foot, Rotor Broken Bars

• Using AnomAlert Toolkit and Scout data collector

Day 3

• Workshop on Demonstration and Diagnostics of Motor Malfunctions as Bearing Damage, Misalignment

• Using AnomAlert Toolkit and Scout data collector

Learning path

Next steps

• Machinery Diagnostics

(MDS)

• Machinery Applied

Diagnostics Workshops

AEM

BENEFITS

3 days (21 hours)

Practice Workshops on

efficient use of the

AnomAlert and MCSA to

support decision making.

+ Prerequisites

• Fundamentals of vibrations (VIBFU)

• Review of data acquisi-tion CBT solution (Reference 168836-01-01)

15 | [email protected]

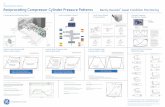

Reciprocating Compressor Condition

Monitoring & Diagnostics

RECIP

Duration

Audience

Objectives

• Describe the compression process and interpret vibration readings of reciprocating compressors. • Relate reciprocating compressor components to various failure modes. • Recognize and select plots used to assess the health of reciprocating compressors and interpret PV Plots. • Calculate rod load conditions (reversal). • Discover the full application and benefits of rod position instead of rod drop measurements. • Conduct a compressor vibration analysis.

• Engineers desiring to learn about reciprocating compressor components and mechanics.

• Engineers willing to understand reciprocating com-pressor performance theory.

• Engineers interpreting reciprocating compressor vibration and analyzing malfunctions to diagnose and optimize assets.

• Engineers involved in the design, acceptance testing and maintenance of reciprocating machinery.

Program

• Basic Elements of Reciprocating Compressors

- Compressor overview

- Reciprocating compressors in industry

- Components and Nomenclature

- Lubrication Systems

- Compressors Types

• How to Monitor a Reciprocating Compressor

• Importance of Vibration and Pressure Measurements

• Which Plots are Used to Evaluate the Health of the Recipro-cating Compressor

• Monitoring Strategies

• Reciprocating Compressor Diagnostics:

- Crosshead and Frame Vibration

- Pressure Monitoring and Diagnostics

- Rod Load and Rod Reversal

- Reciprocating Compressor Capacity Control and the Impact on Vibration and Pressure Monitoring

- Rod Position and Rod Drop Analysis

- PV Analysis of Multistage Compressors

- Workshops and Presentation of Case Histories

Learning path

Next steps

RECIP

Prerequisites

• Interest in the reciprocating compressor monitoring and maintenance

BENEFITS +

3 days (21 hours)

Hands-on workshops at our Recip-kit and actual case histories.

16 | [email protected]

Machinery Diagnostics

MD

Duration

Audience

Objectives

• Explain how the fundamentals of machine design and behavior are reflected in the vibration measurements. • Reduce machine vibration data into usable plot formats. Explain which plot formats are best to use in the different stages

of machine diagnostics. • Describe the causes, effects and indicators of the typical machine malfunctions; including recognition of problems such as

unbalance, misalignment, rubs, shaft cracks and fluid induced instabilities.

• Engineers interpreting machine vibration and position data to determine machine condition.

• Engineers involved in the design, acceptance testing and maintenance of rotating machinery.

• Engineers desiring to learn about machinery vibration diagnostic.

• Engineers and technicians.

Program

Day 1

• Introduction to Machinery Management & Diagnostics

• Phase Measurements

• Steady State Data Formats

Day 2

• Fundamental Synchronous Rotor Response

• Single Plane Balance Response

• Transient Data Formats

Day 3

• Plot Interpretation

• Multiplane Balance Response

• Partial Radial Rubs

Day 4

• Preloads and Radial Position Measurements

• Vibration Types and Resonances

• Fluid-Induced Instabilities

Day 5

• Shaft Crack Detection

• Case History Workshop

Learning path

Next steps

• Machinery Applied Diagnostics Workshops (ADW)

• Advanced Machinery Dynamics (AMD)

MD

Prerequisites

• Fundamentals of vibrations (VIBFU)

• Review of data acquisi-tion CBT solution (Reference 168836-01-01)

BENEFITS

5 days (35 hours)

Provides the fundamen-tals needed to make confident operational decisions.

+

17 | [email protected]

Applied Diagnostics Workshops

ADW

Duration

Audience

Objectives

• Practice on real data from the field from different rotating machines and learn about their typical malfunctions. • Analyze actual machine case histories using System 1 or ADRE databases. • Organize data in plot formats believed to be indicative of the machine fault. • Present conclusions and make recommendations.

• Engineers and technicians involved in the analysis and interpretation of vibration data.

• New machinery diagnosticians willing to gain knowledge and confidence.

• Experienced diagnostics people willing to gain addi-tional insight needed to efficiently solve complex machinery problems.

• Engineers and technicians.

Program

Covered Malfunctions

• Unbalance

• Lose parts

• Preload and misalignment

• Instability

• Shaft crack

• Rub

• Thermal unbalance

• Coupling lockup

• ESD...

Machinery Cases

• Steam turbines

• Gas turbines

• Motors

• Centrifugal compressors

• Generators

• Exciters

• Gearboxes

• Pumps

• Fans

Learning path

Next steps

• Advanced Machinery Dynamics (AMD)

ADW

Prerequisites

• Machinery Diagnostics (MD)

BENEFITS

5 days (35 hours)

Customized training according to equipment.

Be proficient in using the System 1* or ADRE systems.

+

18 | [email protected]

Objectives

• Extend knowledge on machinery diagnostic techniques and rotor dynamics for rotating machinery. • Recognize, explain and account for effects of complex rotor dynamics interaction of modes, mode shapes, thermal changes,

bearing design, torsional vibration and structural modes by using rotor modeling, actual machine data and case history. • Use standard vibration diagnostic tools on machine-simulating rotor kits through demonstration. • Analyze and discuss case histories that highlight the vibration documentation, analysis and machine malfunction corrective

techniques.

Advanced Machinery Dynamics

AMD

Duration

Audience

• Engineers desiring to advance their machinery vi-bration diagnostics skills.

• Engineers involved in the design, acceptance testing and maintenance of rotating machinery.

• Academic researchers and professors involved in rotor dynamics.

• Post-graduate engineering participants.

Program

• Rotor Modeling as a Machinery Diagnostics Tool

• Bearing Design (Fluid bearings and Magnetic bearings)

• Diagnose and mitigation of Fluid Induced Instabilities

• Modal and Operating Deflection Shape Analysis

• Tortional vibrations measurements and analysis

• Rotor Model

• Anisotropy

• Shaft Cracks

• Signal processing

• Balancing Machines

• Rotor to Stator Rubs

• Gear forces Analysis

Learning path

Next steps

AMD

Prerequisites

• Machinery Diagnostics (MD)

BENEFITS

5 days (35 hours)

For each theme, some historic cases will be used to show practice of each technique.

+

In order to put theory into practice, this training includes real-life demonstrations and 25 case

19 | [email protected]

Advanced Field Balancing

AFB

Duration

Audience

• Machinery diagnosticians. • Startup engineers. • Remote diagnostic center specialists.

Program

• Fundamentals

- Unbalance and other malfunctions with similar symptoms.

- Making the decision, selecting the strategy.

- Ensuring the repeatability and minimizing non-linearity.

- Trial weight calculations.

• Basic calculations and conventions

- Vector operations.

- Locating the position of unbalance.

- Finding angular location on a rotor.

• Single Plane Balancing with Workshop.

• Static/Couple Balancing with Workshop.

• Influence Vector Method (multiplane) Balancing.

• Bently Balance – introduction and data acquisition process.

• Bently Balance – configuration and importing data.

• Bently Balance – calculations and solution evaluation.

• Workshop: balancing in two planes, using Bently Balance*

• Relation between Static/Couple and Influence Vector meth-ods.

• Workshop: influence vectors - import, export, recalculation between methods.

• Balancing for compromise conditions.

• Evaluation of balancing quality. Balancing report.

• Workshop/Examination – multiple planes balancing.

Objectives

• Conduct effective balancing of machine trains in the field: calculation of trials, evaluation of results, decision making. • Select strategy ensuring minimum disruption costs and proper data quality. • Use calculation tools the most applicable to situation, evaluate inputs and outputs and recalculate between balancing

methods and data conventions. • Get a deep understanding of balancing process allowing effective supervision of solution weights installation and trouble-

shooting data integrity problems.

Learning path

Next steps

AFB

Prerequisites

• Machinery Diagnostics (MD)

BENEFITS

5 days (35 hours)

Deep understanding of balancing methods and confidence with hands-on practice on test rotors.

+

20 | [email protected]

ISO 18436 Category I Basic Vibration Analyst

CAT I

Duration

Audience

Objectives

• Understand the benefits of performing condition monitoring and improving reliability. • Learn how machines work and how vibration measurements assess the condition of the machine. • Discover Fmax, resolution, averaging and other analyzer settings. • Analyze vibration spectra and the basics of fault diagnosis. • Set alarm limits (introduction).

• New vibration analysts. • Engineers collecting vibration data. • Engineers analyzing vibration data. • Whoever wanting to develop skills in the field of

machine condition & vibration analysis. • Whoever willing to get certified to international

standards (ISO-18436).

Program

• Maintenance practices

• Condition monitoring

• Principles of vibration

• Introduction to vibration measurement

• An introduction to the time wavefrom

• An introduction to the spectrum

• An introduction to forcing frquencies

• Explaining the different vibration units

• A brief introduction to phase

• Data acquisition

• A quick review of data acquisition

• How do we measure vibration?

• Where to place the sensor on the machine

• Understanding axial, radial, vertical and horizontal readings

• A quick introduction to mounting the accelerometer and surface preparation

• Naming conventions

• What are « routes » and how do you create them?

• Signal processing

• A quick tour of your analyzer

• Spectral averaging

• Vibration analysis

• The spectrum analysis process

• What is resonance—a quick introduction

• Diagnosing common fault conditions

• Setting alarm limits

Learning path

Next steps

• ISO 18436 Category II Intermediate Vibra-tion Analyst Certifica-tion (CAT II)

CAT I

Prerequisites

• 6 months of experience is required for certifica-tion

BENEFITS

4 days (28 hours)

3D animations and soft-ware simulations make complex concept easier to understand.

+

ISO CERTIFICATION

21 | [email protected]

ISO 18436 Category II Intermediate Vibration Analyst

CAT II

Duration

Audience

Objectives

• Understand how a well-designed program and a reliability centered maintenance approach improve the bottom line. • Discover the condition monitoring technologies. • Learn how machines work and how to select the correct measurement and the optimum settings. • Analyze vibration spectra , time waveforms, enveloppe and phase measurements. • Diagnose and learn how to balance and align a machine and correct a resonance condition.

• Engineers analyzing a range of fault conditions. • Engineers willing to understand balancing and

alignment. • Engineers desiring to learn about machinery

vibration diagnostic. • Whoever willing to get certified to international

standards (ISO-18436).

Program

• Review of maintenance practices

• Review of condition monitoring technologies

• Principles of vibration: review of basics, waveform, spec-trum (FFT), phase and orbits

• Understanding signals: modulation, beating, sum/difference

• Data acquisition

• Signal processing

• Vibration spectrum analysis

• An introduction to time waveform analysis

• An introduction to orbit analysis

• Phase analysis: bubble diagrams and ODS

• Enveloping (demodulation), shock pulse, spike energy

• Fault analysis

• Equipment testing and diagnostics including impact testing

(bump tests) and phasse analysis

• Corrective action

• Running a successful condition monitoring program

• Acceptance testing

• Review of ISO standards

Learning path

Next steps

• ISO 18436 Category III Advanced Vibra-tion Analyst Certifica-tion (CAT III)

CAT II

Prerequisites

• 18 months of expe-rience is required for certification

BENEFITS

5 days (35 hours)

Competence in quality data acquisition and diagnosing common machine faults.

+

ISO CERTIFICATION

22 | [email protected]

ISO 18436 Category III Advanced Vibration Analyst

CAT III

Duration

Audience

Objectives

• Understand how a well-designed program and a reliability centered maintenance approach improve the bottom line. • Discover the condition monitoring technologies. • Analyze vibration spectra , time waveforms, enveloppe and phase measurements. • Diagnose a wide range of fault conditions. • Learn how to balance and align a machine, correct resonance conditions and employ isolation.

• Engineers confident in spectrum but willing to learn about signal processing, time waveform and phase analysis.

• Engineers involved in condition monitoring. • Whoever willing to get certified to international

standards (ISO-18436).

Program

• Review of condition monitoring technologies and the ISO standards

• Signal processing and data acquisition

• Time waveform analysis

• Phase analysis

• Dynamics (natural frequencies and resonance)

• Testing for natural frequencies

• Operating Deflection Shape (ODS) analysis

• Modal analysis and introduction to FEA

• Correcting resonances

• Rolling element bearing fault detection

• Journal bearing fault detection

• Electric motor testing

• Pumps, fans and compressors

• Gearbox fault detection

• Corrective action

• Running a successful condition monitoring program

• Acceptance testing

• Review of ISO standards

Learning path

Next steps

• ISO Category IV Master Analyst

CAT III

Prerequisites

• 36 months of expe-rience is required for certification

• ISO Category II

BENEFITS

5 days (35 hours)

Developing knowledge of machine dynamics.

+

ISO CERTIFICATION

23 | [email protected]

Be confident in your employees’ competences

BHGE can start working on defining the competency matrix and setting up the

competence development plan to make sure your team is equipped with all the

knowledge and confidence to efficiently manage your assets.

For more information, visit:

https://www.gemeasurement.com/services/bently-nevada-training

24 | [email protected]

@2017-18 Baker Hugues, a GE Company. All Rights Reserved.

Baker Hugues reserves the right to make changes in specifications and features shown

herein, or discontinue the product described at anytime without notice or obligation.

Contact your BHGE representative for the most current information. The Baker Hugues

logo is a trademark of Baker Hugues, a GE Company. The GE monogram is a trademark of

the General Electric Company. Bently Nevada and System 1 are commercial trademarks

of the General Electric Company.

BNEU001

bhge.com