BCA Basement Waterproofing - Design Guide

description

Transcript of BCA Basement Waterproofing - Design Guide

D E S I G N G U I D E

B a s e m e n tw a t e r p r o o f i n g

F o r e w o r dThis publication is one of a series related to basements for housing. It has been produced under the direction of theBasement Development Group, which was initiated and is co-sponsored by the British Cement Association.

A c k n o w l e d g m e n t sThe British Cement Association (BCA) is grateful to the British Structural Waterproofmg Association (BSWA) for co-sponsoring this publication. It is also grateful for the assistance and comments provided by members of the BasementDevelopment Group and for the considerable work of its Waterproofing Task Group in drafting and progressing thispublication. Particular thanks go to Maria Hudlass and Steven Edwards of Servicised for the production of the figures.Thanks are also extended to all others who provided input to and comments on the preparatory drafts.

Basement Deve lopment GroupB Aspin (Chairman), House Builders FederationA K Tovey (Secretary), TecnicomF Atkins, National Housebuilding CouncilD Burke, Zurich MunicipalM A Clarke, British Cement AssociationP Hart, Institute of Building ControlD James, Bovis Homes South WestA Jones, Stewart Milne Group LimitedB Keyworth, ArchitectR S Reynolds, Institute of Clerks of WorksG R Sharpe, Association of Building EngineersP Trotman, Building Research Establishment

Supporting Trade GroupsAutoclaved Aerated Concrete Products AssociationBritish Sructural Waterproofing AssociationConcrete Block AssociationMortar Producers AssociationReady-mixed Concrete Bureau

48.058First published 1994ISBN 0 7210 1475 5Price group D© British Cement Association 1994

Waterproofing Task GroupA K Tovey (Chairman), TecnicomS Brown, Sika LimitedV Connolly, Renlon LimitedM Falla, Booth Engineering Services LimitedZ Ginai, Marley Waterproofing LimitedP Hewitt, Vandex UK LimitedT Holloway, Renlon LimitedM Lenaghan, Servicised LimitedI J Moffat, Fosroc Expandite LimitedJ A M Padley-Smith, Mastic Asphalt Council and

Employers Federation LimitedA J Parker, SCL Group LimitedM Radford, RIW Limited

Published byBritish Cement Association

Century House, Telford AvenueCrowthorne, Berks RG11 6YS

Telephone (0344) 762676Fax (0344) 761214

From April 1995 the code will be (01344)

All advice or information from the British Cement Association is intended for those who will evaluate the significance and limitations of its contents and take responsibility for its use and

application. No liability (including that for negligence) for any loss resulting form such advice or information is accepted. Readers should not that all BCA publications are subject to revision

from time to time and should therefore ensure that they are in possession of the latest version.

C o n t e n t s Introduct ionScope

Design principles

Basement usage

Site information

Deciding on form of constructionForms of constructionFactors affecting choice of constructionCharacteristics of construction formsSuitability of construction forms

Form and characteristics of

waterproof ing sys temsCategory 1: Bonded sheet membranesCategory 2: Cavity drain membranesCategory 3: Bentonite clay active membranesCategory 4: Liquid-applied membranesCategory 5: Mastic asphalt membranesCategory 6: Cementitious crystallization active SystemsCategory 7: Proprietary cementitious multi-coat renders,

toppings and coatings

Ancil lary materialsWaterstopsBandage joint systemsMembrane protection products

Other design considerationsThermal insulationCondensationVapour controlChemical barrierSystem restraintSubstrate movementExpansion jointsDefects and repair

Site invest igationsGroundwaterSoil type and conditionsMovement risks likely to affect basements

Construction optionsBasement site locations and formsDesign factors affecting construction

Waterproofing detai lsDetails of waterproofing optionsand forms of construction

Selection procedureGuide to assessing basement designs

Assessing risk

Glossary

ReferencesOther publications relating to basement structures

2

2

2

2

3

5

7

7

8

1 0

13

1 7

1 8

1 9

Production: Words & Pages

1

I n t r o d u c t i o nBasements provide an opponunity for the builder toachieve a good return on his outlay, and his customer tobenefit by being offered houses with greater potential(1).Including a basement maximises available land space,provides more stable construction, is thermally efficientand offers ideal quiet areas and further space for storageor accommodation. Basements can be economicallyintroduced onto most sites and, in particular, have clearadvantages on sites with poor ground that may otherwisebe regarded as difficult and possibly uneconomic to buildon. This publication is intended to help the builder ordesigner arrive at the most appropriate form of construc-tion and waterproofing solution.

A companion publication, Basement waterproofing: Siteguide(2) provides advice on the application or installationof the various waterproofing systems, and comments onother associated construction matters.

S c o p e

The details and comments given in this publication arelimited to Grade 2 and 3 internal environments, asdefined in BS 8102, which are appropriate for residentialbasements.

The Grade 2 environment is for use as workshops andplant rooms, and other areas where the performancelevel permits no water penetration, but higher levels ofwater vapour would be tolerable and surface condensa-tion may occur.

Proposed Basement use

development Environmental

requirements

Geology

Site surveyWater table

TopographySoil drainage

Design House type and

considerations shape

Foundations

design

Basement

constructionType A/B/C

Selection of

waterproofing

system

Is

N oconstructionbui ldable?

Y e s

Solution

The Grade 3 environment is for ventilated residential andworking areas which require a drier environment.

D e s i g n p r i n c i p l e sThe specification of waterproofing systems is a special-ised task. It is recommended that, once the design teamhas given the system some thought, the manufacturers ofthe systems under consideration are contacted immedi-ately for early advice and help on the waterproofingdesign. The British Structural Waterproofing Associationcan provide details of manufacturers of the differentgeneric waterproofing systems and of appropriatespecialist waterproofing contractors.

Choosing a suitable basement construction may bedivided into four main steps:

Decide on basement usage

Gather site information

Decide on form of construction

Decide on form of waterproofing

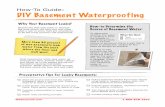

These and other factors needing consideration are shownin the flow chart in Figure 1.

B a s e m e n t u s a g eTable 1 of BS 8102 relates environmental performancelevels to basement usage, and defines them in Grades1 to 4. Most basements will be for domestic accommoda-tion, which is Grade 3. Some basements may be forpermanent workshops or garages, and a Grade 2 envi-ronment would be acceptable. However, since usagemay change, it is better to construct a basement to a

Grade 3 environment than to upgrade it later. Certainforms of construction and waterproofing may lendthemselves to upgrading more readily than others (seeConstruction options on page 10).

It is unlikely that a Grade 4 environment would berequired in a domestic situation. If it did become neces-sary, a Grade 1 environment may be upgraded toGrade 2 by introducing a drained cavity system orinternal waterproofing. A basement performing to Grade2 can be upgraded to Grade 3 or 4 by incorporatingadditional ventilation and/or dehumidification.

Figure 1: Principle select ion cri teria

S i t e i n f o r m a t i o nThe gathering of site information is dealt with in Siteinvestigations on page 8. However, a few points need tobe considered when selecting the form of constructionand waterproofing system.

High water tables present the greatest risk of failure ofthe water-tightness of a basement. If there is a perma-nently high water table, it is important to identify it.A watercourse or water table that rises and falls withclimatic changes must also be identified. How often andfor how long the water table stays high are also impor-tant. If the water table rises briefly - say, after heavy rain- and then immediately falls again, the risk of waterpenetration through external waterproofing and thenthrough the structure is less than if the water table stayshigh for a much longer period.

2

The likely presence of water and the position of thewater table must also be established for constructionpurposes. The main contractor may need to lower thewater table temporarily to enable the construction andwaterproofing to go ahead. In addition, any lowering ofthe water table will need to maintained until the loadsacting on the basement, from either itself or in combina-tion with the superstructure, are greater than the forcesthat would be generated by the water pressures as thewater table returns to its original level.

The existence of any aggressive elements in the groundand/or the groundwater must be established to ensure

the most suitable combination of structure category andwaterproofing system is selected.

D e c i d i n g o n f o r m o f

c o n s t r u c t i o n

Forms o f cons truct ionBS 8102 describes three forms of basement construction:Type A, B and C. These are shown diagrammatically inFigure 2, and discussed overleaf, together with thefactors affecting their choice.

External Sandwiched Intenalwaterproofing waterproofing waterproofing

Type A structures - tanked protection

External or internal Crystallisation, hydrophilic,waterstop as required or injected waterstop

A non-integral kicker

Water-resistant will require one waterstopWater-resistant

reinforced where it adjoins the slabreinforced

concrete and another at its

wall and slab intersection with the wall concretewall and slab

Type B structures - structurally integral protection

Floor drainage options Preformed cavity floor and wall drain system

Engineering brick withopen joints at intervals Floor finishes

Cavity drainagesystem

Drained and Drainage Tiles Membrane No fines

ventilated cavity former concrete Drainage sumpwith pumped outlet

Type C structures - drained protection

Figure 2: The three forms of basement construction

3

Type A (tanked protection) structures have no integralprotection against water penetration and therefore relytotally and permanently on a waterproofing membrane tokeep water out. The chosen structural waterproofingsystem must be able to withstand hydrostatic pressurefrom groundwater, together with any superimposed orservice loading.

The structural wall may be prestressed, reinforced orplain concrete or masonry with the structural waterproof-ing system incorporated externally during construction.Or it may be applied internally to the finished basement.Masonry walls may require a cement rendering or flushpointing to produce a surface good enough to accept awaterproofing system.

This Form of construction can, depending on the water-proofing system used, also provide high resistance towater vapour movement.

Type B (structurally integral protection) structuresrequires the structure itself to be constructed as anintegral water-resistant shell.

Invariably built of reinforced or prestressed concrete, thebasement structure must be designed within certain strictparameters to ensure it is water-resistant. Most designswould be carried out according to the recommendationsof BS 8007 or BS 8110, which give guidance on the gradeof concrete and steel spacing.

Without the addition of a separate membrane, this formof construction may not be as resistant to water vapourmovement as a Type A or C.

Type C (drained protection) structures incorporate adrained cavity within the basement structure. There ispermanent reliance on this cavity to collect groundwaterseepage through the structure and direct it to drains or asump for removal by drainage or pumping.

Structural walls may be prestressed, reinforced or plainconcrete or masonry. The external basement wall mustprovide enough resistance to water ingress to ensure thecavity accepts only a controlled amount of water ordampness. If this is not so, the cavity system may notcope with the deluge of water from a high water table orduring storm/flood conditions.

This form of construction can, depending on the water-proofing system used, also provide high resistance towater vapour movement.

Factors affecting choice of constructionTo consider the performance and likely reliability ofthese three types of structure, many factors need to beknown (Figure 1). These include natural groundwaterlevels or perched water tables, groundwater contami-nants, natural drainage and soil type. Of these, by far themost significant is water table level, which depends uponmany factors and no two sites can, therefore, be said tobe the same. However, they can be generally classifiedas follows:

• A high or perched water table where, by definition,the groundwater level is consistently above the levelof the basement floor.

• A permanently low water table, or free-drained site,where the water table is consistently below the levelof the basement floor.

• A variable water table, where the levels may varybetween the two extremes described above.

Characteristics of construction formsAny structural waterproofing membrane designed toresist a hydrostatic head should not let any free waterpass through it. However, in practice, consideration mustalways be given to what would happen as a result of anydefect. The effects of water table conditions on the threebasement types are discussed below.

Type AThe watertightness of the Type A basement relies totallyon the effectiveness of the waterproofing system. With ahigh water table, any defects will allow water to pen-etrate the structure, finally entering the basement as freewater. If this water is not removed, the basement will fillto the level of the water table.

Since total reliance is placed on the waterproofing systemin Type A structures, account must be taken of the needto gain access if a defect occurs. Externally appliedsystems will require subsequent excavation. Locating thesource of a defect in a system not continuously bondedto the substrate wall can add further complications.

Where access is, or is liable to be, severely restricted by,for example, a permanent external in-situ pavement orpatio, then an internally applied membrane may beeasier to maintain. Defects can then be more readilyfound and repaired. An internal system could be usedwith an integral construction or external system toreduce the risk (see Assessing risk on page 18). Theperformance of internal waterproofing systems can beaffected by the attachment of skirtings etc. or by fittingsapplied subsequently.

Where the site is permanently free-drained, any defectsin the system will allow moisture to move under capillaryaction. Where the defect is small, this will usually resultin some dampness in the structure, but will not necessar-ily show itself on the internal surface. However, anydecoration or surface coating that acts as a vapour checkwill increase the risk of interstitial condensation andhence possible damage.

With a varying water table, significant water ingressthrough defects will occur only during storm or water-logged conditions. If the water table is high only briefly,the ingress might not be enough to show itself. Thelonger it stays high, the greater the risk of significantdampness or even partial flooding.

Type BThe watertightness of the Type B construction is totallyreliant upon the design and construction of the basementas an integral shell, using a concrete of low permeability,and appropriate joint details.

The most common defects are permeable concretethrough lack of compaction, honeycombed concrete,contamination of construction joints, cracking due tothermal contraction and shrinkage. These can all bereduced by correct specification and design and bycareful construction.

Type B structures need to be carefully constructed toavoid defects that let water through. Although they aredesigned to be water-resistant, additional waterproofingsystems may be applied either internally or externally tothe faces of the walls and floors to control water vapourmovement, where appropriate, or to provide furtherprotection.

4

Construction joints need particular attention as these arethe areas most commonly associated with leaks. Whileattention needs to be paid to jointing and positioningwater stops, great care is required in the placing andcompaction of the concrete. An alternative method ofcontrolling water ingress at construction joints is to use acrystallization or hydrophilic system that reacts in thepresence of water to seal the joint.

The construction of a ‘kicker’ either during or afterpouring the floor slab should not be encouraged as it isdifficult to construct without defects. Modern types offormwork and kickerless construction techniques meanthat kickers no longer need be part of the constructionprocess (see Figure 2 on page 3).

With a high water table, minor defects in the concreteusually result in only small amounts of water penetrating,and stopping these is usually fairly straightforward.Remedial action can usually be carried out from theinside, so avoiding the need for external excavation.

Variable water tables present less of a problem, unlessthe water table stays high for a long time.

In a free-draining site, it is rare for a defect to be soserious that water comes through by capillary action.

Type CThe Type C construction relies totally on water collectedin the cavity being taken away. The amount of free waterentering will depend on the volume of external waterand its hydrostatic pressure, and on the initial resistanceof the structure to water ingress.

With a permanently high or variable water table, defectscan arise in several ways:

••

Failure of drains or mechanical pumps could result inflooding.

Blockage of the cavity by silt or other contaminantscould result in flooding. (The design of the structureshould allow for clearing of silt and rodding of drainsshould blockages occur.)

An increase in the ingress of water could exceed thedrainage capacity and result in dampness or flooding.

On a free-drained or sloping site, the cavities may be ledto a soakaway to handle any ingress from, say, percolat-ing surface water. If the soakaway silts up or the drainbecomes blocked, dampness on the internal surfacebecomes a possibility.

Suitability of construction formsGenerally, Type A structures are not recommended inareas with an undrainable high water table.

A well-built Type B construction carries a low risk ofserious failure in a high water table. This is becausethese structures can themselves be designed to beresistant to the ingress of water under a hydrostatic head.Care in the placement of concrete and waterstops(Figure 2) at construction joints is essential. Additionalwaterproofing protection may be used, but defects inType B structures are less likely to result in water ingressowing to the integral protection of the structure.

A Type C construction could provide a suitable form ofstructure, where any water can be easily drained to aconvenient point, for example on sloping sites where theback is completely retaining but the front is not.

With a very high water table, a Type B construction witha preformed plastic drained cavity former appliedinternally (effectively turning the construction intoType C) could be considered to carry the smallest risk offailure.

Where the site drains well enough to prevent thebuild-up of hydrostatic water pressure, all three forms ofconstruction carry little risk of damp penetration.

F o r m a n d c h a r a c t e r i s t i c s o f

w a t e r p r o o f i n g s y s t e m sSince reliance has often to be placed on the waterproof-ing system, the designer must ensure the materials areproperly selected and adequate for the proposed locationand conditions. It is imperative that all continuoushorizontal, sloping or vertical waterproofing be specified,and executed, in one proprietary waterproofing system.Hybrid systems - using one system with another - mustbe avoided because of the danger of incompatibility. Donot mix hot and cold systems.

Most proprietary systems and materials are covered byBritish Standards, Agrèment certificates or manufacturers’warranties.

There are several categories of structural waterproofing:

Category 1: Bonded sheet membranesCategory 2: Cavity drain membranesCategory 3: Bentonite clay active membranesCategory 4: Liquid-applied membranesCategory 5: Mastic asphalt membranesCategory 6: Cementitious crystallization active systemsCategory 7: Proprietary cementitious multi-coat renders,

toppings and coatings

Category 1: Bonded sheet membranesBonded sheet membranes are generally cold-applied orheat-bonded to the finished structural walls. Both aremodified bitumen on a range of carrier films. They areapplied externally, or internally with a loading coatstrong enough to resist hydrostatic pressure. Compositepolymeric sheet membranes are also available. They areattached to the enabling works (reverse tanking), butsubsequently fully bonded by means of a specificallyformulated pressure-sensitive adhesive, to the poutedconcrete.

Design considerations

• Flexible and able to adapt to minor movement andshrinkage within the substrate

• They are of consistent thickness and quality

• May provide protection against aggressive soils andgroundwater when applied externally

• When applied internally, they need to be restrainedby a loading coat

• Substrate must be free from surface water for bondingto occur

• Generally, suitable only for uncomplicated foundationsystems such as plain rafts

Category 2: Cavity drain membranesCavity drain membranes are high-density dimpledpolyethylene sheets, placed against the structure. Thedimples form permanent cavities between the structure

5

and the internal shell. They are used internally to drainand control water ingress.

Design considerations

••••

••••

Installed after the construction of the basement

Defects may he rectified before completion

Minimum preparation of substrate needed

There is no hydrostatic pressure on the system: waterentering the cavity is collected and drained orpumped away

They are of consistent thickness and quality

Flexible and able to adapt to minor settlement andshrinkage within the substrate

Simple internal applications can overcomecomplicated designs, e.g. piles and ground beams

With high or variable water tables, blockages orfailure of drains/pumps may lead to flooding

•

•••

•

Category 3: Bentonite clay activem e m b r a n e sBentonite clay active membranes are sheets of sodiumbentonite clay sandwiched between two layers ofbiodegradable cardboard. When the clay meets water, itcan swell to many times its original volume, sealing anygaps or voids in the membrane. This category ofmembrane is used externally.

Design considerations

•••

••

Minor defects in placing should self-seal

They are simple to apply

The substrate does not need to be dry beforeapplication

••••

•••

Minimum preparation of substrate is required

Must not be used in acidic or excessively alkaline soils

Category 4: Liquid-applied membranesLiquid-applied membranes are one- or two-part systems.They are applied cold, generally in two coats as abitumen solution, elastomeric urethane or modifiedepoxy. They can be applied both externally and inter-nally. In the latter case, the loading coat must be strongenough to resist hydrostatic pressure, unless used as avapour barrier in Type B construction.

Design considerations

• Being jointless, they maintain continuity of membrane

• Easily applied to difficult substrate profiles

• Elastic and flexible, thus accommodating minormovement and shrinkage within the structure

• Can protect the structure against aggressive soils andgroundwater when applied externally

• Have high substrate adhesion and chemical resistance

• Must be applied to a dry surface

• When applied internally, must be restrained by aloading coat if subjected to a hydrostatic waterpressure, as in Type A construction

• Require good surface preparation

• Careful application needed to achieve correctthickness of dried film

Category 5: Mastic asphalt membranes

Mastic asphalt membranes are applied in three coats as ahot, mastic liquid. They cool to a hard, waterproofcoating, but retain a degree of flexibility. Application canbe external or internal. If internal, the loading coat mustbe strong enough to resist hydrostatic pressure.

Design considerations

Because of the multiple coats, there is little risk ofdefects in one coat being carried right through thetotal membrane

May provide protection against aggressive soils andgroundwater when applied externally

Substrate must be dry before application

Requires protective screed on horizontal membranebefore loading coat is installed

Externally applied membranes are generallyunsuitable for complicated foundations such as piles

Category 6: Cementitious crystallizationactive systemsCementitious crystallization active systems are coatingsapplied as internal or external slurries. By reacting withfree lime in concrete, renders or mortars, they blockcracks and capillaries.

Design considerations

Provide in-depth waterproofing of concrete andconstruction joints

The chemicals remain active and will self-seal leaks

In construction joints, they assist repair of local defects

Applied externally, may protect against aggressivesoils and groundwater

Will not self-seal cracks greater than hairline (0.3 mm)

Cannot be used on building materials containing nofree lime

Will not waterproof defective concrete, such ashoneycombing

Category 7: Proprietary cementitiousmulti-coat renders, toppings and coatingsProprietary cementitious multi-coat renders, toppings andcoating are applied as a layer(s) to form a dense,waterproof membrane. Waterproof renders or toppingsconsist of a layer or layers of dense cementitious materialincorporating a waterproofing component. Cementitiouscoatings are premixed slurries applied as a thin layer. Allare designed to be used inside the structure but can beexternal.

Design considerat ions

• Can be applied internally with no loading coatrequirement

• Effective against severe groundwater infiltration

• Easily applied to difficult substrate profiles

• When applied internally, defects are easy to find andrepair

• Provide a durable surface suitable for direct finish

• When appplied externally, can protect againstaggressive soils and groundwater

6

• Being rigid, they may reflect any cracking of thesubstrate

• Fittings fixed mechanically through the system cancause problems and should be avoided

A n c i l l a r y m a t e r i a l s

WaterstopsWaterstops for basement construction may be of one ofthe following types, according to the location andfunction:

• Rubber or flexible PVC extruded profiles

• Strips or profiles of hydrophilic materials which swellin water, either alone or as pan of a composite with arubber or PVC extrusion

• Cementitious crystallization products

• Post injected systems

Rubber or flexible PVC waterstopsThese are extruded profiles fabricated with junctionpieces to provide a linked continuous system through allthe joints or discontinuities within a concrete structure.

Plain web profiles are available for non-moving or low-movement construction and contraction joints. Profilesincorporating a centre bulk or box are used where thereis movement, as in expansion joints.

Alternatively, waterstops may be cast totally within thesite-placed concrete. These are known as internal orcentrally placed waterstops. Internal waterstops willresist the passage of water through a joint from eitherface. However, as they are more difficult to install andcan cause problems when the concrete is being placedand compacted, they are best avoided.

External waterstop profiles are also available and arepositioned on one face of the concrete. These rear-fixedor surface waterstops simplify the shuttering and installa-tion but will resist the passage of water only from theface in which they are installed.

Water-swellable waterstopsSuch waterstops depend upon a sealing pressure beingdeveloped by the water absorption of a hydrophilicmaterial or filler. They are available as strips for bondingor nailing to the first-placed concrete immediately beforethe second pour. The strips may be wholly of hydrophilicmaterial, or compounded with a rubber, or part of acomposite profile. They can be applied against existingconcrete since they avoid the problems of breaking outto install a conventional rubber or PVC waterstop. Theuse of water-swellable strips is limited to low-movementconstruction and contraction joints.

Hydrophilic material may be applied to a conventionalPVC waterstop profile to provide a combined system thatmay also cater for expansion joints.

Cementitious crystallization waterstopsThese differ from the previous two categories in that theproduct consists of cements, fillers and chemicals to bemixed on site as a slurry. The slurry is applied to the faceof the first-poured concrete before the second pour. Thewaterstopping action results from salt crystallization, inthe presence of water, within the pores and capillaries ofthe concrete. These products are not suitable for use inexpansion joints.

Post injected waterstopsThese consist of a perforated or permeable tube fixed tothe first pour of concrete in the construction joint witheither end attached to fittings connected to theformwork, or protruding from underneath it. The tube isthen cast into the construction joint.

After the concrete has hardened a polyurethane resin orother propriety fluid is injected under low pressure toflow through the tube and, when the exit of the tube issealed, it flows freely out of the perforations into anycracks, fissures or holes in the construction joint. Theinjected material then sets to seal all water paths throughthe joint.

Bandage joint systemsWhere large or unusual movement is expected in jointsor cracks - in both new and remedial work - bandagejoint systems may be used. These consist of strips ofsynthetic polymer membrane, bonded across the jointwith a suitable adhesive. As systems vary, the manufac-turer’s advice on application method and adhesiveshould always be followed.

Membrane protection productsIf construction operations may damage applied mem-branes, adequate protection must be provided. This canconsist of vertical blockwork and a 50 mm screed tohorizontal surfaces. Alternatively, protection boardssupplied by most membrane manufacturers may be used.They are more convenient since they provide immediateprotection. They also eliminate a 'wet trade' operationand allow the following works to continue immediatelyafter laying.

Protection boards should be rot-proof and robust enoughto withstand site operations. They should therefore bechosen in consultation with the supplier of the water-proofing system.

A protection board may be used in vertical applications.Alternatively, if vertical protection and drainage arerequired, a geocomposite drainage sheet could be used:its greater cost may be offset by the reduction or elimina-tion of hydrostatic pressure on the membrane as a resultof the better drainage.

O t h e r d e s i g n c o n s i d e r a t i o n sAs well as the general characteristics of the categories ofwaterproofing already given, certain aspects are commonto several systems. The final selection will depend on theform of structure and on other design and constructionaspects such as the need to control water vapour.

Thermal insulationIncluding a basement can improve the thermal insulationof the structure since the lower basement slab is moreefficient than a slab at ground level. The surroundingearth will also improve the thermal transmittance of thebasement walls and there may be no need to providefurther insulation to comply with the Building Regula-tions However, where insulation is required, it may -depending on whether it is placed inside or outside thebasement walls - dictate the form of construction andwaterproofing system. Any external insulation must havelow water absorption and be frost resistant to preventloss of its thermal insulation properties.

7

Condensat ionBecause window areas are often reduced, there tends tobe less natural ventilation in basements than in otherareas of a house. They are therefore generally moreprone to condensation, so heating and air circulationneed to be carefully designed to ensure condensation iscontrolled.

Condensation in basements is too complex to be coveredin detail here. Reference 3 explains how to estimate itsrisk and effects.

Water vapour tends to move from areas of high vapourpressure to low vapour pressure. The vapour pressure ina specific area relates directly to the humidity of the air atthat point, which in turn depends on the temperatureand the amount of free water available to be releasedinto the air.

Although it is commonly thought that water vapour willalways pass from the ground into a basement, this is notso. In most domestic situations, water vapour will move,if the water table is low, from within the structuretowards the ground. If the water table is high, watervapour will penetrate the basement but usually at such alow rate as to be of little consequence.

A vapour-permeable waterproofing system can thus beadvantageous if the vapour tends to move from theinside to the ground, but will allow relative humiditywithin the basement to rise if the reverse conditionsapply.

A system that acts as a vapour check can be advanta-geous if the vapour tends to move from the ground intothe basement but similarly will allow the relative humid-ity to rise if the reverse is true. However, a vapour checkapplied externally can cause interstitial condensation (3).This should not be a problem as long as it is allowed forin the design.

In general, careful consideration must be given to theeffect that the waterproofing system has on the resistanceto water vapour. In practice, where internal conditions ina basement are controlled by properly designed heatingand permanent ventilation, the condensation risk can bereduced to be no worse than in the rest of the dwelling.The advantages/disadvantages of vapour permeable/impermeable systems are then usually negligible.

If the environment is controlled solely by natural airmovement, the condensation risk increases and morecare is needed in the choice of waterproofing andinsulation systems.

Vapour controlAs well as controlling water ingress, categories 1 to 5 canalso act as an effective vapour check. Although this isoften seen as an advantage, some structures need toallow for water vapour movement, in which case acategory 6 or 7 system will be needed. The vapourresistance of category 7 systems can vary significantlywith the product. It is important, therefore, to decidewhether water vapour needs to be controlled or not - seeCondensation above.

Chemical barrierAn external membrane can protect the main structure.However, if the ground or groundwater is contaminatedwith aggressive chemicals, methane and other gases,their precise nature and concentration must be

determined and the membrane manufacturer must beconsulted.

System restraintCategories 1, 3, 4 and 5 need to be restrained so thatthey can resist the forces involved. When appliedexternally, the structure provides the restraint. Whencategories 1, 4 and 5 are employed internally, they needto be restrained by a loading coat. This will take upspace within the structure. Categories 2, 6 and 7 can beused internally without a loading coat.

Substrate movementCategories 1 to 5 have reasonable strain capacity and willusually accommodate some flexing or design cracking ofthe structure. Categories 6 and 7 are more brittle withlow strain capacity and so are less tolerant of structuralflexing. They will crack if the substrate cracks but maystill control moisture ingress if the cracks are fine.

Expansion jointsCare is needed when considering systems used withexpansion joints: always consult the manufacturer.However, although joints can be detailed to cater formovement, it is far better to design the structure in a waythat avoids expansion joints.

Defects and repairCategories 1, 3, 4, 5 and 7 rely on their impermeability tocontrol water ingress. Defects in the materials or in theirjointing may require remedial treatment. With externallyapplied systems, this may mean excavation. It is oftendifficult, therefore, to reach defects in externally appliedsystems, and there can be problems in locating defects insystems that are not continuously bonded. Particulardifficulties will arise where the water table is highpermanently or for long periods, since ground de-watering would be required. Access following construc-tion may not be desirable or possible, in which case aninternal waterproofing system may be preferable.However, the performance of internal waterproofingsystems can be affected, as indicated in Characteristics ofconstruction forms on page 4, by the attachment ofskirtings etc., or by the application of subsequent fittings.Categories 3 and 6 are active systems and can ‘self-heal’,even years later.

S i t e i n v e s t i g a t i o n sAs stated in BS 5930 (4), “Investigation of the site is anessential preliminary to the construction of all civilengineering and building works”. This is particularlyimportant for basements, since the materials used and theperformance of the finished structure will be greatlyinfluenced by the ground conditions. Several factors needto be assessed and reference should be made to BS 5930for detailed information on site investigations. Briefdetails of some of these aspects are given below.

GroundwaterWater tableThe existence of a watercourse or water table and itsseasonal position below ground will need to be estab-lished. The site history and name clues such as “PondLane” can help. Evidence of a flooding site could suggestan impermeable soil or a high or perched water table.

8

Table 1: Characteristics of soils which effect basement construction

Material D r a i n a g e

c h a r a c t e r i s t i c s

S h r i n k a g e

o r s w e l l i n g

p r o p e r t i e s

Coarse soils andother materials

Slight to medium

Fine soils

M a j o r d i v i s i o n s

Boulder andcobbles

Other materials

Gravels andgravelly soils

Sands and sandysoils

Soils having lowcompressibility

Soils havingmediumcompressibility

High

High

High

Soils having highcompressibility

Sub-groups

Boulder gravels

Hard: hard broken rock,hardcore, etc.

Soft: chalk, soft rocks,rubble

Well graded gravel andgravel-sand mixtures,little or no fines

Well graded gravel-sandmixtures with excellentclay binder

Uniform gravel withlittle or no fines

Poorly graded gravel andgravel-sand mixtures,little or no fines

Grave1 with fines, siltygravel, clayey gravel,poorly graded gravel-sand-claymixtures

Well graded sands andgravelly sands, littleor no fines

Well graded sand withexcellent clay binder

Uniform sands withlittle or no fines

Poorly graded sands,little or no fines

Sands with fines, siltysands, clayey sands,poorly graded sand-claymixtures

Silts (inorganic) andvery fine sands, rock flour,silty or clayey fine sandswith slight plasticity

Clayey silts (inorganic)

Organic silts of lowplasticity

Silt and sandy clays(inorganic) of mediumplasticity

Clays (inorganic) ofmedium plasticity

Organic clays of mediumplasticity

Micaceous ordiatomaceous fine sandyand silty soils, elasticsilts

Clays (inorganic) ofhigh plasticity, fatclays

Organic clays of highplasticity

Good

Excellent

Fair to practicallyimpervious

Excellent

Practically impervious

Excellent

Excellent

Fair to practicallyimpervious

Excellent

Practically impervious

Excellent

Excellent

Fair to practicallyimpervious

Fair to poor

Practically impervious

Poor Medium to high

Fair to poor Medium to high

Fair to practicallyimpervious

Fair to practicallyimpervious

Poor

Practically impervious

Practically impervious

Almost none

Almost none

Almost none toslight

Almost none

Very slight

Almost none

Almost none

Almost none toslight

Almost none

Very slight

Almost none

Almost none

Almost none tomedium

Medium

High

High

Fibrous organic soils with very high Peat and other highly Fair to poor Very high

compresibility organic swamp soils

9

Ground drainage

Cut-off drain

Perimeter drain todischarge to downside

(a) Semi-basement

Perimeter drain todischarge to downside

(b) Split-level dwelling

The topography of the land and the direction andmovement of any groundwater should be determined asthey will have a bearing on any proposals to providedrainage to reduce local groundwater pressures.

If there are any drains or land drains, their positionsshould be established. Any new construction proposalsshould not interrupt drains that still function unlessmeasures are taken to redirect them or to intercept thewater by a new drainage system.

Soil type and conditionsThe type of soil can greatly influence the quantity ofwater reaching the basement wall. Free-draining soilspresent fewer problems than clays, which tend to beimpermeable. It is important, therefore, to determine thesoil type and, in particular, its drainage characteristics.Table 1, adapted from reference 5, gives the characteris-tics of the main soil types.

Some soils contain chemicals that may harm both thestructure and the waterproofing system. Check theground for materials that are detrimental, such as peatand sulfates.

The presence of, or potential for, natural gases such asradon and methane should be ascertained. The likeli-hood of radon can be established from the underlyinggeological structure, and guidance for its control may befound in reference 6.

Methane and other gases are likely to be linked to infilland made-up ground, particularly where large amountsof organic matter have been buried. Such sites can alsopresent risks from acid wastes, mineral oil shales, andother fill materials.

Some slags and other residues often contain toxicmaterials and some furnace ashes may be reactive.Reference 7 gives information on site preparation andresistance to moisture, and includes guidance on groundcontaminants.

Movement risks likely to affect basementsA change in ground moisture content - caused, forexample, by the removal of trees - can result in groundmovement and affect the loadbearing capacity of soil.Clay and peaty soils are particularly prone to volumetricchanges leading to varying foundation pressures andmovement.

The remains of former buildings or structures on the siteneed to be assessed. They are best removed to avoiddifferential movement due to bearing over strong points.Steeply sloping sites may have high land-slip risks, whichshould be assessed before proceeding further.

Particular care is needed where there are changes in thesoil strata that may cause differential foundation move-ment. Although such matters can be catered for structur-ally, they do present problems. For example, althoughexpansion joints are a common solution, they may not beappropriate because of the difficulties of maintainingwatertightness, particularly in a waterlogged site.

If the risk of movement is high, movement joints shouldbe considered. Where possible, designers should notattempt to create waterproofed expansion joints, butinstead should design discrete boxes that can be sepa-rately waterproofed.

C o n s t r u c t i o n o p t i o n s

Basement site locations and formsThere are many potential basement locations. Designforms and waterproofing methods will therefore dependon, for example, the prevailing terrain, soil conditions,water tables, proximity of adjacent buildings and therequirement of the end user. Typical locations and formsof basement construction are illustrated and summarizedfor three types of site: sloping, flat and infill.

Sloping sitesSloping or elevated sites allow both full and semi-basements or split-level dwellings to be built, with cut-and-fill options (Figure 3). Since these sites can normallybe effectively drained, properties would be at little riskfrom percolating groundwater. Economical Type Atanked basements or Type C structures can therefore bebuilt, simply designed in concrete or masonry, withdrainage provisions.

Flat sitesFlat sites provide the opportunity for basements whollyor partially below ground (Figure 4). Excavated materialmay be re-used to landscape around basements partiallybelow ground, giving the dwelling an elevated aspect.

Type A or C construction may be used if the site is free-draining or is in an elevated position with drainageprovisions.

Figure 3: Basements on sloping or elevated sites

10

Cut-off drain

Cut-off drain

(c) Split-level with basement wholly below ground and withside access

Cut-offdrain

Perimeter drain todischarge to downside

(d) Projecting basement

Figure 3: Continued

(a) Basement partially below ground

Drainage sump Retaining bund wall

(b) Basement wholly below ground

Basements constructed on a flat site in low-lying areaswith impermeable soils can be difficult to drain. As theremay be problems with perched, fluctuating or perma-nently high water tables, substructures designed inwater-resistant Type B construction would therefore beadvisable. Any window fire exit must be above thehighest anticipated water level.

Infill sitesInner city areas provide more opportunities for housebasement construction because high kind values increaseproperty costs. Infill sites between adjacent dwellings canbe developed (Figure 5). However, these may be moresusceptible to periodic flooding from existing defectivewater mains. Design preference is for Type B construc-tion, perhaps with internal waterproofing or drainedcavity provision.

Where adjacent properties have to be underpinned, itcan be difficult to achieve continuity in external or pre-applied waterproofing systems. Alternative systemsshould therefore be looked at.

Semi-basements on infill sites can probably use a bundedcatchment area. If so, the bund walls should be designedas Type A tanked construction or Type B water-resistantconcrete, with a drainage sump (Figure 5(b)) for rain-water. Clearly, this form of construction can be adoptedfor both flat and sloping sites.

(a) lndependant structure with basement wholly below ground

(b) Semi-basement on inflll terrace development

11

Figure 4: Basements on flat sites

Design factors affecting construction

Basement drainageAttention should be given to the drainage requirementsfor Type A tanked structures and reinforced concreteType B structures. Lack of proper drainage to basementsurrounds may result in hydrostatic pressure and subse-quent leakage through defects in the waterproofing orconcrete.

Installing a geocomposite drainage sheet and fin or landdrains will help deflect and drain water away from theperimeter of buildings, so improving the total water-proofing (see Waterproofing details on page 13).

Stepped and staggeredfoundations make it difficultto achieve continuity ofwaterproofing. Therefore thepreference is for sandwichconstruction with provisionfor external relief drainage

An additional water-activated pump may be used to dealwith run-off water. This can be particularly useful wherethe water table becomes perched because the soil is tooimpermeable to handle the percolating surface water, aswith a clay soil. Such pumps, which are normallyinstalled outside the structure, can be used to ensure thatthe severity of water conditions does not exceed thattaken for design. They can be used either to extend theapplication of Type A and B construction or to providean additional escape for water, but may not be appropri-ate for all water-proofing systems. The outlet from suchpumps must discharge to areas where the water cannotfeed back to the pump inlet.

(c) Staggered foundations

The orientation of the basement area to the general flowof groundwater should also be considered - see Figure 6.Any L- or U-shapes with a re-entrant angle against thenatural drainage flow can act as dams and increase therisk of hydrostatic pressure. Where basements areconstructed against the flow of water, sub-drainageshould be provided and graded to storm drains or openoutlets on the downside of the building.

Drainage may be requireto alleviate build up ofhydrostatic head

(a) Non-preferred orientation

Orientation of basementdesign to avoid possible'damming' of the groundwater flow

(b) Preferred orientation

Figure 6: Continued

Foundation designStructures should be designed to keep foundations assimple as possible. Expansion joints and complicatedshapes are best avoided, since they are points of weak-ness and need a lot of attention to detail.

Complicated foundation designs do not lend themselvesto external waterproofing. When deciding on the form ofconstruction and waterproofing, the designer shouldconsider 'buildability' and the acceptable level of risk,relative to cost of achieving the desired performance.Consideration must also be given to how remedial workmay be carried out if this performance is not attained.

Common foundation designs are shown in Figure 7 withsuggested waterproofing options.

Type A structure

Confine to sloping orelevated sites with gooddrainage

External or internalwaterproofing

High-risk design due to lackof continuity between walland floor. Reinforcementmay be required to controlcracking

(a) Strip foundation

Type A structure

Confine to sloping orelevated sites with gooddrainage

External waterproofing maybe required to modify theexposure situation of theretaining wall

Difficult to achieve continuityof waterproofing membranewhen applied externally

(b) Piled ring beam and reinforced masonry wall

Figure 6: Drainage and orientation Figure 7: Typical foundation designs

12

Type C structure

Ideal for sloping orelevated sites

External waterproofing maybe required to modify theexposure situation of theretaining wall

Difficult to achieve continuityof waterproofing membranewhen applied externally

(c) Piled foundation

Type A structure

Confine to sloping orelevated sited with gooddrainage

Simple design

External waterproofingmay be required tomodify the exposuresituation of the retainingwall

Two leaves ofstructural wall(not tied)

Membrane

(d) Reinforced masonry wall with reinforced concrete raft

Type B structure

Suitable for permanentor variable water tablesabove slab level

Reinforced concretedesign to BS 8110 orBS 8007 as appropriate

May be combined withexternal/internalwaterproofing or drainedcavity construction toenhance performance

Membrane/waterproofrender

Concrete or masonrystructural wall(not waterproof)

Protection/loading coat(if required)

(e) Reinforced water-resistant concrete box

Type C structure

Suitable for permanentor variable water tablesabove slab level

Reinforced concretedesign to BS 8110 orBS 8007 as appropriate

Internal drained cavityconstruction

Protection (as specified)

Membrane

Concrete or masonry

structural wall(not waterproof)

(f) Drained cavity construction with piled foundation

Figure 7: Continued

W a t e r p r o o f i n g d e t a i l s

Details of waterproofing options and formsof constructionThe principal form of construction outlined in Decidingon form of construction on page 3 may involve a varietyof waterproofing options. The principal details andelements of the main waterproofing systems are shownin Figure 8.

(a) Sandwiched waterproofing

(b) lnternal waterproofing

(c) External waterproofing

Figure 8: Alternative waterproofing systems

13

Basement

Basement

Basement

Basement

Permanent masonryenabling works

Concrete or masonrystructural wall(not waterproof)

Membrane fastened/bondedto temporary/enabling works

Water-resisting structuralwall to BS 8110 or BS 8007as appropriate

Preformed cavitydrainage system

Inner skin

(d) External (reverse) waterproofing

(e) Drained cavity with integral protection

Protection (if required)

Preformed cavitydrainage system

Membrane

Inner skin

Water-resisting structuralwall to BS 8110 or BS 8007as appropriate

(f) Drained cavity with integral protection and externalwaterproofing

Enabling works

Preformed cavitydrainage system

Membrane fastened/bonded to temporary/enabling works

Water-resisting structuralwall to BS 8110 or BS 8007as appropriate

Inner skin

(g) Drained cavity with integral protection and external(reverse) waterproofing

Figure 8: Continued

14

Figure 9: External drainage

To be effective, all laps in the waterproofing system mustbe fully weathered and sealed. The system will generallyneed to be continuous around the basement walls andfloors (Figure 10) and extend at least 150 mm aboveground level. Continuity of waterproofing between thejunction of the superstructure and the basement wallsmust also be assured (Figure 11).

Figure 8: Continued

As already indicated, each waterproofing system may beused as the sole protection or combined to give addi-tional protection. The final choice depends on the siteconditions and the level of waterproofing necessary.Some systems may also make use of externally appliedgeocomposite drainage sheets to prevent or lessenhydrostatic pressure reaching the external structure orwaterproofing system (Figure 9).

Structural wall

Ventilated cavity

Concrete or masonrystructural wall(not waterproof)

Inner skin

Basement

(h) Drained cavity, no waterproofing to walls, structure notproviding Type B standard

Basement structure

External or internalwaterproofing as appropriate

Percolatingground water

Perimeter drainage (fin or land drainto discharge water to downside)

drainage sheet(alternative togranular backfill)

Geocomposite

External or Internalwaterproofing as required

Basement structure

The effect foundations have on achieving continuity inthe waterproofing system must be assessed (see Founda-tion design on page 12). Details to cater for steps in thefoundation can be produced as in Figure 12.

Figure 10: Continuous waterproofing to basement

DPM

Continuity ofwaterproofingwith DPM

Externalwaterproofing

Basement slabwith drainageas required

Horizontalwaterproofingwith protectionwhere required

DPC

AirbrickCavitytray

Consult withExternal manufacturerswaterproofing for specific detail

(a) External waterproofing

(a) Linking of external waterproofing with DPC/cavity tray

Continuity ofwaterproofingwith DPC and DPM

DPMInner loading wall

AirbrickCavity tray

Internal

Consult with waterproofing

manufacturersfor specific detail

Waterproofmembrane

Cavity fill(no wall ties)

DPC Loading slab to resisthydrostatic pressure

External drainageas required

Fin drain

(b) Sandwich construction(b) Linking of internal waterproofing with DPC/cavity tray

Figure 12: Continuity of waterproofing - step changes inconstruction

Figure 11: Continuity of waterproofing - linking withsuperstructure

1 5

DPM DPC

Continuity ofwaterproofingwith DPC and DPM

Inner waterproofing orcavity drainage system

Inner loading wall andslabs as required

Weepholes

Stepped DPC Airbrick

DPC withsealed laps

Inner blockwork

Slab may require Fin drain to

a DPM which may intercept surface water

need bonding to DPC (alternative to pipe and

aggregate drainage)

Waterproof membranewith protection board

Reinforced masonrywall

Airbrick for ventilationSuspended slab

Chamfer to discharge water

WeepholesFin drain or land drainto discharge to

downside

(c) Internal waterproofing

Continuity of waterproofingCavity

with cavity traytray

Continuous waterproofingsystem. Roof area to be laid

to falls with drainage provision

Projecting basement roof

(d) External waterproofing of projecting basement roof

Figure 12: Continued

Discontinuity can sometimes be acceptable, as shown inFigure 13 where a masonry wall is detailed for use on asloping site. The detail could also he appropriate on afree-draining flat site. This is not a cavity drain system(Type C) but in effect a Type A construction that canintercept water finding its way through the outer leaf.The Figure also shows the necessary ventilation of thecavity, and waterproofing to the top of the retaining wall.The detail is shown with the inner leaf tied to the outerleaf. Where the cavity is to be the main intercept, with

no outer waterproofing, it would be acting as a cavity-drained system. The wall ties would therefore need to beomitted and the inner leaf designed as a loadbearingsingle-leaf wall. Appropriate floor details would alsohave to be adopted.

Figure 13: Discontinuity of waterproofing on freedraining site

Discontinuity of waterproofing is possible here becauseany water rising by capillary action is effectivelyprevented from reaching the inside face of the inner leaf.In addition, any water penetrating the outer leaf isintercepted by the cavity and discharged below the slablevel. Such construction cannot be used where the watertable is high or variable. Nor is it feasible with soils oflow permeability on a flat site, as water could build upwithin the cavity and rise above slab level. Discontinuityof the waterproofing system must, therefore, beconsidered only where the ground and structure are ableto prevent water ingress. This is possible only withcertain constructions on sloping sites or in freely drainingsoils with a low water table. Discontinuity may also onlybe acceptable where natural gases such as methane andradon are not present.

Preference should always be given to taking services upand over the walls to avoid penetrating the basementwalls below ground. If holes are unavoidable, they mustbe properly detailed. Details will vary according to thecategory and size of the penetration and the waterproof-ing system being used. Figure 14 shows a typicalapproach. The service itself must also be waterproofedinto the service penetration.

Because of the variations between different waterproof-ing systems and type and form of service, they mustbe discussed with the manufacturer and specific detailsdecided for the project in hand. Avoid using generalmanufacturer’s details as they are most unlikely to suitevery case.

16

Note: Service penetrations below ground should

be avoided wherever possible

Any service withinpenetration will alsoneed to be sealed

Waterproofingmembrane

Alternative oradditionalhydrophilic stripor crystallisationcoating

Figure 14: Service penetrations through waterproofing

Selection procedureTo ensure that the risk of moisture penetration is kept toan acceptably low level for the life of the structure, theappropriate systems must be combined and consideredtogether. Having completed the investigation alreadyoutlined, the design team should now be able to decidethe waterproofing strategy. Figure 15 is provided to helpin the selection process. However, it was shown at thebeginning that choosing and specifying a waterproofingsystem is a specialised task. It is therefore most desirablethat the manufacturers of the likely systems are contactedearly. Their expertise will help ensure success.

Guide to assessing basement designsFigure 15 gives general guidance on the suitability ofvarious forms of construction under differing water tablepositions.

The broken lines represent the maximum acceptable riskand therefore the minimum acceptable construction for

the prevailing water table. Constructions to the right ofthe broken lines have progressively lower risk, quantifiedby the variation in depth of tint. A line running througha box indicates a variable risk of acceptance andunacceptance, depending on the prevailing soil condi-tions as learned from the site survey.

The position of the line within the box is an attempt tofurther quantify the risk. For example, a Type Aconstruction with waterproofing in a low water table islikely to provide an acceptable solution in many soils butmay be unsuitable or require additional drainage orwaterproofing in soils with particularly low permeability.At the extreme, the low permeability might cause atemporary perched water table, so creating in effect avariable water table or hydrostatic pressure on the wall.

Similarly, if a variable water table stays high for sometime, thus behaving like a permanently high water table,a Type A construction with drainage might not beacceptable without further upgrading. Such upgradingcould involve internal waterproofing or the creation of adrained cavity.

An example of a degree of upgrading of a Type Aconstruction is given in Figure 13 in which a conven-tional cavity wall provides a secondary means of defenceagainst water ingress, and would be effective undercertain ground/soil conditions (see Waterproofing detailson page 13).

The above shows the significant effect that the watertable has on the selection process, and how, in consulta-tion with the waterproofing manufacturers, it may bepossible to modify a basic construction to make itsuitable for a more severe situation.

A Grade 3 or Grade 4 environment can be achieved byusing a similar construction to that required for Grade 2,but with additional ventilation or dehumidification, thecost of which may be influenced by the initial type ofconstruction and the external soil conditions.

17

Figure 15: Design assessment guide to assessing designs for basements

Water tableNo integral protection

Type A

WaterproofingPlus

drainage BS 8110*Plus

waterproofing BS 8007**Plus

waterproofingBS 8110*

Plus moisture barrier

BS 8007

Type C

Drained cavity

Type BWater-resistant concrete

Low (soilpermeabilitymay affectrisk)

Variable(subject toprevailing soilconditions)

High

* Design to 0.2mm crack widths except for low hydrostatic head

** Alternatively design to BS 8110 with 0.2mm crack width for low or variable hydrostatic pressure

Decreasing risk

Assessing riskGround conditions dictate the options available. The leastsevere give the most options, while the most severeleave the design team with very few. The severity fallsinto three basic categories according to the position ofthe water table, although variations can occur withinthem. If natural gases are present, specialist adviceshould be sought.

Permanently low water tableIf the water table is permanently low, and there is nosignificant risk of percolating water building up ahydrostatic head, then conditions are the least severe. Inthis situation, the design team has an almost free hand tochoose the most appropriate form of construction andwaterproofing system.

With low-permeability soils such as some clays, there is arisk of a perched or variable water table - and thereforeof water pressure against the structure - unless adequatedrainage can be provided. Such drainage could, forexample, consist of land drains discharging to thedownside on a sloping site.

An alternative would be a water-activated submersiblesump-pump taken below the lowest slab level. This mayalso be considered on a normally free-draining site tocater for unexpected adverse conditions.

Where groundwater contains aggressive chemicals suchas sulfates, the choices are reduced to Type A or Bconstruction in consultation with the membrane manufac-turer. If Type A is used, the structure should be tankedwith an external membrane capable of resisting theaggressive chemical. With Type B, the concrete mustbe able to withstand the aggressive chemicals. If indoubt, consider applying a suitable external protectivemembrane.

Damp-proof

Variable water tableIf the site cannot be drained and the water table risesoccasionally, the severity is increased. Just how severedepends on how high and for how long the water tablerises. Generally, in these circumstances, only a Type B orC construction can be considered to carry an acceptablylow level of risk.

Damp-resistant

When selecting a Type B construction, consider incorpo-rating some form of waterstop in construction joints (seeFigure 2). If the water table remains high for longperiods, then a second, back-up waterproofing systemcould be considered. However, do not lose sight of thefact that the water-resistant structure must remain the firstline of defence against water penetration. External

waterproofingWhen a Type C construction is selected, the structuremust still to play a major role in keeping out water. Ifmoisture ingress is too rapid, the cavity is more likely tobe unable to cope with the water. In addition, themethod of getting the ingress water away plays animportant part in assessing the risk. If pumps or drainsfail, water is likely to enter the basement.

If the groundwater contains aggressive chemicals such assulfates, a Type B construction should consist of asuitably resistant concrete or have an appropriateexternally applied membrane. Type C constructionshould include an externally applied membrane toprotect the structure.

1 8

Permanently high water tableIf the water table is permanently above floor level, theseverity is increased. However, if a drainage system canbe installed to lower the water table permanently, theseverity is proportionally reduced, leaving the designteam with the same options as given above for Perma-nently low water table.

However, if there is any doubt about the long-termeffectiveness of the drainage system, the risk is increasedand the structure must be considered to be in a categoryof either variable or permanently high water table.

In this, the most severe category, the nature of the risk isthe same as for a variable water table except that the riskis higher. This is because the water exerts a permanentpressure on the structure. To reduce risk, a back-upwaterproofing system should always be considered.

All other factors discussed under Variable water table

apply.

G l o s s a r y

Air dry

Combined system

Construction joint

Damp

Damp resistance

Drained cavity

Expansion joint

External(reverse)waterproofing

Free-draining

High water table

Hydrostatic head

When the surface humidity of a materialis equal to that of the ambientsurrounding air

Two or more waterproofing systemsused together

Joint formed in-situ, for example inconcrete, when continuity is not possible

The condition of a material when wetterthan air dry

Impervious to moisture, not permittingmoisture to enter

The ability of a material to excludemoisture

Having a high resistance to moisturepenetration

A continuous cavity which intercepts anddrains away incoming water

Joint that permits relative movementcaused by expansion and contractiondue to changes of temperature ormoisture

Where the waterproofing system ispositioned and placed against theoutside face of the main structure

Where the waterproofing is positionedoutside the main structure but placedagainst the enabling works

Ground through which free water rapidlydrains away

Where the water table is above theunderside of the lowest floor level

Water pressure, expressed as anequivalent depth of water

Hydrostatic pressure

Integral protection

Kicker

Kickerlessconstruction

Loading coat

Low-permeability

Low water table

Membrane

Moisture

Perched water table

Protection layer

Sandwichedwaterproofing

Vapour check

Vapour resistance

Vapour-resistant

Variable water table

Water

Waterstop

Waterproof

Waterproofing

system

Water-resistant

Water vapour

The water pressure exerted as a result ofa hydrostatic head

Where the structure itself provides thenecessary protection to the passage ofwater

Small concrete upstand, cast above floorlevel to position wall or columnformwork for the next lift

A mechanical means of retainingformwork in position, eliminating akicker

A material applied to the waterproofingmembrane to enable it to resisthydrostatic pressure

Resistant to water penetration

Where the water table is permanentlybelow the underside of the lowest floorlevel

A material which forms a continuouseffective barrier to the passage ofwater

Water in the form of vapour as well asliquid

Where, because of insufficientpermeability of the soil, percolatingwater is held above the underside of thelowest floor level, resulting inhydrostatic pressure

An element used to provide protectionto a waterproofing system

Where the waterproofing system isbetween the two non-tied leaves of themain structure

A continuous vapour-resistant layer

The ability of a material to resist vapourpenetration

Excludes water and has a high resistanceto vapour penetration

Where the water is occasionally abovethe underside of the lowest floor level

Water in its liquid form

A product or system, placed in-situ, toprevent the passage of water through adiscontinuity or joint in site-placedconcrete

Impervious to water, not permittingwater to penetrate

The total method or combination ofmaterials used to create a waterproofprotection

Having a high resistance to waterpenetration

Water in its gaseous form

R e f e r e n c e s

(1) BRITISH CEMENT ASSOCIATION. Options for quality inhousing: Basements 1: - benefits, viability and costs.Slough (now Crowthome), British CementAssociation, 1992. 37 pp. (Ref. C/10).

(2) BRITISH CEMENT ASSOCIATION & BRITISH STRUCTURAL

WATERPROOFING ASSOCIATION. Basementwaterproofing: Site guide. BCA, Crowthorne, 1994.20 pp. (Ref. 48.059)

(3) BUILDING RESEARCH ESTABLISHMENT. Interstitialcondensation and fabric degradation. BRE, Garston,1992. Digest 369. 8 pp.

(4) BRITISH STANDARDS INSTITUTION. BS 5930 : 1981. Code ofPractice for site investigations. London, BSI, 1981.148 pp.

(5) JACKSON, N AND DHIR, R. (Editors) Civil engineeringmaterials. Basingstoke, Macmillan Education 4th Ed.,1988. 429 pp.

(6) BUILDING RESEARCH ESTABLISHMENT. Radon: guidanceon protective measures for new dwellings. BRE,Garston, 1991. BR211. 10 pp.

(7) DEPARTMENT OF TH E ENVIRONMENT AND TH E WELSH

OFFICE. The Building Regulations 1991. ApprovedDocument C. Site preparation and resistance tomoisture. London, HMSO, 1991. 23 pp.

Other publications relating to basementstructuresBRITISH STANDARDSBS 8007: Code of practice for design of concrete

structures for retaining aqueous liquids.BS 8102: Code of practice for protection of structures

against water from the ground.BS 8110: Structural use of concrete. Part 1: Code of

practice for design and construction.BS 8301: Code of practice for building drainage.

NATIONAL HOUSEBUILDING COUNCIL. NHBC Standards.Vol. 1. Parts 1-5. Amersham, NHBC, 1991.Chapter 3.1 'Siting of dwellings' reviews items to betaken into account when developing sites. Relevant areasinclude waterlogging, retaining walls and groundstability.Chapter 4.1 'Foundations - finding the hazards' givesguidance on the identification of hazardous site condi-tions which need to be considered (e.g. groundwater).Chapter 5.1 'Substructure and ground-bearing floors'includes guidance on habitable rooms wholly or partiallybelow ground level, masonry below DPC and tankingmaterials.Chapter 5.3 'Drainage below ground' includes guidanceon groundwater drainage.

ZURICH MUNICIPAL. Building guarantee technical manual.Farnborough, Zurich Municipal, 1994.Section 3 'Damp proofing' includes requirements andguidance on subsoil drainage to prevent waterlogging,and on the application of basement tanking.Section 13, Clause 13.5 'Damp proofing' gives guidanceon the application of tanking to existing walls in base-ments.

1 9

BASEMENT WATERPROOFING: DESIGN GUIDE

BRITISH CEMENT ASSOCIATION PUBLICATION 48.058

CI/SfB

UDC643.8 : 699.82

British Cement Association