Basic Layout Techniques

-

Upload

bui-doi-lam-chip -

Category

Documents

-

view

31 -

download

5

description

Transcript of Basic Layout Techniques

Basic Layout Techniques

Rahul Shukla

Advisor: Jaime Ramirez-Angulo

Spring 2005

Mixed Signal VLSI LabKlipsch School of Electrical and Computer Engineering

New Mexico State University

Outline• Transistor layout

• Resistor Layout

• Capacitor Layout

• Common Centroid and Inter-digitization Techniques

• Example layouts

• Pad Frame

Transistor layout

S

D

GB

1.5um/0.6um

• NMOS

D

S

GB

• PMOS

1.5um/0.6um

NMOS Bulk terminal in AMI 0.5µm process is always tied to p substrate which is tied to Vss. S/D G D/S

PMOS Bulk terminal in AMI 0.5µm process is free (N Well process) and can be connected to any voltage but usually connected to Vdd or the source ‘S’ terminal. S/D G D/SB

Transistor layout• A single large transistor layout is not a good idea !!!

• To make a large transistor we split the large transistors and connect them in parallel.

120um/1.8um 30um/1.8um 30um/1.8um 30um/1.8um 30um/1.8um

Generally PMOS width (W) < 50µm/1.8µmNMOS width (W) < 30µm/1.8µm

G G G G

S S SD DD S

G

B B B B B

Transistor layout

120um/1.8um

D S

G

B S/D

D/S

G

Transistor layout

D

S

GB

150µm/1.05µm

S

D

G

B

PMOS Bulk terminal connected to the source ‘S’ terminal reduce body effect. Four transistor of 37.5µm/1.05µm connected in parallel

Resistor layout• Resistor value is calculated using R=Rs (L/W) where Rs is sheet resistance of ELEC layer and its value in AMI 0.5µm process is 1024Ω/ ٱ L and W are length and width of resistor.

• Resistor is implemented using a POLY2 layer or ELEC as it is called in Cadence.

• A High-Res layer is also used as a layer ID.

• Use minimum W of ELEC to calculate length of ELEC layer

• Value of W and L calculated using formula is an approximate value. To get a value close enough to desired value, layout the resistor, extract the layout using the extractor tool in Cadence andand see the value in extracted view of your cell and change the size of the resistor in layout view to get to a desired value. This, as we can see is an iterative process.

Resistor layout• Example 5kΩ resistor layout.

ELEC HighresM1_ELECContact

• Extracted view of the resistor

L

W

Resistor layout• For laying out a big resistor it is recommended to split it into

series connection of small resistors. E.g.: 25kΩ using five 5kΩ resistor layout. (note the 25kΩ is not a large value resistor)

Capacitor layout• Capacitor value is calculated using R=Cox W.L where Cox is

capacitance of oxide layer per unit area. Its value in AMI 0.5µmprocess is 2.4fF/µm2, L and W are length and width of capacitor.

• A parallel plate Capacitor is implemented using a POLY2 layer or ELEC as it is called in Cadence and POLY layer. The two layer actact as the parallel plate.

• A cap-id layer can also be used as a layer ID.

• Use minimum W=L so that a square capacitor implementation is possible.

• Value of W and L calculated using formula is an approximate value. To get a value close enough to desired value, layout the capacitor, extract the layout using the extractor tool in Cadence and see the value in extracted view of your cell and accordingly change the size of the capacitor in layout to get to a desired value. This, as we can see is an iterative process.

Capacitor layout

ELEC

• Example 1pF capacitor layout.

M1_ELECcontact

POLY

M1_POLYcontact

Oxide layer

Cross section

Common Centroid and Inter-digitization Techniques

• Process variations during fabrication may limit accuracy and desired performance of analog circuits.

• Matching between components in layout of analog circuits is an important issue in many designs. For e.g. current mirrors, differential pairs.

• Inter-digitization and common centroid are the most basic techniques to match components in layouts. [1]

[1] “CMOS Circuit design, layout and simulation,” R. Jacob Baker, Harry W. Li and David E. Boyce, chapter 20 and 24, IEEE press. 1998

Common Centroid and Inter-digitization Techniques

• A simple example of how process variation affects circuit performance

W/L M1 4W/LM2

IoutIin

D S

G

B

G G G G

S S SD D

W/L M1 W/L M21 W/L M22 W/L M23 W/L M24

Assuming that we split M2 in 4 equal sized transistor anddo the layout in following fashion. If process was ideal(W/L)M2= 4(W/L)M1

Since the process is non-ideal we assume a linear variation along horizontal axis for example a 1% increase in W/L ratio of each transistor as we go along left to right.Ideally Iout= 4Iin

(neglecting 2 order effects)

D S

G

B

G G G G

S S SD D

W/L M1 1.01W/L M21 M22 M23 M241.02W/L 1.03W/L 1.04W/L

Practically Iout= 4.1Iin(neglecting 2 order effects)

Vin+ Vin-

Vout

Vbias

Vdd

M1 M2

M3 M4

M5

• Process variations do not only affect W/L ratio (aspect ratio) but also other variation like Vt i.e. threshold voltage etc.

• Mismatch in a simple differential amplifier will lead to undesirable effects like offset, poor CMRR etc.

Differential Amplifier

Matching important between

• Differential pair

• Mirror

Common Centroid and Inter-digitization Techniques

Common Centroid and Inter-digitization Techniques

We have to match two components A and B ( A and B can be anything like capacitor, resistor or transistor). Lets split A and B into 4 small components i.e. A1-A4 and B1-B4.

•Inter-digitization Technique: Placing alternate components

A1 B1 A2 B2 A3 B3 A4 B4

• Common centroid Technique: Placing components such that bothcomponents have same centroid.

A1 B1 B2 A2 A3 B3 B4 A4.Both A and B have commoncenter

Example of common centroid technique (Matching between M3 and M4 of differential amplifier). (W/L)M3= (W/L)M4

M3 M4 M4 M3 M3 M4 M4 M3

Another example of common centroid technique (W/L)M1= 2(W/L)M2

M1 M1 M1 M1M2M2

An alternative approach of M1 M1 M2 M2 M1 M1 can also be used !!!

Another example of common centroid technique for matching in capacitor array at the input stage of a DAC.

C

2C

4C

8C

16C

Dummy capacitors

Poly serves as the common bottom plate

Done by Milind Sawant for input stage of a DAC

Example layouts

Use NTAP contact around transistors and try to use M2 for horizontal connections and M3 for vertical connections or vice versa.

Example layouts

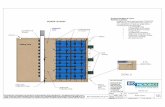

Pad Frame• 40 PINS• P pins are protected

pins• + is VDD pin• - is VSS pin• Pins with no names

are bare pins.• It has a global

guard rings.

Guard rings

Pin # 1Pin # 40