Base Plate Design by Aisc-Asd

-

Upload

purnima-arkalgud -

Category

Documents

-

view

134 -

download

5

description

Transcript of Base Plate Design by Aisc-Asd

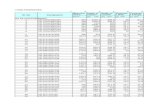

DESIGN OF BASE PLATE

Geometry Data

Item Value Unit FPS UNIT

Code AISC-ASD

Analysis Method Rigid Plate

Base Plate Minimum Length 0.65 m 2.13 ft 25.59 in

Base Plate Maximum Length 0.7112 m 2.33 ft 28.00 in

Base Plate Minimum Width 0.65 m 2.13 ft 25.59 in

Base Plate Maximum Width 0.7112 m 2.33 ft 28.00 in

Base Plate Increment of length and width 0.00635 m 0.02 ft 0.25 in

Base plate thickness 0.0127 m 0.04 ft 0.50 in

Base Plate Increment of Thickness 0.003175 m 0.01 ft 0.13 in

Base Plate Fy 248211.28404 kN/m2 174.876 lbs/in2

Base Plate E 199947978.81 kN/m2 140872.721 lbs/in2

Pedestal F'c 28181.87 kN/m2 4000 psi 281.81875

Pedestal Fp[ For Fp(Use ACI 318-99 value)] 8273709.468 kN/m2 5829.216

Pedestal Length 2 m 78.74

Pedestal Width 2 m 78.74

Number of Bolts along Length 2 m 78.74

Number of Bolts along Width 2 m 78.74

D1 0.25 m 9.84

D2 0.25 m 9.84

D3 0.25 m 9.84

D4 0.25 m 9.84

Bolt Positions

Bolt No. X-Position Z-Position Unit

1 -0.25 -0.25m -9.84 -9.84

2 -0.25 0.25m -9.84 9.84

3 0.25 -0.25m 9.84 -9.84

4 0.25 0.25m 9.84 9.84

Property Data

Item Value Unit

Country US(Imp)

Shape W

Dimension W8x31

Attachment Type

Item Value Unit

Select Type of Attachment None

Select Type of Stiffener Connection Type A

No of Bolts Inside The Stiffeners Along The Length

No of Bolts Inside The Stiffeners Along The Width

Minimum Stiffener to Bolt Distance 0.0762 m 3.00

Stiffener Plate Height 0.6096 m 24.00

Stiffener Plate Thickness 0.0635 m 2.50

Anchor Bolt Data

Material Type A307

Minimum Embedded Length 305.00 cm 120.07874

Minimum Embedded Edge Distance 122.00 cm 48.0314961

Bolt Diameter 10.00 cm 3.93700787

Allowable Shear Stress of Bolt 20684.27 kN/m2 14.573 lbs/in2 2098.51778 lbs/ft2

Allowable Tensile Stress of Bolt 20684.27 kN/m2 14.573 lbs/in2 2098.51778 lbs/ft2

Yeild Stress of Bolt 248211.28 kN/m2 174.876 lbs/in2 25182.2134 lbs/ft2

Young's Modulus of Bolt 20500000 kN/m2 14443.211 lbs/in3 2079822.34 lbs/ft3

Material Type A307

Yeild Stress of Bolt 170322.24 kN/m2 120.000 lbs/in2 17280 lbs/ft2

Bolt Size 0.635 cm 1/4 in

Fc 2838704 kN/m2 2000.000 lbs/in2 288000 lbs/ft2

Bolt Area 0.32258 sq.cm 0.05 in2

Bolt Embedded Length 6.350 cm 2.5 in

Edge Distance 3.810 cm 1.5 in

Bolt Spacing 7.620 cm 3 in

Bolt offset distance 9.853 in

Load Data

Item Value Unit

Vertical Load (P) 45 kN 2045.45455 lb

Horizintal Shear Along The Length (Vx) 10 kN 454.545455 lb

Horizintal Shear Along The Width (Vz) 10 kN 454.545455 lb

Moment About The Axis Along The Length (Mx) 200 kNm 2982581.72 lb-ft 35790980.7 lb-in

Moment About The Axis Along The Width (Mz) 20 kNm 298258.172 lb-ft 3579098.07 lb-in

Shear Lug Data

Item Value Unit

Is there a Shear Lug along the Length of the Base Plate? No

Width of the Shear Lug Along the Length of the Base Plate 0.3048 m 12

Is there a Shear Lug Along the Width of the Base Plate? No

Width of the Shear Lug Along the Width of the Base Plate 0.3048 m 12

Friction Coefficient 0.4

Thickness of Grout 0.0127 m 0.5

Axial Load 0 kN

Calculation Sheet Report

Check the width W and length L of the plate for Edge of Concrete

Support Pier Length 200.000 78.74 in

Support Pier Width = 200.000 78.74 in

Allowable Minimum Edge Distance = 50.000 19.685 in

75.001 cm 29.528 in

Edge distance is 29.528 > Minimum Edge Distance = 50.000 cm 19.685 OK

75.001 29.528 in

Edge distance is 29.528 > Minimum Edge Distance = 19.685 OK 75.001 29.528 in

Compute the Corner Stresses

P 25695.661 10116.402

Mz 98.9547 177014.648

Mx 989.5473 kN-m 1770146.48 lb-in 147512.207 lb-ft

17.498 in

174.978 in

Size of plate:

Bp = 65.000 25.59

Lp= 65.000 25.59

Area of the Plate = 4225.000 ` 654.87631 Sq.in

Section Modulus z = 45770.833 2793.108 Cu.in =

Section Modulus x = 45770.833 2793.108 Cu.in

f1=Mz/Zz 63.376

f2=Mx/Zx 633.755

P/A= 15.448

Stress = Axial Force / Area + Moment x / Section Modulus x + Moment z / Section Modulus z P/A+ Mx/Zx+ Mz/Zz Total

The Anchor Bolt Closer to the on the Length Side Edge is Bolt Number 1 and the Edge distance is

The Anchor Bolt Closer to the on the Width Side Edge is Bolt Number 1 and the Edge distance is

Eccentricity in e x = Mz / Pu=

Eccentricity in e z = Mx / Pu=

p1 15.448 -633.755 63.376 -554.932

p2 15.448 -633.755 -63.376 -681.683

p3 15.448 633.755 -63.376 585.827

p4 15.448 633.755 63.376 712.579

Pmax=Maximum Corner stress= 712.579 psi

Allowable stress= 2800.000

Pmax< Allowable Stresss OK

Section depth=td= 8

Calculating the thickness based on the anchor bolt tension

Distance e = ( Plate Length - 0.95 * Section Depth ) / 2.0 - ( Plate Length / 2.0 - Bolt OffSet Dist )

6.053 in

W = 2.0 * e = 2.0 * 6.043 = 12.085 12.106 in

Tension in anchor bolt 63586.218 169014.217

Fy= 36000 psi 25.364

Moment in bolt= 113269.051 lb-in

6.751 cm 2.66 in2

Calculating the thickness based on the base pressure Moment

5.02 in

Designed plate thickness 13.0175 cm 5.125

Fu= 58000

Anchor Bolt Design

= ( Lp - 0.95 * td ) / 2.0 - ( Lp / 2.0 - Loff )

Plate Thickness for ASD tp = e6.0 * Tenison * e / ( 0.75 * Fy * W )

Plate Thickness for ASD tp = e6.0 * M / ( 0.75 * Fy )

Bolt 1

Bolt Tension = 0.00.

Bolt dia= 10 cm 3.94

Required Bolt Length

Mininimum Embedded length =12 * dia = 47.244 in 120 cm 47.24 in

Bolt 2

Bolt Tension = 51682.17

17.247 cm2 2.67 in2

Bolt Area Required < Bolt Area OK

408.583

28.9667088875419 11.404 in

Cone Surface is overlaping, the length of the bolt is increased to 31.51378 12.407 in

Required Bolt Length 12.407 < Mininimum Embedded length ( 12 * dia ) 47.244. Provided length =47.244 in

Bolt 3

Bolt Tension = 0.00. So, Required Bolt Length = Mininimum Embedded length 12 * dia = 47.24

Bolt 4

3.32

Bolt Area Required < Bolt Area OK

Bolt Area Required = T / ( 0.33 * Fu ) = 51682.170 / ( 0.33 * 58000.000 )

Projected Surtface Area Apsf = T / ( 2 eFc ) =

Required Bolt Length = e( Apsf / p ) =

Cone Surface is overlaping, the Adjusted Apsf 457.240 for the length of the bolt = 12.407 in

Bolt Area Required = T / ( 0.33 * Fu ) =

502.69

12.650

Cone Surface is overlaping, the length of the bolt is increased to 13.653 in

Required Bolt Length 13.653 < Mininimum Embedded length ( 12 * dia ) 47.244. Provided length =47.244 in

Design of Weld Size for Column and Plate

Thickness of Flange = 0.435 in

Thickness of Web = 0.285 in

Maximum Weld Size = Minimum Thickness of the Section - 1/16 = 0.285 - 1/16 = 0.222 in

For the section with the Minimum Thickness is less than 1/2 inch, Minimum Weld Size = 3/16 in

Projected Surtface Area Apsf = T / ( 2 eFc ) =

Required Bolt Length = e( Apsf / p ) =

Cone Surface is overlaping, the Adjusted Apsf 536.068 for the length of the bolt = 13.653 in