Base Plate

-

Upload

muhammed-ali -

Category

Documents

-

view

390 -

download

51

description

Transcript of Base Plate

Design of base plate

Project/Client :-

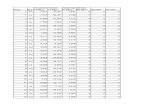

S.No Calculations References

1 Design forces

Factored Axial load Pu = 17 KN From analysis

Nature of axial load = ompression

Factored Shear force Fy = 2 KN

Dia of anchor bolts (HT bolts) = M 20 mm

No of bolts = 4 Nos

Grade of bolts = 8.8

Ultimate Tensile strength of bolt fu = 100 Mpa

Ultimate Tesile strength of plate fcu = 250 Mpa

Yield stress of plate fy = 250 Mpa

Yield stress of bolt fyb = 250 Mpa

Cube compressive strength of concrete fck = 20 Mpa

2 Geometric properties

Column section = ISMB

Depth of section = 400 mm

Width of flange = 140 mm

Clearence of holes = 2 mm

Dia of holes = Nominal dia of bolt + clearen = 22 mm

Minimum Edge distance = 33 mm Clause 10.2.4

Maximum edge distance = IS:800:2007

= 192 mm

ε =

= 1

Edge distance provided = 150 mm

O.K

25 25

16

450

150 150 150

50

30

10

0

14

0

20

0

12tε

(250/fy)1/2

10

0

400

14

0

20

0

50

450

Minimum spacing of bolts (2.5 d) = 50 mm Clause 10.2.2 &

Maximum spacing of bolts (lesser of 32t or 3 = 300 mm 10.2.3

Spacing of bolt provided = 150 mm IS:800:2007

O.K

3 Check for base pressure

Bearing pressure of plate w = Pu/Ap

= 0.19 Mpa

Allowable bearing pressure = 0.6fck

= 12 Mpa

Safe

4 Check for Minimum Thickness of base plate Clause 7.4.3.1

Thickness of plate required IS:800:2007

= 1.22 mm

Thickness of plate required = 16 mm

Safe

4 Check for shear capacity of bolts Clause 10.3.3

Design shear strength of bolt, = IS:800:2007

= 32.63 KN

= 26.104 KN

Calculated shear force per bolt Vd = 0.5 KN

Safe

5 Check for bearing capacity of bolts Clause 10.3.4

Design bearing strength of bolts = IS:800:2007

=

= 0.4

= 32 KN

= 25.6 KN

Calculated bearing strength of bolt Vb = 4.25 KN

Safe

6 Check for tension capacity of bolts

ts

Vdsb Vnsb/עmb

Nominal shear capacity, Vnsb

Vnsb

Vdsb

Vdpb Vnpb/עmb

Vnpb 2.5kb d t fu

kb

Vnpb

Vdpb

t s≥√2 .5w (a2−0 .3b2 )γmo/ fy>tf

Design tension capacity of bolt =

Nominal Tensile capacity of bolt

=

= N.G Mpa

= N.G Mpa

Nominal Tensile capacity of bolt = N.G Mpa

Design tension capacity of bolt = N.G Mpa

Calculated tension per bolt T = N.G Mpa

N.G

7 Check for combined shear and tension

N.G+

N.G= N.G > 1.0

N.G N.G

N.G

Tdp Tnp/עmb

Tnp 0.9fubAn<fybAsb(עmb/עmo)

0.9fubAn

fybAsb(עmb/עmo)

Tnp

Tdp

Design of base plate

Project/Client :-

S.No Calculations References

1 Design forces

Axial load Pu = 156 KN From analysis

Nature of axial load = ompression

Bending moment about xx Mx = 0 KN.m

Bending moment about yy My = 0 KN.m

Lataral force along xx Fx = 0 KN

Lataral force along yy Fy = 0 KN

Dia of anchor bolts (HT bolts) = M 20 mm

No of bolts = 4 Nos

2 Geometric properties

Dia. Of pile = 300 mm

Width of column/pedestal = 450 mm

Depth of column/pedestal = 700 mm

Minimum spacing of piles = 750 mm

Centre to Centre distance of two adjacent pil = 750 mm

Edge projection from face of piles

(Min 100-150mm) = 150 mm

Width of pile cap = 600 mm

Length of pile cap = 1350 mm

Depth of pile cap ( assumed) = 600 mm

Clear cover to the reinforcement = 75 mm

Grade of concrete fck = 20 Mpa

Grade of Steel fy = 415 Mpa

3 Load calculations

Weight of pile cap = 12.15 KN

Additional load due to moment = 0 KN

Total load on each pile = 84.08 KN

= O.K

4 Calculation of reinforcement

a)Bending theory

Bending moment about xx = 21.44 KN.m

Design bending moment = 32.161 KN.m

Dia of Main reinforcement = 12 mm

Dia of secondary reinforcement = 12 mm

Effective depth of pile cap = 519 mm

Mu/bd2 = 0.2

pt = 0.056 %

pt,min = 0.12 %

Area of steel required = 373.68

b)Truss theory

Tension at bottom =

= 97.69 KN

Area of steel required = 270.57

Area of steel required

(max of bending & truss theory) = 373.68

No of bars required = 4 Nos

No of bars provided = 4 Nos

Area of steel provided = 452.16

5 Check for shear

a)One way shear

As per IS:2911-Part-1,

clause:5.6

As per IS:2911-Part-1,

clause:5.12.5

mm2

Pu/12ld(3l2-a2)

mm2

mm2

mm2

Percentage of steel provided = 0.145 %

ß = 0.87fy/6.89pt

= 17.42

= 0.273 Mpa Clause 40.5

Nominal shear stress ,ζv = 0.41 Mpa IS:456-2000

Shear span, av(C/C of pile/2-d/2+20% pile di = 0.18 m

Enhancement factor (2d/av) = 5.77

Modified shear strength, ζv = 1.57 Mpa

1.57>0.41

O K

b)Two way shear

Punching shear, V = 234 KN

Perrimeter of column, = 2300 mm

Punching shear stress, = 0.2 Mpa Clause 31.6.3

Permissible shear stress, = 1.118 Mpa IS:456-2000

1.1180339887499>0.2

O K

Permissible shear stress, ζc

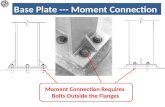

Design of base plate

Project/Client :-

S.No Calculations References

1 Design forces

Factored Axial load Pu = 1100 KN From analysis

Nature of axial load = Tension

Factored Shear force Fy = 300 KN

Dia of anchor bolts (HT bolts) = M 36 mm

No of bolts = 4 Nos

Grade of bolts = 8.8

Ultimate Tensile strength of bolt fu = 100 Mpa

Ultimate Tesile strength of plate fcu = 250 Mpa

Yield stress of plate fy = 250 Mpa

Yield stress of bolt fyb = 250 Mpa

Cube compressive strength of concrete fck = 25 Mpa

2 Geometric properties

Column section = BUILT-UP I SECTION

Depth of section = 400 mm

Width of flange = 300 mm

Clearence of holes = 2 mm

Dia of holes = Nominal dia of bolt + clearen = 38 mm

Minimum Edge distance = 57 mm Clause 10.2.4

Maximum edge distance = IS:800:2007

= 144 mm

ε =

= 1

Edge distance provided = 160 mm

Not OK

50 50

12

500

160 180 160

10

0

50

20

0

30

0

40

0

12tε

(250/fy)1/2

20

0

400

30

0

40

0

10

0

500

Minimum spacing of bolts (2.5 d) = 90 mm Clause 10.2.2 &

Maximum spacing of bolts (lesser of 32t or 3 = 300 mm 10.2.3

Spacing of bolt provided = 180 mm IS:800:2007

O.K

3 Check for base pressure

Bearing pressure of plate w = Pu/Ap

= 5.5 Mpa

Allowable bearing pressure = 0.6fck

= 15 Mpa

Safe

4 Check for Minimum Thickness of base plate Clause 7.4.3.1

Thickness of plate required IS:800:2007

= 10.29 mm

Thickness of plate required = 12 mm

Safe

4 Check for shear capacity of bolts Clause 10.3.3

Design shear strength of bolt, = IS:800:2007

= 105.73 KN

= 84.584 KN

Calculated shear force per bolt Vd = 75 KN

Safe

5 Check for bearing capacity of bolts Clause 10.3.4

Design bearing strength of bolts = IS:800:2007

=

= 0.4

= 43.2 KN

= 34.56 KN

Calculated bearing strength of bolt Vb = 275 KN

Unsafe

6 Check for tension capacity of bolts

ts

Vdsb Vnsb/עmb

Nominal shear capacity, Vnsb

Vnsb

Vdsb

Vdpb Vnpb/עmb

Vnpb 2.5kb d t fu

kb

Vnpb

Vdpb

t s≥√2 .5w (a2−0 .3b2 )γmo/ fy>tf

Design tension capacity of bolt =

Nominal Tensile capacity of bolt

=

= 73.25 Mpa

= 289.02 Mpa

Nominal Tensile capacity of bolt = 73.25 Mpa

Design tension capacity of bolt = 58.6 Mpa

Calculated tension per bolt T = 275 Mpa

Unsafe

7 Check for combined shear and tension

75+

275= 6.863 > 1.0

34.56 58.6

Unsafe

Tdp Tnp/עmb

Tnp 0.9fubAn<fybAsb(עmb/עmo)

0.9fubAn

fybAsb(עmb/עmo)

Tnp

Tdp