BAG FORMING - European Snacks Association · Forming Code printer ... and vertical seal Horizontal...

Transcript of BAG FORMING - European Snacks Association · Forming Code printer ... and vertical seal Horizontal...

BAG FORMING

Stefano Rizzato

TNA

Contents

1. What’s difficult about bagging savoury snacks?

2. Types of bag makers on the market

3. Reel loading

4. Film carriage

5. Code printing

6. Forming shoulder

7. Film drive and back seal

8. Film sealing

9. Film cutting – types of knife

10.Bag types available

11.What type of machine should I choose?

What’s difficult? – the product

Loose product

Irregular shapes

Loose particles

and seasoning

Oily or sticky

products

Variable piece

size

High volume,

low mass

What’s difficult? – the film

• Flexible film is difficult to control

• Large range of film types – although mainly OPP

and OPP/OPP laminates used for snacks

• Large range of different bag widths, lengths and

film thicknesses

• Many different pack formats which can require

special films

How does the film affect performance?

Thickness/stiffness – Use lighter laminates for high speed and small bag

weights, heavy films for premium products, larger

and slower packing speeds.

Slip or friction - Some stiffer films will be difficult to pull through the

machine and will benefit from a slip layer added to

the film.

Hot tack strength - Ensure that the hot seal can resist the weight of

the product and the stripping action during the

bagmaking cycle.

Sealing properties - The sealing layer is added to the OPP laminate

during the converting process. Ensure that this is a

high quality to prevent pinhole leaks where the film

folds over.

How does the film affect performance?

Reel consistency - Ensure that the reel quality is consistent

from reel to reel so that reel changes don’t

result in downtime.

Reel tension - Each reel should be wound with equal

tension across the reel and through the

reel.

Print consistency - Ensure the print position is in the same

position through the reel and from reel to

reel.

Artwork design - Design the Artwork to be as machine

friendly as possible

Elements of a bagmaker

Film spindles.

Two required

for quick

change-over

Film dancer

controls film

unwind

Film drive.

Feeds the

film at the

required rate

Code printer Forming

shoulder and

product infeed

Film pull down

and vertical

seal

Horizontal seal

and product

stripping

mechanism

Control system

and HMI

What’s on the market

Types of bag maker

Systems available

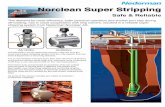

All vertical form fill and seal (VFFS) machines for packaging snacks must

incorporate some form of product stripping action to ensure maximum

efficiency.

What is product stripping?

Systems available

Intermittent machines

• Mechanical or pull down machine (mostly obsolete)

• Single axis jaw motion – not generally suitable for snacks

Continuous machines

• Rotary flat jaw or D motion – longer sealing time for some heavier

films and speciality packs

• Rotary machine – one, two or three sets of jaws for high speeds

• Box motion machine – highly versatile for speciality packs

Types of machine – mechanical

Mechanical draw down action

An example of an intermittent machine

• Vertical seal made when the film is

stationary

• Stationary tubeclosers catch next

dump well above the jaws

• 75mm of stripping is possible

• Long seal time possible

• Moving jaw assembly pulls film

through the machine

• Speed restricted by mechanical

mass and the time lost when

the film is stopped.

Box motion principle

Strip zone

Seal zone

Film cut

Servo control of:

• Strip length

• Seal time Open/Close speed

• Film speed and position

Box motion principle

Bag forming – rotary flat jaw principle

Bag forming – typical rotary flat jaw principle

Typical rotary jaw principle

Rotary triple jaw principle

Reel loading – cantilevered mandrel

Cantilevered

film spindle

Film unwind

rate controlled

by dancer

Film carriage

Controls the

entire film path

Mounting for:

• Reel holders

• Dancer

• code printer

• film drive

• Other ancillary

equipment

Tracks entire

film path

Film carriage

• Manual or automatic tracking

• Machines with side mounted pull belts tend to require

automatic tracking due to unbalanced belt/film slippage

• Automatic tracking can be an unnecessary complication

• Simple film paths enable quick bag size changeovers

• Most machines incorporate some form of film splicing table to

facilitate reel changes.

• A few machines manufacturers also provide the option to

include an automatic film splicing attachment that can save

significant production time.

Auto splice assembly

Date code printing

Types of coders

• Continuous coding

• Rotary coders, ink rolls

• Thermal Transfer

• Intermittent coding

• Hot stamp, wet ink pads

Forming shoulder

Forming shoulder – important points

• Product infeed

• Product path

• Cross section of tube

• Back seal bar

• 80/80 rule

• For maximum efficiency the

largest product length must

be no more than 80% of the

internal tubeformer diameter

and the product volume

should be no greater than

80% of the internal volume

of the bag.

• Weight of former

• Ease of change

• Film path

• Gas flushing

Forming shoulder

FILM/BAG DETAILS (Circle figure below to select required backseal type.)

Standard Formers are FLOFIN Design. FLOFIN formers can produce Lap or Fin backseals depending on film reel width.

Please contact engineering if lap is required and film width > FBW X 2 + 1

For dimensions refer below:

QUANTITY REQUIRED: TWO

TNA RECOMMENDED FILM REEL WIDTHS:

FLAT BAG WIDTH: 130 mm Inches LAP SEAL: FILM WIDTH = (FBW x 2) + 12

FIN SEAL FBW < 120mm: FILM WIDTH = (FBW + 12) x 2

FILM REEL WIDTH: mm Inches FIN SEAL FBW => 120mm: FILM WIDTH = (FBW + 15) x 2

USED ON INTEGRATED SYSTEMS

TYPE OF FILM: OPP USE OF ABRASIVE FILM TYPES WILL CAUSEB=DIA 100 IF FBW <= 100mm

RAPID WEAR ON FORMER SHOULDERS. B=DIA 150 IF FBW >= 101 UP TO <= 220mm

FILM THICKNESS: 50 microns B=DIA 200 IF FBW > 220mm

GAS FLUSH FLOW RATE REQUIRED

A=380mm (STANDARD HEIGHT) YES <150 FBW FLOW RATE 250l/m @ 1 BAR

=>150 FBW FLOW RATE 350l/m @ 1 BAR

AVAILABLE ON REQUEST

IS WASH DOWN APPLICATION FORMER REQUIRED? NO SPECIAL COMMENTS - JUSTIFICATION REQUIRED

FOR NON STANDARD FORMER

IS GAS FLUSHING REQUIRED? YES

IS PLUNGER REQUIRED? NO

PROJECT MANAGER TO ENSURE EACH ROBAG INCLUDES:

- PNEUMATIC CONNECTION KIT (Integration Leg) TNA-0041655

- PNEUMATIC CONNECTION KIT (Non- Integration Leg) TNA-0041656 SALES AUTHORISATION:

Signature……….. Andre Tombült Date 13-Jun-14

DOES FILM HAVE HORIZONTAL PREAPPLIED ZIPPER NO

- PROJECT MANAGER TO ENSURE EACH ROBAG INCLUDES TNA-0055001 SPECIAL PEC BRACKET ENGINEERING AUTHORISATION: M GRUS

Signature……….. Date

IS BAG AGITATOR USED? NO

NOTE: SPECIAL FULL TUBE FORMER REQUIRED MANUFACTURING AUTHORISATION: M HERZOG

Signature……….. Date

Circle figure below to define unwind and print surface arrangement.CUSTOMER FILM REEL DETAILS

Film drive

• Mechanical pull down

• Belt pull down

• Wheel pull-down

• Vacuum belt pull down

• Side mounted

• Front/back mounted

Vacuum drives

Drives mounted in front of and behind

the film tube

• Promotes self tracking

• Provides easy access for

maintenance

• Allows easy removal and

replacement of the tubeformer

• Requires minimal internal

tube so maximising internal

space for product flow

• Not ideal for speciality packs

Vacuum drives

Drives mounted either

side of the film tube

• Requires internal

tube greater than

50% circumference

• Ideal for speciality

packs such as

block bottom

Back seal

Heat seal

Intermittent seal – Film is sealed while stationary. Stationary film

sandwiched between heated sealing bar and fixed

back bar. Heated sealing bar moves in and out -

usually by pneumatic actuator

Continuous seal – Film is moving as it is sealed. Film is

sandwiched between either a stationary heated

sealing bar and a fixed back bar – drag seal – or a

moving sealing band (heated) and a fixed back bar

Back seal

Whatever to configuration of the

machine the vertical seal there will

be a heated bar that provides a

combination of heat and pressure

to seal the tube of film

Film sealing

• Heat seal – accounts for 99% of all snack food packaging

• Purpose – presentation, seal through product, bag

hanger

• Size – narrow to maximise internal bag volume, wide

for presentation

• Tooth profile – stretch film and increase sealing pressure

• Material – must incorporate a heat sealable layer

• Temperature – must be accurately controlled. Too hot will burn,

too cold will not seal

• Pressure – requirement will depend on quality of the sealing

layer and the thickness of the film

• Time – time can be used for thicker films to enable the

temperature to be reduced.

• Special effects – Seals can incorporate holes and slots for hanging

the bag or promotional banners

Film sealing

Alternative sealing methods:

• Cold seal – Requires and adhesive layer to be incorporated into

the film laminate. Pressure alone is required to

make the seal

• Ultrasonic – Requires special films. Produces a narrow but

strong seal. An expensive option and not widely

available

Film cutting

• Cutting knives – used where the film is stationary between the jaws during the

sealing process

• Relies on a series of sharp points to pierce the film before slicing

between the initial penetration

• Usually pneumatically operated although can be operated by cam and

lever

• Can produce a zig zag cut

• Perforated cut and string bags are possible

• Modern materials can provide long life

• Crush cut knives – used on all rotary sealing machines

• Uses high pressure between a fixed knife and a fixed anvil to cut

the film

• Point contact between knife and anvil created by a helix knife

design

• Modern hard materials can give very long life. Ceramics can last

over a year but are very prone to breakage

• System not very flexible due to fixed nature. Zig zag cuts are

possible.

Available bag formats

Pack format Required bag maker configuration

BM

BM

BM

BM

BM RJ

Available bag formats

Pack Format Required bag maker configuration

BM

BM

BM

BM

BM

RJ

RJ

RJ

RJ

RJ

Available bag formats

Pack Format Required bagmaker configuration

BM RJ

BM

BM

BM

BM

RJ

RJ

RJ

RJ

Premium bag formats

How to maximise profit

• Choose the right bag maker for your requirements to ensure that you

optimize your output

• Keep your machines running

• Quick product change overs

• Automate as much as possible both on machine, upstream and

downstream

• Minimize waste

So, which bag maker?

• Depends on your primary packaging requirements:

• High speed pillow – rotary double or triple jaw for simplicity

• Premium film quad pack or block bottom bags – Box motion or D-

motion for maximum film control

Which bag maker?

Twins or single tube machines?

• Single tube machines generally offer the highest level of performance

due to scale and product transfer arrangements.

• Duplex machines can provide and advantage on very small bags –

not generally applicable to snacks

• Twins take up less space than two singles but don’t generally offer

twice the performance

Bag forming – the future

Speed - packaging small bags of snacks at speeds of

over 200bpm coupled with downstream

automation to match

Productivity - a reduction in the need for operator

intervention and downtime to increase output

per head

Efficiency - an increase in the percentage of good bags

produced to maximize machine output

Premium bag formats – as more companies look to differentiate their

product, premium bag formats will become

more common

THANK YOU