August 2006 Memphis Buff

-

Upload

sandy-gold -

Category

Documents

-

view

220 -

download

1

description

Transcript of August 2006 Memphis Buff

M.J. Scanlon PhotoM.J. Scanlon PhotoM.J. Scanlon Photo

Volume Volume 33, 33, Issue Issue 88

August 2006August 2006

THE MEMTHE MEMPHPHIS BUFFIS BUFF

NRHS MEMPHIS CHAPTERNRHS MEMPHIS CHAPTER

The Harahan Bridge asThe Harahan Bridge as Described in 1915Described in 1915

City Rejects CSX Price for City Rejects CSX Price for Cordova BranchCordova Branch

The Lights ofThe Lights of BroadwayBroadway

P A G E 2 T H E M E M P H I S B U F F

Last Month’s Meeting After taking off last month due to the heat, we had twenty-two attendees including three guests. One of our guests, Joe Lowry, brought a large scale aerial map of the city of Memphis in the early 1970s. Needless to say, many of the attendees stayed until we were kicked out of our meeting space looking at the aerial photos. Kenny Broomfield gave the presentation for the evening on the Columbus and Greenville Railroad. It included many photos from the mid to late 1980s as well as some more up to date shots taken since the late 1990s. Kenny reminisced about his first cab ride, which occurred on C&G #621 (of which he also has an HO scale model) and other memories of his childhood related to the C&G. There were also some interesting slides of the machine shop, which included various older machinery, rolling stock and MOW equipment. The most interesting aspect of the machine shop is the belt drive system which runs all the various tooling equipment. Today, the C&G is really two railroads split in two. The line from Greenwood to Greenville remains in service with an interchange in Greenwood with the Canadian National, and the primary customers on the line are catfish farmers who have feed delivered in bulk. The other half of the line is primarily in the Columbus area, with limited trackage rights on the KCS. Our August meeting will offer a repeat performance by Irv Cooperman. For those of you who may have missed the first time, Irv Cooperman presented in April on his experiences in Memphis and the railroad community in the 1940s while working in the Frisco Railroad freight house at the main Frisco yard on Georgia Street. If anyone is interested in presenting this fall, we have several open months available, please let one of the Chapter officers know.

---- Oliver Doughtie Oliver Doughtie Oliver Doughtie Oliver Doughtie

PresidentPresidentPresidentPresident - David Chase [email protected] Vice President Vice President Vice President Vice President ---- Walter Lang [email protected] National Director National Director National Director National Director - Bill Strong [email protected] SecretaSecretaSecretaSecretaryryryry - Oliver Doughtie [email protected] Treasurer Treasurer Treasurer Treasurer ---- Thomas Doherty [email protected] Librarian Librarian Librarian Librarian ---- Mike Pendergrass Publication Editor Publication Editor Publication Editor Publication Editor ---- M.J. Scanlon [email protected]

Memphis Chapter Officers

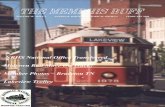

Cover Shot - UP 2210 leads the MNLMED train on the westside approach of the Harahan Bridge in Arkansas. The structure

attached to the Harahan was once used for automobile traffic pre-1950's. BNSF's Frisco Bridge approach is seen at the top of the

photo. (M.J. Scanlon Photo)

P A G E 3 V O L U M E 3 3 , I S S U E 8

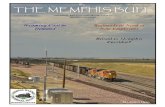

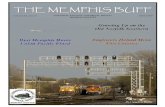

BNSF 5820 crosses under the newly activated signals on Broadway at CN Junction with the C-BAMMHS0-13A train on the tracks on UP’s Memphis Sub. This loaded coal is bound for the NS and will soon make the transition to their tracks that begin at Tower 17 a few yards ahead. The H-MEMGAL1-16A, with BNSF4388 out front, waits for a signal to proceed west (timetable northbound). The signals seen here represent all RR’s involved with this crossing. The two signal bridges hold the lights for the westbound (timetable north) movement of the BNSF. The eastbound UP signal can be seen on the backside of the second structure while the westbound signal stands alone to the right of the coal train. The CN signals are to the left of the second signal bridge and the two CSX signals are to the far right of the photo with the westbound facing and the backside of the eastbound in the distance blending into the bridges.

M.J. Scanlon PhotoM.J. Scanlon PhotoM.J. Scanlon PhotoM.J. Scanlon Photo

The Lights of Broadway

P A G E 4 T H E M E M P H I S B U F F

lower -- $15.7 million. Both appraisals were based on an "over-the-fence" method of setting value. It means the land price was based on what it would be if it was an extension of adjoining property lots. With the high appraisals in hand, CSX rejected a city-county offer of $2 million for the corridor. Bill Goss, manager of real estate services for the county, said the offer was fair. "It appears the only market for that corridor was local government," he said. Eldred said CSX is demanding too much for the corridor, especially since it has become a "festering scar across the city" as a result of the railroad's lack of maintenance. "CSX has chosen not to be reasonable," Eldred said. But CSX spokesman Gary Sease said the company is obligated to seek the market price when selling land. "We are a for-profit company and we're responsive to our shareholders, so we don't give the property away. We sell it for fair market values," Sease said. Last year, the city and county had unsuccessfully tried to persuade CSX to lease the corridor so the trail project could get under way. Sease said he didn't know the full reason behind the company's rejection of the lease option. Goss said that even though federal and private grants are available to help with the purchase of recreational property, both mayors felt those funding sources should be directed at higher-priority projects. As for the CSX corridor, "the city and county were not in a position to embrace a price anywhere close" to the figures in the appraisals, Goss said. Bob Schreiber, president of the board of directors for Greater Memphis Greenline, said the group will continue to try to raise funds for the project. "We're waiting to see what happens," he said.

©©©© 2006 The Memphis Commercial Appeal 2006 The Memphis Commercial Appeal 2006 The Memphis Commercial Appeal 2006 The Memphis Commercial Appeal

By Tom CharlierBy Tom CharlierBy Tom CharlierBy Tom Charlier July 17, 2006July 17, 2006July 17, 2006July 17, 2006

Balking at a price that's nearly eight times more than they had offered, Memphis and Shelby County officials have dropped their efforts to buy an abandoned railroad corridor for use as a recreational trail system and possible light rail conduit. In a recent letter, City Mayor Willie Herenton and County Mayor A C Wharton notified CSX Transportation that the minimum $15.7 million cost of the 13.3-mile corridor connecting Cordova and Midtown is well beyond the means of local government. "Unfortunately, given the current financial condition of both the City of Memphis and Shelby County together with our immediate need to secure funding for our more urgent, higher priority projects, we are not in a position to pursue a land acquisition of this magnitude," the jointly signed letter says. A separate private investment group that had planned to raise funds to help the city and county with the purchase also has suspended its efforts, citing the price. "There's just no one we're aware of who wants to participate in that kind of pricing," said Darrell Eldred, who has headed the group. That means it's likely up to Greater Memphis Greenline Inc. -- a non-profit organization spearheading efforts to develop the trail project -- to try to raise money to acquire the corridor. Local officials and recreation enthusiasts have coveted the 100-foot-wide corridor ever since CSX received federal permission to discontinue rail service on it in 2003. They envision a trail network for bikers, hikers and joggers, with long-range plans also including a light-rail line on the corridor. When they began talks with the railroad, local officials said they believed the price would be less than $2 million. Herenton and Wharton signed a letter of intent to buy the acreage. But a CSX appraisal of the property last year set its value at $17.8 million. The local governments hired their own appraiser to counter that, but A.E. Balkin & Associates this spring arrived at a sum that's not much

Plans to Purchase Old Railroad

Corridor Screech to a Halt

P A G E 5 V O L U M E 3 3 , I S S U E 8

July 25, 2006July 25, 2006July 25, 2006July 25, 2006 Commercial Appeal EditorialCommercial Appeal EditorialCommercial Appeal EditorialCommercial Appeal Editorial This is no way to run a railroad. We're speaking of the stance CSX Transportation has taken with regard to an unused section of rail line stretching from Midtown to Cordova. Memphis and Shelby County officials want to buy the 13.3-mile sliver of land and convert it into a bicycling, walking and jogging trail. At least they did want to buy it, until they heard CSX's asking price. City and county officials were hoping to get the tract for about $2 million. CSX wants at least eight times that much, based on a rather strange assumption used in estimating the land's value. Two appraisers have used the so-called "over-the-fence" method to suggest values of $17.8 million and $15.7 million, respectively. That method assigns a value based on what the land would be worth if it were an extension of adjoining lots. That's not a very realistic approach in this case. This property is only about 100 feet wide. Not even our community's most determined home builders could shoehorn a subdivision into a space that skinny. (Some might like to try, but zoning and development regulations actually wouldn't permit that, anyway.) Gary Sease, a CSX spokesman, insisted that if the city and county aren't willing to pay what the railroad considers to be a fair price, then somebody else might. "We are a for-profit company and we're responsive to our shareholders, so we don't give the property away," Sease said. "We sell it for fair market values." Yeah, if CSX officials can find someone interested in

developing a chain of one-lane bowling alleys, then they're sitting on a potential gold mine. Otherwise, some of those CSX shareholders might want to ask why their company would want the responsibility for maintaining land that hasn't been used for rail service since 2003. Speaking of that, CSX hasn't exactly done a bang-up job of keeping the property looking good since rail service was discontinued. Some portions of the property are heavily overgrown with brush and weeds, which makes it easier for rats, snakes or other varmints to travel through residential areas along the route. The property could also be a haven for two-legged varmints, who might want to case the area for potential burglary targets. Sease said CSX officials plan to visit the site next month to determine if any improvements are needed. If that's a first step toward sprucing up the property, that's good. But there's a right way and a wrong way to approach maintenance. While weeding and pruning work is definitely in order, some nearby property owners worry that CSX might clear cut the property, or use powerful herbicides that could run off into neighboring land. CSX could earn some good will in the community by developing a maintenance plan that is both esthetically pleasing and environmentally sensitive. The railroad could earn even more good will by taking a more flexible approach on the price of the property. A new trail for outdoors enthusiasts would be a terrific amenity for the region. The cost of developing such a trail has to make sense to someone who's not relying on an arcane appraisal method, though.

©©©© 2006 The M 2006 The M 2006 The M 2006 The Memphis Commercial Appealemphis Commercial Appealemphis Commercial Appealemphis Commercial Appeal

Get Land Talks Back on Track

Below are two photos of the CSX Cordova Branch as it crosses High Point Terrace. The photo on the left was taken in November, 2003, and the one on the right in August 2006. The growth is overtaking the ROW and will soon be over taking backyards in the High Point neighborhood unless CSX does something about it. (M.J. Scanlon Photos)(M.J. Scanlon Photos)(M.J. Scanlon Photos)(M.J. Scanlon Photos)

P A G E 6 T H E M E M P H I S B U F F

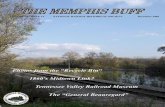

Originally presented in the March 1915 issue of theOriginally presented in the March 1915 issue of theOriginally presented in the March 1915 issue of theOriginally presented in the March 1915 issue of the Rock Island Employes’ MagazineRock Island Employes’ MagazineRock Island Employes’ MagazineRock Island Employes’ Magazine By B.M. Case - Resident Engineer The foundations for the new bridge over the Mississippi River in Memphis have recently been completed. This bridge is being built by the Rock Island, the Cotton Belt and the Iron Mountain systems and is located just two hundred feet up stream from the present single track Frisco bridge over which all traffic into Memphis from the West now passes. The new bridge will carry two railroad tracks spaced fourteen feet centers and located between the trusses and two road ways fourteen feet wide placed on brackets on the outside of the trusses. The main bridge is 2,550 feet in length with a channel span of 790 feet between pier centers. The approach over the Arkansas bottoms consists of a tower and girder viaduct 2,363 feet long which is reached by a double track earth embankment fifty-five feet high at the abutment and about three-quarters of a mile long. Work on this earth embankment is now being started by the contractors, Ball & Peters. The fill at the western approach to the bridge will be about three-fourths of a mile long and run from 25 to 60 feet in height, being double tracked to connect with permanent bridge. The embankment will be constructed first temporarily by a pile trestle bridge built to permanent grade, a part of which is now erected. Following this the bridge will be filled and widened by means of steam shovels and dump cars. There will be placed on this work as much of (the) following outfit as required: 2 steam shovels 60 dump cars 4 locomotives 2 spreader cars Boarding cars Water stations, etc. All this equipment is standard gauge. This firm is made up of railroad men of long experience. J.J. Ball was with the Gould railroads for many years in the construction and operating department. F.H. Peters was connected with the engineering department for many years, his last position being chief engineer to the Chicago, Rock Island & Gulf Railway during construction. The superstructure of the main bridge is being fabricated by the Pennsylvania Steel Company who have the work well advanced in their shop at Steelton, Pa., and are now making active

preparations for the erection at the bridge site. The Virginia Bridge and Iron Company have the contract for the approach viaduct and are now fabricating this material in their Memphis shop. The Western States Lumber Co. of Kansas City has furnished approximately 3,500,000 feet of lumber on the bridge work.

The first field work on the bridge was started in June, 1913, and consisted in building two miles of track from the old Hopefield Rock Island Line to the bridge material yards at the bank of the river. When this track was completed on July 29, 1913, there were sixty cars of timber and machinery waiting for delivery. This material was used largely in building barges and the first three months were occupied almost entirely with the building of fifteen barges and the construction of the plant and assembling of the large amount of equipment necessary for the rapid and economical prosecution of the work. The floating equipment on the work eventually included twenty-one barges, a tug and two launches. This does not include several barges and a second steamboat that were chartered from time to time when the bridge company’s fleet proved inadequate to keep all parts of the work running without delay. The rigs built on barges consisted of a pile driver, three derricks, a concrete plant, and a power plant for the pneumatic caisson work. The balance of the barges were used for delivering sand,

(Continued on page 7)

New “Harahan” Bridge

Across the Mississippi River at Memphis

Outfit of Ball & Peters at West Approach where big fill is to be made

P A G E 7 V O L U M E 3 3 , I S S U E 8

(Continued from page 6)

gravel, cement, timber and other materials used on the work. The power barge carried four locomotive type boilers with a combined capacity of three hundred horsepower with the necessary feed pumps and feed water heaters. Three low pressure compressors furnished air for the caisson work and smaller high pressure machine furnished compressed air for operating boring tools and pneumatic hammers. In addition this barge carried a direct connected dynamo to supply current for the lights at night and to operate an elevator referred to later. A power driven pipe cutting and threading machine was installed to expedite the heavy pipe fitting required on the caissons and other parts of the work. The whole was assembled on a barge 36x100 feet and when suitably housed constituted a rather complete and satisfactory appearing power station.

Other preliminary work consisted of building a dock and derrick on the Arkansas bank on which the yard tracks ran out to the river so that a locomotive crane serving the yard could deliver framed timber and other material at the dock and transfer it to barges for delivery at the piers. A yard and dock was also provided on the Tennessee shore for the storage of granite and cement. The cut granite was shipped from Stone Mountain, near Atlanta, Ga., and naturally called for storage on the cast side of the river. The cement house of three thousand barrels’ capacity was for the storage of the reserve supply only on the Tennessee side of the river. The granite yard was equipped with a traveling gantry crane which unloaded the granite from the cars and later delivered it onto push cars which could be run out onto the dock where a stiff leg derrick transferred it to barges for delivery under the massive floating derrick under the massive floating derrick with which it was finally set in place in the piers. The greater part of the cement was

delivered by boat from St. Louis and unloaded directly into either of two storage houses of fifteen hundred barrels’ capacity built on barges. This avoided considerable expense of handling cement since these storage barges could be moored immediately bellow the concrete mixing plant where the car that raised it into the mixer could be run under the roof of the house thus minimizing delays in rainy weather and avoiding damage and consequent loss of sacks. The cement intended for the storage warehouse was shipped by rail and used only when the deliveries by water were delayed or suspended by the river conditions. This was but a small part of the 59,000 barrels used on the work and could be handled from the warehouse by sliding the sacks down an iron lined trough which led directly into the house on the cement barge. This preliminary work had progresses so that the construction of the first caisson was started on

(Continued on page 8)

Another view of the West Approach

Launching Caisson III from Pontoon

Sinking Caisson

P A G E 8 T H E M E M P H I S B U F F

(Continued from page 7)

September 20, 1913. This caisson for the pier three was 42x90 feet in plan and was built on a pontoon moored alongside the Arkansas dock for convenience in delivering timber from the yard. The caisson resembles a huge box open at the bottom and having a roof seven feet above the steel cutting edge. The side walls are forty-five inches thick and the roof thirty-three inches thick. Above the roof the walls are reduced to eighteen inches in thickness and carried up a few feet before launching. This entire structure is built of timber but very strongly bolted and framed together and then caulked like a boat to make the working chamber under the roof air tight. When built up fourteen feet from the cutting edge the caisson was launched into the water by flooding the pontoon. This caused the pontoon to submerge until the caisson was floating in the water. The pontoon was then moved from under the caisson by separating along a longitudinal joint provided for that purpose and the two halves were later jointed together and the pontoon used the following summer for the caisson of pier two.

This floating caisson for pier three was then moved into a position directly over the final position of the pier and held in place by lines attached to a dock which had been previously driven around three sides of the pier site. The building up of the vertical water tight walls forming the crib could then be resumed. These walls were eventually built up to a height of fifty feet above the cutting edge. The space enclosed by these walls and above the roof of the caisson proper or working chamber was filled with concrete, this being placed from day to day as the walls of the crib were built up. As weight was added the immersion of the caisson gradually increased until the cutting edge came into bearing on the bed of the river. The depth of water was about thirty feet in the case of pier three.

The essential feature of the pneumatic process was then brought into play. Air pressure from the power plant was applied through the concrete and roof of the caisson into the working chamber underneath. This air pressure is increased to and maintained at a pressure equal to that of the water at the cutting edge. The air forces the water out under the cutting edge leaving the workmen chamber free of water. The workman, known as “sand-hogs”, can then enter the working chamber through a vertical steel shaft built in through the roof of the caisson at the time of its construction. The principal man shaft was six feet in diameter and was equipped with an electric elevator which took current from the power barge for the use of the workman. Another man shaft three feet in diameter fitted with a ladder provided an additional means of entering or leaving the working chamber. Five shafts two feet in diameter were used for removing the excavating material. Each shaft was provided with a lock, or chamber with two doors, opening inward, to permit passage into the working chamber without allowing the escape of air pressure. The sand-hogs in the working chamber excavated the material on the bed of the river and sent it out through the material shafts and the caisson and pier were then lowered into the hole they had excavated. The working chamber was well lighted by electric lamps and the conditions are not unlike a damp cellar without a floor. No peculiar sensations of any sort are experienced until the pressure reaches the higher limits during deep sinking. The process of sinking outlined above was carried on simultaneously with the building up and the concreting of the crib. When the crib was built up and filled with concrete to a height of fifty feet above the cutting edge the granite masonry of the pier was started and built up as the sinking proceeded. Sinking was stopped when a

(Continued on page 9)

Looking East

Concrete Backing Course

P A G E 9 V O L U M E 3 3 , I S S U E 8

piers on shore the caissons were fist built on blocking resting directly on the ground but after sinking was started the process was identical. Pier two, the first pier out from the Tennessee shore was started after the spring freshets of 1914. This pier was identical with three previously described and was constructed by the same general method except that certain provisions were made for much deeper water as the river is fifty feet deep at this point when at normal stages. A willow brush mat was sunk at the site of the pier and covered with rip rap stone to prevent the bed of the river from scouring. The caisson was then landed on this mat and a hole cut through it just large enough to pass the caisson. Similar mats were afterwards placed on the river bed along the bridge line the entire distance between piers two and three to protect the false work which will be driven for

the erection of the steel work. The Arkansas bank was also protected with a mat and rip rap from the bridge up stream for a distance of a thousand feet. The pedestal foundations for the approach viaduct rest on sixteen thirty-foot concrete piles which were made at the bridge

(Continued on page 10)

(Continued from page 8)

satisfactory foundation was reached on a very hard clay stratum 103.5 feet below the surface of the river which required an air pressure of forty-five pounds per square inch. The working chamber was then filled with concrete sent in through the five material shafts after which the air pressure was removed and all shafts filled so that the foundation becomes a solid mass of concrete. There remained at this time only the wok of building up the granite masonry to the top of the finished pier or copying which stands two hundred feet above the hard clay on which the cutting edge now rests and about ninety feet above the river surface when at a normal stage. Pier one on the Tennessee shore and piers four and five on the Arkansas bank were put down in a similar manner during the winter of 1913 and 1914. For the

Shore Protection - Arkansas Side

P A G E 1 0 T H E M E M P H I S B U F F

(Continued from page 9)

site, driven, the pedestals completed during the summer of 1914. The last coping stone was set on pier two in January, 1915, thus completing the foundation work in about eighteen months after the first material was unloaded. Mr. Ralph Modjeski is the consulting engineer in charge of the design and the construction of the bridge. The Union Bridge & Construction Co., of Kansas City, had the construction of the entire sub-structure. They were represented in Memphis by Mr. H.K. Seltzer during the first season’s work and later by Mr. J.F. Wilhelm. Mr. I.I. Newman was their general foreman. The writer is the resident engineer representing Mr. Modjeski and the railroads.

©©©© 1915 Rock Islan 1915 Rock Islan 1915 Rock Islan 1915 Rock Island Employes’ Magazined Employes’ Magazined Employes’ Magazined Employes’ Magazine Thanks to Oliver Doughtie for this contribution.Thanks to Oliver Doughtie for this contribution.Thanks to Oliver Doughtie for this contribution.Thanks to Oliver Doughtie for this contribution.

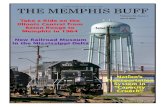

West Approach Looking West

P A G E 1 1 V O L U M E 3 3 , I S S U E 8

Recent Harahan Bridge Photos

The 2MMEEWX crosses into Arkansas on the Harahan Bridge of the UP. The

structure in the lower half of the picture was an automobile access for the bridge. The auto access was used from 1917-1949.

As seen from Martyr’s Park in downtown Memphis the Harahan Bridge, as well as the Frisco and Memphis-Arkansas bridges,

span the mighty Mississippi River connecting east to west.

The foreign power of a Norfolk Southern GE C40-9W, engine 9833, brings a string of empty auto racks, UP ASPMEX, across the Harahan Bridge destined for NS's Forrest

Yard near the fairgrounds.

All Photos by M.J. ScanlonAll Photos by M.J. ScanlonAll Photos by M.J. ScanlonAll Photos by M.J. Scanlon

Meeting ScheduleMeeting ScheduleMeeting ScheduleMeeting Schedule August 14, 2006August 14, 2006August 14, 2006August 14, 2006 September 11, 2006September 11, 2006September 11, 2006September 11, 2006 October 9, 2006October 9, 2006October 9, 2006October 9, 2006 Meetings are the 2nd Monday of each month in Meetings are the 2nd Monday of each month in Meetings are the 2nd Monday of each month in Meetings are the 2nd Monday of each month in the White Stathe White Stathe White Stathe White Station Branch Library from 7 tion Branch Library from 7 tion Branch Library from 7 tion Branch Library from 7 ---- 9 pm. 9 pm. 9 pm. 9 pm. 5094 Poplar Avenue5094 Poplar Avenue5094 Poplar Avenue5094 Poplar Avenue Memphis, TN (in front of Clark Tower)Memphis, TN (in front of Clark Tower)Memphis, TN (in front of Clark Tower)Memphis, TN (in front of Clark Tower)

Contact the EditorContact the EditorContact the EditorContact the Editor M.J. Scanlon 3549 Kenwood Avenue Memphis, TN 38122 [email protected]

CABOOSECABOOSE

THE MEMPHIS BUFF welcomes contributions for publication. Copyrighted materials must contain the source. Original documents and photos are preferred for clarity. Enclose a SASE

for the return of your materials. Articles sent via the Internet should be in Microsoft Word format. Photos should be JPEG files @ 72 dpi and at least 800x600 size. Consideration for a

cover photo would require a much higher resolution. THE MEMPHIS BUFF is a not-for-profit publication for the Memphis Chapter of the NRHS.

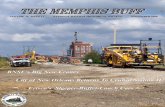

While running through old MoPac territory in central Arkansas I ran across this caboose in outside of the Lyda Miller Public

Library in Bald Knob, across from the tracks of UP’s Hoxie Subdivision. (M.J. Scanlon Photo)