[Rita L. Atkinson, Richard C. Atkinson, Edward E. (BookZZ.org)

Atkinson Mini TL HFN Nov78

Transcript of Atkinson Mini TL HFN Nov78

AM I NI.LINE'TMNSMISSION'LINEcompoct design by PAtkinson

EXPERIMENTS both be fore and a f te r theL publication of my 'State ol the Art ' loud-speaker design (HFIV/RR Apri l 1976) haveconv inced me o f the fo l low ing po in ts .

(a ) Cab ine t r ig id i ty i s fundamenta l to lowcoloration.

(b ) Transmiss ion l ines g ive bass wh ichcan be bo th c lean and deep.

(c) The relat ionship between cross-sec t iona l a rea and length o f the l ine(assuming r igidity of cabinet) canaf fec t the need fo r damping in the l ine .

(d) This in turn affects crossover require-ments .

Th is work has caused me to th ink aga in on the'State of the Art ' speaker, result ing in animproved crossover (a simpli f icat ion of the

The miniJine and maxi-lineside by side, The latter hasalmost identical dimensions tothe State of the Art but totailydiffercnt internals.

exist ing network). This in turn led to a rotal lynew Maxi-Line and, as with the Mini-Line anda Midi-Line which I have also constructed, nodamping is used in the l ine , on ly in thede-coup l ing chamber ,

Space w i l l no t permi t d iscuss ion oJ thework done to f ind suitable drive units for theMin i -L ine , bu t my f ina l cho ice was one w i thwh ich lcou ld ob ta in the requ i red resu l ts ,Although several alternative tweeters weret r ied , the lsophon KK8 l inked bes t w i th theKEF 8110 in this part icular speaker. My faithin the 8110 has no t been shaken by l i s ten ingto i ts competitors and, since the object was toproduce a des ign hav ing the smal les t poss ib lephys ica l d imens ions and low we igh t (essent ia lfo r she l l mount ing or mob i le aud io -v isua lpresentation) but retaining a ful l range per-formance, the 8110 was the obvious choice.

To achieve the above requirements I haveused a rather novel method of constructionus ing 6 mm ( | in . ) p ly . The {o l low ing bu i ld inginstruct ions are aimed at those with only amin imum o l woodwork ing equ ipment andexperience. The more {ortunate couldmachine the outer panels from 12 mm ({ in,)ply or veneered chip-board (with a conse-quential increase in weight,) Resin bondedply is almost essential for the outer skin inorder to ensure sound edges, but standardgrade ply can be used {or al l inner members inthe interest of cost and l ightness. l t can alsobe argued that the use of laminations ofdif ferent densit ies wil l improve damping

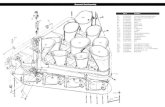

00vELmllfftAI RUR

scflAP vfw v/EBw2

= = - - - W g m S l T i 0 X- - t oowxmflof i

AtrwtBSFRoM 6mm PLYCUTIOSLI

L=,'-cuI crRcuuR H0trs tx &c( 8 m0RIfmMmsurT(t f 8n0 &ls0Rfl i xKE

HI-FI NBWS & RECORD REVIEW NOVEMBER I97E

propert ies, but i f the more wealthy wish to useres in -bonded p ly th roughout they may do so .In e i ther case, on ly PVA adhes ive shou ld beused.

The cons t ruc t iona l techn ique is based onthe bui lding of an inner core f irst, but i t isnecessary to start with both inner and outerfront baff les. This to ensure accurate al ign-ment of the driver cutouts on f inal assemblv.ThereJore proceed as fol lows:(a) Mark outthe pairof outer{ront baff les (19)

fo r the c i rcu la r ho les , cu t ou t and f i le i inecessary, then posit ion (19) on (18) andmark th rough. Cut the ho les in (18) andagain f i le to suit . Re-posit ion (19) on (18)and ins ta l l the 8110 and KK8 then markround the profi les. Cut out and f i le theprofi les, as necessary, f i t (19) and (19)together ancj make sure that the driverscan be instal led with (19) in the correctpos i t ion on (18) .

(b ) When a l l i s we l l , spo t th rough the f i x ingholes in the drivers then open these holeiup with a f, in. dri l l to receive the 2 BAtee-nuts. These wil l be too long for the6 mm p ly so scrap p ieces o f p ly shou ld bedri l led f in, dia, and pressed onto thetee-nuts. ,A dab of two-part epoxy resin(Araldite or similar) should be addedround the protruding stem which can nowbe fed through one of the holes from theins ide o f (18) . When a l l e igh t a re inposit ion on each lront panel, l ighf ly smearround the holes with Vaseline to prevent

accidental adhesion, then clamp thedrivers in place so that the tee-pieces wil lbe in exac ta l ignmentwh i ls t the res in se ts .

(c) Next, careful ly mark out the four innersides (3) and cut the slots for baff les (9)(10) (14) (15) (16) and (20) BUT NoT (12),Make any adjustments necessary toensure easy assembly .

(d) The back (8), front ( '18), top (2), andbot tom (5) inner pane ls shou ld be used asa g lue ing f i x tu re ; these pane ls shou ld besecured by a few panel pins only-NOTGLUED. When a l l i s ready , assemble thebaf f les in s ide pane ls and p in (no t g lue)the sides to the top, bottom, front andback inner pane ls . Make sure tha t a l l i ssquare before applying glue to baff les inthe s lo ts in the s ide pane ls . Concent ra teon good assemblya t th is s tage, us ing on lya min imum of adhes ive . Sea l ing can beaccompl ished la te r and is no t too im-portant in this design anyway. Set asideto dry,

(f) When the inner core assembly has set,remove the front, back, top and bottompane ls . G lue the ang le p ieces (1 .1 ) inp lace and make sea l ing runs oJ adhes iveon both sides ol joints between the sidepanels and internal baff les. Set aside todry'

(g ) Ho les shou ld be dr i l led in ba f f les (10) and(12) and two-co lour l igh t ing f lex cab lespassed th rough and sea led w i th s i l i conerubber (ba th sur round sea lan t ) . G luebaff le (12) in posit ion.

0 25m1, (Ftmllt C0RE0l

(h) Check webs W1, W2, WB (2 off), Wa(2 off), W5 and WO (2 off), in turn for sizeand shape by t ry ing in pos i t ion and whensatisfactory glue the webs to the innercore sub-assembly .

( i) Dri l l the inner (8) and outer (7) back

panels forthe two colour-coded terminals.Do not use recessed terminal panels. Setaside the outer panel and pass inputcab les th rough the ho les in inner back (8 ) ,g lue and p in to the inner core us ing theinner top panel (2) as a sett ing guide.

( j ) G lue and p in the inner top pane l (2 ) to theinner core .

(k ) GIue and p in the inner bo t tom pane l (5 ) tothe inner core and se t sub-assemblv as ideto dry.

( l) Cut inner front panel ( '18) to form oufleto r i f i ce , g lue and p in to sub-assembly .G lue and p in midd le base (6 ) in p lace .

(m) Dr i l l a l l the 6 mm dowel ho les and l igh f lycountersink to provide recess for a r ing ofg lue around each dowel . Take a length o fdowel , pu t a dab oJ PVA adhes ive on oneend and pass i t square ly th rough a dowelhole unti l i t buttons on a web or balTle asthe case may be. Cut the dowel off f lushwi th the inner core pane l and add a r ing o fglue in the recess provided. Repeat foreach dowel and set aside to drv,

(n ) When comple te ly se t , the sub-assemblvshou ld be c leaned up as necessary w i th iSur fo rm (or s im i la r ) b lock p lane. Try a l lthe ou ter pane ls in pos i t ion and ad jus t fo rsize and shape as necessary. They cannow be glued in place start ing with outerback (7 ) th rough wh ich the input w i resmust be th readed. As th is pane l w i l l no tbe veneered, on ly a min imum of p ins ( i fany) shou ld be used. G lue the ou ter f ron t(19) making sure that the recess round theedges is equa l round the top and s ides ,

(o) When the outer back and front havecompletely set remove the drive units andg lue and p in top (1 ) , s ide (4 ) and lowerbase (17) panels in place,

(p) Construct a gri l l f rame from 4 mm (g/16 in.)ramin wood to f i t in the recess at front.The width oJ this ramin str ip wil l dependon individual preference as to whether thecloth is to be f lush with cabinet or is toprotrude sl ightly. Paint the frame mattblack and f ix the cloth with paper staplesto the back edge of the frame, No f ixingdevices should be required but, i f necess-ary, str ips of Velcro can be used in theg roove.

(q) Either bui ld the network from the com-ponents i temised or use an Isophon FWI

PLAIi

lnner case complete Two views of the crossovet Res/stors behind KKa Outer surfaces applied

HI.FI NEWS & RECORD REVIEW NOVEMBER 1978

devised by MauriceTagga rtCLUES ACROSSI (and 2t _down) ls it present only in records in mrnl condition? (6_4)7 The other lth (with i resat sub_titte). (7i-

' - - '-

6 Meros goaboutandtake. in a note, coming upwith Strauss opera, (6)l0 French composer of a celebrated ,'eei"""je;,- ibj'-'l l (see 12 down).

!9 3^":l{t!," seventh desree, we hear, for circuit bypass. (S)rr -ongs ot praise_belonging to the male of the species?

' (S)

l8 Brass and woodwind c jmo' ine f - " ; ; ; ; . '

i i i " - - ' - '?9 !1".t and I set together to produce an insiruinint, (O)* v.edi opera comel back in ine, tat ins in J;e; iy- . ' tb j23 Vetgran British band-teader, sidty a"pfet"Jliif,'e.,ii. t3_+l24 Pedals the electrical perioAi. (Oi

CLUES DOWN

? (ald 5) _Tape recorder component, heard with ease somehow. (E-4)3 Good French lollows the 6ackwaro fiJn"n a"itfi. *itn u fini"h of not"- for member of the brass family. (8)4 Pictures at an exhibition-bv Debirisv? (6)5 (see 2).6 Stop from labour done to music. (7)

.9 . Brief inspection returning in climax-experfly engineered. (4)! | lqa y.across) The ut t imatetransducbr?

-(8_8i" - - '

:: !:]9i:ll" crazv colin.to produce odd An:reriian tube. (7)ro 5nape one way around the melodic uni t . (6)f7 Near around 18th century English compos,jij t+l19 Modern Mexican compoier vjtro is sinfufai'itdi'a quiet start. (b)2l (see I across).

A €3_record,token will be awarded for each of the first five correctsolutions picked from those which a..i"i Ov li""eriier r4trr

LASTMoNTH'swlNNERS:'Mr'BruceDick,westwood,La.mbrookRoad,sheptonBeauchamp,ltminster,somerser. Dr.B.N,Mceuade,4TLatehamRoad'J,i,{"!!i;!li!!!;i{,lliF,?;,/!i:#;,*a-nl::j;,,:;:*e; ii;;";,-H;;.;;;,;i;;i:'f;ir;. M-;",...1;,;,:si;;i,i,oZtiion",

crossover with the two f ixed resistorssoldered to the KKg connections, The2 ohm resistor is connected in series andthe 21 ohm in paral lel. Values are noicri t ical and certainly variat ions within1 ohm in either direct ion should make noaudible dif ference.

(r) Solderthe inputconnections to the cross_over and to the terminals. Solder colour_coded leads to the crossover for the drive_units, f ix the crossover to the slooinobaff le (12). (Alternatively, gtue two block!to web to support network as in thephoto.) Fix the terminals to the cabinetback using epoxy resin, Make sure of al ipolari t ies and that both cabinets aieidentical,

(s) Veneer the-front edges, sides, top andbottom surfaces according to the veneermanufacturers' instruct ions, Finish asrecommended.

(t) S.l ip th.e seal ing gasket over the appropri_ate drive unit cables and soldei ' to theconnections,

_.making sure of polari ty.Lighfly f i l l the de_coupling i tramlerbehind the 8110 with long f iaired wooi(about 2 oz per cabinet) and screw theunits in place.

(u) Fix the front gri l l in place, connect to asuitable system and sit back and enjoy themus ic ,

The f ixed resistors give about 3 dB attenu_ation to the KK8, and whilst more complexnetwork designs give a f latter response curv;and a better impedance characterist ic, theyare.more costly, consume more power and,in th is case, do no t p roduce a be i te r sounJ ,I ne ou tpu t i s about b dB down a t 50 Hz

compared with the 200 Hz f igures, and whilethis can be considered to be very good for thes ize .o f cab ine t (many Ia rger speakers a remuch worse), another very important fact isth.at the output levels out again at this figure.The 42Hz t rack on the JBL,Sess ions ,record, for instance, comes through loud andclear. Because of the cabinet iesign, ihe

bass control of an ampli f ier can be used to l i f tthe output at these frequencies to produce avery clean, deep bass with excel lent transientresponse.

The speakers are reasonably eff icient butcan withstand considerable inputs to giveclean outputs well above 90 dB in an auer-agelistening room. O

Part List (per speaker)

t Outer top2 Inner top3 Inner s ide4 Outer side5 Inner base6 Middle base7 Outer back8 Inner backI Top bame

l0 Rear bafflel l Angle support

12 Angle bafflel3 Crossover14 Baffle15 Bafflel6 Baffle17 Lower base

213x244 mm213x220436x220 mm460x244 mm1232x201 mm226x213 mm460x225 mm448x213 mm213x87 mm213x213 mm160 mm x45"

W2 fromW3 fromW4 from

240x200 1 off200x70mm 2ofr220x50 mm 2 of f

1 o f f1 o f f2o f r2o f f1 o f f

off

off

off

off

off

2of rto suit1 o f i

t8 Inner front bafile 442x219 mm 1 off19 Outerf rontbaf f le g90x200mm I of f20 Horizontal baffle 201 x 70 mm 1 off2I KEF B11O22 lsophon kk8Outer members are resin-bonded 6 mm ply.All inners are standard 6 mm ply.Wl 1A0xS5 mm 1 of f

201 x115 mm

213 x 170 mm 1 of f213x180 mm 1 of f213x180 mm 1 of l246x213 mm 1 of f

W5 220x40 mm 1 offW6 22Ox4O mm 2 offDowel 6 mmx2 m (per pair )PVA adhesive 1 pint (per pair)Veneer (top and sides only) 8 ft x 1 ft

(2 standard 4 ftxl ft sheets)Note: We believe that Badoer Sound Seruices of 46 Woo! Street, Lytham St, Annes, Lancashirc arcIookins into the possibitity-of supptyins *ii

"iin"'pLlri" i.i this project.

HI-FI NEWS & RECORD REYIEW NOVEMBER 1978

![Two-way standmount loudspeaker Made by: Sonus faber SpA ... · Aida [HFN Apr ’12], Lilium [HFN Jun ’15] and particularly ‘Il Cremonese’ [HFN Aug ’16], and the revamping](https://static.fdocuments.us/doc/165x107/5f60376dbd71ed04124f3d4f/two-way-standmount-loudspeaker-made-by-sonus-faber-spa-aida-hfn-apr-a12.jpg)