At Sche dule: 3 (a), Cenvironmentclearance.nic.in/writereaddata/Online/TOR/01...2.Mr.Sanjay Agrawal...

Transcript of At Sche dule: 3 (a), Cenvironmentclearance.nic.in/writereaddata/Online/TOR/01...2.Mr.Sanjay Agrawal...

AProposed 0.2At Village – Dist-Kendujh

27 MTPA Iron Raika, P.O-Shar, State – O

M/s N

UG-

Ema

n Ore Pellet Serenda, P.S-Odisha,

Sche

Narayan

1, JagaNagCo

ail ID –

Plant -Barbil,

edule: 3

ni PelletRegi

t Chamgpur- 4ontact -carouna

At

3 (a), C

By:ts and Aistered Ober, Ne40008.M+91-86akagraw

Categor

:- Alloy PrOffice ear AmbMahara6687628wal@re

ry: A

rivate Li

bedkar Sastra 848, diffmai

imited

Squre

il.com

Page 1

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 2

INDEX

Chapter Tittle Page no

Chapter – 1 Executive summary 3 - 10

Chapter – 2 Introduction of the project 11 - 14

Chapter – 3 Project description 15 – 22

Chapter – 4 Site analysis 23 – 24

Chapter – 5 Planning brief 25 – 26

Chapter – 6 Proposed structure 27

Chapter – 7 Rehabilitation & resettlement 28

Chapter – 8 Project schedule & cost estimates 29

Chapter – 9 Analysis proposal 30-31

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 3

CHAPTER – I

EXECUTIVE SUMMARY

1.0 Introduction

PREAMBLE

Steel being a basic commodity for all industrial activities, quantum of its consumption is considered an index of industrial prosperity. Since independence, there has been a substantial growth in the steel sector in India from 1.5 Million ton in 1950-51 to about 50 Million ton at present. Additional steelmaking capacity of about 8 to 10 Mt/Yr exists in the secondary steel sector. Despite the above growth in the steel sector, the per capita steel consumption continues to remain at a level of about 40 Kg only, compared to about 350 to 450 Kg in the developed countries and 60 to 100 Kg in some of the developing countries. Further, with nearly 20% of the world population, India’s contribution is only of the order of around 4% of world steel production. Hence, shortterm and long-term strategies are necessary in planning the development of the steel industry in the country to improve the level of per capita steel consumption.

India’s steel story looks enticing, as the country is close to a demand inflexion point that promises to convert it into a key player on the world stage, both as a producer and a consumer. Infrastructure, construction, urbanization, the automobile industry and corporate capex programme are likely to be some of the key growth areas for the sector. As a norm, for developing economies like India, demand for steel consumption grows at about 1.3 times of GDP growth rate. This means that if the economy is to grow over 7% p.a. for the next few years, steel consumption has to grow over 9% p.a. Iron and steel are production in the country from both the integrated steel sector and the secondary steel sector. While the primary sector consist of those plants which have capacities of 1.0 Mt/Yr and above are fully integrated, beginning with iron ore as metallic input and finishing with rolled products, the secondary sector consists of mini steel plants which have capacities less than 1.0 Mt/Yr and are based on electric arc furnace (EAF) or induction furnace (IF) as the primary melting unit and iron ore/DRI/ steel scrap/ pig iron as metallic input. The units in the secondary steel sector starting with iron ore as metallic input and having facilities for production semi-finished/ finished products may be called integrated mini steel plant. The Concept of mini steel plants for the manufacture of common variety of steels and special steel became predominant in the sixties and seventies, mainly due to the long gestation period and the huge capital outlay required for establishment of integrated steel plants.

With the opening up of the steel sector, changes in the management and operations of steel plants have become a necessity. The need for cost- effective operations for maintaining its competitive edge in both the domestic and international markets has been re-emphasized. Use of low cost metallic like iron ore fines to generate iron for production of steel is one such step to remain competitive.

India enjoys certain natural advantages which lends it a competitive edge to emerge as a location of choice for steel manufacture. Some of the key advantages can be summarized as:-

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 4

Access to high quality iron ore. Competitive labour costs. Skilled labour force with mining and steel making experience. High domestic growth drivers and low per capita consumption. Proximity to key consuming markets and coastal location.

IRON ORE India has abundant deposits of high quality iron ore, particularly along the eastern region of the country. Of its 17 bn MT of iron ore reserves, one of the largest in the world, a large part (about 75%) is high grade hematite, with an iron content of more than 63%. This is a major reason why the country is emerging as a prime destination of fresh steel capacity addition. The reserves are largely located in Orissa, Jharkhand, and Chhattisgarh in the eastern and central parts of the country. COAL As per Geological Survey of India estimates, India has coal reserves of 245 bn MT. However, a majority of these deposits comprise of the non-coking coal variety (thermal coal), whereas coking coal reserves are only around 32 bn MT, or 13%. What it implies is that while for primary steel production India has to rely on imported coking coal, abundant non-coking coal reserves make it an ideal place for the secondary route of steel making (the sponge iron route). LOWER LABOUR COSTS Other than natural endowments of raw material resources, India enjoys lower labour costs vis-à-vis major steel producing countries in the developed world. Also, with an almost century-old legacy of iron and steel making and a strong technical pool of population, there is an abundance of skilled workforce and an inherent experience in iron and steel making. LARGEST PRODUCER OF SPONGE IRON IN THE WORLD As mentioned above, due to abundance of iron ore and non-coking coal, India has emerged as the world’s largest producer of coal-based sponge iron, technically known as DRI (direct reduced iron). Sponge iron is a substitute for scrap and one of the lowest cost metaliks for steel production through the secondary route. In CY05, Indian sponge iron production at 10.6 mn MT accounted for about 19% of global production share of 56.2 mn MT. Some of the integrated coal-based sponge iron producers in the country have emerged as the lowest cost producers of sponge iron globally due to inherent cost advantages and backward linkages with abundant reserves of high quality iron ore and steam coal, competitive labour costs, high domestic demand growth drivers, and proximity to key consuming markets of Asia, India is well poised to emerge as a key producer and consumer of steel. This has led to large capacity expansion projects being pursued – both by existing domestic producers as well as several large international majors. TECHNOLOGIES CONVERTING WASTE TO PRIME - TO BENEFIT THE MOST In a scenario where raw material prices have gone up substantially over the past few years due to global tightness, vertically integrated players with technology adopted to use abundantly available

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 5

inferior grade raw material will benefit the most. In the metal value chain, the producer converting waste to prime, capture the largest chunk of value. Besides value maximization, in an anticipated tight supply scenario, sourcing of the raw material itself becomes easier to purchase due to lower demand of such material.

Considering the potential demand in India. M/s Narayani Pellets Private Limited., decided install the facility for the production of 0.27 MTPA Iron Ore Pellet at Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar (Odisha).

1 Name of the Company M/s Narayani Pellets Private Limited.

2 Registered Office Plant & Admin Office

At Plot No – 5/138, 7,6 Village-Raika, P.O. – Serenda, P.S – Barbil, Dist: Kendujhar, State : Odisha Corporate Office : UG-1, Jagat Chamber Near Ambedkar Squre Nagpur- 440008. Maharastra

3 Name of the Directors

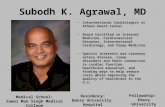

1.Mr.Birendra Kumar Yaduka 2.Mr.Sanjay Agrawal 3.Mr Rohit Goyal 4.Mr Abhisek Agrawal

4 Proposed Sector Primary Metallurgical Industry

5 Area of plant 4.69 Acre (1.89Hec)

6 Topo Sheet No 73F8

7 Project Site Co-ordinates

Latitude Longitude 22°4'22.90"N 85°25'14.06"E22°4'23.10"N 85°25'17.61"E22°4'15.58"N 85°25'18.56"E22°4'15.16"N 85°25'20.56"E

8 Proposed Units & Total Capacity

Production of Iron Ore Pellet Capacity = 0.27 MTPA

10 Cost of Project Rs.1600 Lakhs

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 6

1.2 Identification of Project and Project Proponent M/s Narayani Pellets Private Limited., decided install the facility for the production of 0.27 MTPA Iron Ore Pellet at Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar (Odisha). Project Promoters: M/s. Narayani Pellets Private Limited is promoted by,

Mr.Birendra Kumar Yaduka Mr.Sanjay Agrawal Mr Rohit Goyal Mr Abhisek Agrawal

1.3 Employment Generation – Manpower During Construction Phase:-

Total 100 local workers required for the construction of the project for the duration of six months.

During Operation Phase:-

Around 25 persons who will include Supervisors and Skilled and unskilled work force.

1.4 Project Description M/s Narayani Pellets Private Limited., decided install the facility for the production of 0.27 MTPA Iron Ore Pellet at Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar (Odisha). & for this the company has already acquired around 4.69 Acre( 1.89 Hec) of land & the estimation cost of project will be Rs.1600 Lacs.

Staff S.No Designation No’s

1 Supervisor 03 2 Manager 01

Workmen S.No Designation No’s

1 Operator 03 2 Skilled Workmen 06

Total 25

S.No Unit Capacity

1 Iron Ore Pellets 0.27 MTPA

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 7

1.5 Site Location

The manufacturing location is proposed at Plot No 5/138, 7, 6, In village- Raika, P.O - Serenda, P.S - Barbil, Dist. Kendujhar (Odisha). Land required for the proposed Project is 4.69 Acre (including 33% green belt) Narayani Minerals pellet has already acquired land. The availability of labour is not an issue at all. The land is a rectangular plot with almost completely leveled and not much leveling work is required. The promoters have taken this decision to locate the manufacturing facility at Raika) after considering the various factors necessary to make it commercially success.

1.6 Raw Material Requirement & Source.

Major raw material constitutes are Iron Ore, Bentonite/molasis/resine, Lime Stone/Dolomite, Coke breeze, F.O & Coal 1.6.1 Raw material specifications & quantity: Iron Ore : Specific Consumption @ 1.1

Fe (T) 62.00%min FeO 1.00%max SiO2+Al2O3 1.00%max S 0.01%max P 0.04%max CaO & MgO 3.00%max LOI 3.50%max Size 0-5 mm Moisture 8% max Qty 99,000 MT per annum

Bentonite/molasis/resine: Specific Consumption @ .01

SiO2 66.70% Al2O3 28.30%

CaO 1.50%

MgO 3.50%

H2O 5.00%

Qty 900 MT per annum.

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 8

Lime Stone/Dolomite: Specific Consumption @ 0.05

CaO 50.0%min MgO 3.0%min SiO2 5.0%max Al2O3 1.5%max Qty 450 MT per annum

Coke breeze: Specific Consumption @ 0.0075

Moisture 5%max Ash 15%max Fixed Carbon 80%min S 0.6%max Qty 675 MT per annum

Coal : Specific Consumption: 0.055 @ GCV OF COAL IS 5000

Moisture 09%max Ash 20%max VM 10%max Fixed Carbon 60%min S 1%max Qty 4950 MT per annum.

1.6.2 Source Raw material availability is not a constraint & easily available in the local mines of the Odisha & Jharkhand 1.7 Water and Power Requirement The water consumption for the plant is about 4 KL per day. The incoming Iron ore fines contain 7-8% moisture so in pelletizing additional 1-2% water is require for summer season & source of the water tanker will be private tanker only during the operation phase because water consumption is very less which is required only for the drying the ore.

The construction power is estimated around 300 KVA. This power will be made available from existing 11KV system, from the nearest substation of electrical grid. Alternatively diesel operated equipment/DG sets will be arranged by erection contractors during installation of the plant. The maximum demand for the plant is 300KVA.

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 9

1.8 Waste Generation and Management No waste water will be generated during the process. Hazardous waste: There is no hazardous waste from the plant except for used oil with approx quantity of 200 Liters per annum, during course of production of and is also saleable to the registered recyclers in the market.

1.10 Site Analysis The site is within notified Industrial Area and has all the facilities for the proposed project. Also it has good connectivity with the rail and road.

1. Road Connectivity: The site for the proposed project is well connected to National

Highway-215 which is at 3.12 KM towards South. 2. Rail Connectivity: The nearest railway station is Deojhar railway station at 5.65 Km towards

west direction and Barabil railway station at a distance of 6.16 km from the proposed project site.

3. Airport: Nearest airport to the project site is Sonari Airport, Jamshedpur at distance of 112 KM towards North-West direction from the project site.

4. Approach Road: Durgapur-Purulia-Raghunathpur road (12mtr wide) is at distance of 150mtr towards south direction.

1.11 Proposed Infrastructure

a) Industrial - Plant Area

The setting up of the Main Plant Facilities, Storage, Auxiliary facilities, etc. requires 4.69 Acre (1.89 Hec) & company will use nearest road for materials transportation and manpower connectivity.

b) Green Belt & Plantation A greenbelt & plantation development plan will be prepared and implemented along with the project Total area shall 1.54 Acres which is 33% of the total area. The main objective of the greenbelt is to provide a barrier between the plant and the surrounding areas.

c) Rehabilitation and Resettlements (R & R) Plan

No R & R involved. Land is already acquired.

1.12 Project Schedule and Cost Estimates a) Project Schedule

The total project implementation schedule is six months from project start date. The external

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 10

agencies such as consultant, machinery suppliers, contractors of civil construction and equipment will be selected carefully well in advance.

b) Project Cost

An indicative estimated capital cost of the proposed Plant is around Rs. 1600 Lakh.

1.13 Analysis of Proposal The project is technically viable as located near by the roads & highway. Also there are existing facilities which will be used by the project. Overall no negative impact on the socio economic environment is anticipated.

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 11

CHAPTER – 02

INTRODUCTION OF THE PROJECT/BACKGROUND INFORMATION 2.1 Identification of Project and Project Proponent

M/s. Narayani Pellets Private Limited is a company registered under the indian companies act with the registrar of companies, mumbai. The company came into existence on 3rd day of september 2003, and is having its registered address of business at shop no 10 gayatrilok apts ambedkar chowk. The main object of the company is manufacturing of iron ore pellets. The plan to setup 0.27 MTPA per annum of iron ore pellets on a 300 days production year assumption at plot no 5/138, 7, 6, in village- Raika, PO - Serenda, PS - Barbil, Dist. Kendujhar (Odisha).

Project Proponent & Promoters: M/s. Narayani Pellets Private Limited has been promoted by following Directors:

1.Mr.Birendra Kumar Yaduka 2.Mr.Sanjay Agrawal 3.Mr Rohit Goyal 4.Mr Abhisek Agrawal

The Promoter of Narayani Pellets Private Limited are from business communities. The Promoter are very well experienced and established. Shri Sanjay Memraj Agrawal He is aged about 48 Years. He has completed his Bachelor of Commerce and has also completed Bachelor in Law. He had started the business of Transport in the year 1992 in the name of M/s Sheetal Carrying Corporation which is running successfully till date. Simultaneously he started the business of trading in Steel Plates in 1999 which was carried on by him till 2002. In the Year 2003 he ventured in the business of trading of Iron Ore from Orissa to various parts of the country and subsequently installed Crushing Unit in the same year. The company had good profitability in both the ventures but in the year 2011 Orissa Government Banned the Crushers and did not renew their licenses. This had resulted in discontinuation of the Orissa Operations of the company and the promoter But the Orissa government has in May 2015 lifted the ban. He is thus having vast experience in the activities pertaining to Steel, Iron Ore, and Transportation and Mining (including crushing). Shri Shubham Sanjay Agrawal He is aged about 23 years and is a pursuing his Masters in Business Administration. He has been assisting to his father in his businesses since last few years. He is looking after day to day operations

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 12

of the company and has special thrust in the management of financial and legal matters. He is also looking after the marketing team of the company. Both the promoters having wide experience in the steel industry business. The Promoters belong to a well established business family of Sheetal Group.

2.1.1 Project Details

M/s. Narayani Pellets Private Limited is a company registered under the indian companies act with the registrar of companies, mumbai. The company came into existence on 3rd day of september 2003, and is having its registered address of business at shop no 10 gayatrilok apts ambedkar chowk. The main object of the company is manufacturing of iron ore pellets. The plan to setup 0.27 MTPA per annum of iron ore pellets on a 300 days production year assumption at plot no 5/138, 7, 6, in village- Raika, PO - Serenda, PS - Barbil, Dist. Kendujhar (Odisha).

2.2 Brief Description of Nature of the project

It is category A project under primary metallurgical unit, as per EIA Notification 2006 and require prior environmental clearance from MoEF & CC.

Iron ore pellete is being used for manufacturing of Alloy Steel, Super Steel, Tool Steel such as tensile, elongation etc. and for manufacturing of Corros ion Resistant and Abrasion Resistant steel.

2.3 Need of the Project and its Importance to the Country and/or Region

The project objective is to upgrade the abundant iron ore fines stored at the mine heads through Pelletization Process and make it fit for use in DRI Kiln/ Blast Furnace, thus preventing the loss of revenue our country is losing by selling these low grade iron as ore reject materials. Higher percentage of Iron Ore Reserves in the country comprises of fines and lumps. These Iron ore fines/lumps cannot be directly used for steel making. These precious material resources (fines) are being dumped in Export market in nominal prices. In order to preserve this precious iron ore , Beneficiation and its onward Pelletization is most sought after agglomeration process than sintering process in view of higher productivity, energy consumption and eco-friendly manufacturing process. The Ministry of Environment and Forest also encourages for establishment of Iron Ore Pelletization plant to utilize the huge stock pile of iron ore fines. The Pelletization of iron ore fines, which remain unutilized in most of the time or exported at nominal prices is definitely helping the State/Nation in value addition and also increases the resources of iron ore reserves including earning of additional revenues from mineral for the State/Nation. Required grade of Iron Ore and better grade Iron Ore pellet will be available to DRI plants of the region which are at the edge of shut-down due to non-availability of required grade of iron ore as well as quantity. Looking at the projection of demand for Steel in the present market, it can be realized that there is a considerable demand of Pellet in the steel making industries. To meet the demand, new industries have to be installed. Hence, the existing Pelletization Plant by M/s Narayani Pellets Pvt Ltdis of great significance under present scenario.

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 13

2.4 Demand – Supply Gap With reference to the National Steel Policy 2012 and as per Mineral Conservation and Development Rules 1988, Government is facilitating for installation of Iron Ore Pelletization Plant for Iron Ore fines which is stocked abundantly in all the mines for pellet making. The reason behind it, is to extract all the mineral contents of the Iron ore for utilization in steel making as a step towards mineral conservation and simultaneously reduce the accumulated iron ore fines stored in all the mines As per National Steel Policy 2012, India is having a total resource of 28 Billion Tonnes of High grade Iron Ore taking cut-off grade of Iron Ore is having 50% Fe and the fact that the figure can rise with greater efforts towards exploration. The currently assessed reserved of Iron Ore seem inadequate for a long period if the steel industry capacity expansion and production potential are to be fully realized. Therefore, best utilization of the mineral resources (in this case ‘Iron Ore’) is required. Whatever the mineral constituent present in the ore need to be extracted from the ore for best utilization of the ore, Beneficiation and Pelletization are two such processes by which the iron ore reject and low grade Iron ore can be made ready for steel making purpose. For long term supply of iron ore to the steel manufacturers with the increasing demand of Steel & simultaneously to reduce the demand and supply gap of the iron ore in the present scenario following steps are being taken by the Government. Government is enhancing its support for intensive R & D efforts for developing techno-economically viable technologies of Beneficiation and Agglomeration suitable for the mineral extracted from different iron ore regions of the country. The Government is taking appropriate fiscal measures, whenever deemed necessary to encourage beneficiation and agglomeration with special emphasis on manufacture of pellets to substitute consumption of precious lump ores by steel producers and thereby add to efforts of conservation and environmental degradation caused by accumulation of iron ore fines. The Government bringing different schemes to encourage investment in beneficiation depending on the ownership of the Iron Ore, such as those coming from captive mines and those bought out from the market. Mineral Conservation & Development Rules1988 is a step towards MineralConservation and waste reduction. As per Mineral Conservation & Development Rules’ 1988, and increasing global demand, the iron ores fines are to be upgraded through Pelletization for DRI / BF usage. The targeted demand of the steel sector can be fulfilled in this way and the Iron Ore can be utilized rather than stored as a waste. The prevailing demand and consumption rate of mineral resources indicates that it will come to an end in near future. So best utilization of all mineral resources need to be done. High grade and low grade mineral fines need to be utilized for the purpose. The Iron Ore Processing Industries and Steel making industries have started adopting various modern technology for utilization of low grade mineral/ mineral reject for the purpose of steel making. Demand of Beneficiation and Pelletization process is increasing each year in Indian market and also in global market. The pellet market consists of a small group of sellers controlling a majority of pellet capacity worldwide. Long term contracts for supply of pellets are the norm in the Industry. Some of the largest pellet manufacturers are from Latin America and Sweden. The market leader in the industry is CVRD (Brazil), whose prices are generally considered as benchmark price for pellets.

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 14

Percentage use of pellets in various blast furnaces in the world varies from 10% to 100%. Considering specific consumption of iron bearing raw materials in blast furnaces as 1.55 ton per ton of hot metal and replacement of iron ore & sinter by pellets on all India basis was 7.5% during 2004-05, 10% during 2006-07, and 20% during 2011-12. Existing all India capacity of Pellet production is 30-36 Million Tonne /Annum and it is likely to go up to 50 Million Tonne in another one or two years. India is targeting pellet capacity of 80 Million Tonne by 2015-16. As per the National Steel Policy 2012, the Department of Steel, Government of India has projected production of 300 MT of Steel by the year 2025-26. On the basis of 30% replacement of Calibrated Lump Ore (i.e. CLO) by pellet on minimum side, the requirement of pellet would be 51 MTPA against the present installed capacity of about 30-36 MT. Besides, the sponge iron plants in the country which are in verge of closure due to non-availability of requisite CLO both in quantity and quality will consume more than 60% of the pellet in the mix. Presently more than 400 Sponge Iron units are there in the country. During 2008-09, about 250 Sponge Iron plants were operating in the country and the production was about 20 MT. Assuming only 400 units will be in operation up to 2020 (Government does not encourage the establishment of more sponge iron units as these units are one of the major contributor of pollution) then these 400 units can produce about 30 MT of Sponge Iron and will require additional 20 MT and more of pellet. So our iron ore pellet making is a supportive step to fulfil the iron ore demand of our country. 2.5 Export Possibility and Domestic/Export Market Generally, Iron ore rejects/sub grade ore are exported at nominal price. If it will be export after required up gradation then more revenue can be obtained which will help to improve the economy of our country.In the export market, the present & future DRI / HBI producers in South-East Asia and the Middle East / North African Region are the potential destinations for the Indian Pellets. Supplies from Brazil and Sweden are meeting the present Middle East/ north Africa DR pellet requirement. With transport cost being a competitive factor, Paradeep proximity to South-East Asia and Middle East/ North Africa would definitely give advantage to Indian pellet market over the suppliers from Brazil, North America & Sweden.Due to higher cost of quality raw materials, countries like China are looking to import Iron Ore pellets, considering the techno-economic advantages using pellets for hot metal production. India produces about 65 MT of Steel /year, yet with a population of 1.15 billion, its per capita consumption is just 40 Kg / year compared to a global average of 150 Kg/year. Government is evaluating every plan to encourage this consumption level higher, which is making a very natural impact on demand of steel with the supports from growing middle class and massive long term infrastructure investment plans. Invariably we may say that the potential of processed iron ore or pellets are huge. India's Ministry of Steel is preparing a policy document on the infrastructure that will be required by an industry capable of producing as much as 300 MT of Steel per year - illustrating the long term goal. Considering the huge Demand & Supply pattern, the future of the existing Pelletization plant is encouraging. 2.6 Employment Generation (Direct and Indirect) Due to the Project. Around 25 persons who will include Supervisors and Skilled and unskilled work force.

PropoAt VillDist-K

3.1 TyThe PLime

It is aMoEF

3.2 LThe P.O -3.12 K

osed 0.27 MTlage – Raika,

Kendujhar, St

ype of ProjProject invoStone/Dolo

a Category F & CC. Pro

ocation manufactur

- Serenda, PKM (approx

TPA Iron Ore , P.O-Serendtate – Odisha

ject Includolves produomite, Coke

A project aoject is not

ring locatioP.S - Barbilx) from the

Fig 1: Go

Pellet Plant da, P.S-Barbia,

PROJ

ing Interlinuction of iroe breeze, Co

as per EIA interlinked

on is propl, Dist. KenNational H

oogle Image

il,

CHAPTERJECT DESC

nked & Inton ore pelleoal

Notificationand interde

posed at Pndujhar (Odighway - 21

e of project

R - 3 CRIPTION

terdependeets using ir

n and requiependent.

Plot No 5/disha). This15. No addi

t Site (500

N

ent Projectson ore, Ben

ires Environ

/138, 7, 6s land is sititional land

meter Rad

s ntonite/mol

nment Clea

6, In villagtuated at a dwill be acqu

dius)

Page 15

lasis/resine,

rance from

ge- Raika, distance of uired.

f

AProposed 0.2At Village – Dist-Kendujh

F

3.2.2 Plan

The layout Proc

serv Suff Gre

27 MTPA Iron Raika, P.O-Shar, State – O

Fig 2: Topo

nt Layout

of the plant

cess will bvice facilitiefficient spaceen belt, plan

n Ore Pellet Serenda, P.S-Odisha,

osheet Show

t will be dev

e consolidaes available e for storagntation, RW

Plant -Barbil,

wing Proje

veloped tak

ated into cofor the exis

ge of raw maWH & space

ct Site & 10

king into fol

omprehensivsting unit waterials ande for pollutio

0km Area

lowing con

ve productiwill be used.d finished pron control f

Around th

siderations:

ion units. T

roducts. facilities wi

P

he Site

:

The major u

ll be provid

Page 16

utilities and

ded

d

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 17

Layout Plan

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 18

3.3 Site Selection The selection of project site/location has been based on the factors as given below:-

Availability of adequate flat land for the proposed plant and its rational future expansion.

Proximity to raw materials.

Proximity to finished goods market.

Existence of road connection in the vicinity for transportation of incoming & Outgoing materials.

Availability of industrial infrastructure facilities, e.g. power, water & skilled personnel.

3.4 Size or Magnitude of Operation Total manufacturing of Iron Ore Pellets will be approx. 0.27 MTPA for which they have acquired the 4.69 Acre (1.89 Hec) land.

3.6 PROCESS DETAILS Three process stages are involved to produce pellets from raw materials: Raw material preparation Formation of green pellets In duration of green pellets

Stage 1: Raw Material Preparation

Dry Grinding Vs Wet Grinding of Iron Ore Fines

SL No. Parameters Wet Grinding Dry Grinding

1 Production Cost Grinding cost Rs.275-325/ton of IOF

Grinding cost Rs.450-500/ton of IOF due to higher consumption of fuel & electricity.

2 Grinding of Additives

Separate grinding facility for additives

All raw materials like IOF ,Limestone & Coal can be grounded together

3 Grinding media consumption

1-1.2kg/t of IOF 0.03-0.05 Kg/t of IOF

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 19

4 Filtration Required to bring down moisture to 9%

Thickening & Filtration not required

5 Eletrical energy consumption

16-17 kwh/t of pellet 20-22kwh/t of pellet

6 Pollution Hazards

Nil dust hazard Requirement of extensive pollution control measure to counter dust nuisance

7 Capital cost Lower than dry

Stage 2: Formation of Green Pellets Purpose of green ball formation

Stage 3: In duration of Green Pellets Green pellets have low mechanical strength – hence need for hardening for further process Method for hardening pellets is In duration in which pellets are heated to 1300-1350°C in controlled manner. Travelling Grate Vs Grate Kiln S.No Items Travelling Grate Grate Kiln

1 Heat hardening

cycle

Drying, preheating, in duration and cooling are done on a single grate

Drying and preheating on a grate, in duration in rotary kiln and cooling in

annular cooler

2 Grate bars Grate bars subjected to high temperature; side & bed layers necessary

No side or bed layers necessary Bed depth is nearly half

3 Pellet movement Pellet remains stationary throughout the process

Pellets tumble continuously in

rotary kiln

4 Burners Large number of burners along the length of In duration furnace.

Single burner is used in for the

kiln.

5 Fans Several fans operating in series with multiple fan

Less number of fans with single

“The purpose of the green ball formation is to obtain pellets of the desired size range ( 9 -16mm) and having a mechanical strength which enable them to be safely transported from the balling equipment to the in duration machine.”

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 20

controls. fan control.

6 No. of Passes Multiplicity of passes Grate generally of two pass

design

7 Pellet grades Both BF & DR grades Both BF & DR grades

8 Largest Machine 768m2 (CVRD) and 744m2

(Samarco) with Capacity of 6MTPA

each.

LKAB-3, GIIC-Bahrain &

Tildon-2 with capacity of 4

MTPA each.

Details of Plant and Machinery The project to produce 86 Tonnes of briquettes per day require machine with focus to adapt latest technology with ease for maintenance. The complete line plant of machinery consisting of Screw Conveyer, Hopper and Hydraulic Pressure Chamber are made by reputed companies in India with decades of experience in making such machineries. The Firm proposes to purchase two machines from “Jay Khodiyar Machines Tools, Rajkot, Gujrat,”. The manufacturer is old and world class player in this industry and successfully implemented so many Briquettes manufacturing units all over the World. 3.6 Safety Envisaged In the Project Fire Protection Facilities: In order to combat any occurrence of fire in plant premises the following tire protection facilities have been envisaged for the various units of the plant.

Portable Fire Extinguishers: All plant units, office buildings, stores, laboratories etc will be provided with adequate number of portable fire extinguishers to be used as first aid fire appliances. The distribution and selection of extinguishers will be done in accordance with the requirement of IS: 2130-92.

Hydrant System: Internal hydrants will be provided at suitable locations and at different levels inside the major plant units. Yard hydrants will be provided normally along the road and in the close vicinity of the units to meet the additional requirement of water for existing fire.

3.8 Resource Optimisation 3.8.1 Water Requirement Total water requirement for the project will be approx. 4KL/day which will be meet through the private tanker on the daily basis from the local vendor.

3.8.2 Power Requirement The construction power is estimated around 300KVA. This power will be made available from existing 11KV system, from the nearest substation of electrical grid. Alternatively diesel operated equipment/DG sets will be arranged by erection contractors during installation of the plant. The maximum demand for the plant is 300KVA.

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 21

3.9 Quantity of Wastes to Be Generated (Liquid and Solid) and Scheme for Their Management/Disposal

3.9.1 Air Environment – Mitigation Measures

Sources of air pollution and control measures

Section Source of Pollution

Pollutants Air pollution control Measures

Raw material handling & sizing section

Pulverizer for grinding of raw material

Dust and particulate matter

Dust catcher and Bag filter

Over all Plant area

Open space Fugitive dust emission

Pucca roads within the premises, water sprinkling in dusty areas and green belt/plantation to arrest the fugitive dust emission.

The pollution control equipments will regularly be operated and maintained.

Fugitive emission will be regularly monitored and suitable action like cleaning, water sprinkling will be taken.

3.9.2 Waste water Generation and Management No water generated during the manufacturing of the iron ore pellets 3.9.3 Hazardous waste: There is no hazardous waste from the plant except for used oil with approx quantity of 200 Liters per annum, during course of production of and is also saleable to the registered recyclers in the market. 3.9.4 Noise Levels There is no major noise prone process except equipment for crushing, milling, separators,

compressors etc. The noise control will be done in three ways namely: By selecting low noise generating equipment, which would have below 75 dBA at 1m

distance. This is taken care at the equipment design stage. By isolating the noise unit from the working personnel’s continuous exposure by providing

acoustic aids for plant personnel. By administrative & safety measures, providing noise level monitoring, remedial measures,

providing noise safety appliances. 3.9.5 Green Belt Development The Greenbelt & plantation will be developed in 1.54 Acre (0.623 Hec) of plant area so as to mitigate the effects of emissions from the plant. The treated waste water from the plant will be

AProposed 0.2At Village – Dist-Kendujh

utilized formitigation m

3.10 SchPur

Environmenachieving th

27 MTPA Iron Raika, P.O-Shar, State – O

r the greenbmeasures w

hematic Reprpose.

nt Impact he sustainab

n Ore Pellet Serenda, P.S-Odisha,

belt developwill be provi

presentatio

Assessmenble develop

Plant -Barbil,

pment. Roaded to prev

ons of the F

nt and Envpment of the

ds for vehivent fugitive

Feasibility

vironment Me project. Th

cular movee emissions.

Drawing W

Managemenhe process i

ement will b.

Which Giv

nt Plan is s depicted b

P

be paved an

e Informat

an importbelow:

Page 22

nd adequate

tion of EIA

tant tool in

e

A

n

AProposed 0.2At Village – Dist-Kendujh

ConnectiviThe site is has good co

1. Roa

Hig2. Rai

wessite.

27 MTPA Iron Raika, P.O-Shar, State – O

ity within noti

onnectivity

ad Connecghway-215 wil Connectivst direction .

n Ore Pellet Serenda, P.S-Odisha,

ified Industwith the rai

ctivity: Thewhich is at 3vity: The neand Barabil

Plant -Barbil,

C

SIT

trial Area anil and road.

e site for 3.12 KM toearest railwl railway sta

HAPTER-

TE ANALY

nd has all t

the proposowards Soutway station i

ation at a d

-04

YSIS

the facilities

sed projectth. is Deojhar ristance of 6

s for the pr

t is well c

railway stati6.16 km from

P

oposed proj

connected t

ion at 5.65 Km the propo

Page 23

ject. Also i

to Nationa

Km towardsosed projec

it

al

s ct

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 24

3. Airport: Nearest airport to the project site is Sonari Airport, Jamshedpur at distance of 112 KM towards North-West direction from the project site.

4. Approach Road: Durgapur-Purulia-Raghunathpur road (12mtr wide) is at distance of 150mtr towards south direction.

4.1 Land Form, Land Use and Land Ownership

Total land requirement for the proposed unit is about 4.69 acres (1.89 Hec) which already has been purchased.

4.2 Existing Land Use Pattern

Total land requirement for the proposed unit is about 4.69Acre (1.89 Hec) which already has purchased. The present land use is industrial.

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 25

CHAPTER – 05 PLANNING BRIEF

5.1 Planning Concept

M/s. Narayani Pellets Private Limited is a company registered under the indian companies act with the registrar of companies, mumbai. The company came into existence on 3rd day of september 2003, and is having its registered address of business at shop no 10 gayatrilok apts ambedkar chowk. The main object of the company is manufacturing of iron ore pellets. The plan to setup 0.27 MTPA per annum of iron ore pellets on a 300 days production year assumption at plot no 5/138, 7, 6, in village- Raika, PO - Serenda, PS - Barbil, Dist. Kendujhar (Odisha).

5.2 Employment & Population Projection Around 25 persons who will include Supervisors and Skilled and unskilled work force.

5.4 Assessment of Infrastructure Demand (Physical & Social) The existing infrastructure facility is adequate in the proposed project site. The social infrastructure like school, college, temples and playground already exist in this area. The above infrastructure facilities need no further development for the project nor is any major change in the infrastructure envisaged due to the project.

System Design for high Unit availability The high availability of the Unit and associated auxiliaries objectives will be achieved by

adopting the following principles; Use of equipment and systems of design performance and high availability which has been

fully established by a considerable record of successful operation for similar service conditions in coal fired utility stations.

Use of only proven design concepts and conservative designs.

Strict implementation of quality assurance norms during design, manufacture as well as installation and commissioning stage.

Strict compliance with the project company approved pre-commissioning and commissioning procedures as well as standard checklists forming a part of commissioning documents for the project.

Staff S.No Designation No’s

1 Supervisor 03 2 Manager 01

Workmen S.No Designation No’s

1 Operator 03 2 Skilled Workmen 06

Total 25

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 26

5.5 AMENITIES / FACILITIES

The following facilities shall be provided at the project site:

Canteen and welfare center

Toilets and Rest rooms

Car parks and cycle / scooter stands

Time and security offices

First aid and fire fighting station

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 27

CHAPTER – 06 PROPOSED INFRASTRUCTURE

6.1 Processing Area – industrial use The processing area will comprise of various plant facilities within the premises they are – Raw material handling & processing area, & product handling area. 6.2 Residential Area (Non-Processing Area) There is no proposal of any residential colony as the required manpower will be sourced from local populace. Few highly skilled posts may be filled from outsiders for whom houses will be leased in nearby residential area. Non-processing area will comprise of facilities within the premises such as –administrative block, road & pollution control equipment area etc. Other social infrastructure like housing, schooling and medical facilities area already developed in nearby area, hence, no residential colony/township is envisaged for employees. 6.3 Green Belt A greenbelt development plan will be prepared and implemented along with the implementation of project. Total green belt & plantation area shall be 1.54 Acre or 0.623 Hec. The main objective of the greenbelt is to provide a barrier between the plant and the surrounding areas.The species selection will depend upon type of soil and local species with good survival rate will be selected 6.4 Socio-Economic Benefits & Social Infrastructure This is an industrial land with adequate facilities. The existing infrastructure facility is adequate in the proposed project site. The social infrastructure like school, college, temples and play ground already exist in this area. The above infrastructure facilities need no further development for the project nor is any major change in the infrastructure envisaged due to the project. Only direct and indirect employment generation is envisaged.

6.5 Sewage System Sufficient and suitable toilet facilities of proper standard and hygiene shall be provided. 6.6 Industrial Waste Management There will be no waste water discharge from the plant 6.8 Solid Waste Management All the solid wastw generated in the process will be re used within the plant only for the manufacturing purpose only.

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 28

CHAPTER – 07

REHABILITATION AND RESETTLEMENT (R & R) PLAN 7.1 Policy to Be Adopted for R & R Plan With Respect To Project - Not Required The land already has been purchased by the project proponent & it is a vacant land so there is no displacement of any houses, habitation or livestock. Thus the project does not require any R & R plan.

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 29

CHAPTER – 08 PROJECT SCHEDULE & COST ESTIMATES

8.1 Project Schedule In this industry, any one of the following three alternate modes of project execution will be adopted:

Turnkey

Semi Turnkey

Packaged procurement mode

Statutory Clearances The proposed project will require various statutory approvals and clearances from various authorities of the Government. Clearances required for the proposed project are identified and necessary action initiated to obtain the same. Project Schedule It is envisaged that total project will be completed within a period of 6 months from `Go-ahead'. Land acquisition on lease is completed. The external agencies such as consultant, machinery suppliers, contractors for civil construction and equipment will be selected well in advance. An effective project team has been formulated with Director as its leader. 8.2 Project Cost An indicative estimated capital cost of the proposed Plant is Rs. 1600 Lakhs as below:

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 30

CHAPTER – 09 ANALYSIS OF PROPOSAL

Over the last few years, there has been a great change in the Indian Economic Scenario due to Global slowdown which affected the whole world including India. The major sector which took the toll was Steel & Power Sector. Various alloys of iron, which are used in the production of mild steel, carbon steel, special alloy steel and stain less steel. India’s steel production is increasing every year, thereby the consumption of Ferro alloys is also increasing. The Indian Ferro Alloy industry has a capacity of 5.15 million tonnes. It is accounting for nearly 10% of the world’s ferro alloy production and is among the 10 largest producers of the material in the world. The Directors / Vice Presidents of M/s Narayani Pellets Pvt Ltd are experienced Industrialist in the field of production of Ferro Alloys. The technology involved in the project is well proven and reliable. Many plants are operating all over the country in this pattern are successful. All equipment purchased shall be brand new & latest in model and will be purchased from reputed suppliers. For O&M of the plant, experienced Engineers /Technicians are available in the region. The region shall also be benefited from the project as there will be direct employment of people in the Steel plant. Preference will be given to the people of the state possessing requisite skill and qualification criteria. Also there will be lot of scope for indirect employment of the people of the state in and around the project site like in transportation sector. In view of the above the proposed Project of M/s Narayani Pellets Pvt Ltd. is technically feasible and financially viable thus, we request EAC to recommend TOR for conducting the EIA Study for obtaining Environmental Clearance from Ministry of Environment, Forest & Climate Change.

Proposed 0.27 MTPA Iron Ore Pellet Plant At Village – Raika, P.O-Serenda, P.S-Barbil, Dist-Kendujhar, State – Odisha,

Page 31

PROMOTERS M/s Narayani Pellets Pvt Ltd

Project For Manufacturing facility of Iron Ore Pellets

Plant location Plot No 5/138, 7, 6, In village- Raika, P.O - Serenda, P.S - Barbil, Dist. Kendujhar (Odisha).

Markets Local & export

Plant capacity 0.27 MTPA (Iron Ore Pellets)

Water requirement For process and domestic use – 4 m3/day

Water sources Private Water Tanker

Max. power demand 300 KVA

Main storages For raw materials and products – space available

Manpower 25Nos.

Implementation period 6 months

Proposed Investment Rs. 1600 lakhs

Conclusion Based on the performance indicators, the project is technically & financially viable, Under both normal and contingent conditions.

![Thesis Agrawal[1]](https://static.fdocuments.us/doc/165x107/545abd35b1af9f39378b5eba/thesis-agrawal1.jpg)