ASTRIX LABORATORIES LIMITED

Transcript of ASTRIX LABORATORIES LIMITED

ASTRIX LABORATORIES LIMITED SY. NO. 10 & 42, IDA, GADDAPOTHARAM VILLAGE,

JINNARAM MANDAL, MEDAK DISTRICT, ANDHRA PRADESH

FORM I

Project No. 0314‐21‐02March 2014

Astrix Laboratories Limited Sy. No. 10 & 42, IDA, Gaddapotharam (V), Jinnaram (M), Medak (Dist.) ‐ 502 319 Phone: +91 040‐3049 3876, 8008001511 E‐mail ID: [email protected]

STUDIES AND DOCUMENTATION BY TEAM Labs and Consultants B‐115‐117 & 509, Annapurna Block, Aditya Enclave, Ameerpet, Hyderabad‐500 038. Phone: 040‐23748 555/23748616, Telefax: 040‐23748666

SUBMITTED TO MINISTRY OF ENVIRONMENT AND FORESTS,

GOVERNMENT OF INDIA PARYAVARAN BHAVAN, LODHI ROAD, NEW DELHI

Astrix Laboratories Limited

Form I Page 1

APPENDIX – I (See Paragraph – 6)

FORM I

I) Basic Information S.No. Item Details 1 Name of the Project/s M/s Astrix Laboratories Limited 2 S. No in the Schedule 5 f – A category 3 Proposed capacity/area/length/tonnage

to be handled/command area/lease area/number of wells to be drilled

Proposed to enhance the production capacity of Active Pharma Ingredients (API’s) from 38.2 TPM to 70 TPM and addition of Co‐Generation power plant of 5 MW capacity. Cost of the project (Expansion): 60 Crores

4 New/Expansion/Modernization Expansion 5 Existing Capacity/Area etc. Existing Capacity: 38.2 TPM

Area Existing: 28.5 Acres 6 Category of Project i.e 'A' or 'B' “A” 7 Does it attract the general condition? If

yes, please specify Yes. The Unit is Located in Notified Industrial Estate / Area. Critically Polluted Area of Pattancheru and Bollaram are located at a distance of 5.4 KM’s from the Site.

8 Does it attract the Specific condition? If yes, please specify.

No

9 Location Plot/Survey/Khasra No. Sy. No. 10 & 42, IDA Village Gaddapotharam (V) Tehsil Jinnaram (M) District Medak District State Andhra Pradesh

10 Nearest railway station/airport along with distance in kms.

Nearest Railway Station is Secunderabad at a distance of 30 KM from the site.

11 Nearest Town, City, District Headquarters along with distance in kms.

Town & District HQ – Jeedimetla ‐ 20 KM distance from site City ‐ Hyderabad ‐ 35 KM distance from site

12 Village Panchayats, Zilla Parishad, Municipal Corporation, Local body (complete postal address with telephone nos. to be given)

Sy.No. 10, IDA, Gaddapotharam, Jinnaram Mandal, Medak District – 502319 Direct : 040 3049 1328 Mobile : 8008001511

Astrix Laboratories Limited

Form I Page 2

13 Name of the Applicant G. Srinivas Rao 14 Registered Address Mylan Laboratories Limited, Plot No 564/A/22,

Road No 92, Jubile Hills, Hyderabad‐500034 15 Address for Correspondence: Name G. Srinivas Rao Designation(Owner/Partner/CEO) General Manger – EHS Address Sy. No. 10 & 42, IDA, Gaddapotharam, Jinnaram

Mandal, Medak District – 502319 Pin Code 502319 E‐mail [email protected] Telephone Number Direct : 040‐3049 3876

Mobile : +91 8008001511 Fax No.

16 Details of alternative Sites examined, if any. Location of these sites should be shown on a topo sheet.

‐NA‐

17 Interlinked Projects ‐NA‐ 18 Whether separate application of

interlinked project has been submitted? No

19 If yes, date of submission 20 If no, reason 21 Whether the proposal involves

approval/clearance under: if yes, details of the same and their status to be given. (a) The Forest (Conservation) Act, 1980? (b) The Wildlife (Protection) Act, 1972? (c) The C.R.Z Notification, 1991?

‐NA‐

22 Whether there is any Government Order/Policy relevant/relating to the site?

No

23 Forest land involved (hectares) No 24 Whether there is any location pending

against the project and /or land in which the project is propose to be set up? (a) Name of the Court (b) Case No (c) Orders/directions of the Court, if any and its relevance with the proposed project.

No Individual Court case against the Project.

However Green Tribunal Case, W.P. No. 19661 of 2002 on the file of Hon’ble High Court of Andhra Pradesh / Application No. 90 of 2013 before NGT is filed against CETP Members. (Presently we are not discharging any effluents to CETP, as the plant has ZLD based effluent Treatment System)

Astrix Laboratories Limited

Form I Page 3

(II) Activity

1. Construction, operation or decommissioning of the Project involving actions, which will cause physical changes in the locality (topography, land use, changes in water bodies, etc.) S.No. Information/Checklist confirmation Yes/No Details thereof (with approximate quantities

/rates, wherever possible) with source of information data

1.1 Permanent or temporary change in land use, land cover or topography including increase in intensity of land use (with respect to local land use plan)

NO The proposal is for expansion of API’s manufacturing capacity in the existing unit. No additional land. Total Land area after proposed expansion 28.5 Acres.

1.2 Clearance of existing land, vegetation and buildings?

NO Industrial

1.3 Creation of new land uses? NO 1.4 Pre‐construction investigations e.g.

bore houses, soil testing? YES Soil Testing completed

1.5 Construction works?

YES Construction activity involves creation of manufacturing facility and additional utilities like Boiler, Chilling Plant etc and Co‐Generation Power Plant.

1.6 Demolition works? NO

1.7 Temporary sites used for construction works or housing of construction workers?

NO Construction labor from local villages shall be employed.

1.8 Above ground buildings, structures orearthworks including linear structures, cut and fill or excavations

YES Storage facilities shall be constructed. No major cut and fill or excavation is anticipated.

1.9 Underground works including mining or tunneling?

NO

1.10 Reclamation works? NO 1.11 Dredging? NO 1.12 Offshore structures? NO 1.13 Production and manufacturing

processes? YES Enclosed in Annexure – I

1.14 Facilities for storage of goods or materials?

YES Raw materials and solvents shall be stored with safety precautions.

1.15 Facilities for treatment or disposal of solid waste or liquid effluents?

YES Solid waste shall be disposed to end users/recyclers or sent to landfill or incineration. Effluent generated from the plant are treated and reused. Details presented in Annexure II

Astrix Laboratories Limited

Form I Page 4

1.16 Facilities for long term housing of operational workers?

NO Local people shall be employed.

1.17 New road, rail or sea traffic during construction or operation?

NO

1.18 New road, rail, air waterborne or other transport infrastructure including new or altered routes and stations, ports, airports etc?

NO

1.19 Closure or diversion of existing transport routes or infrastructure leading to changes in traffic movements?

NO

1.20 New or diverted transmission lines or pipelines?

NO

1.21 Impoundment, damming, culverting, realignment or other changes to the hydrology of watercourses or aquifers?

NO

1.22 Stream crossings? NO 1.23 Abstraction or transfers of water

form ground or surface waters? YES Total water required shall increase from

164.01 KLD to 916.5 KLD out of which 666 KLD shall be met from HMWS (Industrial Supply) and the balance shall be recycled water.

1.24 Changes in water bodies or the land surface affecting drainage or run‐off?

NO

1.25 Transport of personnel or materials for construction, operation or decommissioning?

YES The construction material shall be drawn from local sources within 10 – 15 km. There is no transport of personnel, as the construction workers are from local villages.

1.26 Long‐term dismantling or decommissioning or restoration works?

NO

1.27 Ongoing activity during decommissioning which could have an impact on the environment?

NO

1.28 Influx of people to an area in either temporarily or permanently?

YES The proposed project shall increase the employment potential and hence may lead to migration to surrounding villages.

1.29 Introduction of alien species? NO 1.30 Loss of native species or genetic

diversity? NO

1.31 Any other actions? NO

Astrix Laboratories Limited

Form I Page 5

2. Use of Natural resources for construction or operation of the Project (such as land, water, materials or energy, especially any resources which are non‐renewable or in short supply): S.No. Information/checklist confirmation Yes/No Details thereof (with approximate quantities

/rates, wherever possible) with source of information data

2.1 Land especially undeveloped or agricultural land (ha)

NO Existing Unit

2.2 Water (expected source & competing users) unit: KLD

YES Total water required shall increase from 164.01 KLD to 916.5 KLD out of which 666 KLD shall be met from HMWS (Industrial Supply) and the balance shall be recycled water. (Water Balance Enclosed in Annexure III)

2.3 Minerals (MT) NA 2.4 Construction material – stone,

aggregates, sand / soil (expected source – MT)

YES Shall be sourced from the local villages.

2.5 Forests and timber (source – MT) NO 2.6 Energy including electricity and fuels

(source, competing users) Unit: fuel (MT), energy (MW)

YES The required energy shall be drawn from APTRANSCO. Backup DG sets of 2 x 380, 1 x 500, 1 x 750 and 1 x 1025 existing and 2 x 1025 and 2 x 1500 KVA proposed, shall be provided to cater to energy requirement during load shut downs. The other energy source is Coal fired boilers of 8 TPH, 4TPH FO fired boiler existing and proposed 30 TPH coal fired boiler to meet the steam requirement both for co‐generation, process and ZLD system. The required quantity of fuel (coal) is 120TPD and FO is 4 KLD. Diesel for Standby DG sets shall be 175 KL/month.

The surplus steam and Power generated from the 5 MW Captive power generation plant of M/s Astrix Laboratories Limited (Group of Mylan Laboratories Limited) will be utilized in Mylan Laboratories Limited, Unit – 1, which is adjacent to our plant and also part of Mylan Group of industries.

2.7 Any other natural resources (use appropriate standard units)

NA

Astrix Laboratories Limited

Form I Page 6

3. Use, storage, transport, handling or production of substances or materials, which could be harmful to human health or the environment or raise concerns about actual or perceived risks to human health. S.No. Information/Checklist confirmation Yes/No Details thereof (with approximate

quantities/rates, wherever possible) with source of information data

3.1 Use of substances or materials, which are hazardous (as per MSIHC rules) to human health or the environment (flora, fauna, and water supplies)

YES Solvents shall be used as reaction media. MSIHC rules shall be followed during storage, transportation and handling of raw materials and hazardous chemicals.

3.2 Changes in occurrence of disease or affect disease vectors (e.g. insect or water borne diseases).

NO

3.3 Affect the welfare of people e.g. by changing living conditions?

YES Shall increase the employment potential for locals and affect the living conditions for betterment.

3.4 Vulnerable groups of people who could be affected by the project e.g. hospital patients, children, the elderly etc.,

NO No sensitive receptors are present in the immediate vicinity of the site. The project shall not have any significant impact on vulnerable groups of people.

3.5 Any other causes NO

4. Production of solid wastes during construction or operation or decommissioning (MT/month) S.No. Information/Checklist confirmation Yes/No Details thereof (with approximate

quantities/rates, wherever possible) with source of information data

4.1 Spoil, overburden or mine wastes NO 4.2 Municipal waste (domestic and or

commercial wastes) NO Wastes from canteen are generated. The

canteen wastes shall be in the range of 50 kgs/day

4.3 Hazardous wastes (as per Hazardous Waste Management Rules)

YES The quantity of hazardous waste generated during operation contain salts from evaporators, stripper distillate, process residue, and solvent residues, ETP sludge and filtration media etc. enclosed in Annexure – IV

4.4 Other industrial process wastes YES Enclosed at Annexure IV 4.5 Surplus product NO 4.6 Sewage sludge or other sludge from

effluent treatment YES Sludge from Effluent treatment plant and

Salts from MEE & ATFD shall be sent to TSDF.

Astrix Laboratories Limited

Form I Page 7

4.7 Construction or demolition wastes YES Construction activity involves creation of manufacturing facility, additional utilities like Boiler, Chilling Plant etc and Co‐Generation Power Plant.

4.8 Redundant machinery or equipment NO

4.9 Contaminated soils or other materials NO

4.10 Agricultural wastes NO

4.11 Other solid wastes YES Enclosed at Annexure IV

5. Release of pollutants or any hazardous, toxic or noxious substances to air (Kg/hr) S.No. Information/Checklist confirmation Yes/No Details thereof (with approximate

quantities/rates, wherever possible) with source of information data

5.1 Emissions from combustion of fossil fuels from stationary or mobile sources

YES Coal and FO Shall be used as fuel. Quantity of fuel and emissions details are enclosed in Annexure V

5.2 Emissions from production processes YES Enclosed in Annexure ‐ VI 5.3 Emissions from materials handling

including storage or transport NO Material transfer takes place in closed

pipeline systems. 5.4 Emissions from construction activities

including plant and equipment YES Dust may rise during transport of material and

construction activity. The dust emissions shall be mitigated by water spraying on the roads within the premises.

5.5 Dust or odors from handling of materials including construction materials, sewage and waste

YES Dust may rise during transport of material and construction activity. The dust emissions shall be mitigated by water spraying on the roads within the premises.

5.6 Emissions from incineration of waste NO 5.7 Emissions from burning of waste in

open air (e.g. slash materials, construction debris)

NO

5.8 Emissions from any other sources NO

Astrix Laboratories Limited

Form I Page 8

6. Generation of Noise and Vibration, and Emissions of Light and Heat: S.No. Information/Checklist

confirmation Yes/No Details thereof (with approximate

quantities/rates, wherever possible) with source of information data with source of information data

6.1 From operation of equipment e.g. engines, ventilation plant, crushers

YES Material transport and construction equipment shall be source of noise, while transfer pumps, vacuum systems, DG sets are the sources of noise during operation.

6.2 From industrial or similar processes

YES From Turbine and DG sets, and controlled by providing Acoustic Enclosures.

6.3 From construction or demolition YES Noise during construction shall be due to construction equipment and emergency DG sets.

6.4 From blasting or piling NO

6.5 From construction or operational traffic

NO The increased traffic shall not have any significant impact.

6.6 From lighting or cooling systems NO

6.7 From any other sources NO

7.Risks of contamination of land or water from releases of pollutants into the ground or into sewers, surface waters, groundwater, coastal waters or the sea: S.No. Information/Checklist

confirmation Yes/No Details thereof (with approximate

quantities/rates, wherever possible) with source of information data

7.1 From handling, storage, use or spillage of hazardous materials

NO All the hazardous materials will be stored in drums, in a covered shed and no contamination of soil is expected

7.2 From discharge of sewage or other effluents to water or the land (expected mode and place of discharge)

NO All the wastes from domestic operations are sent to Biological treatment in “ZLD” system.

7.3 By deposition of pollutants emitted to air into the land or into water

NO All the emissions from process are controlled by providing control equipment like scrubbers, Dust Collectors and emissions from boiler shall be controlled by providing bag filter.

7.4 From any other sources NO 7.5 Is there a risk of long term build

up of pollutants in environment from these sources?

NO

Astrix Laboratories Limited

Form I Page 9

8.Risk of accidents during construction or operation of the Project, which could affect human health or the environment S.No. Information/Checklist confirmation Yes/No Details thereof (with approximate

quantities/rates, wherever possible) with source of information data

8.1 From explosions, spillages, fires etc from storage, handling, use or production of hazardous substances

YES All Inbuilt Safety precautions will be adopted and there will not be any damage to environment or human health

8.2 From any other causes NA 8.3 Could the project be affected by natural

disasters causing environmental damage (e.g? Floods, earthquakes, landslides, cloudburst etc)?

NO

9.Factors which should be considered (such as consequential development) which could lead to environmental effects or the potential for cumulative impacts with other existing or planned activities in the locality S. No. Information/Checklist confirmation Yes/No Details thereof (with approximate

quantities/rates, wherever possible) with source of information data

9.1 Lead to development of supporting. facilities, ancillary development or development stimulated by the project which could have impact on the environment e.g.: • Supporting infrastructure (roads, power supply, waste or waste water treatment, etc.)• housing development • extractive industries • supply industries • other

YES The project shall enhance the socio economic status of the area by increasing the demand for housing, improving the employment. There are no major support industries required for this plant.

9.2 Lead to after‐use of the site, which could haven impact on the environment

NO

9.3 Set a precedent for later developments NO 9.4 Have cumulative effects due to proximity to

other existing or planned projects with similar effects

NO The baseline environmental status of the surrounding areas is within the prescribed limits as observed from the Secondary data.

Astrix Laboratories Limited

Form I Page 10

(III) Environmental Sensitivity S.No. Areas Name/

IdentityAerial distance (within 15 km.) Proposed project location boundary

1 Areas protected under international conventions, national or local legislation for their ecological, landscape, cultural or other related value

NA

2 Areas which are important or sensitive for ecological reasons ‐ Wetlands, watercourses or other water bodies, coastal zone, biospheres, mountains, forests

YES Danara Cheru– Southeast– 7.8 Km, Lingam Cheru‐ Northwest‐ 4.9 Km, Pirshab Cheru‐ Northwest‐ 5 Km, Akkam Cheru – Northwest – 7.6 Km Tunkini Cheru – West – 8.1 Km

3 Areas used by protected, important or sensitive species of flora or fauna for breeding, nesting, foraging, resting, over wintering, migration

NA

4 Inland, coastal, marine or underground waters NO 5 State, National boundaries NO 6 Routes or facilities used by the public for access

to recreation or other tourist, pilgrim areas NO

7 Defense installations NO 8 Densely populated or built‐up area YES Sambhupur village at 0.95 km from

site. 9 Areas occupied by sensitive man‐made land

uses (hospitals, schools, places of worship, community facilities)

NA

10 Areas containing important, high quality or scarce resources (ground water resources, surface resources, forestry, agriculture, fisheries, tourism, minerals)

NO

11 Areas already subjected to pollution or environmental damage. (those where existing legal environmental standards are exceeded)

YES Patancheru and Bollaram Industrial areas at a distance of 5.4Km.

12 Areas susceptible to natural hazard which could cause the project to present environmental problems (earthquakes, subsidence, landslides, erosion, flooding or extreme or adverse climatic conditions)

NO

Astrix Laboratories Limited

Form I Page 11

(IV) Proposed Terms of Reference for EIA studies Scope of Work of EIA “...The EIA shall cover the following: Description of the proposed project: The first task:” Description of the proposed project” forms a vital component of the Environmental Impact Assessment (EIA) as it provides the basis for evaluating the likely causes of Environmental Impacts.

Existing Environment and Baseline Conditions: The baseline assessment will be carried out to identify potentially sensitive and critical areas that may be affected by the project in an area of 10 km surrounding the project location. The critical and sensitive targets shall be plotted on land use map of project impact area. The existing environment and baseline conditions should be established from:‐ Analysis of existing information published and secondary data. ‐Consultation with relevant statutory authorities, and Field visits for supplementation of missing gaps.

The key subject areas which the EIA shall address include Ecology and Nature conservation, Air quality, surface and water quality in project impact area, soil quality, cultural heritage, landscape, land use, noise quality, etc. Natural habitats like national parks, wildlife reserves, sanctuaries, sacred grove, protected areas, forests, wetlands, major rivers and waterways if any, shall also be identified and marked.

Assessment of Environmental Impacts: Based upon the results from the review of existing information, field visits, site data collection and consultation, for each component of environment (physical, biological and socio economic) the positive, negative, direct and indirect, temporary and permanent impacts will be evaluated along with an indication of the degree of impact, i.e., whether the impact is significant, moderate, minor or negligible. The degree of impact shall also be quantified by using state of the art air quality impact prediction models based on ISCST3 algorithms.

Environment Management Plan And Mitigation Plan: For each significant negative impact identified, specialist shall work closely with the engineering team/technical consultants to suggest practicable measures to avoid or mitigate the impact. The mitigation of environmental impacts will be by three mechanisms. =>Introduction of mitigation features through the engineering practices. =>Implementation of environmental controls during construction and operation. =>Legislative control involving compliance with Indian environmental laws. The Environmental management plan shall include an estimate of capital and recurring costs of mitigation measures and will identify the institutional framework for implementation.

Monitoring Plan: Having identified the significant environmental impact that is likely to arise as a result of the project, the project team shall specify what monitoring is required during the various phases of the project cycle. The monitoring plan will identify parameters and frequency of monitoring and responsible organization.

ASTRIX LABORATORIES LIMITED SY. NO. 10 & 42, IDA, GADDAPOTHARAM VILLAGE,

JINNARAM MANDAL, MEDAK DISTRICT, ANDHRA PRADESH

ANNEXURES

SUBMITTED TO MINISTRY OF ENVIRONMENT AND FORESTS,

GOVERNMENT OF INDIA PARYAVARAN BHAVAN, LODHI ROAD, NEW DELHI

Astrix Laboratories Limited Form I Annexures

Page 1

Loca

tion

Map

of A

stri

x La

bora

tori

es L

imite

d

Astrix Laboratories Limited Form I Annexures

Page 2

Plan

t Lay

out o

f Ast

rix

Labo

rato

ries

Lim

ited

Astrix Laboratories Limited Form I Annexures

Page 3

ANNEXURE - I M/s. Astrix Laboratories Limited obtained consent for establishment and operation for

Bulk Drugs & intermediates at Sy. No. 10 & 42, IDA, Gaddapotharam village, Jinnaram

mandal, Medak district, Andhra Pradesh. It is proposed to expand the manufacturing

capacity of API’s from 38.2 TPM to 70 TPM with addition of 5MW Co-generation power

plant. The expansion entails a capital cost of Rs. 60 crores towards Manufacturing capacity

enhancement , power plant & for additional Environmental management systems on

account of increased production. Manufacturing capacity is presented in Table A-1. The

proposed manufacturing capacity is presented in Table A-2.

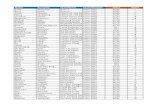

Table A-1 Manufacturing Capacity – Permitted

S.No Name of the Product Quantity TPM Kg/day

Group-A (Any 2 Products) 1 Nevirapine 12 400 2 Zidovudine 3.1 103.33 3 Lamivudine 20 666.67 4 Efavirenz 1 33.33 5 Lopinavir 0.5 16.67 6 Ritanovir 0.5 16.67 7 Clopidogrel Bisulphate 0.5 16.67 8 Atomoxatine HCl 0.1 3.33 9 Didanosin 0.2 6.67

Group-B (Any 1 Product) 1 Emtricitabine 6.2 206.67 2 Stavudine 0.5 16.67 3 Fluindione 0.5 16.67

Total –(Worst case any 3 Products) 38.2 1273.33

Astrix Laboratories Limited Form I Annexures

Page 4

Table A-2 Manufacturing Capacity – After Expansion

S.No Name of the Product Quantity TPM Kg/day

1 Nevirapine 15 500 2 Lamivudine 30 1000 3 Emtricitabine 15 500 4 Zidovudine 5 166.67 5 Efavirenz 0.8 26.67 6 Stavudine 0.7 23.33 7 Lopinavir 0.5 16.67 8 Ritanovir 0.5 16.67 9 Didanosin 1 33.33

10 Clopidogrel Bisulphate 0.5 16.67 11 Atomoxatine HCl 0.1 3.33 12 Fluindione 0.4 13.33 13 Validation products 0.5 16.67 Total 70 2333.3 Co-Generation Power Plant 5 MW

Astrix Laboratories Limited Form I Annexures

Page 5

Process Description of Zidovudine

Chemical Reaction of Zidovudine

Stage I

Stage II

MeOH,PTSAEtOAc,Na2CO3NaCl,Toluene

Process Description for Zidovudine

Stage I: Preparation of 2,3’-Anhydro-5’-O-trityl thymidine

Β-Thymidine reacts with trityl chloride in presence of TEA base and 1,4 Dioxane to get

5’-O-trityl thymidine, this futher reacting with Methane sulfonyl chloride to get 3’-O-

trityl thymidine, which on futher cyclised in presence of Methanol and TEA and

isolation in Toluene, TEA, water yields 2,3’-Anhydro-5’-O-trityl thymidine.

Stage II:2,3’-Anhydro-5’-O-trityl thmidine(stage I) is converted to 3’-azido-5’-O-trityl

thymidine with Sodium azide in Dimethyl sulfoxide, which on hydrolysis with p-

Toluene sulfonic acid(p-TSA) in Methanol followed by isolation in Ethy acetate and

purification in water yeilds 3’-Azido-3’-deoxythmidine(Zidovudine).The process flow

diagram is presented in Fig A-1 and material balance is presented in Table A-3.

Astrix Laboratories Limited Form I Annexures

Page 6

Fig A-1 Process Flow Diagram of Zidovudine

Astrix Laboratories Limited Form I Annexures

Page 7

Table A-3 Material Balance for Zidovudine Stage: I

Input Output S.No Name of the Material Per Batch Name of the Material Per Batch

Kgs Kgs 1 Beta Thymidine 229 Stage -I 400.00 2 1,4- Dioxane 2389 2nd crop 127.71 3 Triethylamine (TEA) 726 Waste Water 3588.57 4 Trityl Chloride 332 1,4- Dioxane 84 5 Methane Sulfonyl chloride 137 Triethylamine (TEA) 14.51 6 Methanol 2059 Methanol 28.82 7 water 3589 Toluene 6.49 8 Toluene 649 Sodium Bicarbonate 22.86 9 Sodium Bicarbonate 23 Methane Sulfonyl chloride 100.00

Trityl Chloride 70

Solid waste

1,4- Dioxane 2293.0 Organic residue 22.56 Triethylamine (TEA) 696.69 Emissions Methanol 2017.3 Triethylamine (TEA) 7.257 Toluene 635.7 Methanol 10.29

Toluene 5.19 Total 4487.86 4487.86

Stage: II Input Output

S.No Name of the Material Per Batch Name of the Material Per Batch Kgs Kgs 1 ZDU - I 400.0 Zidovudine 168 2 Dimethyl sulphoxide 2048 2nd crop 533 3 Sodium Azide 224.0 Waste Water 5800.00 4 Ammonium Chloride 58 Dimethyl sulphoxide 28.7 5 Sodium Chloride 745 Toluene 24.22 6 Toluene 3027 Methanol 26.04 7 Hyflo 24 Ethyl Acetate 45.18 8 Methanol 3254.8 Sodium Azide 224.0 9 P-Toluene Sulfonic Acid 50.0 Ammonium Chloride 58.0

10 Sodium Carbonate 22.0 Sodium Chloride 600.6 11 Ethyl Acetate 4518.0 Para Toluene Sulfonic Acid 5.0 12 Carbon 57.6 Sodium Carbonate 22.0 13 Water 5800.0 Solid waste

Organic residue 16.41 Inorganic salts 37.7

Recoveries(-) Spent carbon Dimethyl sulphoxide 1966.08 Carbon 84.32 Toluene 2936.19 Emissions Methanol 3157.16 Dimethyl sulphoxide 10.24 Ethyl Acetate 4382.46 Toluene 30.27

Methanol 32.55 Ethyl Acetate 40.66

Total 7786.51 7786.51

Astrix Laboratories Limited Form I Annexures

Page 8

ANNEXURE – II: Wastewater Treatment Facilities

The effluent generated from the proposed expansion of M/s. Astrix Laboratories Limited

is mainly from process, washings, and scrubbers, cooling towers & boiler blow downs and

domestic effluent. HTDS effluent sent to Stripper, Multiple Effect Evaporator followed by

ATFD, Biological treatment and RO. LTDS effluent from process, washings, scrubbers,

Solvent recovery system, DM rejects, Cooling towers, boiler bow downs, detoxification

effluent, ZLD washings and domestic effluents shall be sent to Biological treatment

system followed by RO. The treated effluent reused for cooling towers. Total Effluent

generated and mode of treatment before and after expansion is presented in Table A-4

and quantity and quality of effluent generated from process after expansion is presented

in Table A-5.

Table A-4 Quantity of Effluent Generated – After Expansion (Tentative)

Description of Effluent Quantity (KLD) Mode of Final Disposal Permitted After

Expansion HTDS Effluents

Process 23.9 51.5 Treated in effluent treatment plant consist of Stripper, MEE, ATFD and Biological treatment followed by RO.

RO Permeate reused for cooling tower makeup and RO rejects sent to MEE.

Total HTDS 23.9 51.5 LTDS Effluents

Washings Effluent 2 Sent to Biological Treatment System followed by RO. RO permeate reused for cooling tower makeup. RO rejects sent to MEE.

Scrubber Effluent 5 Solvent recovery plant 2 Boiler 8 20 Cooling Tower 5 80 DM Plant, Softener & Purified water system

7 35

Detoxification 5 ZLD Washings 10 Domestic 14 40

Total LTDS 34 199 Grand Total (HTDS+LTDS)

57.9 250.5

Astrix Laboratories Limited Form I Annexures

Page 9

Table A-5 Quantity and Quality of Effluent Generated from Process (Tentative)

S.No Name of the Product Quantity (Kg/day) Conc. (mg/l) Water Input

TDS Load COD Load

Total Effluent

TDS COD

1 Zidovudine 9314 898 429 9743 92195 44041 2 Lamivudine 15401 153 302 15388 9912 19597 3 Nevirapine 8586 357 105 8979 39771 11704 4 Efavirenz 1760 54 28 1810 29947 15345 5 Lopinavir 893 83 8 901 91961 9143 6 Emtricitabine 6548 208 305 6135 33957 49642 7 Stavudine 1849 8 34 1884 4300 17829 8 Fluindione 223 43 9 249 173745 35370 9 Clopidogrel Bisulphate 793 43 21 818 52928 25661

10 Atomoxatine HCl 1125 51 13 1149 43976 11285 11 Didanosin 3496 400 56 3763 106392 14919 12 Ritanovir 583 42 22 650 64335 34344 13 Validation Products 17 7 5 22 327273 227273 Total 50587.3 2347.82 1336.11 51490.4 45597 25949

Astrix Laboratories Limited Form I Annexures

Page 10

ANNEXURE – III: Water Balance

The total water requirement shall increased from 164.01 KLD to 916.5 after expansion out

of which 666 KLD shall be drawn from HMWS (Industrial Supply) and balance shall be

recycled water. The water balance for daily consumption after expansion is presented in

Table A-6.

Table A-6 Total Water Balance – After Expansion (Tentative)

Purpose INPUT (KLD) OUTPUT (KLD) Fresh Water

Recycled Water

Loss Wastewater

Process & Washings 53 53.5* Scrubber 5 5 Solvent recovery plant 2 2 Boiler 216 196 20 Process & Utility RO rejects to Cooling tower make-up

144.04** 250.5 420.54 80

Cooling Tower 106 DM Plant, Softener & Purified water system

35 35

Detoxification 5 5 ZLD Washings 10 10 Water for gardening 50 50 Domestic 40 40 Gross Total 666 250.5 666.5 250.5 Total 916.5 917

* Process effluents contain soluble raw materials, byproducts, solvents etc. **144.04 KLD generated from process & Utility RO is being recycled into Cooling Tower for make up.

Astrix Laboratories Limited Form I Annexures

Page 11

ANNEXURE – IV: Solid Waste

Solid wastes generated from the process shall be sent to TSDF/ Cement Industries for Co-

incineration. Stripper distillate shall send to TSDF/ Cement Industries for Co-incineration.

Evaporation salts from MEE and ATFD and ETP Sludge shall be sent to TSDF. The total

solid waste generated and mode of disposal is presented in Table A-7.

Table A-7 Solid Waste Details – After Expansion (Tentative) S.No Description of waste UOM Permitted After

Expansion Disposal method

1.Hazardous Waste with Disposal Option: 1 Forced Evaporation Salts Kg/day 430 3125.6 TSDF 2 ETP Sludge Kg/day 100 2000 TSDF 3 Process Inorganics Salts Kg/day 787.33 1078.47 TSDF 4 Mixed Spent Solvents KL/day 16.7 25 TSDF / Cement

Industry 5 Spent Carbon Kg/day 283.3 1587.9 TSDF / Cement

Industry 6 Distillation bottom

residue (including process organics)

Kg/day 645.7 1501.1 TSDF / Cement Industry

7 Thermocol Kg/day 50 TSDF 8 Insulation Waste Kg/day 50 TSDF 9 Glass wool Kg/day 50 TSDF

10 Softener / DM Plant Resins

Kg/day 35 TSDF

11 Off specifications, rejected & Discarded Raw materials, lab chemicals & products etc

Kg/day 25 TSDF / Cement Industry

12 Stripper Distillate ( VOC) KL/Day 2 TSDF / Cement Industry

13 Used Filters (HEPA filters Oil Filters etc)

Nos / Month

20 TSDF for Incineration

14 Discarded PPE Kgs / day 30 TSDF for Incineration 2.Hazardous Waste with Recycling Option :

15 Discarded Container & liners Dispose off to outside agencies after detoxification

a HDPE containers No's/ M 300 500 b Glass Bottles No's/ M 250 300 c Plastic Containers No's/ M 250 300 d Liners & bags Kg/day 500 1000

16 Used Oil LPM 200 500 Authorized recyclers 17 Distilled Industrial waste KL/day 10 Sale to authorized

Astrix Laboratories Limited Form I Annexures

Page 12

solvent after recovery (colorless )

recyclers

18 Spent Solvents KL/day 24.266 25 Recovered within the premises / Sale to authorized recyclers

19 Lead acid batteries No's/Year 50 Authorized recyclers 20 E- Waste Kg/day 50 E – waste Disposal

facility 3. Non Hazardous Waste :

21 Paper, cotton waste & Packing materials i.e.wood, carton , ropes

TPM 25 Sale to out side agencies/ recyclers

22 Ply wood containers/ broken glass etc

TPM 10 Sale to out side agencies/ recyclers

23 Metal scrap ( MS, SS, GI ,Aluminum)

TPM 25 Sale to out side agencies/ recyclers

24 Coal Ash / Fly Ash TPM 1000 TSDF to use as a stabilizing agent / Brick manufactures

Astrix Laboratories Limited Form I Annexures

Page 13

ANNEXURE – V: Stack Emissions Details

The sources of air pollution in the plant are from the existing 1x8 TPH Coal fired boiler,

1x4 TPH FO fired boiler and proposed 30 TPH coal fired to meet the steam requirement

both for co-generation and process and existing backup DG sets of 2x380, 1x500, 1x1025

and 1x750 KVA and proposed 2x1025 and 2x1500 KVA, to cater to energy requirement

during load shut downs. The proposed air pollution control equipment for coal fired

boiler is bag filter. DG sets shall be provided with stack heights based on the CPCB

formula for effective stack height. The emission rates of SPM, SO2, NOx and SPM from

each stack are presented in Table A-8.

Table A-8 Stack Emission Details S.

No

Stack Connected to Stack Ht (m)

Dia of stack at top(m)

Temp. of exhaust

gases (0C)

Exit Velocity (m/sec)

Pollutant Emission Rate (g/sec)

SPM SO2 NOx

Permitted 1 8TPH Coal fired

Boiler 30 1.5 130 6.05 0.6 0.7 0.25

2 4 TPH FO fired Boiler 30 1.5 146 5.57 0.09 0.33 0.17 3 2 x 380KVA DG Sets* 8.5 0.2 165 6.2 0.01 0.02 0.03 4 1 x 500KVA DG Set* 11 0.2 180 8.8 0.01 0.03 0.04 5 2 x 1025KVA DG

Sets* 12 0.2 151 10 0.02 0.03 0.05

6 1 x 750KVA DG Sets* 8.5 0.2 165 6.2 0.01 0.02 0.03 Proposed

1 30TPH Coal Fired Boiler

42 2.0 200 15 2.5 4.5 5.1

2 2 x 1025KVA DG Sets*

12 0.2 151 10 0.02 0.03 0.05

3 2 x 1500KVA DG sets*

12 0.2 151 10 0.022 0.04 0.05

*DG sets will be used during load shut down by APTRANSCO.

Astrix Laboratories Limited Form I Annexures

Page 14

ANNEXURE – VI: Process Emissions Details

Table A-9 Quantity of Process Emission Generated and Mode of Treatment/Disposal (Tentative)

S.No. Name of product Stage Name of the gas Quantity (Kg/day)

Treatment/Disposal

1 Nevirapine II Hydrogen 36.5 Safely let into atmosphere 2 Lamivudine I Hydrogen 12.7 Safely let into atmosphere 3 Lopinavir I Carbon dioxide 0.8 Safely let into atmosphere 4 Ritanovir I Carbon dioxide 1.4 Safely let into atmosphere

II Carbon dioxide 1.8 Safely let into atmosphere 5 Didanosin I Carbon dioxide 6.7 Safely let into atmosphere

Hydrogen 0.1 Safely let into atmosphere 6 Clopidogrel Bisulphate I Carbon dioxide 8.4 Safely let into atmosphere 7 Fluindione I Carbon dioxide 4.39 Safely let into atmosphere 8 Efavirenz II Carbon dioxide 1.6 Safely let into atmosphere Total 74.5

ASTRIX LABORATORIES LIMITED SY. NO. 10 & 42, IDA, GADDAPOTHARAM VILLAGE,

JINNARAM MANDAL, MEDAK DISTRICT, ANDHRA PRADESH

Status of Compliance of the conditions and Environmental safeguards

stipulated in Environment Clearance

Astrix Laboratories Limited Sy. No. 10 & 42, IDA, Gaddapotharam (V), Jinnaram (M), Medak (Dist.) ‐ 502 319 Phone: +91 040‐3049 3876, 8008001511 E‐mail ID: [email protected]

SUBMITTED TO MINISTRY OF ENVIRONMENT AND FORESTS,

GOVERNMENT OF INDIA

ASTRIX LABORATORIES LIMITED SY. NO. 10 & 42, IDA, GADDAPOTHARAM VILLAGE,

JINNARAM MANDAL, MEDAK DISTRICT, ANDHRA PRADESH

STUDIES AND DOCUMENTATION BY TEAM Labs and Consultants QCI: MoE&F OM, List A-1, S.No. 150. (An ISO 9001:2008, ISO 14001:2004 & OHSAS 18001:2007 Certified Organization) B-115, Annapurna Block, Aditya Enclave Ameerpet, Hyderabad-500 038. Phone: 040-23748 555/616, Telefax: 040-23748666 Email: [email protected]