Association Helmholtz the Member of€¦ · Plasma-facing armor (tungsten) Heat sink tube (CuCrZr...

Transcript of Association Helmholtz the Member of€¦ · Plasma-facing armor (tungsten) Heat sink tube (CuCrZr...

Mem

ber o

f the

Hel

mho

ltz A

ssoc

iatio

n

Advanced Materials

Christian Linsmeier

Forschungszentrum Jülich | Institut für Energie- und Klimaforschung – Plasmaphysik

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Advanced materials

● Fiber-reinforced copper composites

● Pseudo-ductile tungsten composites

● Self-passivating W alloys

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Background: Efficiency increase by hotter coolant

- heat flux: 15 MW/m² - coolant: 320 °C (15.5 MPa) - heat sink: max. 530 °C

Maximum parameters

*PPCS Model A (WCLL)

Current design parameters*

- heat flux: 15 MW/m² - coolant: 150 °C - heat sink: max. 300 °C - efficiency: 31 %

Water-cooled monoblock module

300 °C 320 °C

15 MW/m²

Plasma-facing armor (tungsten)

Heat sink tube (CuCrZr alloy)

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Consequence for heat sink and armour materials

max 1000

800

600

400

200

0 min

(MPa) Stress (vM) 1300

1100

900

700

500

300

(°C) Temperature

Plastic strain 0.05

0.04

0.03

0.02

0.01

0

5 %

Stresses σy σx

xy

max 900

600

300

0

-300

-600

-900 min

(MPa) 15 MW/m²

CuCrZr heat sink Tungsten armour

New material solutions: Metal-matrix composites CuCrZr flat tile: SiC fibers / Cu matrix CuCrZr monoblock: W fibers / Cu matrix Bulk W: W fibers / W matrix

J.-H. You

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

SiCf / Cu

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

SiCf-Cu: From single fiber to MMC

W

CuCrZr

SiCf enforced copper

SCS6 fibre

titanium PVD-copper

galvanic copper

5 µm

carbon

100 µm

5 mm

Unidirectional (UD) single layer

500 µm

Paffenholz, Brendel

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

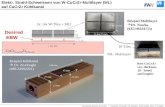

SiCf-Cu: From MMC to mock-up

CuCrZr MMC W-tiles

Brazing of components: • CuCrZr heat sink • MMC interlayer • 8 W tiles (10 x 13 x 5 mm³)

Paffenholz

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

GLADIS high heat flux test of mock-up

Cyclinc loading: 10.5 MW/m², 40 cycles + 40 cycles (6 W-tiles) Overheating of one W-tile ➔ Stop after 40 cycles ➔ Shadowing of damaged W tile Continuous temperature rise at surface of W tiles ➔ Stop after 80 cycles

2 40

41 80

Paffenholz, Greuner

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Post-mortem microscopy

200 µm

500 µm

good bonding between layers

no crack growth

500 µm

Overheated tile:

failure at MMC edge weak points are braze interfaces to

tile and heat sink Paffenholz

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Wf / Cu

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Wf – Cu: processing

Wf reinforced Cu

Cu-MMC Tube

300 °C

W

Heat flux

Fiber coating (magnetron, galvanic)

20 mm

HIP process

W fiber reinforced Cu

Herrmann, You

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Fiber-matrix interface

Optimized adhesion between W and Cu Interfacial shear strength increase x6 by graded interface and

annealing Layers interconnected by Ostwald ripening

Combination of microsctructuring and interface concepts into a

mock-up

Cu island

500 nm W substrate

RT

100% W

100% Cu 81% Cu 19% W

44% Cu 56% W

14% Cu 86% W

Composition determined by RBS, Ion: 4He2+ Energy: 6 MeV

400 nm

800°C

W substrate

Herrmann

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Tests of optimized Wf / Cu monoblock mock-up

HHF Temperature data followed prediceted thermal behavior (FEM) Fibers remained stably embedded up to 10.5 MW/m2

Thermal cycling and in situ neutron diffraction W fibers compensate compressive matrix stresses by tension Successful implementation of novel Wf / Cu MMC

1000 µm

200 µm

Herrmann, Schöbel

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Pseudo-ductile tungsten composites

Johann Riesch1, J.-Y. Buffière2, T. Höschen1, M. di Michiel3, M. Scheel3, S. Wurster4, J.-H. You1

1. Max-Planck-Institut für Plasmaphysik, Garching 2. GEMPPM INSA Lyon, Villeurbanne Cedex, France 3. European Synchrotron Radiation Facility, Grenoble, France 4. Erich-Schmid Institut, Leoben, Austria

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Tungsten: Brittleness problem

Lower limit: ductile-brittle-transition temp. TDBT (260-650°C)

Upper limit: recrystallization temp. Trec (1300°C)

plus: neutron embrittlement

● scattering in strength (small Weibull modulus)

● no damage tolerance ● uncertainty in lifetime prediction

Limitations of operation temperatures for tungsten:

Solution: extrinsic toughening (ductilization) mechanisms

⇒ local energy dissipation ● crack bridging ● fiber oull-out ● crack deflection

[Chawla 1993]

Rising load bearing capacity

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Extrinsic toughening mechanism

Main advantages for fusion

● damage tolerance ● mechanical effect ⇨ less susceptible to operational

embrittlement

Chawla 1993

● Engineered fibre/matrix interfaces → controlled crack deflection

● Interfacial debonding/friction → internal energy dissipation

⇨ Increase of fracture energy

key factor: Interfaces

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

e.g. full tungsten tile under cyclic loading

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

catastrophic failure by brittle fracture after a random number of cycles or caused by overload

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Wf/W under cyclic loading

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Crack is bridged by fibres

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Further loading still possible Resistance against fracture = Toughness

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Range of application

Extrinsic toughening no plasticity required

Works below DBTT

Works under embrittled state

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

● Fibre Drawn tungsten wire (d = 150 µm): high strength + some ductility

● Interface PVD coating: Optimised adhesion + stability

● Matrix Interface integrity + high density Develop chemical vapour infiltration (CVI) technique for Wf/W No mechanical impact Low process temperature

Architecture of Wf/W

Matrix: W-CVI

Fibre: drawn

W-wire

Interface: oxide ceramic

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Development

200 µm

80% 200 µm

86% 200 µm

92% 200 µm

>95% Dual step CVI

Developement steps

Den

sity

[%]

2009

Matrix Fibre

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Experimental verification

● Macroscopic toughening effect

● Resistance against embrittlement

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

3-Point bending test (ESI Leoben)

Stepwise 3-point bending Multi-fibre composite → W-CVI → 10 layers x 9 fibres → 2.2 mm x 3 mm

In-situ surface observation in electron microscope

Artificial notch

First fibre layer half cut

2 mm

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Stable crack propagation

Theoretical curve

Controlled crack propagation + rising load bearing capacity

Displacement [µm]

Load

[N]

Matrix-matrix debonding

Fibre-matrix debonding

bulk material failure

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Synchrotron tomography

● High energy synchrotron radiation (Strong X-ray attenuation of tungsten)

Sample diameter 1 mm; spatial resolution up to 1,5 µm

● Miniaturized samples → Single-fibre composite samples As-produced Heat-treated

● Stepwise mechanical testing Tension 4-point bending

Fibre

Matrix

Fibre

Matrix

Notch

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Bending test + tomography (ESRF)

Grenzfläche Er2O3; wärmebehandelt (1730° C, 30 min) Interface Er2O3; heat treated (1730° C, 30 min)

Displacement [µm]

Load

[N]

Crack stopping + bridging effective after embrittlement

Fibre

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Bending test + tomography (ESRF)

Fibre pull-out is active after embrittlement

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Toughening in comparison

[Ahsby 2005] and [Gludovatz 2010] ΔKIC = (ΔG ∙ E)0.5

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Self-passivating tungsten alloys

F. Koch1, J. Brinkmann1

1. Max-Planck-Institut für Plasmaphysik, Garching

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Accidential loss of coolant in reactor

Temperature profile in PPCS Model A, 10 days after accident with a total loss of all coolant. [Final Report of the European Fusion Power Plant Conceptual Study, 2004]

• Accidental loss of coolant: peak temperatures of first wall up to 1200 °C due to nuclear afterheat

• Additional air ingress: formation of highly volatile WO3 (Re, Os)

• Evaporation rate: order of 10 -100 kg/h at >1000°C in a reactor (1000 m2 surface) → large fraction of radioactive WO3 may leave hot vessel

Development of self-passivating tungsten alloys

Power plant conceptual study

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Idea: Tungsten alloys

Normal operation (600°C): Formation of tungsten surface by depletion of alloying element(s) due to preferential sputtering

structural material

W & alloying element(s) Tungsten

Accidental conditions: (air ingress, up to 1200 °C) Formation of protective barrier layer

structural material

barrier W & alloying element(s)

Self passivating tungsten-based alloys:

Surface composition automatically adjusts to the requested property

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Idea: Tungsten alloys

Normal operation (600°C): Accidental conditions: (air ingress, up to 1200 °C) Formation of protective barrier layer

structural material

barrier W & alloying element(s)

Surface composition automatically adjusts to the requested property

TRIDYN numerical simulation of sputter erosion of W-Si-Cr alloy (D ions, 30 eV, fluence 1018/cm²)

Self passivating tungsten-based alloys:

surface bulk

0,0

0,2

0,4

0,6

0,8

1,0

0 20 40 60 80 100Depth [A]

Con

cent

ratio

m

W, 44 at.%

Si, 36 at.% Cr, 20 at.%

W, 86 at.%

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Idea: Tungsten alloys

Normal operation (600°C): Accidental conditions:

Surface composition automatically adjusts to the requested property

TRIDYN numerical simulation of sputter erosion of W-Si-Cr alloy (D ions, 30 eV, fluence 1018/cm²)

Resin

Sapphire substrate 5 µ m 5 µ m

W-Si-Cr alloy

W, Si, WO3, SiO2

Cr2O3

Cross section of sputter deposited W-Si-Cr film after oxidation at 1000°C for 1h

Self passivating tungsten-based alloys:

surface bulk

0,0

0,2

0,4

0,6

0,8

1,0

0 20 40 60 80 100Depth [A]

Con

cent

ratio

m

W, 44 at.%

Si, 36 at.% Cr, 20 at.%

W, 86 at.%

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Tungsten alloy compositions – ternary alloys

• pure material: W

• alloys - binary: W-Si, W-Cr - ternary: W-Al-Cr,

W-Si-Al, W-Si-Ni, W-Si-Y, W-Si-Zr, W-Si-Cr W-Cr-Ti

- quaternary: W-Si-Cr-Al, W-Si-Cr-Zr, W-Si-Cr-Y W-Cr-Zr-Y

Oxidation rate has been calculated from weight increase versus time, linear fit. Compositions are given in wt.%.

0.7 0.8 0.9 1.0 1.1 1.210-7

10-6

10-5

10-4

10-3

10-2

10-1 1400 1300 1200 1100 1000 900 800

W WSi14 WSi13Zr13 WSi9Y13 WSi8Cr12

k [ m

g cm

-2 s

-1]

103 / T [K-1]

Temperature [K]

Arrhenius plot of oxidation rates: Tungsten and tungsten alloys

Tested compositions

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Tungsten alloy compositions – Si-free alloys

• pure material: W

• alloys - binary: W-Si, W-Cr - ternary: W-Al-Cr,

W-Si-Al, W-Si-Ni, W-Si-Y, W-Si-Zr, W-Si-Cr W-Cr-Ti

- quaternary: W-Si-Cr-Al, W-Si-Cr-Zr, W-Si-Cr-Y W-Cr-Zr-Y

Tested compositions “Active elements”: influence to diffusion at grain boundaries

Self passivation like ternary W-Si-Cr alloys, with higher tungsten content! Protection scale: Cr2O3

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

W-Si-Cr bulk material

width of cut: ~75 µm

3D morphology identical to surface

Collaboration with CEIT, San Sebastían, Spain (C. García-Rosales)

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Cross section bulk W-Si10-Cr10

32µm

From EDX analysis: no pores! alloy matrix W grains free of Cr Si-O precipitates

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Oxidation rates for bulk W Si10 Cr10

strong passivation at 800°C, comparable to quaternary alloy layers

Comparison of parabolic rate constants

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Alloys at first wall: deuterium impact

Erosion by deuterium ions (500 eV, 1.1 ∙ 1024 D/m2, 600 °C)

1000 2000 3000

1

10

100

Si Cr WC

Inte

nsity

(a.u

.)

Energy (keV)

as-deposited: inside erosion spot:

● RBS 4He 3.2 MeV

⇨ W enrichment at alloy surface

M. Balden

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Si-free alloy: W-Cr-Ti bulk manufacturing

Two powder metallurgical routes under investigation ⇒ demonstrate feasibility of technical production

powders

mixing

bulk alloy

sintering 1800°C, H2-atm, 1bar

compaction to be determined

machining to be determined HIPing

1300°C, 200MPa, 1h

compaction cold, unaxial pressing

mechanical alloying

1h-20h, planetary mill

mixing

490 μm

Tungsten SE-Image

Titanium Chromium

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

W-Cr-Ti oxidation rates

Comparison of bulk and thin film W-Cr-Ti

1000/T[K]

● good passivation for thin films

● depending on Cr concentration

● bulk samples show different behavior, also passivation

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Summary

SiCf / Cu and Wf / Cu composites

Extension of base material operational parameters Mock-ups successfully tested under HHF conditions Engineering of: interface, fiber, matrix

W fiber / W matrix composites

Mechanical solution to tungsten brittleness Increase of fracture toughness (“pseudo-ductility”) and controlled

crack growth Proof-of-principle, also demonstrated for recrystallized tungsten

Self-passivating W alloys

Up to 1/1000 reduction of oxidation rates for ternary alloys Transfer from thin films to bulk material successful PWI processes: W enrichment confirmed

Ch. Linsmeier | ICTP-IAEA PMI in Fusion Devices | 2014-11-03

Conclusions and outlook

Multi-component materials

Retention and release mechanisms different from pure metals Dynamic evolution of composition during operation Composites and alloys: new transport/trapping channels for T

DEMO: open issues, new ideas

Steel first wall / breeding blanket: T permeation barriers required Neutron damage: large T inventory, erosion behavior? Transmutations: formation of alloys (see above!)