Assignment front page for the student of university of Gujrat

-

Upload

university-of-gujarat -

Category

Education

-

view

508 -

download

1

Transcript of Assignment front page for the student of university of Gujrat

Assignment #: 01 Roll #: 11013323-

031

Subject code:

CHT-313

Topic of Assignment:“primary and secondary crusher and

Grinders”

Subject Name:“Partical Technology”

Submitted to:“Engr.Waqas Qamar”

Submitted by:“Ateeq Ahmad”

Submission date:18/11/2013

Marks

Department of Chemical Engineering (BS.Technology)

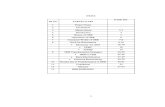

Content1) Primary Crusher

a) Jaws crusheri) Dodge type jaw crusherii) Blake type jaw crusher

b) Gyratory Crusherc) Rolling crusherd) Toothed roll crusher

2) Secondary crushera) Hammer mills b) Impactedc) Rolling compression machined) Attrition mills

3) Grindera) Fluid energy millb) Afiraled millsc) Colloid mill

1. Primary Crusher:A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust.

Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily

disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of

different composition can be differentiated. Crushing is the process of transferring a force amplified

by mechanical advantage through a material made of molecules that bond together more strongly, and resist

deformation more, than those in the material being crushed do. Crushing devices hold material between two

parallel or tangent solid surfaces, and apply sufficient force to bring the surfaces together to generate enough

energy within the material being crushed so that its molecules separate from (fracturing), or change alignment

in relation to (deformation), each other. The earliest crushers were hand-held stones, where the weight of the

stone provided a boost to muscle power, used against a stone anvil. Querns and mortars are types of these

crushing devices.

Primary crushing reduces this run-of-mine rock to a more manageable size. The different types of primary crushers are: jaw crushers, gyratory crushers, impact crushers, and autogenous crushers. Crushing is the first step in converting shot rock into usable products. Essentially, crushing is no more than taking large rocks and reducing them to small pieces. Crushing is sometimes continued until only fines remain.Mining operations use crushers, commonly classified by the degree to which they fragment the starting material, with primary and secondary crushers handling coarse materials, and tertiary and quaternary crushers reducing ore particles to finer gradations. Each crusher is designed to work with a certain maximum size of raw material, and often delivers its output to a screening machine which sorts and directs the product for further processing. Typically, crushing stages are followed by milling stages if the materials need to be further reduced. Additionally rock breakers are typically located next to a crusher to reduce oversize material too large for a crusher. Crushers are used to reduce particle size enough so that the material can be processed into finer particles in a grinder. A typical processing line at a mine might consist of a crusher followed by a SAG mill followed by a ball mill. In this context, the SAG mill and ball mill are considered grinders rather than crushers.At some operations, all the crushing is accomplished in one step, by a primary crusher. At other operations, crushing is done in two or three steps, with a primary crusher that is followed by a secondary crusher, and sometimes a tertiary crusher.There are several different types of primary crushers, however, there are many similarities in the job procedures followed by crusher operators.Raw material, of various sizes, is brought to the primary crusher by rear-dump haul units, or carried by a wheel front-end loader. Primary crushing reduces this run-of-mine rock to a more manageable size. The different types of primary crushers are: jaw crushers, gyratory crushers, impact crushers, and autogenous crushers.

a) Jaws crusher:

A jaw crusher uses compressive force for breaking of particle. This mechanical pressure is achieved by the two jaws of the crusher of which one is fixed while the other reciprocates. A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called as fixed jaw while the other jaw, called as swing jaw, moves back and forth relative to it. The volume or cavity between the two jaws is called as the crushing chamber. The movement of the swing jaw can be quite small, since complete crushing is not performed in one stroke. The inertia required to crush the material is provided by a weighted flywheel that moves a shaft creating an eccentric motion that causes the closing of the gap. Jaw crushers are heavy duty machines and hence need to be robustly constructed. The outer frame is generally made of cast iron or steel. The jaws themselves are usually constructed from cast steel. They are fitted with replaceable liners which are made of manganese. Steel or Ni-hard (a Ni-Cr alloyed cast iron). Jaw crushers are usually constructed in sections to ease the process transportation if they are to be taken underground for carrying out the operations.Application area: mining, building, railway, highway, metallurgy, chemistryProcessing stage: primary crushingCrushing material: limestone, gypsum, talcum, calcite, bauxite, granite, slag, iron ore etc. (<Moh’s harness 8)Crushing ratio: 4-6Main components: body frame, movable jaw, fixed jawProtection type: toggle plate Quickwear parts: high manganese steel

What is the Moh’s harness?The Mohs scale of mineral hardness characterizes the scratch resistance of various minerals through the ability of a harder material to scratch a softer material.

Jaw crusher Main Features and Benefits: 1) High reliability 2) Flexible capacity 3) Simple structure and easy to operate 4) Over-loading protection 5) Easy replacement of wear and spare parts 6) Long service time 7) High efficiency 8) Wide ranges of choices

How Jaw Crusher works:Jaw crusher reduces large size rocks or ore by compressing, a fixed jaw, mounted in a “V” alignment is the stationary breaking surface, while the moveable jaw plate exerts force on the rock by compressing it against the fixed jaw plate. The space at bottom of the “V”, aligned jaw plate , is the output size gap, or the maximum size of the crushed product.Due to the features of simple structure, reliable performance, convenient maintenance and safeuse, our jaw crushers of various models are widely used in the crushing operation in metallurgy, mining, building materials, chemical industries and cement enterprises.

Classification of jaws crusher:Jaw crushers are classified on the basis of the position of the pivoting of the swing jaw

1. Blake crusher-the swing jaw is fixed at the upper position2. Dodge crusher-the swing jaw is fixed at the lower position3. Universal crusher-the swing jaw is fixed at an intermediate position

i) Dodge type jaw crusher:In the Dodge type jaw crushers, the jaws are farther apart at the top than at the bottom, forming a tapered chute so that the material is crushed progressively smaller and smaller as it travels downward until it is small enough to escape from the bottom opening. The Dodge jaw crusher has a variable feed area and a fixed discharge area which leads to choking of the crusher and hence is used only for laboratory purposes and not for heavy duty operations.

ii) Blake type crusher:The Blake crusher was patented by Eli Whitney Blake in 1858. The Blake type jaw crusher has a fixed feed area and a variable discharge area. Blake crushers are of two types- single toggle and double toggle jaw crushers.

a. Single toggle jaws crusher:In the single toggle jaw crushers, the swing jaw is suspended on the eccentric shaft which leads to a much more compact design than that of the double toggle jaw crusher. The swing jaw, suspended on the eccentric, undergoes two types of motion- swing motion towards the fixed jaw due to the action of toggle plate and vertical movement due the rotation of the eccentric. These both motions, when combined, lead to an elliptical jaw motion. This motion is useful as it assists in pushing the particles through the crushing chamber. This phenomena leads to higher capacity of the single toggle jaw crushers but it also results in higher wear of the crushing jaws. These type of jaw crushers are preferred for the crushing of softer particles.

b. Double toggle jaw crushers:In the double toggle jaw crushers, the oscillating motion of the swing jaw is caused by the vertical motion of the pitman. The pitman moves up and down. The swing jaw closes, i.e., it moves towards the fixed jaw when the pitman moves upward and opens during the downward motion of the pitman. This type is commonly used in mines due to its ability to crush tough and abrasive materials.

b) Gyratory CrusherA gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head; both surfaces are typically lined with manganese steel surfaces. The inner cone has a slight circular movement, but does not rotate; the movement is generated by an eccentric arrangement. As with the jaw crusher, material travels downward between the two surfaces being progressively crushed until it is small enough to fall out through the gap between the two surfaces.

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used

for primary or secondary crushing. The crushing action is caused by the closing of the gap between the mantle line (movable) mounted on the central vertical spindle and the concave liners (fixed) mounted on the main frame of the crusher. The gap is opened and closed by an eccentric on the bottom of the spindle that causes the central vertical spindle to gyrate. The vertical spindle is free to rotate around its own axis. The crusher illustrated is a short-shaft suspended spindle type, meaning that the main shaft is suspended at the top and that the eccentric is mounted above the gear. The short-shaft design has superseded the long-shaft design in which the eccentric is mounted below the gear.

Application area: mining, cement, coal, metallurgic material, construction material, road building, and petroleum & chemical industriesProcessing stage: primary and secondary crushingCrushing material: limestone, gypsum, talcum, coal, calcite, bauxite, granite, slag, iron ore etc. (<Moh’s harness 9)Crushing ratio: 5Main components: Step bearing, ShellPinion shaft, Mantle, Main Shaft Sleeve, Main ShaftWorking principle: the gap between movable cone and fixed cone changes with the rotation of main shaft, thus the material is squeezed to the required sizeDischarge opening: 150mm~170mm

c) Rolling crusher:A factory or machine in which metal is rolled into sheets, bars, or other forms.

1. (Engineering / Metallurgy) a mill or factory where ingots of heated metal are passed between rollers to produce sheets or bars of a required cross section and form.2. (Engineering / Metallurgy) a machine having rollers that may be shaped to reduce ingots, etc., to a required cross section and form.

Advanced Design, High Performance Roller CrusherRoller crushers are used mainly for crushing easily fractured materials such as soft limestone, chalk, and clay to between 1/3 and 1/5 of its original size.

The Fields Of Application: Double roll crushers are used for both, primary and secondary crushing. They guarantee a strictly defined final grain size with a minimum of fine grains.

The Feed Materials: Raw materials, secondary materials and byproducts such as coke, sinter, coal, soft to medium-hard rock, ore, chalk, broken glass and similar products.

How To Work With Double Roller Crusher?The motor drives the fixed roller and movable roller to work via reducer and coupling. Materials are put into the space between the two rollers via the feed entrance. As the two rollers inward turning,

the input materials are crushed, pressed, ground, and at last come out from the base of the machine.

Rolling mills are machines which are used to process metal. They vary in size from bench-mounted

hand-cranked mills used by jewelers to massive rolling mills utilized in industrial metals production

and processing. The primary function of a rolling mill is to shape the metal being passed through the

mill in some way, and many come with attachments and accessories which can be used for different

types of tasks. Both hot and cold rolling mills are available for different metalworking applications.

A basic rolling mill is designed to produce sheet metal. The metal is passed between two tough

cylinders numerous times, with the distance between the cylinders

being decreased with each pass so that the metal becomes thinner

and thinner. Using a rolling mill, an ingot of aluminum can be

transformed into aluminum foil. Rolling mills are used to make

sheet metal in a variety of thicknesses, and they can also be used to

create custom sizes in a workshop by a metalworker who does not

want to keep an array of sizes on hand.

Rolling mills can also be used to produce wire. The wire may be

square, octagonal, or otherwise shaped by its passage through the

rolling mill. In this case, the metal is moved through a series of progressively smaller slots in the

rolling mill as it is

cranked through.

Rolling mills may also

cut metal with a

cutting attachment

which can be used to

create uniform

standardized cuts.

Rolling is a metal

forming process in which metal stock is passed through a pair of rolls. Rolling is classified according

to the temperature of the metal rolled. If the temperature of the metal is above

its recrystallization temperature, then the process is termed as hot rolling. If the temperature of the

metal is below its recrystallization temperature, the process is

termed as cold rolling. In terms of usage, hot rolling processes

more tonnage than any other manufacturing process, and cold

rolling processes the most tonnage out of all cold

working processes.

Roller

There are many types of rolling processes, including ring rolling, roll bending, roll forming, profile

rolling, and controlled rolling

A rolling mill, also known as a reduction mill or mill, has a common construction independent of the specific type of rolling being performed

Work rolls Backup rolls - are intended to provide rigid support required by the working rolls to prevent

bending under the rolling load Rolling balance system - to ensure that the upper work and back up rolls are maintain in proper

position relative to lower rolls Roll changing devices - use of an overhead crane and a unit designed to attach to the neck of the

roll to be removed from or inserted into the mill. Mill protection devices - to ensure that forces applied to the backup roll chocks are not of such a

magnitude to fracture the roll necks or damage the mill housing Roll cooling and lubrication systems Pinions - gears to divide power between the two spindles, rotating them at the same speed but

in different directions Gearing - to establish desired rolling speed Drive motors - rolling narrow foil product to thousands of horsepower Electrical controls - constant and variable voltages applied to the motors Coilers and uncoilers - to unroll and roll up coils of metal

Slabs are the feed material for hot strip mills or plate mills and blooms are rolled to billets in a billet mill or large sections in a structural mill. The output from a strip mill is coiled and, subsequently, used as the feed for a cold rolling mill or used directly by fabricators. Billets, for re-rolling, are subsequently rolled in either a merchant, bar or rod mill. Merchant or bar mills produce a variety of shaped products such as angles, channels, beams, rounds (long or coiled) and hexagons.

d) Toothed roll crusherToothed roll crusher is suitable for crushing raw coal in coal, metallurgy, mine, chemistry and building materials industry especially in large coal mines and coal dressing plants. Toothed roll crusher has very big crushing ability, and the electromotor is connected with the reducer with Limit type hydraulic coupler to prevent dynamic overload, so that the sensor is safe and reliable. The adjustment of the space between the two rolls belongs to hydraulic adjustment and the bearing of the rolls are lubricated centrally. The toothed roll crusher has the advantages of small size, big crushing ratio, low noise, simple structure and convenient maintenance and the features of high productivity, even granularity of the crushed materials, low over-crushing rate and flexible over-load protection.

Performance Characteristics1. Compared with other types of crushers, this series of crusher has many advantages such as big crushing ratio, no requirement for the water content of the materials to be crushed, low noise, low vibration, low energy consumption, small coverage size and simple and convenient maintenance.

2. It is equipped with hydraulic automatic yielding device which can effectively prevent the iron from damaging the roll and prevent wood and soft materials from damaging the normal work of the roll.3. It is equipped with intelligent clearing device which can automatically remove the materials sticking on the chamber wall using the working intervals.4. This machine adopts mechanical, equipment and hydraulic protective device and interlocking device, thus effectively protecting the electromotor, crusher and the whole system.5. This product becomes the first choice of the heat-engine plant to replace import crushing equipment due to its advantages of high efficiency, energy conservancy and environment protection. It is suitable for crushing crisp materials with medium and low hardness such as soft coal, blind coal, lignite and gangue and also suitable for processing sinter, coke, slag, shale and limestone.

Working PrincipleToothed roll crusher is mainly composed of driving tooth, reducer, hydraulic coupler, electromotor, motor-driven fuel feed pump, passive toothed roll, arch toothed plate, side toothed plate, and side toothed plate base, lower frame and velometer.Toothed roll crusher mainly splits and crushes the materials using unique wear-resisting toothed roll rotating with high speed, forming high-productivity mechanism. This toothed roll crusher is mainly composed of driving device, rack part, crushing roll, and mechanical spring device and link gear. Toothed roll crusher has very big crushing ability, and the electromotor is connected with the reducer with Limit type hydraulic coupler to prevent dynamic overload, so that the sensor is safe and reliable. The adjustment of the space between the two rolls belongs to hydraulic adjustment and the bearing of the rolls are lubricated centrally.

2) Secondary Crusher

This crusher is usually for re-crushing the primary crusher run smaller or rejects from the primary crusher run.

a) Hammer Crusher OverviewHammer crusher also called hammer mill crushes by the collisions between high-speed hammer and material, which features in its simple structure, high reduction ration, high efficiency, ect. The hammer crushers were developed for the both dry and wet crushing of brittle, medium-hard materials for the mining, cement, coal, metallurgic, construction material, road building, and Petroleum & Chemical industries.

Application area: mining, construction, metallurgy, chemistry, cement, coalProcessing stage: primary crushingCrushing material: Coal gangue, coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains, alum, brick and tile, calcite, bauxite, granite, iron ore etc. (<100Mpa)Main components: frame ,rotor, grizzly bar, Impeller bar,and other adjustment equipmentQuickwear parts: high manganese steel Hammer Crusher Detail Info

Hammer crusher application Hammer crusher is applicable for both dry and wet crushing, and it is widely used for medium or fine crushing for medium hard and brittle materials by departments of mine, cement, coal, building material, metallurgy, chemical industry, road construction, gas chemical industry and thermal power generation, etc. Coal gangue, coke, slag, limestone, phosphate rock, salt, whiting, gypsum stains, alum, brick and tile, etc. can be crushed by this equipment. The compression strength of the materials shall not exceed 100MPa, while the moisture content shall be lower than 15%.

Hammer crusher PartsHammer crusher consists of frame ,rotor, grizzly bar, Impeller bar,and other adjustment equipment.

Hammer Crusher Working Principle

The main working part of hammer crusher is rotors with hammer. The rotors consist of main shaft, disk, pin shaft and hammers. The motor drives the rotors to rotate quickly in the crushing cavity. Raw materials enter the crusher through the feed opening and are stricken, impacted, cut and ground by the high-speed hammer to small size. There is a screening plate under the rotor, so that materials with size smaller than the screen mesh will be screened out and others are left to be further hammered and ground until reach the standard size. The size of the final product can be adjusted by changing the screening plate. The gap between the rotors and the screening plate can also be adjusted according to different requirement.

a) Impacted Impact crushers, which are also called hammer mills, break rock by impacting the rock with hammers that swing on a rotating shaft. The practical use of impact crushers is limited to soft materials, such as phosphate, gypsum, weathered shales, etc.

Impact crushers cannot handle as large a top sized material as jaw, or gyratory, crushers can; however, impact crushers can make a finer sized product.

Impact crushers involve the use of impact rather than pressure to crush material. The material is contained within a cage, with openings on the bottom, end, or side of the desired size to allow pulverized material to escape.

Impact crusher (impactor crusher machine) is suitable for materials whose compressive strength is under 360Mpa, and particle size is less than 500mm. This kind of machine features easy maintenance, high crushing ratio and crushing efficiency etc. With end products in cubic shape, impact crushers are the ideal crushers for aggregates processing in high-type highway building, water conservancy and power construction.

Application area: road and railway building, dam, constructionProcessing stage: secondary crushingCrushing material: limestone, gypsum, talc etc. (<Moh’s harness 4)Crushing ratio: 10-20Main components: body frame, rotor, impact rackWorking principle: the rotor rotates at the high speed and hits the entering materials, which will be shot back by the impact rack; the material is crushed due to the constant impactProtection type: impact rack self weightQuickwear parts: high manganese steel, high chromium steel

Impact crusher application Impact Crusher is the most common equipment of the stone crushing production line , adopting the latest producing technology, features many advantages: special structural design, cubic shaped desired products, dealing with the material with the side length 500mm, not more than 350Mpa anti-pressure strength, Impact Crusher can be widely used in crushing the coarse, midium, and fine material(E,g. granite, limestone, concrete).

Impact crusher main features and benefits

1. Energy-efficient.

2. Unique structure, keyless connection.

3. Blow bar made of high chromium steel, impact plate with a special shape.

4. End products with cubical shape.

5. Easy operation and maintenance and high reliability.

Impact Crusher Working PrincipleThe impact crusher uses plate hammer on the rapidly rotating rotor to generate high-speed impact to crush the materials in the crushing cavity, and casts the crushed materials along tangential

direction to impact plate at the other end of the crushing cavity. The materials are crushed again, and then, they return to the plate hammer to undergo the process above repeatedly.The materials are bumping with each other when being sent between the plate hammer and the impact plate. The materials become cracked, loose and then comminuted by knocking by the plate hammer, impact with impact plate and bump between materials. The materials with grain size smaller than the gap between impact plate and plate hammer will be discharged.

Classification of Impact crusher

Horizontal shaft impactor (HSI) / Hammer mill:

The HSI crushers break rock by impacting the rock with hammers that are fixed upon the outer edge of a spinning rotor. HSI machines are sold in Stationary, trailer mounted and crawler mounted configurations. HSI's are used in recycling, hard rock and soft materials. In earlier years the practical use of HSI crushers is limited to soft materials and non abrasive materials, such as limestone, phosphate, gypsum, weathered shales, however improvements in metallurgy has changed the application of these machines.

Vertical shaft impactor (VSI):

VSI crushers use a different approach involving a high speed rotor with wear resistant tips and a crushing chamber designed to 'throw' the rock against. The VSI crushers utilize velocity rather than surface force as the predominant force to break rock. In its natural state, rock has a jagged and uneven surface. Applying surface force (pressure) results in unpredictable and typically non-cubical resulting particles. Utilizing velocity rather than surface force allows the breaking force to be applied evenly both across the surface of the rock as well as through the mass of the rock. Rock, regardless of size, has natural fissures (faults) throughout its structure. As rock is 'thrown' by a VSI Rotor against a solid anvil, it fractures and breaks along these fissures. Final particle size can be controlled by 1) the velocity at which the rock is thrown against the anvil and 2) the distance between the end of the rotor and the impact point on the anvil. The product resulting from VSI Crushing is generally of a consistent cubical shape such as that required by modern SUPERPAVE highway asphalt applications. Using this method also allows materials with much higher abrasiveness to be crushed than is capable with an HSI and most other crushing methods.

VSI crushers generally utilize a high speed spinning rotor at the center of the crushing chamber and an outer impact surface of either abrasive resistant metal anvils or crushed rock. Utilizing cast metal surfaces 'anvils' is traditionally referred to as a "Shoe and Anvil VSI". Utilizing crushed rock on the outer walls of the crusher for new rock to be crushed against is traditionally referred to as "rock on rock VSI". VSI crushers can be used in static plant set-up or in mobile tracked equipment.