...- - g assignment) (homework assignment) (short assignment) ? 121 page

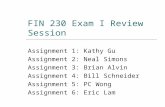

Assignment

description

Transcript of Assignment

Take this assignment from Mr. Pai and give that assignment to students

Class: F. Y. M. E. (Production-Manufacturing and automation)

Subject: Industrial Automation

Assignment No.: 02

1. Discuss various ways by which guidance of AGV’s can be accomplished. 2. Explain the effect of part population, effect of speed, and effect of number of reciprocating

strokes on the feed rate in case of reciprocating fork feeder used in automated assembly systems.

3. Explain with neat sketch any two types of rotary feeders. 4. Expalin various principles of material handling systems. 5. Expalin the use of oscillating disks for automated orientation of workpiece.6. Explain with neat sketch any two types of escapements. Also mention their industrial

applications. 7. Explain with suitable example the gravity fed magazine, weight operated magazine, and

friction fed magazine. 8. A feeder selector device at one of the stations of an automatic assembly machine has a

feed rate of 25 parts/min and provides a throughput of one part in four. The ideal cycle time of the assembly machine is 10 sec. The feeder stops for 20 parts in feed track and will start while 10 parts in feed track. Determine how long will it take for the feeder to turn on once it is turned off and how long it will take to turn off once it is turned on?

9. In an automated material handling system AGVs are used for material handling. A number of deliveries and empty returns are indicated in a from-to chart in Table 1. The corresponding distances are indicated in Table 2. The speed of an AGV is 100 ft/min. Considering a traffic factor of 0.9, determine:

i) The total transport work.ii) Average total time per delivery, the handling system efficiency, and the resulting

average number of deliveries per hour. iii) Number of vehicles needed to satisfy the indicated deliveries per hour.

Table 1: From-To chart showing number of moves per hour between different stationsTo

From 1 2 3 41 0 7D 5D 3D2 4E 0 0 3D3 5E 0 0 04 6E 0 0 0

(Deliveries indicated by ‘D’ and Empty moves indicated by ‘E’)

Table 2: From-To chart showing distances between different stationsTo

From 1 2 3 41 0 150 100 1302 150 0 NA 803 100 NA 0 NA4 130 NA NA 0

(NA: not applicable)