Assembly Procedure Electrical Specification DATA...

-

Upload

nguyendang -

Category

Documents

-

view

240 -

download

6

Transcript of Assembly Procedure Electrical Specification DATA...

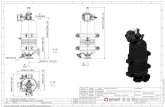

c

b

ad

32 REF

1.7

REF

3.2

REF

0.4

REF

9 RE

F

22 REF 10 REF

7 SLEEVE / SPRING NYLON N/A

6 INSULATOR PTFE N/A

5 OUTER CONTACT PHOSPHOR BRONZE GOLD

4 CRIMP SLEEVE BRASS NICKEL

3 INNER CONTACT BERYLLIUM COPPER GOLD

2 LATCHING SLEEVE BRASS NICKEL

1 BODY BRASS NICKEL

ITEM DESCRIPTION MATERIAL PLATING

DRAWN

CHK'D

APPV'D

DIMENSIONS ARE IN MILLIMETERS

NAME SIGNATURE DATE

DO NOT SCALE DRAWING

REVISION

SHEET 1 OF 1

A4GE

IG

04/04/2007

17/12/2007

310-825-TNG-RG179

HD43 4FSDescription

Part Number

A03INTERFACE COMPONENTS LTD6-8 COLNE ROAD, TWICKENHAM,MIDDLESEX. TW1 4JR

THE INFORMATION IS GIVEN AS AN INDICATION ONLY AND IS SUBJECT TO CHANGE WITHOUT NOTICE. IN

THE CONTINUAL GOAL TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO MAKE ANY

MODIFICATIONS NECESSARY WITHOUTPRIOR NOTICE.

Tel: +44(0)20 8538 9008 Fax: +44(0)20 8538 9007 Email: [email protected]

DATA SHEETElectrical Specification

Impedance:

Frequency:

Dielectric W/V:

Insulation res:

Mechanical Specification

Centre contact retentionAxial Force:

Cable Retention:

Mating cycles:

Environmental Specification

Operating Temp:

Tooling

Centre Contact:

Crimp Sleeve:

75 Ohm

0 - 3 Ghz

1500 V rms min

500 M-Ohm min

22N min

60N min

250

-40 to +100 Deg C

INDENT MH800 (GB109)

HEX 3.25mm A/F

STRIPPING DIMENSIONS

a =

b =

c =

d =

4.5 mm

8.0 mm

21.0 mm

16.5 mm

C.

200

7. T

HIS

DO

CUM

ENT

IS T

HE P

ROPE

RTY

OF

INTE

RFA

CE

CO

MPO

NEN

TS L

TD. R

EPRO

DUC

TION

OR

CO

MM

UNIC

ATIO

N IN

AN

Y FO

RM T

O A

THI

RD P

ART

Y IS

PRO

HIBI

TED

WITH

OUT

PRI

OR

WRI

TTEN

CO

NSE

NT

- Place adaptor over cable.- Place contact on centre conductor.- Ensure centre conductor is visible in the inspection hole in centre contact.- Place in appropriate tool and crimp.- Remove adaptor for reuse.

- Place crimp sleeve over cable.- Trim cable to dimensions shown.- Ensure centre conductor is not damaged.

- Slide the crimp sleeve over the braid.- Crimp the crimp sleeve using the appropriate sized crimp tool. (trim excess braid if necessary)

Assembly Procedure

- Fan the braid out.- Push contact into body sub-assembly.- Ensure contact "CLICKS" in place into insulator with ferrule between braid and dielectric.

1.

2.

3.

4.