Asian Battery Conference - 2013

-

Upload

karen-hampton -

Category

Documents

-

view

248 -

download

11

description

Transcript of Asian Battery Conference - 2013

Full conference listingof exhibitors, booths

Techno-wizardry, new battery alchemies await

Bringing the industry togetherwww.batteriesinternational.com

stry togetherrnational.com

SPECIAL SUBSCRIPTION DISCOUNT: S

EE INSIDE!

Inside track view onmain themes of the event

Life outside the meetings: Singapore's other side

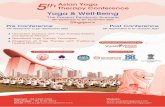

September 10 to 13, 2013 15th ABC, Singapore

Ready for the chargeLead acid poised for next Asian challenge

Oak Press Solutions Inc. 504 Wade Street • Sturgis, MI 49091 • U.S.A.

email: [email protected]

USA / AMERICAS • Sorfin Yoshimura, Ltd. • email: [email protected] • Sorfin Yoshimura Tokyo, Ltd. • email: [email protected] • Sorfin Yoshimura Qingdao, Ltd. • email: [email protected] • Sorfin Yoshimura Europe • email: [email protected] • Sorfin Yoshimura Sao Paulo • email: [email protected]

THE field-proven technology.

PGP punching systems from OAK Press Solutions are in batteryplants right now producing very consistent, high-quality grids for a variety of applications. OAK’s technology is based on more than 50 years of experience designing and building punching systems and precision punching dies.Now you can join the growing list of companies who have selected OAK for their needs:

• 16 battery grid punching systems• 35 battery grid punching dies

Choose OAK’s experience, quality and support network. It’s THE proven technology you can trustwherever you make batteries.

MAKE HIGH-QUALITY GRIDS WITH

P30P30784784 BattBatterieeries Ins Intl.itl.indd ndd 1 1P30P30784-784-BattBatterieeries Ins Intl itl inddndd 11OPOPOOOOOOOOOO 00003333PPPP 0000OOOP3OP3OP30 MMMMMMMMAAMMAAAAAA4 A4 A4 A4 A7/167/16/13 /13 9: 9:24247/167/16/13/13 9:9:24247777 AAAAMMMMMMMMMMMMMMMM7777 447/167/16/13/13 9:9:24 A24 AMM7/ 4 AM

www.batteriesinternational.com Batteries International • 15th ABC Show Guide • Summer 2013 • 1

EDITORIAL

Pollution has a price tag. And that price — as one of the major themes that the 15th Asian Battery Conference will explore — comes in various shapes and forms.

Air pollution in northern China is, according to a recent study, shortening the average life of its citizens by fi ve years. According to another study, this time by the Chinese, the annual cost of environmental degradation was $230 billion in 2010. Not cheap.

But another price tag is the competitive advantage for ignoring the environment altogether.

While European and North American fi rms have steadily cleaned up their acts, they’ve also paid a price tag. For them the present low levels of lead in the blood of their workers could easily add another $10 to the cost of making their automotive batteries.

For a long time Asia as a whole — and China in particular — paid scant attention to the environment in their mad dash for growth. It made little sense to be ecologically diligent when you are creating industrialized economies from scratch.

It was the price you willingly paid to put yourself on the economic map. In China’s case to create a middle class of half a billion people in a bare couple of decades.

This new middle class has a political clout totally different from its agrarian roots. People aspire to the standards, values and health of the west.

So at a certain point the economics of disregarding the environment no longer make sense politically. Or economically too. Recent studies show that one can take around four percentage points off China’s gross domestic product fi gure as the price the country pays — from the massive strains on health care, to the tens of millions of days of work lost, to providing clean drinking water and much more — for this explosive growth.

All this means is that Asia’s energy storage industry is having to face up to tremendous challenges in the way that it does business. Importantly, every indication is that the environment has steadily moved up regional governments’ agenda in terms of its importance.

In China’s case, the crack-down on battery manufacturers two years ago, was just the

fi rst shot across the bows in an engagement that, in the end, only the government can win. Tighter legislation is being drawn up, a rethink of how resources will be used is resulting in a dramatic shift to renewables.

The country could be self-suffi cient in electricity by 2030 just from wind generation, or some studies say.

Within a generation Asia has become the most important battery manufacturing region in the world, the challenge is to maintain that lead as well as maintain the clean up.

Mike HallsEditor

Environmental issues to set the agenda for Asian battery industry

2 • Batteries International • 15th ABC Show Guide • Summer 2013 www.batteriesinternational.com

CONTENTS

LEAD ACID — UNSTOPPABLE, THE INDUSTRY MARCHES ONThe 15th Asian Battery Conference in Singapore between September 10-13 — and the preceding

3rd International Secondary Lead Conference on September 9-10 —could well be the most

popular lead events in Asia this side of the new millennium.

In our special pre-conference guide we look at the editorial agenda and interview many of the

luminaries that will be presenting or chairing the sessions.

EDITORIAL 1Environmental issues to set the agenda for Asian battery industry

SINGAPORE 4Where to go in the Lion City

VIEW FROM THE CHAIR ... AND THE SPONSORS 7

OVERVIEW 14Driving global growth figures

Asia is increasingly driving lead pricing

Exponential growth forecast for India

SECONDARY LEAD 20The upcoming revolution: disbelieve it at your peril

TECHNOLOGICAL ADVANCES 16Accelerating the pace of development

Ultrabattery comes to the rescue of renewables

A is for additives, B is for battery

Stop-start technology is go-go-go

EXHIBITORS: WHO’S WHERE 18

BATTERY HEROES 34, 44Jun Furukawa and L Pugazhenthy

REGULATORY 38Breathe deep and tell us you feel better!

ENVIRONMENTAL IMPACT 40Legacy issues — dealing with past malpractice

More osculatory than regulatory but both have their part to play 38

New lexicography for advanced lead acid batteries 33

Where high fliers in Singapore perch between presentations 4

Publisher: Karen Hampton,

+44 (0) 7792 852337

Editor: Michael Halls,

+44 (0) 7977 016 918

Supplements editor: Wyn Jenkins,

wyn.Jenkins@serenglobalmedia.

com, +44 (0) 792 293 222

Business development manager

June Moultrie

+44 (0) 7775 710 290

Reception:

+44 (0) 1787 729 320

fax: +44 1787 729 330

Subscriptions and admin

manager:

Claire Ronnie,

subscriptions@batteriesinternational.

com

+44 (0) 1787 729 320

Research editor

William Aslan

Staff reporters:

Philip Moorcroft, William Aslan

Production/design: Antony Parselle,

+44 (0) 1727 899 360

International advertising representa-

tion:

advertising@batteriesinternational.

com

The contents of this publication are

protected by copyright. No

unauthorised translation or

reproduction is permitted.

ISSN 1462-6322

(c) 2013 Mustard Seed Publishing,

UK company no: 5976361.

Printed in the UK via

ThisismethodUK

Disclaimer: Although we believe in

the accuracy and completeness of the

information contained in this magazine,

Mustard Seed Publishing makes no

warranties or representation about this.

Nor should anything contained within it

should be construed as constituting an

offer to buy or sell securities, or constitute

advice in relation to the buying or selling of

investments.

EXHIBITION GUIDE, 28-32

Our comprehensive listing of exhibitors in the main

hall includes a full run down of sponsors of this pre-

conference guide and an alphabetical and numerical

list of which firm can be found —and where!

4 • Batteries International • 15th ABC Show Guide • Summer 2013 www.batteriesinternational.com

Reasons to be fearful — part 1

If you suffer even the merest hint of vertigo, this surely the one experience in Singapore that you’ll want to avoid (or failing that wear a blindfold). The Singapore Flyer is a huge Ferris wheel some 42 stories high — roughly half the height of the Empire State Build-ing and the tallest Ferris in the world.

Although Feng shui masters decid-ed in 2008 that the wheel direction should be reversed — clockwise has so much better “vital qi” — the Flyer has had a troubled fi nancial history and although open for business was last heard of as being in receivership.

Where to fi nd itThe Singapore Flyer is located near the shore of Singapore’s Marina Bay. 30 Raffl es Avenue. Nearest MRT, Promenade

Early birds, worms and tai-chi

Jet lagged and don’t know what to do at 5am? Join the earliest of early risers with a visit to Singapore’s Botanic Gardens. The gardens are open from 5am-midnight.

On the main boardwalk it is still possible to wander through swathes of virgin rainforest —some six hectares in size which predate the creation of the park in 1859.

Other fun is to identify some of the huge trees, the Terminalia Subspathulata is close to 50 me-tres high, or enjoy the delights of local joggers ruining the start of the day in style.

Don’t forget to look in at the Na-tional Orchid Garden — entrance fee S$5 but open 8.30am to 7.00pm — which boasts 1,000 different types of orchid.

The entire 74 hectare park is 2.6 kilometres at its longest.

Where to fi nd it1 Cluny Road, MRT station Botanic Gardens is the main entrance to the park.

Shop till you drop

Two of the hottest spots for shopping — Funan Digitalife Mall and Sim Lim Square — are the places to go for pos-sibly the widest range of electronic products in the world. These two massive multi-storey emporia offer the most bewildering range of hand-

Where to go in the Lion CityWelcome to Singapore— a

glittering space where Asian and international wealth and

wisdom meet in a spectacular fashion. The shopping is some of the best in the world, attracting top brands at highly competitive prices.

It’s also a place to eat well. This ranges from fi ne dining — including the best of Eurasian fusion cooking —

There are four offi cial languages: English, as a legacy of its history as a former UK colony but also refl ecting its international dimension, as well as Malay, Chinese and Tamil. Roughly three quarters of the population are

of Chinese extraction.Although Singapore’s towering

skyscrapers refl ect its modern culture, the earliest settlement on the spot dates back to the second century but the greatest part of its history dates back to the arrival of Thomas Stanford Raffl es in 1819 and its sale to the British fi ve years later. Here are three places that we’d recommend.

15th ABC SHOW GUIDE

15th ABC SHOW GUIDEDEE

15th ABC Show Guide • Summer 2013 • 5

cams, portable DVD players, mo-bile phones, hi-tech cameras, MP3 players and laptops in just about every imaginable confi guration.

The prices are usually about 10% to 20% cheaper than at other com-mercial outlets.

Remember to bargain though! At Sim Lim Square especially,

good deals can be had with some serious haggling, and many retailers will knock off a few extra dollars if you pay in cash.

Where to fi nd itFunan Digitalife Mall: 109, North Bridge RoadFive minute walk from City Hall MRTOpen 10am-10pmSim Lim Square, 1 Rochor Canal RoadFive minute walk from Bugis MRT and Little India MRTOpen daily 10.30am-9.00pm

Singapore has an excellent bus

and underground (MRT) service.

Travel is cheap and frequent. The

best ticket for visitors is probably

the Singapore Tourist Pass — S$10

(US$8) a day or S$20 for three

days.

One quirk of the system is that

a deposit system operates. You

deposit S$10 for the pass and get

this back when you return it.

The nearest MRT station to the

conference hotel, the Shangri-La,

is on Orchard Road. It’s about a 10

minute walk.

For iPad, iPhone and iPod touch, the free Singapore app is well worth a look. Billed as the ultimate travel app for tourists visiting the island state this has comprehensive information of over 1,000 things that you can see and do in Singapore. It also provides you with maps, route suggestions, travel fare estimation and quick dial taxi booking!

The app was developed by the Singapore Tourism Board.

There are further free apps for Singapore including those for use of the MRT (underground) and the bus service.

There’s also offi cial iPhones apps for Singapore largest IT and electronic shopping mall! It features the latest highlights and promotions from Sim Lim Square and provide a detailed fl oor maps with of all of the contacts of the shops.

Advice to all visitors to Singapore? Leave your chewing gum at home.

The import, sale and manufacture of chewing gum has been against the

law since 1992.

Although a single packet may squeeze through — presumably for

consenting adults to chew in private — bringing in more will land you in trouble.

There was even a time in the early 1990s when chewing gum smuggling was big

business for what the Singapore government called “delinquents” from Malaysia.

Don’t worry if you need nicotine gum, however. That’s perfectly legal but remember to

take some ID to the pharmacy!

Singapore laws — and remember the city-state is a democracy — can certainly be

quirky. But oddly enough they make a kind of sense in the end. Clearing up chewing

gum from the underground, where it was clogging up train doors, was costing tens of

millions of dollars.

Face painting, even for children, is forbidden as is wearing “any form of disguise”.

Don’t even think about bungee jumping (illegal) as is walking around naked in your own

home (pornographic).

And don’t forget! Failure to fl ush a public toilet can result in hefty fi nes. True!

FREE APPS FOR SINGAPORE

DON’T BITE OFF MORE THAN YOU CAN CHEW!

tt IITT dd l tt ii hh ii

atat hhhomomome.e.

aaaagagaaaininnststststss ttttheheehe

aaablblbb y y yy fofofofforr rr

ll llanananana ddd ddd yoyoyooooyoyouu inininnini ttttrororooooubububublelelele. .

mm smsmsmsmmuguguu glglglg inninnggggg wawawaw ss s s bibig g gggg

nntsts”””” fffrfromomomomm MMMMMalalalalayaya sissiaaa

GETTING ROUND THE CITY

S

a

T

b

th

(U

d

a

d

th

c

is

m

G

*Payment for subscription has to clear by 30 September 2013 to be eligible for this offer

I would like to subscribe to Batteries International for ■■ 1 year (4 issues + free copies of Batteries Industry Guide) at the reduced rate of £99 • €150 • US$180

■■ 2 years (8 issues + free copies of Batteries Industry Guide) at a cost of £185 • €290 • US$340

■■ 3 years (12 issues + free copies of Batteries Industry Guide) at a cost of £245 • €380 • US$450

Company: .........................................................................................................................................................................................................................................

Address: ...........................................................................................................................................................................................................................................

............................................................................................................. Postal/Zip Code: ................................................................................................................

Tel: .......................................................................................................................... Fax: ................................................................................................................

e-mail: ..............................................................................................................................................................................................................................................

Visa ■■ Mastercard ■■ Card number: ........................................................................................................................ Expiry date (mm/yy) .................................

Name of card holder: .........................................................................................................CCV (three digit verifi cation code on back of card) .................................

Mailing address for billing purposes of card holder: ..........................................................................................................................................................................

......................................................................................................................................................... Postal/Zip Code: ...................................................................

Signature .............................................................................................................................................................. Date ..................................................................

Alternatively, please fill in the form below, fax to +44 1787 329730 or post to: Batteries International subscriptions, 10 Temple Bar Business Park, Strettington Lane, Strettington, PO18 0TU, UK

Attendees at 15th ABC can receive up to 25% off if they’d like to subscribe to Batteries International! Just look at the magazine — you know it makes sense.

For a limited time* we are slashing the price of a subscription and giving you the chance to take part in one of the most exciting years in the battery and energy industry.

Don’t be the only one who doesn’t know what’s going on!

Please contact Claire Ronnie at [email protected] for multiple subscription rates.Telephone: +44 (0)779 852337 • Fax: +44 (0)1787 329730

Time to debunk thelithium mythsCase study: growing your business in the teeth of a recession

Excitement: NAATBaat picks Kentucky for HQ

Lead acid fights back

Issue 72

Spring 2009

Why cutting edge lead technology could knockout next generation batteries

Bringing the industry togetherrn

LeLeeeeeaad acidcucuuttttiting teeaadadd daoogoggygyy nonoocockckk

nn

gininngg g tthe indusbatteriesinter

Issue 73

Summer 2009

Bringing the industry together

www.batteriesinternational.com

Life after GM, Chrysler

collapse: it ain’t so bad

Separating flywheel

hype from substance

Thrills and spills: Obama

announces loans, grants

UPS: time

to see the

bigger

picture

d

trna

Issue 76 Spring/Summer 2010

Bringing the industry togetherwww.batteriesinternational.c

Can this separator outsmart the lithium

nail penetration test?

The EV conundrum: time to make the

numbers stand up

Tributes as BCI's Moe Desmarais moves on

Moltenshow p

Optimism unbounded:AABC Orlando reviewand exhibition special

Exide’s‘confidreinven

Ba eriesInternational

Putting the va-va-voom into customer service

North American supplier profiles

Summer 2010

theerrcom

n salpote

ismOrla

xhib

s Cdennt

iesonal

-vaa-voservvice

upplier p

Bringing the industry togetherwww.batteriesinternational

Year aheadad survey: the hohopes and challengeses of 2011Phoenix from the flames: how Firefly Energy was salvaged

Time to chharge for energy, noot for theboxes it comes in

When the gointough: the life times of Axion China motive boom powers on, demand to send lead prices higher

Why Detchko Pavdeserves his lifetachievement awa

Issue 78 Winter 2010/2011

Ba eriesInternational

The first whiff of danger

What rare earth shortages will meean to the battery inddustry

nen

boms

vtia

W

roo

Issue 79 Spring 2011

Ba eriesInternationalIssue 79 Spring 2011

Internrnaaaaaaaattional

Esoteric expertise:the unusual skillsof mold makers

Engineers for thenext generation —the great brain drain

Energy storage for the future: full charge in two minutes

Be there or be square!See our new expandedevents section

Task forces meetin battle to setcommon standards

A life on the road: recollections of a travelling batteryman

Bob Galyen, Magna e-Car and the future of testing

Bringing the industry togetherwww.batteriesinternatio

next generation the great brain drain

Energy storage for thefuture: full charge in two minutes

togetheronal.com

FANCY A BOSS

ANOVA BOYS?

Page 2

9

SPECIAL ABC SUBSCRIPTION OFFER

Remember too that all subscribers to Batteries International receive our Batteries Industry Guide, a comprehensive directory giving profiles, contact details and much more of the whole batteries industry — dealing with the entire supply chain: from providers of raw materials through assembly and manufacturing to marketing, distribution and recycling.

2 Years Subscription 15% discount

$340 • €290 • £185

3 Years Subscription 25% discount

$450 • €380 • £245

1 Year Subscription 10% discount

$180 • €150 • £99

Back by popular demand

2009/2010 DIREC-Ba eriesInternational

• INDUSTRY REVIEWS

• GEOGRAPHICAL NEWS ROUND-UP

• FULL DIRECTORY LISTINGS

• TECHNOLOGICAL DEVEOPMENTS

www.batteriesinternational.com

t i I t ti l il

by p

2010

e srna

UST

OGR

L D

CH

Everything Batteries In One Easy Reference Guide

Ba eriesInternational2010 DIRECTORY

• FULL DIRECTORY LISTINGS• LISTINGS BY SECTOR• LISTINGS BY COUNTRY• TECHNOLOGY UPDATES• INDUSTRY REVIEWS

Published twice yearly$25, £20, €20 per issuewww.batteriesinternational.com

Issue 7 • July 2010BIGThe BIG Batteries Industry Guide

FAFF

uide

•

•

•

p suetteririesesinsinnternation lternational.com

ternational.comcom

Everything Batteries In One Easy Reference Guide

2011 DIRECTORY

Published twice yearly$66, £40, €46 For 2 issues in 2011,

www.batteriesinternational.com

BIGThe BIG Batteries Industry Guide

All subscribers to Batteries

International receive Batteries Industry Guide

FREE OF CHARGE

www.batteriesinternational.com Batteries International • 15th ABC Show Guide • Summer 2013 • 7

VIEW FROM THE CHAIR

Attendance is already looking good for the 15th Asian Battery Confer-ence being held in Singapore in Sep-tember. Mark Stevenson, the organ-izer says more than 500 delegates have registered with two months to go. “These are very positive numbers and I believe it will be extremely well attended,” he says.

He says 118 booths have already been sold and fi ve are on a waiting list – illustrating the popularity of the event.

“It could be a record for the event in terms of delegates and other things – we will have to see. But it is not about that. It is just enjoyable to put on a conference of this type and see everyone get something out of it.”

Stevenson, otherwise the technical manager for Asia for Ecobat Tech-nologies, the world’s largest pro-ducer and recycler of lead says the origins of the origins of the event started in 1987.

This was through an organization called the Zinc and Lead Asian Ser-vice, which was a collection of Aus-tralian and other Asian-based compa-nies involved in smelting and related industries. Their main objective, he says, was to promote learning and education around the use of lead.

The conference was launched in its current format in 1997. Many things have changes since them, Stevenson says.

“The event back then was very technical,” he says. “It has changed a lot since then. Although there are still many very technical papers, we try to ensure these are mixed in with more commercial themes and net-working.

“People want more of a blend from an event such as this. Some papers are very sector specifi c and highly technical and super scientifi c – oth-

ers are not. That works well for us and delegates seem to like it.”

Personal contactsHe says that many delegates use the event to improve their knowledge and brush up their skills and un-derstanding in certain sectors. They also use it to maintain and establish personal contact with industry peers and to touch base with suppliers and customers in one event.

He believes one of the reasons this event is proving so popular is because of the quality of speakers and papers already lined up. It is the strongest for a long time, he says, adding that there is also a waiting list of speakers. “People come for the presentations but also to have a yak and do business,” he says.

“Twenty years ago, the event was far more sedate. Now, people enjoy, they have a good time and they also learn and often understand certain things better as a result of some of the presentations. It is particularly satis-fying to me when people come and say ‘wow, I learned so much from that presentation. I had forgotten some of the technical detail around something but now I get it again. To be, that is the mark of a good presentation and a good conference.”

In terms of the major themes of the event, he says it is tough to pin down a small number of themes, due to the diversity of presentations. But he also observes a discrepancy be-tween the big issues as observed by companies and individuals based in Europe and the US compared with

what Asian forms see as the issues.For example, he says that stop-

start technology is not as big an is-sue in Asia as it is in Europe and the US. He says that cultural differences results in Asian-based companies be-ing more pragmatic about such tech-nologies.

“When the technology is ready, manufacturers out here will just fi t it in,” he says. “They will just get on with it without all the fl uff and gruff you get in the west. All they are in-terested in is selling cars – if it helps or if they have to introduce it, they just get on with it.”

He says a similar dynamic oc-curred with the introduction of elec-tric bikes, which have exploded in popularity in some Asian countries. “It is because they just got on with making the most of the technolo-gies available,” he says. “In the UK there would have been committee after committee over analyzing their usage. Asian countries can be much more fast moving in that sense.”

continued on page 10 >

A word from the conference chairman

Despite the name of the event and the fact it is always held in Asia, the conference is effectively a world event with executives from many countries attending.

Mark Stevenson, the conference organizer and chairman of the Asian Battery Conference, bids a warm welcome to delegates, exhibitors and speakers at the event.

8 • Batteries International • 15th ABC Show Guide • Summer 2013 www.batteriesinternational.com

GROWTH: THE BIG PICTURE

The global stationary batteries market in 2012 grew by just 1.2% from 2011, to $6.2 billion. But explosive growth is on its way, according to the Power Supply & Storage Components divi-sion of IHS Electronics and Media in a new report called Stationary Batteries – World 2013.

The increase — of some $7 billion — that the report projects from 2013 to 2017 is driven by the need for energy storage from renewable applications and the continued strong demand for telecommunications infrastructure with battery reserve power. The mar-ket is forecast to grow to $13.8 billion in 2017.

While growth is predicted in the established market for lead-acid bat-teries, penetration of lithium-ion and sodium-based batteries is predicted to accelerate over the next fi ve years, with particularly strong adoption in certain applications.

Europe the Middle East and Africa (EMEA) was estimated to account for 25% of global revenues in 2012, while The Americas was estimated to ac-count for 28% and Asia for 47%. This is projected to change slightly in 2017 with EMEA accounting for 24%, The Americas for 26% and Asia for 50%.

“The increase in Asia is largely due to the forecast adoption of batteries for renewable energy storage systems,” the report says.

In the EMEA region, the largest por-tion of the market was accounted for by western Europe in 2012 with an estimated 72% of the market. Strong-est growth is forecast for Middle East and Africa due to the demand for tel-ecommunications infrastructure with reserve power and strong demand for installations of renewable energy sys-tems with battery storage systems to-wards the end of the forecast, suggests the report.

The largest proportion of The Amer-icas market in 2012 was accounted for by North America and Canada with 73% of the market. This is predicted to increase to 74% in 2017. Growth in all three regions of the Americas pre-sented is forecast to be accelerated by adoption of renewable energy systems with battery storage.

Japan is identifi ed as the dominant region of the Asian market, accounting for 61.1% of revenues in 2012. This is projected to increase to 62.2% in 2017. The Japanese market is largely served by manufacturers based in Japan.

Growth in India is predicted to be

strong throughout the forecast as in-vestments in telecommunication infra-structure and renewable energy sys-tems accelerates. Meanwhile, China will also deliver strong growth, the report says (see graphs). continued on page 10 >

Driving global growth fi gures

Strong growth is forecast globally for the stationary batteries market over the next fi ve years – up by $7 billon between 2013 and 2017. But Asia will be leading the way in this expansion.

“The increase in Asia is largely due to the forecast adoption of batteries for renewable energy storage systems”

2011 2012 2013 2014 2015 2016 2017

Source: IHS

Revenues $m

8,000

7,000

6,000

5,000

4,000

3,000

2,000

1,000

0

— EMEA — Americas — Asia

Predicted growth in the world market for stationary batteries by region

2011 2012 2013 2014 2015 2016 2017

Revenues $m

5,000

4,000

3,000

2,000

1,000

0

— Japan — China — India — Other Asia

Predicted growth in the Asia market for stationary batteries by major region

Source: IHS

Baarerstrasse 53 * P.O. Box 4362 * CH-6304 Zug * Switzerland Telephone (+41) 41 - 727 2800 * Telefax (+41) 41 - 727 2881

www.mri-group.com

Worldwide presence

We trade: - Refined Lead - Lead Alloys - Lead Bullion

For further information, please contact: Monika Zientara Email: [email protected] +41 79 788 85 53 Alan Liew Email: [email protected]

Proven track-record in: - Non-ferrous, concentrates and

metals - Bulk ores minerals - Petroleum products - Structured and trade finance

solutions - Global logistic freight and storage

capabilities

10 • Batteries International • 15th ABC Show Guide • Summer 2013 www.batteriesinternational.com

GROWTH: THE BIG PICTURE

VIEW FROM THE CHAIR (continued)

> continued from page 7

Seizing opportunitiesHe also notes that this dynamic means it can be hard for US and European companies to exploit op-portunities in Asian markets. “The local companies are usually one step ahead,” he says.

Despite the name of the event and the

fact it is always held in Asia, the con-ference is effectively a world event with executives from many countries attend-ing. “It just happens to be in Asia,” he says. “Most of the presentations and is-sues are global in their nature.”

One theme he agrees will be a big talking point and papers covering it well attended, is around the supply and demand of lead in the region

and how this links into the global dynamic around the price of and availability of lead.

“It will be a big topic of conver-sation that week,” Stevenson says. “There are a number of papers cov-ering this issue and I am looking for-ward to seeing some of those.”

Some of these papers include ‘Status and Outlook of the Lead Market in China’ by Xia Cong, assistant engineer at Antaike; ‘Trends and Issues in the Global Lead Market’ by Neil Hawkes, lead consultant with CRU Interna-tional; and ‘The Development of Lead Acid Battery in China’ by Dong Li, chairman and chief executive of Leoch Battery Shenzhen Corp.

“People want more of a blend from an event such as this. Some papers are very sector specifi c and highly technical and super scientifi c – others are not. That works well for us and delegates seem to like it.”

> continued from page 7

The report covers all types of sta-tionary batteries. In 2012, lead-acid batteries (fl ooded and VRLA com-bined) accounted for an estimated 89% of the market. This is projected to change dramatically over the next fi ve years as lithium-ion and sodium-based technology is adopted. The share of lead-acid in the stationary battery market is projected to decline to 64% in 2017.

In 2012, the application account-ing for the largest proportion of the market was telecommunications with 38%. UPS was estimated to account for 22% of the market and energy and infrastructure for 21%.

Explosive growth is forecast for the market for stationary batteries in en-ergy and infrastructure. Its share is predicted to increase to 55% in 2017 owing to projected explosive growth in demand for renewable and energy storage applications. Despite this, the UPS and telecommunications market are also predicted to remain strong throughout the forecast.

Networking and the exchange of knowledge and ideas are always the two biggest drivers of the Asian Battery Conference and this 15th event will be no different. Organizers promise this event will be a must for those seeking to network with customers, expand knowledge, contacts, stay up to date with new and emerging technologies and

focus on business improvement.“The main reason I attend events

such as this is to make and nurture relationships with clients and industry players,” says Geoffrey May, director of FOCUS Consulting who will give a speech entitled ‘The competitive position of lead-acid batteries for stop and start and micro-hybrid applications.’

NETWORKING AND BIG TALKING POINTS

A word from the conference chairman

www.batteriesinternational.com Batteries International • 15th ABC Show Guide • Summer 2013 • 11

A VIEW FROM THE SPONSORS

Underpinning the 15th Asian Battery Conference is the commitment of a number of corporate sponsors. These companies use the event to connect with clients old and new and, variously, invest in brand awareness within the international battery community.

John Opie, the managing director of Goonvean Fibres, a company that is one of Europe’s largest technical fi bre manufacturers supplying high quality precision fi bres, which are used in many types of batteries around the world, is one of the sponsors along with Beijing Rongxintong (stands 12 & 21).

He describes the event as possibly the premiere conference on the lead acid battery calendar. “Quite simply, anyone who is anyone in the battery industry will attend, so it is a great place to net-work and meet friends old and new, fi nd out about the latest technology, ex-hibit goods and of course share knowl-

edge with the global battery commu-nity,” he says.

Opie believes the main themes of the event will be the price and availability of lead and lead alloys; the latest devel-opments in terms of battery technol-ogy; and challenges facing the lead-acid battery community such as environ-mental issues.

GlobalizationOne of the key challenges that he be-lieves will be discussed at the event is around the expansion of Asian com-panies into the global market.

“Historically, growth has been local-ized to service the home market but as demand at home slows Asian suppliers will look to increase their share of in-ternational markets,” he says. “Advan-tages such as lower manufacturing base costs and in some cases government subsidies may give these countries the

edge. Import duties/taxes for foreign goods can make entry into the Asian markets diffi cult.”

But this dynamic has another side and also offers opportunities, he says. “Companies can also come to Asia, manufacture and supply locally so that your company can compete on a level playing fi eld,” he says. “Many have al-ready done so and many more will fol-low. Add lower costs to high levels of quality and the advantage will swing back towards the ‘implant’ company or joint venture.”

Kevin Campbell, vice president of international business development at Digatron based in Aachen, Germany, illustrates this point. He explains that his business has strong roots in Asia and sees many opportunities there for future development and growth.

“This year, Digatron celebrates 20 successful years since setting up a sales, design and manufacturing operation from a dedicated Digatron China facil-ity in Qing Dao,” says Campbell.

“We view the Asian Battery Confer-ence as the single most signifi cant show on the Asian battery calendar. We be-lieve that the event is very well organ-ized, it has a focus on signifi cant tech-nology improvements and the technical calibre of attendees from all around the Asian region is excellent.”

He says the company is seeing a sig-nifi cant increase in requests from the Asian battery community for state-of-the-art technology, and energy saving testing equipment.

“We believe so strongly in the Asian region that in addition to the Digatron China (Qing Dao) manufacturing op-eration, we are about to embark upon an additional new manufacturing facil-ity in Pune India, through a joint ven-ture with our long-time Indian repre-sentatives Ador Powertron, which is a respected as a world class equipment manufacturer,” he says.

L Pugazhenthy, executive director of the India Lead Zinc Development As-sociation (another event sponsor) and

Lead, lead, glorious lead … there’s nothing quite like it

“We view the Asian Battery Conference as the single most signifi cant show in the Asian battery calendar.”

Expectations for another fascinating and useful conference are refl ected in the major themes that the conference sponsors expect to see this year in Singapore.

12 • Batteries International • 15th ABC Show Guide • Summer 2013 www.batteriesinternational.com

A VIEW FROM THE SPONSORS

who won the International Lead Award at the ABC in Macau, China in 2009, says the importance of the Asian mar-kets to both the supply and demand of lead production mean the conference sits at the heart of the industry’s future growth.

“The ABC takes place in a region in the globe where both lead demand as well as lead battery demand are grow-ing continuously,” Pugazhenthy says. (He is also profi led later on in this sup-plement see page 44.)

“China, India as well as countries in south-east Asia are witnessing a steady growth in the automobile sector, the biggest market outlet for lead batteries. Other sectors like telecom and com-puters are also expanding, where lead battery is an essential component as a standby. New emerging markets like renewable energy and electric mobil-ity indicate more opportunities for lead batteries.

New technologies and designs“Today, while we are fully aware of the health and environmental im-plications of lead and its products, the focus is more on safe lead usage practices. The ABC will also highlight new battery making technologies and design, weight reduction, high per-formance etc. Over a period of time, ABC has truly become the biggest lead battery event in the world, with the highest participation.”

Meanwhile, Christophe Thuet, busi-ness director for Daramic-Asia Pacifi c, will have two hats on at the Asian Bat-tery Conference (ABC) in Singapore. As director for the Asian region, he will be coordinating activities for Daramic at the event, but he will also have one eye on overseeing the overall ABC con-ference as a member of the organizing committee.

He says he is anticipating a well at-tended event this year as the ABC con-tinues to grow and go from strength to strength as a conference. He says that while part of this is due to the central location and easy accessibility of Singa-pore as a location, it also refl ects the in-creasing importance of the Asia Pacifi c region to the development and growth of the battery industry overall.

“The market for lead acid is grow-

ing very quickly in Asia and there is a lot of interest in this event as a result,” he says. “It is a chance to meet all the Asian manufacturers and understand their concerns and needs. This level of interest combined with the easy acces-sibility of Singapore means we could have record attendance”.

Daramic is one of the event’s spon-sors. He explains why the event is im-portant to the US-based global compa-ny. “For us, the ABC is only every two years and it is a must-attend event. It represents a great opportunity for us to meet customers. All the major bat-tery manufacturers will be there and it is an opportunity for Daramic to make announcements about our recent inno-vations and our technological develop-ments.”

He says it is important to understand the market demand and expectations in Asia. The region’s diversity also means it requires a tactical approach that takes into account the differences be-tween countries.

“Asia is the most challenging market to operate in because it has such a wide diversity of battery types and a vari-ety of markets,” Thuet says. “Even in China and India alone, you have very different markets, each with their own specifi cities and product demand.

There is a lot of development and innovation happening in Asia and a growing percentage of overall battery production is moving towards Asia.

“In part, this is driven by very strict environmental standards in the west,” he says. “But you would be making a mistake to say that Asian governments do not care about these issues. China in particular is leading the way in terms of its environmental agenda. It has had a big clean up in terms of its lead acid industry in recent years. They want to reach a world standard in terms of environmental standards. And other countries are following suit.”

Thuet says that at the last ABC, held in India two years ago, many of the pa-pers delivered by lead specialists had at least one section dedicated to environ-mental matters. “That could well be the same this year,” he suggests. “Everyone is interested in how companies can be greener, more effi cient and increase re-cycling while reducing waste.”

Returning to the theme of marketing and business development strategies in Asia, he says that his key piece of ad-vice would be to be versatile. He says that broadly speaking, battery manu-facturers in Asia can be categorized into several tiers, each with unique and separate needs and requirements.

He sees state-of-the-art battery man-ufacturers which are very sophisticated and moving technology forward con-stantly, playing on an international ground. But also manufacturers who are more focused on local demand, not as advanced technically but they are learning fast.

Focus and claritySmaller regional battery manufactur-ers with a much smaller capacity are focused on servicing niche or local markets. They serve the after-market very well and are very focused on pro-ducing quality products but less on technological advancements.

Each of these segments need to be treated according to their needs with an emphasis on different levels of technical support as required.

Thuet says. “Versatility is critical and each country in Asia should be ap-proached differently to refl ect cultural variations and market demands. This region is so diverse and must be tackled with that in mind”.

He says another big theme at the con-ference will be new technology for elec-tric vehicles, micro-hybrids and start-stop technology. “There are a number of new technical concepts that we will see presented and discussed,” he says.

He also notes that although he is not personally presenting a paper, his col-league Kevin Whear, vice president of technology at Daramic will present a paper entitled: ‘The Uniqueness of the Asian Market and the Resultant Novel Separators.’

“Quite simply, anyone who is anyone in the industry will attend the ABC”

John Opie, Goonvean Fibres

The market for lead acid is growing very quickly in Asia and there is a lot of interest in this event — it’s a chance to meet all the Asian manufacturers and understand their concerns and needs

INTERNATIONAL THERMAL SYSTEMS

www.internationalthermalsystems.com email: sales@itsl lcusa.com© 2012 INTERNATIONAL THERMAL SYSTEMS ALL RIGHTS RESERVED

We Focus on Energy forthe Lead Acid BatteryManufacturing Industry.

Partner with ITS for your drying, curing and pasting needs. Contact a

representative today to arrange for an on-site consultation to learn how we

can maximize production efficiencies and minimize energy consumption.

14 • Batteries International • 15th ABC Show Guide • Summer 2013 www.batteriesinternational.com

OVERVIEW

Neil Hawkes lead analyst at CRU, a London-based commodity research consultancy, will present a talk called Global Trends and Issues in the Lead Market. Hawkes is responsible for CRU’s lead market analysis and he is the main author of the company’s quarterly Lead Market Outlook and monthly Lead Monitor.

Hawkes says he will start by cover-ing some of the issues around supply and demand, with a slant on the more interesting supply side of things and in relation to Asia where relevant.

He says demand for lead globally is both steady and reliable and has been relatively immune to the global eco-nomic downturn. Despite some chang-es in technology and other factors, he

expects growth to remain robust for some time to come.

He says that all the big question-marks around lead pricing lay on the supply side. And central to the equa-tion is the role of China in the lead markets.

“It is a very important part of this market as it continues to drive a lot of lead demand and supply growth at the

moment,” Hawkes says. “Asia is cer-tainly the main driver of demand. It now represents around two thirds of total lead demand. It has been the ma-jor growth story of the past 10 years.”

Hawkes notes that changing regula-tions in China could adversely affect this demand, however. He says that a proposal to introduce a 5% tax on lead acid battery manufacturing is de-signed to slow the market’s growth.

But demand remains strong in China as it does in India, which is growing fast, South Korea and Thailand. The Japanese market is slow on the de-mand side in comparison, Hawkes says.

Korea moving inSouth Korea in particular has been quite aggressive in recent years in building up a solid industry around lead smelters and is increasingly win-ning the intense competition around competing for lead scrap metal – of-ten taking scrap from other countries, including Japan and the US.

Other countries are increasingly competing in this market, however. Australian smelter Nyrstar looks close to securing a substantial investment that would make it far more competi-tive in this sector.

He says that he does not expect new technologies and the growth of the electric and hybrid electric vehicle market to change the broader dynamic in terms of lead demand.

“My view is that this represents a very tiny percentage of the total num-ber of vehicles made globally and the

Asia is increasingly driving lead pricing

A major theme of the conference will be how Asia as a region has become the focus for major trends in the production of lead acid batteries and the challenges it faces as a consequence. Wyn Jenkins reports.

“The biggest negative of all is the macro-economic picture, especially in Europe. But against that, China, the rest of Asia and the US are all faring well. On the demand side, it is all very positive and it is tough to see too much of a downside at the moment.”

Beyond Paperwww.glatfelter.com

Metallized Products Composite LaminatesFood & BeverageTechnical Specialties Nonwoven Wallcover Base

Glatfelter Gernsbach GmbH & Co. KGComposite Fibers Business UnitP.O. Box 115576584 Gernsbach, GermanyEmail: [email protected]: +49 7224 66-0 Fax: +49 7224 66-274

Best in classDYNAGRID®Pasting Papers for lowest waste rate and highest battery efficiency.

16 • Batteries International • 15th ABC Show Guide • Summer 2013 www.batteriesinternational.com

OVERVIEW

Klaus-Dieter Merz is a consultant at Abertax Technologies, an independent business within the Abertax group of companies that was formed to research, design and produce innovative products. He previously worked for Exide for 28 years.

Its main focus is developing battery monitoring systems that can be monitored and controlled remotely via the internet. In this event, however, he will focus on battery energy storage systems.

Merz worked on the EUROBAT taskforce looking at batteries for smart grids and rural electrifi cation applications. He says this technology will play a vital role in both the development of a decarbonized power system in Europe and the emergence of power systems in emerging countries across Asia.

“They are a fundamental in terms of the electrifi cation of rural and remote areas,” he says. “In many developing countries such as India, there is no access to main power supplies.

“Electrifi cation is a very important step forward and likely to use wind or solar technologies. But the use of the correct battery technology will make the difference in terms of how effective that is.”

EUROBAT recently published a study examining the potential contribution of battery energy storage at all levels of the electricity grid: generation, transmission, distribution and customer. The paper reviews the four main battery technologies commercially available — lead, lithium, nickel and sodium-based batteries — and makes a series of recommendation for how their mass-market utilisation can be facilitated at a European level.

Another publication issued by EUROBAT recently focuses on increasing energy access in isolated rural areas, including in developing countries but also in small islands. The guidance document was drafted to help installers, operators of rural electrifi cation systems, as well as public authorities, selecting the best

battery technology for use in off-grid and mini-grid systems.

“The document aims to enhance the knowledge about the combination of functions that lead, lithium, nickel and sodium-based batteries can provide across different types and sizes of rural electrifi cation system, and across varying environmental conditions,” Merz says of the report. “We hope the paper will provide authorities in rural areas with concrete data to help them make an appropriate selection.”

He says Abertax is already supporting several companies in India which are rolling out this technology. “In some parts of India there are big power shortages. They might lose power for fi ve or six hours at a time every day. This technology can help manage the electronics around these power storage systems. The focus is on managing that fl ow of power whether it is generated from solar or wind and complementing the grid.

“Battery energy storage (BES) is an effective solution, and has already been implemented in numerous off-grid, mini-grid and hybrid installations across the world,” he says. “Unlike other storage technologies, BES systems are highly fl exible and can be adapted to high power and high energy applications.”

He says that in the paper he is presenting, the authors propose a novel smart battery system that will make the battery an independent energy storage system. “This idea will enable the use of existing grid connected equipment thereby making it suitable for both off grid and on grid applications,” he says.

“This will create a solution that will meet such a variety of applications will also make it more affordable especially for the ever increasing demand to provide energy in rural areas. The project will demonstrate how smart energy storage can contribute to society and help with the global drive towards ‘Energy for All’,

especially in isolated rural areas and small islands.”

He says that this emerging global scenario has become much more interesting in recent years especially with the drop in PV prices. “These possible energy storage solutions offer a very good perspective for the lead acid battery industry and a potential new emerging market is being created. The challenge is to provide standard modular plug and play components that will allow different system setups,” he

says.“This is a new and growing

business area for the batteries industry,” he says. “Many governments are not doing enough to solve these problems. But there are some very good solutions out there. Subsidies are being given in some areas and many of the big battery manufacturers anticipate big growth.”

Merz adds that he expects this to be a big talking point at the conference more generally.

SMART BATTERIES AND RENEWABLE ENERGY

In some parts of India there are big power shortages. They might lose power for fi ve or six hours at a time every day. This technology can help manage the electronics around these power storage systems.

are

emhainyeth“Tsvf

s

www.batteriesinternational.com Batteries International • 15th ABC Show Guide • Summer 2013 • 17

OVERVIEW

vast majority of those use lead acid batteries,” Hawkes says.

“But while electric vehicles grab the headlines, other growth areas for lead go unnoticed. You also have increasing demand on the back-up power side for things like mobile phone and comput-er networks, many of which use lead acid batteries.”

Sectoral pressuresHe says: “You also have unique pock-ets of demand, such as electric bikes in China for example — that is a huge market that is still growing, albeit at a relatively more restrained pace than before. All this means that despite some distributive new technologies and chemistries, demand typically grows each year.”

Another reason for lead’s attraction to investors is that the market is expect-ed to grow by between 2% and 4% a year. “And I expect it to continue to grow at that pace. It is stable (if not ex-plosive) growth and investors like that.

“The biggest negative of all is the macro-economic picture, especially in Europe. But against that, China, the rest of Asia and the US are all far-ing well. On the demand side, it is all very positive and it is tough to see too much of a downside at the moment,” Hawkes says.

“It is a more attractive commodity at the moment because of some of the dynamics around supply and espe-cially the very secure demand story. Whether the lead and lead-acid bat-tery industry likes it or not, investors are looking at it, not only as part of a broader commodity portfolio, but in some cases drilling down into the specifi cs of lead compared to other metals. And given lead’s positive out-look, on the LME, lead’s price typi-cally falls less and rallies more quick-ly than most other metals through the daily/weekly gyrations of the metals complex.”

Alongside healthy demand growth, a number of disrupting factors on the supply side has meant that the price of lead is sitting at historically high levels, though it has become marooned, rarely straying far from $2,000/t. “You do see some fl uctua-tion in line with the wider commodi-

ties markets but lead is less affected by these changes than other metals,” Hawkes says.

One of the key supply dynamics is that the price of ‘scrap’ or ‘spent’ lead-acid batteries has risen dramatically in recent years as the scrap industry has cottoned to the higher value of lead contained within spent batter-ies. They have increased their selling prices, putting pressure on smelters’ profi t margins, in turn.

In terms of pricing, Hawkes believes LME lead prices will remain fairly stable this year. Prices started the year rallying to $2,400 per tonne and al-though the price has subsequently re-treated closer to its $2,000 ‘anchor’ he does not anticipate any dramatic fl uc-tuations this year.

“You can never predict pricing in the short term, but in the medium term it will be relatively stable and trade mostly above $2,000 for the rest of this year,” he says.

Next year, however, he believes the price could increase further. “In the longer term, especially if Europe re-covers and Asian demand remains on a fi rm upward path, prices could push above early 2013 highs. And although

I see that as a trend for next year, if investors anticipate that dynamic, they could move ahead of an further improvement in lead’s own industry fundamentals. Long term, I am fairly bullish about the market.”

“And given lead’s positive outlook, on the LME, lead’s price typically falls less and rallies more quickly than most other metals through the daily/weekly gyrations of the metals complex.”

One of the key supply dynamics is that the price of ‘scrap’ or ‘spent’ lead-acid batteries has risen dramatically in recent years as the scrap industry has cottoned to the higher value of lead contained within spent batteries.

Another big talking point at the event is likely to be improvements and the latest design breakthroughs in stop-start technology. A number of presentations are scheduled that will focus on this including:• Mild-HEV Performance at Micro-

Hybrid Cost: A Low-Voltage Advanced Lead–Acid Battery Approach, presented by Allan Cooper from ALABC;

• The Competitive Position of Lead–Acid Batteries for Stop–Start and Hybrid Electric Vehicle Applications, presented by Geoffrey May from FOCUS Consulting;

• and Development of the UltraBattery for Micro-Hybrid Electric Vehicle Applications, presented by Jun Furukawa from

The Furukawa Battery Company.“Hybrid vehicles will be a big talking point as will stop-start technology,” says Ellis. “Temporary power storage is also a big thing in Asia with big opportunities. The grid is not stable and that could be a good thing for the battery industry.”

A number of presentations will also focus on these issues. Two such presentations are: • A Smart Battery System for Self

Consumption of Renewable Energy by K-D Merz from Abertax; and,

• Integrating Renewables into the Grid: Applying UltraBattery Technology in MW-Scale Energy-Storage Facilities for Continuous Variability Management by John Wood, from Ecoult.

PRESENTATIONS TO LOOK OUT FOR

18 • Batteries International • ABC supplement • Summer 2013 www.batteriesinternational.com

REGIONAL OUTLOOK

The market in India for lead-acid bat-teries is set for exponential growth in the next decade representing many opportunities for global batteries fi rms — but global players must strive to understand the nuances of doing business in India if they are to make the most of this opportunity.

That is the thrust of a speech that will be given by Vinod Dumra, busi-ness adviser Rahimafrooz Batteries, looking at the opportunities and chal-lenges in the Indian market.

He forecasts some startling growth fi gures for the country that will make global players sit up and take notice.

Future valuesDumra believes the lead-acid mar-ket in India could be worth between $9 billion and $10 billion by 2020, a huge increase for a market worth around $4 billion to the sector now. “This is likely to be a very fast grow-ing market with many opportunities,” he says.

India as an economy will increas-ingly represent a challenge and op-portunity to western business, which must learn how to tap into its poten-tial.

“The country has a general election

next year so expect some political tur-moil but nothing too severe.

“The economy is the third largest in the world and growing rapidly. Inter-national businesses cannot afford not to be involved in such a big and fast growing economy.” The battery mar-ket specifi cally is very healthy.

He explains that there is a huge young population in India, a large percentage of which have access to world media and are aspirational and ambitious as a result. India is such a big country that even small segments of the population are still bigger than the total population of some coun-tries.

And the growth potential is huge. At present, only 12 people in every 1,000 own a car. And the total power avail-ability in the country is some 10% to 12% short of total demand.

“You can see there is huge potential for the battery industry specifi cally as a result,” Dumra says. “Renewable energy specifi cally offers huge poten-tial. But it needs battery technology to fully harness it.”

Aside from this presentation it is worth remembering that the Indian market is essentially duopolistic. Two companies, Exide Industries [no rela-

tion to Exide Technologies] and Am-ara Raja Batteries have around a 90% market share. Due to the tremendous brand recall by these companies, most original equipment manufacturers use batteries manufactured by them.

The passenger vehicle space is dom-inated by the two companies is also due to their strong tie-ups with rec-ognized international players. Moreo-ver, power concentration being in the hands of these two players, the pric-ing power remains strong for the in-dustry.

The high effi ciency with which lead acid batteries can be recycled has re-sulted in several recyclers entering the battery business. Since it is easier to make a recycled lead-acid battery than to manufacture a new one, most players fi nd it more convenient to en-ter the battery recycling business.

Dumra forecasts a huge explosion in infrastructure growth over the next decade. He says it needs investment and this will boost the economy fur-ther.

Foreign investmentDespite the vast pool of talent already in the country, India still requires for-eign investment and expertise. But companies need to understand how to navigate specifi c rules and regulations within the market.

“The customers and import duty agreements can be complex,” he says. “We import from Bangladesh because a trade agreement is in place but if goods come in from another country it can be expensive and time consum-ing. Exporters can get baffl ed by the rules.

Certainly, as this magazine remem-bers from the previous ABC in Hy-derabad in 2011 that the import of some 3,000 magazines and directories to India was fraught with diffi culties. It required a whole day at various cus-toms offi ces to bring our material in. A rival publication, for example, was unable to provide magazines at the event by the same customs blockade.

“But the marketing is the same,” Dumra says. “I have seen many west-ern companies get it wrong because

Exponential growth forecast for India but business stilldominated by the top two

“The economy is the third largest in the world and growing rapidly. International businesses cannot afford not to be involved in such a big and fast growing economy.”

www.batteriesinternational.com Batteries International • ABC supplement • Summer 2013 • 19

REGIONAL OUTLOOK

they misunderstand Indian culture. It is also very diffi cult for an outsider to understand what happens in a supply chain in some cases in terms of where taxes apply and the nuances of that.”

He recommends that foreign com-panies starting operations in India al-ways employ a local chief executive, marketing manager and operations manager. “The CFO can be an ex-pat but in terms of some of the other more people orientated roles, it is very

easy to get it wrong,” he says. “You need to understand what we actually mean when we say certain things and how the systems and business proce-dures work out here. The timescales can be completely different.”

There are many examples of global companies that have succeeded in India such as Johnson Controls and Chloride India (Exide). “Others will follow and the opportunities are huge but cultural differences need to be ac-

counted for,” he says.Dumra will also touch on the green

agenda in India in his speech. “There is a dichotomy between what the in-dustry needs to do in environmental terms and seeking growth,” he says. “In the battery industry specifi cally, improvements need to be made. There is still a long way to go there.”

“I have seen many western companies get it wrong because they misunderstand Indian culture. It is also very diffi cult for an outsider to understand what happens in a supply chain in some cases in terms of where taxes apply and the nuances of that.”

India: a complex mix of old and new, rich and poor, developed and developing

MANIKA MOULDS PVT. LTD.

For us every order is like a building relationship that we

nurture with care so it blossoms into full-fledged

partnership.

A partnership for which we are always prepared to go the

extra mile and that's why our client keep coming back to us

with repeat orders and valuing us for our quality, cost,

competitiveness, and our turnaround time as well as for

always being there.

NS40 Kamina Type DE N50 Kamina Type DE N70 Kamina Type DE

N100 Kamina Type SE

DIN66 Kamina Type

DIN88 Kamina Type

MANIKA MOULDS PVT. LTD.Aar-Pee Centre, 601-605, 6th Floor, Gufic Compound, MIDC, Andheri (E),

Mumbai - 400 093, INDIA. Tel.: +91-22-4223 4300 Fax : +91-22-2820 0996

E-mail : [email protected], Website : www.manikamoulds.com

TU.V

.

S DU..

ISO 9001NABCB

QM011

ASSURED BEST IN PRICE & QUALITY ACROSS

THE GLOBE

SHORT DELIVERY LEAD TIME

MOLDED FROM VIRGIN PPCP

MODELS AS PER JIS & DIN STANDARD

USE OF COLD FORGED BUSHINGS

USE OF FLAME ARRESTORS PROCURED FROM

WORLD RENOWNED SUPPLIER

BRAND & CAPACITY EMBOSSING OPTION ON

CONTAINER & COVER

CONTAINER WITH SIDE RE-ENFORCEMENT

(BRICKS DESIGN)

PRODUCT FEATURES

CENTRE FOR PRECISION INDUSTRIAL MOULDING

DIN44 Kamina Type

An ISO 9001-2008 Company

DIN55 Kamina Type

OUR EXCELLENCE

®

®

CR

OS

SP

OIN

T 2

88

9 8

19

4

We would be pleased to welcome you to our booth: numbers 29 & 30

20 • Batteries International • 15th ABC Show Guide • Summer 2013 www.batteriesinternational.com

SECONDARY LEAD

One of the best attended speeches at the conferences could be by Timo-thy Ellis, vice president of research & development, RSR Technologies, who will be presenting some revo-lutionary fi ndings on new technolo-gies the company has developed that can, he claims, create secondary lead with lower levels of contaminants than primary lead — a breakthrough that could have huge signifi cance to a number of industries.

Ellis explains the background to and reason for the research being conducted. “Basically the issue is that there are two types of lead that are used in manufacturing: recycled lead and primary lead. Over the years there has always been a natural ten-sion between the two types of produc-ers about the relative strengths and weaknesses of the lead and which is best for various functions,” he says.

“Ultimately, it boils down to the levels of various contaminants in the lead and the effect that has on various functions when it is used in different type of batteries.

“The Advanced Lead Acid Battery Consortium (ALABC) funded a study a few years ago to look at this and specifi cally the effect contaminants have on gassing or over charging. They discovered there were negative effects. Eventually, the wrong levels can mean a battery becomes drained of its properties such as water and eventually stops working.”

He explains that historically, most sources of primary lead have been low in the specifi c elements that cause gas-sing whereas many types of secondary lead have had problems getting rid of contaminates. This has become in-creasingly problematic, however, for certain industries.

“The ready supply of scrap batteries along with environmental concerns has motivated the present domination of secondary material from recycling facilities allowing lead to have the

highest recycling rate of any of the commodity base metals,” Ellis says.

“This makes sense from an eco-nomic and environmental standpoint. But in some applications such as UPS and telecoms applications there are big long-term gassing issues and they need to use primary lead.”

He says that exacerbated by the recent closure of smelters in North America, this is now causing a prob-lem. “It means there are now no producers of primary lead in North America at all.”

RSR Technologies has been working on a solution to this problem. It has been working with NorthStar, which makes high performance lead-acid batteries for Telecom Power Systems, Uninterrupted Power Supply (UPS) and Engine Start applications to de-velop a new type of secondary lead they have labelled ‘supersoft’ lead.

“It is a very high purity lead compa-rable in its properties to primary lead,” Ellis says. “It is a highly refi ned second-

ary lead with very low levels of impuri-ties to reduce gassing in batteries.”

He says that grey and red oxide have been produced from this highly refi ned secondary material and VRLA batteries were fabricated using these oxides as a replacement for the con-ventional primary lead. This material contains up to 50 ppm silver (Ag) and up to 200 ppm bismuth (Bi).

“Tests of the VRLA batteries has shown that water loss, gassing and cycling characteristic are identical to those for using very low impurities primary lead,” he says. “RSR in North America and EcoBat facilities in Eu-rope and South Africa have developed the capability to produce this material in normal operations.

“That opens many new markets up to secondary lead and changes the market dynamic on its head. It is a very important development because high purity lead is expensive and it saves shipping it in from countries such as China.”

The upcoming revolution: disbelieve it at your peril

The promoters of our Singapore conferences offered us ‘a week of lead in glittering Singapore’ but one talk will be more about the ‘glittering’ opportunities from new refi ning techniques.

www.batteriesinternational.com Batteries International • 15th ABC Show Guide • Summer 2013 • 21

SECONDARY LEAD

In terms of the response he expects to receive in Singapore, he admits that a great deal of scepticism exists around how good the end product can really be. He says the accuracy and reliability of the research being carried out will win through.

“The problem is this technology has the potential to turn the dynamics of the market on its head,” he says. “In

Asia, people will be very sceptical and this technology will raise a few eye-brows. It is a very technical subject but the upshot of the data is that is a very revolutionary material.

“In the tests we have been doing with NorthStar, this actually performs better than primary lead — whether people want to believe that or not is another thing.”

Tranquillity. The Port Prie smelter was built in 1889 for processing early Broken Hill lead concentrates. Since then it has become the largest primary lead smelter in the world. Its blast furnace limits its capacity to 245,000 tonnes a year, however, other parts of the facility have a capacity of approximately 270,000 tonnes. The zinc production facility was commissioned in 1967 and the lead smelter in which gold and silver are largely recovered was rebuilt in 1998.

Australian lead smelter Nyrstar appears to be inching closer to securing a $350 million upgrade of the lead and zinc smelter at Port Pirie to a cleaner operation.

An advanced poly-metallic processing and recovery facility will be built, which the South Australian government says will secure the long-term future of more than 2,500 jobs.

It said the upgrade would substantially reduce lead emissions in the Port Pirie area by replacing the ageing century old smelter with a much cleaner metal processing operation. Nyrstar will put in $200 million for the redevelopment and the federal government will be the guarantor for private equity investment for the rest of the funding.

The planned work is now subject to feasibility studies, but the transformation is expected to lead to a signifi cant improvement in air quality in the regional city.

NYRSTAR INVESTS $350M IN SMELTER UPGRADE

22 • Batteries International • 15th ABC Show Guide • Summer 2013 www.batteriesinternational.com

TECHNOLOGICAL ADVANCES

One of the big themes underlying the 15th ABC meetings can be summed up under the umbrella phrase: im-proving lead acid batteries and look-ing at what are increasingly becoming called advanced lead acid batteries.

Pavel Toser from the Brno University of Technology will be presenting a talk entitled ‘The Infl uence of Conductive and Non-Conductive Additives on the Properties of Negative Electrodes of Lead Acid Battery in PSoC Regime.’ He presented previously at the 13th ELBC conference in Paris and sees this paper as a follow up.

He will focus on the negative elec-trode, especially on additives mixed to the negative active mass (NAM). “Our research team has worked with conductive and non-conductive ad-mixtures for many years and we have a lot of experimental data,” he says. “We tried to improve the lifetime and durability of negative electrodes.”

He says the team has been seeking an optimal or ideal combination of various additives. They tested the cells under specifi c test conditions and dis-

covered several mechanisms via which lead acid batteries can fail.

“The partial state-of-charge (PSoC) mode of operation is very demanding, particularly at high rates of charge/discharge, and sets extraordinary de-mands on the properties of the nega-tive active-material,” says Toser.

Better charging“The carbon particles have one of the biggest benefi ts in NAM because the ability of the electrode to accept high rates of charge is better in common with the growth of sulfate crystals.”

He says he believes additives to NAM will be one of the main topics at the 15th Asian Battery Conference. “In

my opinion we have to comprehend all of the processes in lead acid batter-ies. We have to use all the information from our more experienced colleagues and research teams. The best way to do this is to participate in this confer-ence. Can we improve lead acid bat-tery? The answer is: ‘yes’,” he says.

Another paper in a similar vein is called ‘The Properties of Lead acid Negative Plates Built Around Carbon Felt Micro-Scale Current Collectors’ which will be presented by John Abra-hamson, chief technology offi cer and Stuart McKenzie CEO of ArcActive, a company that uses its proprietary car-bon material, AACarbon, to improve the performance of batteries.

Improving lead acid batteries has been the industry’s goal since the days of Gaston Planté. But the latest generation of alternative battery chemistries has accelerated the rate of lead acid development. And, as various ABC presentations will highlight, huge advances are still being made.

But while both NiMH and Li-ion battery technologies have met, or exceeded, the technical performance requirements, neither system has succeeded in achieving the costs targets necessary for a widespread economic success of NiMH and Li-ion industries and consumer acceptance of EVs/HEVs

Accelerating the pace of development

www.batteriesinternational.com Batteries International • 15th ABC Show Guide • Summer 2013 • 23

TECHNOLOGICAL ADVANCES

ArcActive is also following on from 13ELBC where it discussed the de-velopment of novel negative plates based on coherent connected carbon fabric for the lead acid battery. These electrodes showed promise for higher DCA suitable for stop-start and regen-erative-braking functions in hybrid vehicles, at an acceptable price.

“An update of this development will be given here,” says Abrahamson. “We report on results from a broader test-ing schedule, including more severe DCA tests. Some discussion will be given of why such stable long-term cy-cling is found.”

Greater role for carbonA related talk will be given by Subhas Chalasani, head of R&D at East Penn Manufacturing who will give a paper entitled ‘Mini Cell Testing for Ad-vanced Lead Acid Battery Research’. “Addition of carbon to the negative electrode has sparked renewed inter-est in lead acid battery technology,” he says. “This lead-carbon technology is well suited for micro/mini automo-tive hybrids and for grid energy stor-age applications.

“Numerous types of carbons are being developed for this purpose. Screening such a large number of car-bon additives along with other non-carbon additives is a daunting task for battery manufacturers. Usually, the evaluation of these additives is done by constructing 12V batteries which consumes a lot of manufacturing time and resources. This often leads to small sample size, which deleteriously affects the reliability of test data.

“To circumvent these problems, a mini cell design was developed and standardized for screening large amount of variables at R&D, East Penn. This drastically reduced the testing time from months to days and weeks.” In his presentation, he will discuss mini cell testing methodology in detail. The usefulness of this meth-odology will also be demonstrated with few examples of newly devel-oped technologies.

Subhash Dhar, the founder and CEO of Energy Power Systems, will present a paper called ‘High perfor-mance advanced lead acid batteries for emerging markets’. He will argue that despite the hype surrounding the potential of other battery chemistries in recent years, lead acid could well still present a central solution.

Nickel metal-hydride batteries were introduced in the early 1990s for use in consumer electronic products and