ASI - Resolution Systems

-

Upload

resolution-systems-inc -

Category

Documents

-

view

147 -

download

1

description

Transcript of ASI - Resolution Systems

http://www.hplc-asi.com 1Analytical Scientific Instruments

Innovative Solutions for HPLC and LC/MS

Analytical Scientific Instruments

2 Analytical Scientific Instruments, Inc.

How to Open an Account

Ordering Information

We accept Credit Cards

Please provide account number and expiration date whenyou place an order.

If you know your account number, it will be faster for us to serve you.

� If you are ordering from the US or Canada:

� If you are ordering from outside the US or Canada:

Customer ServiceTo place an order, request price and availability, deliverystatus, or to obtain RA# and all other inquiries, contact us.

Our standard shipping service is UPS Blue unless otherwise specified.

Return Policy

By Fax510-223-9670

We will send an order confirmationwithin 24 hours by fax.

A return authorization number (RA#) must be obtained to return any item.There will be 15% restock charge on all returns unless the return is being requested due toshipping error or damage claim.

Please fax your company credit references along with your billing and shipping address to ASI.Credit Card orders do not require a credit reference.

Your ASI Customer Number: _________

By Telephone800-344-4340510-669-2250

We will send an order confirmationwithin 24 hours by e-mail.

A list of US distributors is available on our web site.www.hplc-asi.com

A list of international distributors is available on our web site.www.hplc-asi.com

Contact ASI directly for international credit, billing, shipping, and payment terms.

http://www.hplc-asi.com 3

Table of Contents

Ordering Information......................................................... 2

What’s New......................................................................... 4

About ASI............................................................................ 6

QuickSplitTM ASI Flow Splitters ........................................ 8QuickSplit Fixed Flow Splitters........................................ 11QuickSplit Makeup-Flow Splitter Manifolds ..................... 22QuickSplit Adjustable Flow Splitters ............................... 24

PrimeLineTM ASI Syringe Pumps ...................................... 32

PrimeLineTM ASI HPLC Pumps .......................................... 33

HyperShearTM ASI HPLC Mixers ........................................ 42HyperShear Static Mixers ............................................... 44HyperShear Dynamic Mixers .......................................... 64

ASI Post Column Reactor.................................................. 65

FlatLineTM ASI Pulse Damper............................................. 68

PrimeLineTM ASI Replacement Parts for HPLC Pumps ... 70Self-priming Check Valves .............................................. 72Replacement Piston Seals .............................................. 74Replacement Pistons ...................................................... 75Parts by Pump Brand ..................................................... 76Installing ASI Check Valves ............................................ 125Maintenance and Trouble Shooting Tips ......................... 126Trouble Shooting Guide .................................................. 129

ASI HPLC Accessories ...................................................... 133In-Line Check Valves ...................................................... 134Reference Manual for HPLC ........................................... 134Fittings and Unions ......................................................... 135Filters .............................................................................. 135Tubing ............................................................................. 137High Pressure Metering Valve ........................................ 137

4 Analytical Scientific Instruments, Inc.

QuickSplitTM Flow Splitters

What’s New

Fixed SplittersNow Available forPrep Range 30 mL - 200 mL/min. Input FlowHigh-Rrep Rrange 200 mL - 1 L/min. Input Flow

Page 15

Adjustable SplittersNow Available forPrep Range 100 mL - 1 L/min. Input Flow

Page 27

Page 33

PrimeLineTM Micro HPLC Pump

10 µL/min. Gradients

http://www.hplc-asi.com 5

HyperShearTM HPLC Mixers

What’s New

Static Mixers

Page 32

PrimeLineTM Syringe Pumps

Now Available forBiocompatible PEEK Micro Flow Series

Page 46

High Pressure SS Static Mixersare available for

Micro Flow, Low Flow, Analytical Flow, High Flow and Combo Micro series

Now Available forStainless Steel & Biocompatible PEEK

Combo Micro Series 1 µL - 100 µL

Page 56

6 Analytical Scientific Instruments, Inc.

About ASIASI manufactures a broad range of instruments and components for High Pressure Liquid Chroma-tography (HPLC). While some of our products may appear rather routine at first glance, ASI instru-ments and components incorporate technology which is totally unique in the industry. The approachto product development at ASI has always been to “build a better mouse trap” to solve some of themost vexing problems that chromatographers face. Our solutions include: PrimeLineTM Self-primingCheck Valves, HPLC Pumps and Syringe Pumps and HyperShearTM Static and Dynamic Mixersand FlatLineTM Damper, and fluid resistor based QuickSplitTM Fixed, Adjustable Flow Splittersand Makeup-Flow Splitter Manifolds. Whatever the product, the final test is customer satisfaction,so we go to great lengths to insure all ASI products work as advertised.

We can also apply our engineering and manufacturing expertise to develop custom products tomeet your specific needs. ASI has worked with, and designed OEM products for most major HPLCmanufacturers. Please let us know if we can provide components or subassemblies for your nextHPLC project.

Engineering Expertise

If the design is not correct to begin with, then eventhe best manufacturing capability in the world cando no more than produce a well made productthat doesn’t work.At ASI, we apply a rigorous engineering analysisto our products before they go to the prototypestage. For our check valves, this entails stressand deflection analysis of critical components suchas the seat, gaskets, and valve casing. A fluidflow analysis is then performed to make certainthat the pressure drop across the valve is withinproper limits. Finally, a tolerance study is performedon the design to insure that the parts fit together(it is here where 90 % of all designs fail!).

Once the prototype is built, we test it to verify thatthe performance matches the theory. Next, webuild several production-like units that allow us toprove manufacturability, reliability, and most im-portant of all, the consistency of the product per-formance and reliability over the specified rangeof manufacturing tolerances.

http://www.hplc-asi.com 7

About ASI

Good design is the essential starting point for per-formance and reliability, but a good design is use-less without the manufacturing capability to executeit properly. For this reason, we have invested muchtime and money into our computer controlled ma-chining centers, inspection equipment, and the ex-perts to set up and operate this equipment prop-erly.

Manufacturing Capabilities

Quality Control and Final Test

Many of our products are manufactured with dimensional toler-ances that are equal to 1/50 of the diameter of human hair. Whilethese tolerances are often tighter than our designs dictate, webelieve that the resulting improvement in reliability and performanceis well worth the added cost in manufacturing.

But even with all this inspection, we know we’renot perfect, so every mixer assembly or checkvalve that we ship is first subjected to a final testto prove that it performs properly under pressure.

We believe it is not possible to manufacture reli-able valves or other fluidic devices without 100%inspection of all critical parts. We believe it is notpossible to manufacture reliable valves or otherfluidic devices without 100% inspection of all criti-cal parts. That is why we inspect every criticaldimension on every part that affects valve perfor-mance.

8 Analytical Scientific Instruments, Inc.

QuickSplitTM Flow Splitters

Fluid resistor technology eliminates tedious adjustments to capillary tubing forsplit ratio optimization

Split ratios are stable and reproducible, and not affected by changes in viscosityor pressure

Adjustable metering valve enables precise direct control over split ratios

Easy to use interchangeable fluid resistors make it possible to achieve splitratios from 1:1 to 20,000:1

Rugged stainless steel construction allows high pressure operation

Ultra low dead volume fluidic design

Applications include LC/MS, pre/post-column flow splitting, and flow fractionation

Multiport flow splitter diverts the inlet flow into 3 or 4 channels for applicationsthat employ multiple detectors and/or a fraction collector

Makeup-Flow Splitter for mass directed fraction collection

�

�

�

�

�

�

QuickSplitTM Flow Splitter Features:

�

�

�

9http://www.hplc-asi.com

QuickSplitTM Flow Splitters

The ASI QuickSplit Flow Splitter is very elegant in its simplicity. Split ratios are created bytwo or more fluid resistors that form a parallel flow path. QuickSplit Flow Splitters are avail-able with a fixed or adjustable split ratio. Interchangeable fluid resistors make it easy tochange split ratios quickly, eliminating tedious adjustments to capillary tubing. The technol-ogy can be applied to all applications where a controlled, reproducible split ratio is requiredincluding LC/MS, flow fractionation, pre/post-column flow splitting mass directed fractioncollection, and capillary chromatography. ASI QuickSplit Flow Splitters come in flow rateranges which make them compatible with micro, analytical, semi-preparative and prepara-tive inlet flows.

QuickSplit Fixed Flow Splitters............................................. 11Post-Column Applications

Binary Fixed Flow Splitters .............................................. 12Analytical ................................................................... 13Semi-Preparative ...................................................... 14Preparative ............................................................... 15High-Preparative ....................................................... 15Performance Data ..................................................... 16

Multiport Fixed Flow Splitters .......................................... 17Analytical ................................................................... 18Semi-Preparative ...................................................... 18

Pre-Column ApplicationsBinary Fixed Flow Splitters .............................................. 19

Analytical ................................................................... 20Fixed FS/Makeup-Flow Splitter Accessories .................. 21

QuickSplit Makeup-Flow Splitter Manifolds ........................ 22

QuickSplit Adjustable Flow Splitters.................................... 24Post-Column Applications

Analytical ................................................................... 26Semi-Preparative ...................................................... 27Preparative ............................................................... 27Selection Charts ....................................................... 28

Pre-Column ApplicationsAnalytical ................................................................... 30

Adjustable Flow Splitter Accessories ............................. 31

Table of Contents

10 Analytical Scientific Instruments, Inc.

○

○

○

○

○

○

�

�

���������

�������

�����������

�����������

�������������

��������

��������

123456789012123456789012123456789012123456789012

123456789012123456789012123456789012

here

�����

��

�������������

��������� ����������������

����������

�������������������

123456789012123456789012123456789012

here

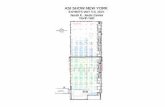

QuickSplitTM Flow SplittersPost-Column Application

- Applies to single and multiple Detectors

Pre-Column Application- Applies to single and multiple Columns

While the diagram below does not cover all possible Post-Column Flow Splitter configurations,it depicts the most common application. Post-Column flow splitters specifications should bereviewed carefully in the subsequent product literature before selecting a splitter to order. Ifyou have questions about which splitter is right for your application, please contact the techni-cal support group at ASI.

While the diagram below does not cover all possible Pre-Column Flow Splitter configurations, itdepicts the most common application. Pre-Column flow splitters specifications should be re-viewed carefully in the subsequent product literature before selecting a splitter to order. If youhave questions about which splitter is right for your application, please contact the technicalsupport group at ASI.

11http://www.hplc-asi.com

Input Flow - QResistor - L2

Resistor - L1

Figure 1. Schematic flow diagram of the QuickSplit Fixed Flow Splitter

= Fixed fluid resistor (resistance value varies depending on cartridge rating)= Fixed fluid resistor (resistance value varies depending on cartridge rating)= Split ratio = Q1/Q2 = Resistance ratio = L2/L1

L1L2R

Low Flow Rate - Q2

High Flow Rate - Q1

QuickSplitTM Fixed Flow SplitterFixed Flow Splitters

Unlike conventional splitters that use long lengths of capillary tubing, the ASI QuickSplit Fixed FlowSplitter uses two compact fluid resistor elements which are designed as cartridges for easy replace-ment. ASI fluid resistors are analogous to resistors used in an electrical circuit. Resistance values(L) are rated in PSI/mL/min. Because of the extremely low internal volume of the fluid resistors, thesolvent composition in both resistors at any instant in time is the same, and therefore viscositychanges associated with gradient runs do not impact the split ratio.

QuickSplit Fixed Flow Splitters provide a fixed split ratio with extremely low dead volume. Delayvolume on the low flow rate side is as low as 100 nanoliters depending upon the resistor cartridgeselected. The split ratio is not affected by changes in solvent viscosity or pressure, and is extremelystable and reproducible. The interchangeable fluid resistors are available in a wide range of valueswhich make it possible to create split ratios from 1:1 to as high as 20,000:1.

The flow path of the QuickSplit Fixed Flow Splitter contains two fluid resistors that form a parallel flowpath. Both low and high flow rate streams pass through fixed resistor cartridges. The ratio of thesetwo resistors creates the split ratio. To understand how the QuickSplit Fixed Flow Splitter works ithelps to look at a diagram, figure 1, of the fluid resistors in relation to the flow paths and how a splitratio is calculated.

Since the flow rate is indirectly proportional to resistance, changing the resistance in either flow pathresults in a change to the split ratio. Changing resistance is accomplished by exchanging the fixedfluid resistor cartridges with a resistor set that has different resistor ratings.

The QuickSplit Fixed Flow Splitter is shipped with resistors installed that deliver the nominal statedsplit ratio. The split ratios have a tolerance range of +/- 10 %. The exact split ratio is measured at ASIand is stated on the certificate shipped with the splitter. The input flow rate can be adjusted tocompensate for the tolerance in split ratios. For instance, a 10 % increase in input flow rate will resultin a 10 % increase in flow at both the low and high flow channels. Flow rate and viscosity changeswill change the backpressure generated by the splitter, but will not affect the actual split ratio. TheQuickSplit Fixed Flow Splitter is shipped configured for either post-column or pre-column applica-tions.

12 Analytical Scientific Instruments, Inc.

Post-column splitting is fairly straight forward. Devices contribute to chromatographic dispersion socare must be given to connecting tubing and fittings, especially at low flow rates. The pressure dropspecification for all input flow ranges is 500 PSI with water at the corresponding inlet flow rate respec-tively. To assure a maximum pressure drop of 500 PSI across the splitter, please specify theinlet flow when the splitter is ordered. Splitters are shipped complete with fluid resistors installed.

InterchangeableFluid Resistor Cartridge

QuickSplitTM Binary Fixed Flow SplitterThis easy to use “plug and play” device comes with a predefined split ratio eliminating tedious adjust-ments to capillary tubing. Split ratio changes are accomplished by changing the resistor set. Thesplit ratio is determined by the ratio of fluid resistors installed in the splitter manifold. The pressuredrop across a fixed splitter for post column applications is typically low, less than 500 PSI. The lowinternal dead volume prevents excessive dispersion and the replaceable inlet filter insures robustoperation. Available in models for analytical, semi-preparative, preparative and high-preparative inletflow rates.

Custom Split RatiosSplit ratios and resistor cartridges other than those listed can be ordered to custom configure theQuickSplit Fixed Flow Splitter. Please contact ASI technical support for additional information aboutcustom splitters. We will gladly assist you in determining the best splitter configuration for yourapplication.

�

Fixed Flow Splitters

Post-Column Applications

13http://www.hplc-asi.com

Analytical Splitters - BinaryAnalytical range, 0.1 mL/min. to 5 mL/min. input flow

QuickSplitTM Binary Fixed Flow Splitters

These splitters will produce under 500 PSI backpressure with water at 1.0 mL/min.* Thebackpressure will decrease or increase in proportion to flow rate changes. In order to assure<500 PSI pressure drop across the splitter, please specify the inlet flow when you order.

Does not come with mounting bracket, please see page 21 for mounting bracket order information.

Post-Column Applications continued

Analytical Replacement Resistor Sets - BinarynoitpircseD rebmuNtraPISA

nmuloC-tsoP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS 1:000,2 30-0111-026

nmuloC-tsoP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS 1:000,1 40-0111-026

nmuloC-tsoP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS 1:005 50-0111-026

nmuloC-tsoP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS 1:002 60-0111-026

nmuloC-tsoP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS 1:001 70-0111-026

nmuloC-tsoP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS 1:05 80-0111-026

nmuloC-tsoP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS 1:02 90-0111-026

nmuloC-tsoP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS 1:01 01-0111-026

nmuloC-tsoP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS 1:5 11-0111-026

nmuloC-tsoP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS 1:3 21-0111-026

nmuloC-tsoP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS 1:1 31-0111-026

nmuloC-tsoP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS motsuC SC-0111-026

noitpircseD rebmuNtraPISA

nmuloC-tsoP,rettilpSwolFdexiFlacitylanA =oitaRtilpS 1:000,2 30-01OP-026

nmuloC-tsoP,rettilpSwolFdexiFlacitylanA =oitaRtilpS 1:000,1 40-01OP-026

nmuloC-tsoP,rettilpSwolFdexiFlacitylanA =oitaRtilpS 1:005 50-01OP-026

nmuloC-tsoP,rettilpSwolFdexiFlacitylanA =oitaRtilpS 1:002 60-01OP-026

nmuloC-tsoP,rettilpSwolFdexiFlacitylanA =oitaRtilpS 1:001 70-01OP-026

nmuloC-tsoP,rettilpSwolFdexiFlacitylanA =oitaRtilpS 1:05 80-01OP-026

nmuloC-tsoP,rettilpSwolFdexiFlacitylanA =oitaRtilpS 1:02 90-01OP-026

nmuloC-tsoP,rettilpSwolFdexiFlacitylanA =oitaRtilpS 1:01 01-01OP-026

nmuloC-tsoP,rettilpSwolFdexiFlacitylanA =oitaRtilpS 1:5 11-01OP-026

nmuloC-tsoP,rettilpSwolFdexiFlacitylanA =oitaRtilpS 1:3 21-01OP-026

nmuloC-tsoP,rettilpSwolFdexiFlacitylanA =oitaRtilpS 1:1 31-01OP-026

nmuloC-tsoP,rettilpSwolFdexiFlacitylanA =oitaRtilpS motsuC SC-01OP-026

Fixed Flow Splitters

14 Analytical Scientific Instruments, Inc.

Post-Column Applications continued

Semi-Preparative Splitters - BinarySemi-Prep range, 5 mL/min. to 40 mL/min. input flow

These splitters will produce under 500 PSI backpressure with water at 20.0 mL/min.** Thebackpressure will decrease or increase in proportion to flow rate changes. In order to assure<500 PSI pressure drop across the splitter, please specify the inlet flow when you order.

Semi-Preparative Replacement Resistor Cartridges - Binary

QuickSplitTM Binary Fixed Flow Splitters

noitpircseD rebmuNtraPISA

rettilpSwolFdexiFevitaraperP-imeSnmuloC-tsoP,egdirtraCrotsiseRwolFhgiH

=oitaRtilpS 1:000,02 H00-0211-026

rettilpSwolFdexiFevitaraperP-imeSnmuloC-tsoP,egdirtraCrotsiseRwolFhgiH

=oitaRtilpS 1:000,01 H10-0211-026

rettilpSwolFdexiFevitaraperP-imeSnmuloC-tsoP,egdirtraCrotsiseRwolFhgiH

=oitaRtilpS 1:000,5 H20-0211-026

rettilpSwolFdexiFevitaraperP-imeSnmuloC-tsoP,egdirtraCrotsiseRwolFhgiH

=oitaRtilpS 1:000,2 H30-0211-026

rettilpSwolFdexiFevitaraperP-imeSnmuloC-tsoP,egdirtraCrotsiseRwolFhgiH

=oitaRtilpS 1:000,1 H40-0211-026

rettilpSwolFdexiFevitaraperP-imeSnmuloC-tsoP,egdirtraCrotsiseRwolFhgiH

=oitaRtilpS 1:005 H50-0211-026

rettilpSwolFdexiFevitaraperP-imeSnmuloC-tsoP,egdirtraCrotsiseRwolFhgiH

=oitaRtilpS motsuC HSC-0211-026

Flow rates higher than 1.0 mL/min. can be used, but may result in a higher pressure drop across thesplitter.

*

Flow rates higher than 20.0 mL/min. can be used, but may result in a higher pressure drop across thesplitter.

**

Does not come with mounting bracket. Mounting bracket is not available.

noitpircseD rebmuNtraPISA

nmuloC-tsoP,rettilpSwolFdexiFevitaraperP-imeS =oitaRtilpS 1:000,02 00-02OP-026

nmuloC-tsoP,rettilpSwolFdexiFevitaraperP-imeS =oitaRtilpS 1:000,01 10-02OP-026

nmuloC-tsoP,rettilpSwolFdexiFevitaraperP-imeS =oitaRtilpS 1:000,5 20-02OP-026

nmuloC-tsoP,rettilpSwolFdexiFevitaraperP-imeS =oitaRtilpS 1:000,2 30-02OP-026

nmuloC-tsoP,rettilpSwolFdexiFevitaraperP-imeS =oitaRtilpS 1:000,1 40-02OP-026

nmuloC-tsoP,rettilpSwolFdexiFevitaraperP-imeS =oitaRtilpS 1:005 50-02OP-026

nmuloC-tsoP,rettilpSwolFdexiFevitaraperP-imeS =oitaRtilpS motsuC SC-02OP-026

Fixed Flow Splitters

15http://www.hplc-asi.com

Post-Column Applications continued

QuickSplitTM Binary Fixed Flow Splitters

Preparative Replacement Resistor Cartridge/Resistor Set - Binary

Flow rates higher than the specified inlet flow rate can be used, but may result in a higher pressuredrop across the splitter.

*

Preparative Splitters - BinaryPrep range, 30 mL/min. to 200 mL/min. input flow

These splitters will produce under 500 PSI backpressure with water at the specified inlet flowrate.* The backpressure will decrease or increase in proportion to flow rate changes. In order toassure <500 PSI pressure drop across the splitter, please contact ASI for assistance inconfiguring your Fixed Splitter prior to ordering.

High-Preparative Splitters - BinaryHigh-Prep range, 200 mL/min. to 1,000 mL/min. input flow

These splitters will produce under 500 PSI backpressure with water at the specified inlet flowrate.* The backpressure will decrease or increase in proportion to flow rate changes. In order toassure <500 PSI pressure drop across the splitter, please contact ASI for assistance inconfiguring your Fixed Splitter prior to ordering.

High-Preparative Replacement Resistor Cartridge/Resistor Set - Binary

noitpircseD rebmuNtraPISA

,nmuloC-tsoP,rettilpSwolFdexiFevitaraperPegdirtraCrotsiseRwolFhgiH

.nim/Lm002-03:egnaRwolFtupnI=oitaRtilpS motsuC HSC-0411-026

noitpircseD rebmuNtraPISA

,nmuloC-tsoP,rettilpSwolFdexiFevitaraperP-hgiHteSrotsiseR

.nim/Lm000,1-002:egnaRwolFtupnI=oitaRtilpS motsuC SC-0611-026

Does not come with mounting bracket, please see page 21 for mounting bracket order information.

noitpircseD rebmuNtraPISA

nmuloC-tsoP,rettilpSwolFdexiFevitaraperP.nim/Lm002-03:egnaRwolFtupnI

=oitaRtilpS motsuC SC-04OP-026

noitpircseD rebmuNtraPISA

nmuloC-tsoP,rettilpSwolFdexiFevitaraperP-hgiH.nim/Lm000,1-002:egnaRwolFtupnI

=oitaRtilpS motsuC SC-06OP-026

Fixed Flow Splitters

Does not come with mounting bracket. Mounting bracket is not available.

16 Analytical Scientific Instruments, Inc.

ACN Gradient 5-95% in 20 min.

0

5

10

15

20

25

30

5 10 20 30 40 50 60 70 80 90 95

% ACN

Flo

w R

ate

ul/m

in

0

200

400

600

800

1000

1200

1400

PS

I

LF SR PSI

Split Ratio vs %IPA

0

5

10

15

20

25

30

1 2 3 4 5 6

Split Ratio Measurements

Sp

lit R

atio

90%H20/10%IPA 50%H20/50%IPA 10%H20/90%IPA

Effect of Gradient on Flow Rate Stability

Effect of Viscosity on Split Ratio

Conditions:Splitter 620-PO10-CSSplit Ratio 15:1Inlet Flow 400µL/min.

Conditions:Splitter 620-PO10-CSSplit Ratio 15:1Inlet Flow 400µL/min.

µL

/min

.

Fixed Flow Splitters

17http://www.hplc-asi.com

Post-Column Applications continued

QuickSplitTM Multiport Fixed Flow Splitters

Divides the incoming flow stream into 3 or 4 channels. The QuickSplit Multiport Flow Splitter is idealfor applications that use multiple detectors and/or a fraction collector. Split ratios can be configuredto be identical in each channel or custom configured to accommodate specific flow rates at eachchannel. The low internal dead volume prevents excessive dispersion and the replaceable inlet filterinsures robust operation. Available in models for analytical and semi-preparative inlet flow rates.Please contact ASI for assistance in configuring your QuickSplit Multiport Fixed Splitter priorto ordering. Please specify inlet flow rate and desired output flow rate in each channel whenyou order.

QuickSplit Multiport Fixed Flow Splitter

Post-column splitting is fairly straight forward. Devices contribute to chromatographic dispersion socare must be given to connecting tubing and fittings, especially at low flow rates. The pressure dropspecification for both analytical and semi-preparative fixed splitters is 500 PSI with water at a flow rateof 1.0 mL/min. and 20.0 mL/min. respectively. To assure a maximum pressure drop of 500 PSI acrossthe splitter, please specify the inlet flow when the splitter is ordered. Splitters are shipped completewith fluid resistors installed.

Fixed Flow Splitters

18 Analytical Scientific Instruments, Inc.

Semi-Prep range, 5 mL/min. to 40 mL/min. input flow

These splitters will produce under 500 PSI backpressure with water at 20.0 mL/min.** Thebackpressure will decrease or increase in proportion to flow rate changes.

Post-Column Applications continued

QuickSplitTM Multiport Fixed Flow Splitters

Analytical Splitters - MultiportAnalytical range, 0.1 mL/min. to 5 mL/min. input flow

Please contact ASI for assistance in configuring your QuickSplit Multiport Fixed Splitter prior to order-ing. Please specify inlet flow rate and desired output flow rate in each channel when you order.

These splitters will produce under 500 PSI backpressure with water at 1.0 mL/min.* Thebackpressure will decrease or increase in proportion to flow rate changes.

Semi-Preparative Splitters - Multiport

Flow rates higher than 1.0 mL/min. can be used, but may result in a higher pressure drop across thesplitter.

*

Flow rates higher than 20.0 mL/min. can be used, but may result in a higher pressure drop across thesplitter.

**

noitpircseD rebmuNtraPISA

nmuloC-tsoP,rettilpSwolFdexiFtroPeerhTlacitylanA =oitaRtilpS motsuC SC-01OP-036

nmuloC-tsoP,rettilpSwolFdexiFtroPruoFlacitylanA =oitaRtilpS motsuC SC-01OP-046

Comes with mounting bracket.

noitpircseD rebmuNtraPISA

,rettilpSwolFdexiFtroPeerhTevitaraperP-imeSnmuloC-tsoP

=oitaRtilpS motsuC SC-02OP-036

,rettilpSwolFdexiFtroPruoFevitaraperP-imeSnmuloC-tsoP

=oitaRtilpS motsuC SC-02OP-046

Comes with mounting bracket.

Fixed Flow Splitters

19http://www.hplc-asi.com

�

Pre-Column Applications

QuickSplitTM Binary Fixed Flow Splitter

This easy to use “plug and play” device comes with a predefined split ratio eliminating tedious adjust-ments to capillary tubing. Split ratio changes are accomplished by changing the resistor set. The splitratio is determined by the ratio of fluid resistors installed in the splitter manifold. The pressure dropacross a fixed splitter for pre-column applications where the pressure is nominally 1,500 PSI. The lowinternal dead volume prevents excessive dispersion and the replaceable inlet filter insures robustoperation. Available in models for analytical inlet flow rates.

Custom Split Ratios

Split ratios and resistor cartridges other than those listed can be ordered from ASI to custom config-ure the QuickSplit Fixed Flow Splitter. Please contact technical support for additional informationabout custom splitters. We will gladly assist you in determining the best splitter configuration for yourapplication.

Fixed Flow Splitters

Pre-column splitting is used for micro, capillary, and nano HPLC applications, where the flow from thepump is split from analytical flow rates down to microliter or nanoliter flows. It is important to notethat even though the split ratio created by the splitter valve will remain constant, the split ratiowill change when a HPLC column is installed. This is due to the added resistance on the low flowrate channel from the HPLC column. This added resistance must be factored in to make sure the fluidresistors selected for the flow splitter provide the correct split ratio. Please contact ASI if you needassistance. Splitters are shipped complete with fluid resistors installed.

When ordering a pre-column flow splitter please provide ASI with the column flow rate andback pressure. If the inlet flow rate or column pressure specification is not provided, ASI willconfigure pre-column flow splitters assuming a 0.5 mL/min. splitter inlet flow rate and a pres-sure drop across the column of 1,500 PSI. Adjustments to the low flow rate channel can bemade by increasing or decreasing the splitter inlet flow rate.

InterchangeableFluid Resistor Cartridge

! Please consider Pre-column Adjustable Flow Splitters on page 30 when you need morethan one split ratio.

20 Analytical Scientific Instruments, Inc.

Analytical range, 0.1 mL/min. to 0.5 mL/min. input flow

QuickSplitTM Binary Fixed Flow Splitters

Analytical Replacement Resistor Sets - BinarynoitpircseD rebmuNtraPISA

nmuloC-erP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS 1:000,2 30-00RP-026

nmuloC-erP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS 1:000,1 40-00RP-026

nmuloC-erP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS 1:005 50-00RP-026

nmuloC-erP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS 1:002 60-00RP-026

nmuloC-erP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS 1:001 70-00RP-026

nmuloC-erP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS 1:05 80-00RP-026

nmuloC-erP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS 1:02 90-00RP-026

nmuloC-erP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS 1:01 01-00RP-026

nmuloC-erP,teSrotsiseRrettilpSwolFdexiFlacitylanA =oitaRtilpS motsuC SC-00RP-026

The pressure drop across a pre-column flow splitter will generally be between 1,000 PSI to 3,500PSI. The exact pressure drop will depend on how the splitter is configured.

Analytical Splitters - Binary

Pre-Column Applications continued

Does not come with mounting bracket, please see page 21 for mounting bracket order information.

noitpircseD rebmuNtraPISA

nmuloC-erP,rettilpSwolFdexiFlacitylanA =oitaRtilpS 1:000,2 30-01RP-026

nmuloC-erP,rettilpSwolFdexiFlacitylanA =oitaRtilpS 1:000,1 40-01RP-026

nmuloC-erP,rettilpSwolFdexiFlacitylanA =oitaRtilpS 1:005 50-01RP-026

nmuloC-erP,rettilpSwolFdexiFlacitylanA =oitaRtilpS 1:002 60-01RP-026

nmuloC-erP,rettilpSwolFdexiFlacitylanA =oitaRtilpS 1:001 70-01RP-026

nmuloC-erP,rettilpSwolFdexiFlacitylanA =oitaRtilpS 1:05 80-01RP-026

nmuloC-erP,rettilpSwolFdexiFlacitylanA =oitaRtilpS 1:02 90-01RP-026

nmuloC-erP,rettilpSwolFdexiFlacitylanA =oitaRtilpS 1:01 01-01RP-026

nmuloC-erP,rettilpSwolFdexiFlacitylanA =oitaRtilpS motsuC SC-01RP-026

Fixed Flow Splitters

21http://www.hplc-asi.com

Fixed FS / Makeup-Flow Splitter Accessories

Fixed Flow Splitters

Replacement Inlet Filters

Mounting Bracket 620

Capillary ResistornoitpircseD rebmuNtraPISA

rotsiseRyrallipaC motsuC PC-00RP-026

noitpircseD rebmuNtraPISA

01RP-026dna06OP-026,01OP-026roftekcarBgnitnuoM 0001-026

Flow Measurement KitsnoitpircseD rebmuNtraPISA

.nim/Lµ5ot.nim/Ln05egnaRetaRwolFacilisdesufDOmµ063otsecafretni

gnibutS0100-006

.nim/Lµ52ot.nim/Lµ5egnaRetaRwolF gnibutKEEPDO”61/1otsecafretni S5200-006

.nim/Lµ001ot.nim/Lµ01egnaRetaRwolF gnibutKEEPDO”61/1otsecafretni S0010-006

.nim/Lµ005ot.nim/Lµ52egnaRetaRwolF gnibutKEEPDO”61/1otsecafretni S0520-006

noitpircseD snoitacilppA rebmuNtraPISA

,ylbmessAretliFtelnI.aid"360.norcim2emuloVLµ1,kcaP/5

-SFdexiF egnaRlacitylanA10-09OP-026rof-troPtelnI,rettilpSwolF-puekaM

puekaM,rettilpSwolF-puekaM segnaRllA-troPtelnI2-3600-026

,ylbmessAgnisuoH&retliFtelnI.aid"521.norcim01

emuloVLµ4,hcae

egnaRperP-imeS-SFdexiF40,20-09OP-026rof-troPtelnI,rettilpSwolF-puekaM

01-5210-32-026

,ylbmessAgnisuoH&retliFtelnI.aid"881.norcim01emuloVLµ01,hcae

egnaRperP-SFdexiF30-09OP-026rof-troPtelnI,rettilpSwolF-puekaM

01-8810-32-026

,ylbmessAgnisuoH&retliFtelnI.aid"881.norcim02

emuloVLµ21,hcae

egnaRperP-SFdexiF30-09OP-026rof-troPtelnI,rettilpSwolF-puekaM

02-8810-32-026

,ylbmessAgnisuoH&retliFtelnI.aid"881.norcim02

emuloVLµ21,hcaeegnaRperP-hgiH-SFdexiF 02-8810-81-026

retliFoN,eloHurhTthgiartSemuloVLµ1.0,kcaP/5

egnaRlacitylanA-SFdexiF 2-2-100-026

retliFoN,eloHurhTthgiartSemuloVLµ1,kcaP/5

egnaRperP-hgiH-SFdexiF 3-2-100-026

22 Analytical Scientific Instruments, Inc.

Makeup-Flow Splitter Manifolds

The ASI QuickSplit Makeup-Flow Splitter Manifold is designed for post-column applications where asmall amount of flow from an HPLC column is efficiently combined with a makeup-flow before itreaches the detector. Although there are many variations of this type of application, one of the mostcommon involves splitting a small portion of the outlet flow from a preparative HPLC column which isthen combined and diluted with a makeup-flow. The combined makeup-flow is used by a detector,typically Mass Spectrometry or UV, to trigger fraction collection from the remaining flow. A minimumdelay time of 5 seconds (maximum inlet flow) is built into the splitter to insure proper sequencingbetween detection and fraction collection. Unique integral resistor design eliminates tees and fittingswithin the splitter, resulting in extremely low peak dispersion. An additional binary splitter (see page12) can be added after the manifold to allow splitting the makeup-flow stream prior to entering thedetector.Custom configuration orders must include inlet flow, split ratio, and delay time. In order toassure <500 PSI pressure drop across the splitter, please specify the inlet flow when youorder.

QuickSplitTM

Makeup-Flow Splitter Manifolds

123456789012312345678901231234567890123123456789012312345678901231234567890123123456789012312345678901231234567890123123456789012312345678901231234567890123123456789012312345678901231234567890123123456789012312345678901231234567890123123456789012312345678901231234567890123

12High Flow Outletto Fraction Collector

Low Flow ResistorHigh Flow Resistor

Delay Coil

Inletfrom Preparative HPLC Column

Makeup Inlet � ��

�

� Low Flow Outletto Detector(s)

�

� � �

ASI Binary Splitter(Optional)

Split Ratio = R2/R1

R11212

R2�

QuickSplit Makeup-Flow Splitter Manifold

Common Hydraulic Schematic for Makeup-Flow Splitter- Applies to single and multiple Detectors

While the diagram on page 23 does not cover all possible Makeup-Flow Splitter configurations, itdepicts the most common application. Post column flow splitters specifications should be reviewedcarefully in the subsequent product literature before selecting a splitter to order. If you have ques-tions about which splitter is right for your application, please contact the technical support group atASI.

23http://www.hplc-asi.com

Makeup-Flow Splitter Manifolds

Please see Page 21 for Replacement Parts

QuickSplitTM Makeup-Flow Splitter Manifolds

noitpircseD rebmuNtraPISA

dlofinaMrettilpSwolF-puekaM .nim/Lm02-1:egnaRwolF =oitaRtilpS 1:000,1 10-09OP-026

dlofinaMrettilpSwolF-puekaM .nim/Lm05-02:egnaRwolF =oitaRtilpS 1:000,1 20-09OP-026

dlofinaMrettilpSwolF-puekaM .nim/Lm051-05:egnaRwolF =oitaRtilpS 1:000,5 30-09OP-026

dlofinaMrettilpSwolF-puekaM .nim/Lm05-02:egnaRwolF =oitaRtilpS 1:000,01 40-09OP-026

dlofinaMrettilpSwolF-puekaM motsuC:egnaRwolF =oitaRtilpS motsuC SC-09OP-026

���������������� ��������

���������

��������

�� ������

������ ���������

����

����������� ��

����������� ����

here

������������� ���

���������

� ��

�����

� ��

���������

�����

�����

�����

�����������������

����������

����� ����123456789123456789

�������� �

���� !���

Common Application Diagram

QuickSplitTM

Makeup-Flow Splitter Manifolds

24 Analytical Scientific Instruments, Inc.

Input Flow - Q

Resistor - L2

Resistor - L1

Figure 3. Schematic flow diagram of the QuickSplit Adjustable Flow Splitter

= Adjustable fluid resistor (metering valve)= Fixed fluid resistor (resistance value varies depending on cartridge rating)= Split ratio = Q1/Q2 = Resistance ratio = L2/L1

L1L2R

Low Flow Rate - Q2

High Flow Rate - Q1

Adjustable Flow Splitters

QuickSplitTM Adjustable Flow SplitterUnlike conventional splitters that use long lengths of capillary tubing, the ASI QuickSplit AdjustableFlow Splitter uses fluid resistors to achieve a wide range of split ratios. The flow path of the QuickSplitAdjustable Flow Splitter contains two fluid resistors that form a parallel flow path. The low flow ratestream passes through a fixed resistor cartridge, while the high flow rate stream passes through anadjustable fluid resistor (metering valve). The ratio of these two resistors creates the split flow ratio.The fixed fluid resistor is analogous to a resistor used in an electrical circuit. The compact fluidresistor elements are designed as cartridges for easy replacement with resistance values (L2) ratedin PSI/mL/min. Because of the extremely low internal volume of the fluid resistors, the solvent com-position in both resistors at any instant in time is the same, and therefore viscosity changes associ-ated with gradient runs do not impact the split ratio.

Due to the rugged design, the split ratio repeatability is +/- 1 % of setting, and unlike alternative splittervalves or tees, will not be affected by actions that effect input flow such as turning the pump off andon, or pressure spikes. Because the QuickSplit Adjustable Flow Splitter incorporates a meteringvalve, split ratios can be changed frequently with flow changes that are stable and reproducible. TheQuickSplit Adjustable Flow Splitter will create split ratios that are not affected by changes in solventviscosity or pressure and provides direct real time control over split ratio optimization.

To understand how the QuickSplit Adjustable Flow Splitter works it helps to look at adiagram, figure 3, of the fluid resistors in relation to the flow paths and how a split ratiois calculated.

Since the flow rate is indirectly proportional to resistance, changing the resistance in either flow pathresults in a change to the split ratio. Changing resistance is accomplished by adjusting the meteringvalve on the high flow rate channel or exchanging the fixed fluid resistor cartridge in the low flow ratechannel with a resistor cartridge which has a different resistance rating. Adjusting the meteringvalve is analogous to changing the capillary tubing length or diameter on conventional tee type flowsplitters. The QuickSplit Adjustable Flow Splitter has a convenient mounting bracket and hand ad-justment knob to control the split ratio. A calibrated indicator rod tracks the split ratio setting and eachsplitter is shipped with calibration data. Split ratios are not affected by changes in solvent viscositiesor pressure, which makes this product suitable for gradient applications as well as isocratic. TheQuickSplit Adjustable Flow Splitter is shipped configured for either post-column or pre-column appli-cations.

25http://www.hplc-asi.com

QuickSplitTM Adjustable Flow Splitter

QuickSplit Adjustable Flow Splitter

QuickSplit Adjustable Flow Splitter

Adjustable Flow Splitters

ASI

ADJUSTMENT KNOB

ADJUSTABLE RESISTOR

RESISTOR CARTRIDGE

INLET FLOW

REPLACEABLE INLET FILTER

SPLIT FLOW OUT

SPLIT FLOW OUT

(HIGH FLOW RATE)

(LOW FLOW RATE)

(CONTROLS ADJ. RESISTOR) METERING RODSCALE

ASI ADJUSTABLE FLOW SPLITTER

Replaceable Inlet Filter

Inlet Flow

Metering Rod ScaleAdjustment Knob

(Controls Adj. Resistor)

Split Flow Out (High Flow Rate)Adjustable Resistor

Resistor Cartridge Split Flow Out (Low Flow Rate)

ASI

26 Analytical Scientific Instruments, Inc.

Custom Split Ratios�

Analytical SplittersAnalytical range, 0.1 mL/min. to 5 mL/min. input flow

Analytical Replacement Resistor Cartridges

Post-column splitting is fairly straight forward. Like pre-column flow splitting, any significant addi-tional pressure (resistance) down stream from the splitter may affect the split ratio. Post-columndevices also contribute to chromatographic dispersion so care must given to connecting tubing andfittings, especially at low flow rates.

Use the back pressure vs split ratio chart on page 28 and 29 to select a QuickSplit Adjustable FlowSplitter that will provide the desired split ratio range and back pressure. These charts correspond toseveral flow rates and solvent systems. The back pressure is directly proportional to flow rate andviscosity. The back pressure estimates on these charts only apply to post-column applications.Splitters are shipped complete with the resistor cartridge installed.

Split ratios and resistor cartridges other than those listed below can be ordered from ASI to customconfigure the QuickSplit Adjustable Flow Splitter. Please contact technical support for additionalinformation about custom splitters. We will gladly assist you in determining the best splitter configu-ration for your application.

QuickSplitTM Adjustable Flow Splitters

To assure optimum pressure drop across the splitter, please specify the inlet flow when thesplitter is ordered.

noitpircseD egnaRoitaRtilpS rebmuNtraPISA

nmuloC-tsoP,rettilpSwolFelbatsujdAlacitylanA ot1:05 1:000,1 10-01OP-006

nmuloC-tsoP,rettilpSwolFelbatsujdAlacitylanA ot1:51 1:052 30-01OP-006

nmuloC-tsoP,rettilpSwolFelbatsujdAlacitylanA ot1:5 1:001 40-01OP-006

nmuloC-tsoP,rettilpSwolFelbatsujdAlacitylanA ot1:1 1:02 60-01OP-006

nmuloC-tsoP,rettilpSwolFelbatsujdAlacitylanA motsuC SC-01OP-006

noitpircseD egnaRoitaRtilpS rebmuNtraPISA

nmuloC-tsoP,egdirtraCrotsiseRrettilpSwolFelbatsujdAlacitylanA ot1:05 1:000,1 10-0111-006

nmuloC-tsoP,egdirtraCrotsiseRrettilpSwolFelbatsujdAlacitylanA ot1:51 1:052 30-0111-006

nmuloC-tsoP,egdirtraCrotsiseRrettilpSwolFelbatsujdAlacitylanA ot1:5 1:001 40-0111-006

nmuloC-tsoP,egdirtraCrotsiseRrettilpSwolFelbatsujdAlacitylanA ot1:1 1:02 60-0111-006

nmuloC-tsoP,egdirtraCrotsiseRrettilpSwolFelbatsujdAlacitylanA motsuC SC-0111-006

Adjustable Flow Splitters

Post-Column Applications

27http://www.hplc-asi.com

Semi-Preparative SplittersSemi-Prep range, 5 mL/min. to 40 mL/min. input flow

Semi-Preparative Replacement Resistor Cartridges

Preparative Splitters

Preparative Replacement Resistor Cartridges

noitpircseD egnaRoitaRtilpS rebmuNtraPISA

nmuloC-tsoP,rettilpSwolFelbatsujdAevitaraperP-imeS ot1:000,1 1:000,02 00-02OP-006

nmuloC-tsoP,rettilpSwolFelbatsujdAevitaraperP-imeS ot1:001 1:000,2 10-02OP-006

nmuloC-tsoP,rettilpSwolFelbatsujdAevitaraperP-imeS ot1:51 1:003 20-02OP-006

nmuloC-tsoP,rettilpSwolFelbatsujdAevitaraperP-imeS ot1:1 1:02 30-02OP-006

nmuloC-tsoP,rettilpSwolFelbatsujdAevitaraperP-imeS motsuC SC-02OP-006

noitpircseD egnaRoitaRtilpS rebmuNtraPISA

,egdirtraCrotsiseRrettilpSwolFelbatsujdAevitaraperP-imeSnmuloC-tsoP

ot1:000,1 1:000,02 00-0211-006

,egdirtraCrotsiseRrettilpSwolFelbatsujdAevitaraperP-imeSnmuloC-tsoP

ot1:001 1:000,2 10-0211-006

,egdirtraCrotsiseRrettilpSwolFelbatsujdAevitaraperP-imeSnmuloC-tsoP

ot1:51 1:003 20-0211-006

,egdirtraCrotsiseRrettilpSwolFelbatsujdAevitaraperP-imeSnmuloC-tsoP

ot1:1 1:02 30-0211-006

,egdirtraCrotsiseRrettilpSwolFelbatsujdAevitaraperP-imeSnmuloC-tsoP

motsuC SC-0211-006

Prep range, 40 mL/min. to 1,000 mL/min. input flow

noitpircseD egnaRoitaRtilpS rebmuNtraPISA

,rettilpSwolFelbatsujdAevitaraperP.nim/Lm521-04:egnaRwolFtupnI,nmuloC-tsoP

motsuC SC-03OP-006

,rettilpSwolFelbatsujdAevitaraperP.nim/Lm002-57:egnaRwolFtupnI,nmuloC-tsoP

motsuC SC-04OP-006

,rettilpSwolFelbatsujdAevitaraperP.nim/Lm000,1-001:egnaRwolFtupnI,nmuloC-tsoP

motsuC SC-06OP-006

noitpircseD egnaRoitaRtilpS rebmuNtraPISA

,egdirtraCrotsiseRrettilpSwolFelbatsujdAevitaraperP.nim/Lm521-04:egnaRwolFtupnI,nmuloC-tsoP

motsuC SC-0311-006

,egdirtraCrotsiseRrettilpSwolFelbatsujdAevitaraperP.nim/Lm002-57:egnaRwolFtupnI,nmuloC-tsoP

motsuC SC-0411-006

,egdirtraCrotsiseRrettilpSwolFelbatsujdAevitaraperP.nim/Lm000,1-001:egnaRwolFtupnI,nmuloC-tsoP

motsuC SC-0611-006

Adjustable Flow Splitters

Post-Column Applications continued

28 Analytical Scientific Instruments, Inc.

10

100

1000

10000

1 10 100 1000Split ratio

Bac

k p

ress

ure

(psi

)

10

100

1000

10000

1 10 100 1000 10000 100000

Split ratio

Bac

k p

ress

ure

(p

si)

QuickSplit Adjustable Flow Splitter Selection ChartsBack pressure vs Split ratio for water at 1 mL/min. 600-PO10 Analytical range

Back pressure vs Split ratio for water at 20 mL/min. 600-PO20 Semi-prep range

Adjustable Flow Splitters

����������� �����������

����������� �����������

���������

����������

����������

����������

29http://www.hplc-asi.com

1

10

100

1000

1 10 100 1000Split ratio

Bac

k p

ress

ure

(p

si)

1

10

100

1000

10000

1 10 100 1000Split ratio

Bac

k p

ress

ure

(p

si)

QuickSplit Adjustable Flow Splitter Selection ChartsBack pressure vs Split ratio for 50/50 ACN/water at 1 mL/min. 600-PO10 Analytical range

Back pressure vs Split ratio for 50/50 ACN/water at 0.5 mL/min. 600-PO10 Analytical range

Adjustable Flow Splitters

����������������������

����������������������

����������������������

����������� �����������

30 Analytical Scientific Instruments, Inc.

Custom Split Ratios�

Analytical SplittersAnalytical range, 0.25 mL/min. to 1 mL/min. input flow

Analytical Replacement Resistor Cartridges

Pre-column splitting is used for micro, capillary, and nano HPLC applications, where the flow from thepump is split from analytical flow rates down to microliter or nanoliter flows. It is important to note thateven though the split ratio created by the splitter valve will remain constant, the split ratio will changewhen a HPLC column is installed. This is due to the added resistance on the low flow rate channelfrom the HPLC column. This added resistance must be factored in to make sure the fluid resistorselected for the flow splitter provides the correct split ratio. Please contact ASI if you need assistance.The charts on page 28 and 29 only estimate the pressure drop across the splitter for post columnapplications and do not include the HPLC column back pressure. Splitters are shipped complete withthe resistor cartridge installed.

Split ratios and resistor cartridges other than those listed below can be ordered from ASI to customconfigure the QuickSplit Adjustable Flow Splitter. Please contact technical support for additionalinformation about custom splitters. We will gladly assist you in determining the best splitter configu-ration for your application.

These splitters will produce under 3,500 PSI backpressure with water at 0.5 mL/min.

QuickSplitTM Adjustable Flow Splitters

When ordering a pre-column flow splitter, please provide ASI with the column flow rate andback pressure. If the inlet flow rate or column pressure specification is not provided, ASI willconfigure pre-column flow splitters assuming a 0.5 mL/min. inlet flow rate and a pressuredrop across the column of 1,500 PSI.

noitpircseD egnaRoitaRtilpS rebmuNtraPISA

nmuloC-erP,rettilpSwolFelbatsujdAlacitylanA ot1:05 1:000,1 10-01RP-006

nmuloC-erP,rettilpSwolFelbatsujdAlacitylanA ot1:51 1:052 30-01RP-006

nmuloC-erP,rettilpSwolFelbatsujdAlacitylanA ot1:5 1:001 40-01RP-006

nmuloC-erP,rettilpSwolFelbatsujdAlacitylanA ot1:1 1:02 60-01RP-006

nmuloC-erP,rettilpSwolFelbatsujdAlacitylanA motsuC SC-01RP-006

noitpircseD egnaRoitaRtilpS rebmuNtraPISA

nmuloC-erP,egdirtraCrotsiseRrettilpSwolFelbatsujdAlacitylanA ot1:05 1:000,1 10-00RP-006

nmuloC-erP,egdirtraCrotsiseRrettilpSwolFelbatsujdAlacitylanA ot1:51 1:052 30-00RP-006

nmuloC-erP,egdirtraCrotsiseRrettilpSwolFelbatsujdAlacitylanA ot1:5 1:001 40-00RP-006

nmuloC-erP,egdirtraCrotsiseRrettilpSwolFelbatsujdAlacitylanA ot1:1 1:02 60-00RP-006

nmuloC-erP,egdirtraCrotsiseRrettilpSwolFelbatsujdAlacitylanA motsuC SC-00RP-006

Adjustable Flow Splitters

Pre-Column Applications

http://www.hplc-asi.com 31

Adjustable Flow Splitter Accessories

Adjustable Flow Splitters

Capillary ResistornoitpircseD rebmuNtraPISA

rotsiseRyrallipaC motsuC PC-00RP-006

Replacement Inlet FiltersnoitpircseD rettilpSwolF rebmuNtraPISA

.aid"360.norcim2,retliFtelnIemuloVLµ1,kcaP/5

egnaRlacitylanAnmuloc-erP/tsoP-SFelbatsujdA 2-3600-006

.aid"521.norcim01,retliFtelnIemuloVLµ4,kcaP/5

egnaRperP-imeS-SFelbatsujdA04,03OP-006rofegnaRperP&

01-5210-006

retliFoN,eloHurhTthgiartSemuloVLµ1,kcaP/5

06OP-006rofegnaRperP-SFelbatsujdA 0-2-820-006

Flow Measurement KitsnoitpircseD rebmuNtraPISA

.nim/Lµ5ot.nim/Ln05egnaRetaRwolFacilisdesufDOmµ063otsecafretni

gnibutS0100-006

.nim/Lµ52ot.nim/Lµ5egnaRetaRwolF gnibutKEEPDO”61/1otsecafretni S5200-006

.nim/Lµ001ot.nim/Lµ01egnaRetaRwolF gnibutKEEPDO”61/1otsecafretni S0010-006

.nim/Lµ005ot.nim/Lµ52egnaRetaRwolF gnibutKEEPDO”61/1otsecafretni S0520-006

32 Analytical Scientific Instruments, Inc.

Syringe Pumps

PrimeLineTM Syringe Pumps

PrimeLineTM Syringe Pump Features:

Spring loaded check valves allow operation in horizontal or vertical mountingposition

� Optical home sensor

� Micro step drive using R232 PC control

� Optional wash seal available for buffer solutions

� Optional 400 to 2,000 count rotary encorder available

� Other stroke volumes available on request

� Custom sizes available for OEM

�

*

Syringe Pump Complete Assembly SpecificationemuloVekortS *noituloseR wolF.xaM erusserP.xaM rebmuNledoMISA

Lm040.0 5.0 sretilonan 5.0 .nim/Lm 005,2 ISP 0400-075

Lm001.0 0.1 sretilonan 52.1 .nim/Lm 000,1 ISP 0010-075

Lm522.0 52.2 sretilonan 5.2 .nim/Lm 054 ISP 5220-075

Lm004.0 0.4 sretilonan 0.5 .nim/Lm 052 ISP 0040-075

Lm009.0 0.9 sretilonan 0.9 .nim/Lm 001 ISP 0090-075

Using micro step drive supplied by ASI

http://www.hplc-asi.com 33

Isocratic Model 501

Gradient System 500G

PrimeLineTM HPLC Pumps

Isocratic Model 501

Gradient System 500G

� Self-priming pump head requires no manual priming

� Patented “Floating Pump Seal” design for extended seal wear

� Available with micro, analytical, semi-prep, and prep pump heads

� Intuitive software control for isocratic and gradient systems

� Programmable solvent compressibility compensation

� Easy maintenance and service for all wetted parts

� Integral prime/purge assembly for quick solvent change

PrimeLineTM HPLC Pump Features:

34 Analytical Scientific Instruments, Inc.

IntroductionThe ASI HPLC pump is designed with the chromatographer in mind. It can be used as a reliablelow cost isocratic pump or integrated into a gradient HPLC System. In either case, the pumpincorporates several key features which make it truly one of a kind in the world of HPLC Pumps.

ASI HPLC Pumps

Features�Self-priming

The pump will prime itself with any solvent and at any flow rate. Turn on the pump and open thepurge valve, the pump will prime itself even from a completely dry start. You will never need touse syringes to prime it.

�Patented Floating Pump SealThe seal actually floats so that it is always perfectly aligned with the piston. Our tests haveproved that the average life with this new patented design is more than 5,000 hours of continu-ous operation at 6,000 PSI and 10 mL/min. with pure water.

�Micro, Analytical, Semi-Prep, and Prep Pump Heads

�Intuitive Software ControlThe control is designed with dedicated keys that allow even a novice to turn on the pump andcreate methods. An easy to read 4-line x 20-character LCD display allows the user to monitorseveral pump parameters from the same screen. The model 501 can be controlled from its ownkeypad or from a Model 500 gradient controller. When configured as a gradient HPLC systemusers can program and store up to 60 methods with 20 lines each. Methods may be linked orrun independently.

�Solvent Compressibility CompensationThe user may select from several different solvents from the on board library. The controlautomatically compensates for compressibility of the selected solvent.

�Easy MaintenanceAll user serviceable components are easily accessed from the front panel. Once the headassembly is removed, the pistons and seals can be replaced quickly and easily without the useof tools.

�Pressure SensorBonded strain gage with flow through design and digital output

�Prime/Purge AssemblyAllows for quick and easy solvent change

daeHpmuP egnaRetaRwolF gnitaRerusserP:daeHorciM .nim/Lm4ot.nim/Lµ5.0 xaMISP000,6

:daeHlacitylanA .nim/Lm01ot.nim/Lµ0.1 xaMISP000,6:daeHperP-imeS .nim/Lm02ot.nim/Lm050.0 xaMISP005,2

:daeHperP .nim/Lm08ot.nim/Lm001.0 xaMISP000,1

http://www.hplc-asi.com 35

Isocratic Model 501The Model 501 is a high performance, compact solvent delivery module that has been designed tocompete with the most expensive pump systems on the market in reliability and performancewithout the high cost. A dual piston design with solvent compressibility feedback assures virtuallypulse-free and accurate solvent delivery. The Model 501 has all of the features of the Model 500,but without gradient programming capability. It may be used as an economical stand alone pumpfor isocratic operation, or in conjunction with a Model 500 for gradient operation.

ASI HPLC Pumps

The Model 500 has been designed to convert the Model 501 from an isocratic pump to a gradientHPLC system. Full operation and gradient control programming is achieved through the keypad onthe front panel of the Model 500. The Model 500 includes a high pressure integral static mixer,connecting tubing, and all the accessories necessary to quickly convert the Model 501 to gradientoperation.

Model 500

SpecificationsAccuracy:

Precision:

Pulsation:Dimensions:

Weight:Power input:

+/- 1 % or +/- 2 µL/min. whichever is greater+/- 1 % or +/- 1 µL/min. whichever is greater (Micro)0.25 % from 0.1 mL/min. to 10 mL/min. at 20 degrees C0.25 % from 0.05 mL/min. to 4 mL/min. at 20 degrees C (Micro)<1.0% � P/P at >1,000 PSI10-1/4” W x 14” D x 6-1/2” H16 lbs. (7.3 kg)85 to 264 VAC, 47 to 63 Hz, 60 watts

+/- 1 % or +/- 2 µL/min. whichever is greater+/- 1 % or +/- 1 µL/min. whichever is greater (Micro)0.25 % from 0.1 mL/min. to 10 mL/min. at 20 degrees C0.25 % from 0.05 mL/min. to 4 mL/min. at 20 degrees C (Micro)<1.0% � P/P at >1,000 PSI60 methods with 20 lines each, methods can be linked to create com-plex gradient programs.Controlled by external contact closure10-1/4” W x 14” D x 6-1/2” H16 lbs. (7.3 kg)85 to 264 VAC, 47 to 63 Hz, 60 watts

SpecificationsAccuracy:

Precision:

Pulsation:Programming:

Remote Start/Stop:Dimensions:

Weight:Power input:

36 Analytical Scientific Instruments, Inc.

10 20 30 40 50 60 70

Minutes

-1

0

1

2

3

4

5

6

m Volts

ASI HPLC Pumps

Gradient Model 500GThe Model 500G is a complete high pressure gradient HPLC system. The system includes oneModel 501, one Model 500, and all necessary electrical and plumbing connections. Specificationslisted on previous page.

PrimeLine Micro Pump Performance Data

Linear and Step Gradient Profiles at 50 µL/min.

HPLC System Configuration:ASI Model 500G Micro HeadDetection: UV214Mixer: ASI HyperShear In-line 25µL

HPLC Conditions:MP: A = H2O, B = H2O doped with 0.05% red dyeFlow Rate: 50µL/min.Step Gradient: 0 to 100% B in 60 min., 10% stepsLinear Gradient: Same, 4 min. T0 hold

Linear Profile

�Step Profile

Minutes

mVolts

SpecificationsProgramming Control:

Gradient Profile:Number of Programmable Files:

Maximum Program Steps:Maximum Time per Step:

Remote Control:Concentration Range Setting:

Flow Rate Accuracy:Gradient Flow Rate Settings:

Alphanumeric keypadStep and linear profiles at multiple levels20 files with the ability to link programs20650 minutes in 0.1 stepsContact closure and RS2320-100% in 1.0% stepsSee pump specifications previous page10 µL/min. to 2.0 mL/min. (Micro)100 µL/min. to 10.0 mL/min.

http://www.hplc-asi.com 37

5 10 15 20 25 30

Minutes

0.25

0.50

0.75

1.00

1.25

1.50

m Volts

1 2 3 4 5 6 7

Minutes

-0.8

0.0

2.5

5.0

7.5

10.0

m Volts

ASI HPLC Pumps

Minutes

mVolts

HPLC System Configuration:ASI Model 500G Micro HeadDetection: UV214Mixer: ASI HyperShear In-line 150µL

HPLC Conditions:MP: A = H2O, B = H2O doped with 0.05% red dyeFlow Rate: 200µL/min. Isocratic 35% BSample: Methyl and Ethyl Parabens

HPLC System Configuration:ASI Model 500G Micro HeadDetection: UV214Mixer: ASI HyperShear In-line 25µL

HPLC Conditions:MP: A = H2O, B = H2O doped with 0.05% red dyeFlow Rate: 20µL/min. Gradient 5 to 95% B in 20 min.Sample: Methyl and Ethyl Parabens

PrimeLine Micro Pump Performance Data

Isocratic Reproducibility at 200 µL/min. RSD’s < 1.0%

Gradient Reproducibility at 20 µL/min.RSD’s < 1.0%

Minutes

mVolts

38 Analytical Scientific Instruments, Inc.

Outlet Check Valve Cartridge

Outlet Housing

Inlet Housing/Cartridge

Spring Housing/Pump Head

Assembly

ASI HPLC Pumps

Easy Maintenance and Repair

Replacing the Check Valve CartridgesThe pump inlet and outlet check valve cartridges are contained in hex nut housings located on the top(outlet) and bottom (inlet) of the pump head assembly.

Outlet Check Valve Cartridge:Using the 1/4” open end wrench (provided) loosen the 1/16” cross over tube nuts and remove the 1/16” cross over tube. Remove the outlet housing with a 1/2” open end wrench and replace the outletcartridge making sure the ASI arrow on the cartridge is aligned with the flow direction. Replace thehousing and cross over tube and tighten all fittings until they are leak free.

Inlet Check Valve Cartridge:Remove the fingertight fitting on the inlet line and follow the same general directions for replacing theoutlet cartridge. Be sure the ASI arrow on the cartridge is aligned with the flow direction.

Using the 9/64” allen wrench with a T bar handle loosen and remove the screws which connect thepump head to the manifold and spring housing. Remove and pull the pump head away from the pump.This step will expose the two piston seal assemblies. The seals may be grasped with the finger tipsand gently pulled forward and free of the piston.

Replacing the Piston Seal Assemblies

http://www.hplc-asi.com 39

Pump Head

Piston SealAssembly

Pump HeadManifold

Spring Housing

Spring HousingPistons

Frame DriveCasting

ASI HPLC Pumps

Push the new piston seal assembly over the end of the exposed piston with a finger tip or thumb. Thisprocedure aligns the piston seal assembly on the piston. When the pump head is pressed firmlyagainst the manifold, the seals will be pressed over the pistons.

Replacing the PistonsUsing the 9/64” T Bar allen wrench, remove the pump head, piston seal assemblies, manifold, andwash seal assemblies, if installed. Using the same tool, remove the screws which attach the springhousing to the frame drive casting. Pull the spring housing free from the pump. The piston shafts arenow visibly protruding from the rear of the assembly. Gently remove the pistons from the springhousing assembly. To re-install pistons, push the pistons back into the spring housing through therear bushings.

40 Analytical Scientific Instruments, Inc.

ASI HPLC Pumps

PrimeLineTM HPLC Pumps & Replacement Parts

Micro HPLC PumpsnoitpircseD rebmuNtraP

105ledoM 2000-105

005ledoM 2000-005

metsyStneidarGG005ledoM 2000-G005

smetievobaehtrofegatlovenilderiuqerlacolruoyyficepsesaelP*

ylbmessAdaeHpmuP/gnisuoHgnirpS 0001-005A

citarcosI,tiKlaeShsaW K3201-005A

tneidarG,tiKlaeShsaW K3301-005A

kcaP/2,ylbmessAlaeShsaW 20-3201-005A

kcaP/01,ylbmessAlaeShsaW 01-3201-005A

ylbmessAeniLtelnItnevloS 10-5312-005

ebuTrefsnarT 10-0821-005

ebuTtcennocretnI 10-5821-005

ebuTrevOssorC 10-2113-005

Lµ051rexiMcitatS 0510-214

Lµ052rexiMcitatS 0520-024

tekcarBgnitnuoMevlaVnoitcejnI 7112-005

i5277evlaVnoitcejnI 6101-005A

recudsnaTerusserP 2104-005A

kcaP/01,23/01stuNleetSsselniatS 2260-009

kcaP/01,selurreFleetSsselniatS 2260-019

kcaP/01,23/01sgnittiFthgitregniF 1360-008

kcaP/2nolfeT,ylbmessAlaeSnotsiP 2-T-9001-005A

kcaP/2WMHU,ylbmessAlaeSnotsiP 2-U-9001-005A

kcaP/01nolfeT,ylbmessAlaeSnotsiP 01-T-9001-005A

kcaP/01WMHU,ylbmessAlaeSnotsiP 01-U-9001-005A

Lm2,repiWlaeSnotsiP 20-7211-005

notsiPcimareC 7111-005A

gnisuoHtelnI 1311-005

gnisuoHteltuO 2311-005

egdirtraCteltuO/telnI 3311-005A

kcaP/5,norcim01,sretliFtnevloS 1260-058

http://www.hplc-asi.com 41

ASI HPLC Pumps

PrimeLineTM HPLC Pumps & Replacement Parts continued

Analytical HPLC PumpsnoitpircseD rebmuNtraP

105ledoM 0000-105

005ledoM 0000-005

metsyStneidarGG005ledoM 0000-G005

smetievobaehtrofegatlovenilderiuqerlacolruoyyficepsesaelP*

ylbmessAdaeHpmuP/gnisuoHgnirpS 1001-005A

citarcosI,tiKlaeShsaW K5001-005A

tneidarG,tiKlaeShsaW K5101-005A

kcaP/2,ylbmessAlaeShsaW 20-5001-005A

kcaP/01,ylbmessAlaeShsaW 01-5001-005A

ylbmessAeniLtelnItnevloS 10-5312-005

ebuTrefsnarT 10-0821-005

ebuTtcennocretnI 10-5821-005

ebuTrevOssorC 10-2113-005

Lµ005rexiMcitatS 0050-024

)dradnats(Lµ053rexiMcitatS 0530-024

retpadArexiM 1113-005

tekcarBgnitnuoMevlaVnoitcejnI 7112-005

i5277evlaVnoitcejnI 6101-005A

recudsnaTerusserP 2104-005A

kcaP/01,23/01stuNleetSsselniatS 2260-009

kcaP/01,selurreFleetSsselniatS 2260-019

kcaP/01,23/01sgnittiFthgitregniF 1360-008

kcaP/2nolfeT,ylbmessAlaeSnotsiP 2-T-6001-005A

kcaP/2WMHU,ylbmessAlaeSnotsiP 2-U-6001-005A

kcaP/01nolfeT,ylbmessAlaeSnotsiP 01-T-6001-005A

kcaP/01WMHU,ylbmessAlaeSnotsiP 01-U-6001-005A

Lm01,repiWlaeSnotsiP 01-7211-005

notsiPerihppaS 4001-005A

gnisuoHtelnI 7611-005

gnisuoHteltuO 6911-005

egdirtraCteltuO/telnI 0501-005A

kcaP/5,norcim01,sretliFtnevloS 1260-058

42 Analytical Scientific Instruments, Inc.

�

�

�

�

�

�

�

�

�

Static or Dynamic Mixers with highly efficient vortex shear mixing

Reduce baseline noise, increase sensitivity, and improve gradient accuracy

Mixing volume optimization is easy with interchangeable mixer cartridges

Available for In-line, Binary, and Ternary formats in SS or PEEK

Ideal for microbore HPLC and LC/MS

Compact design is easily integrated into any HPLC system

Increased reaction efficiency for post column derivatization

Decreased mixing and delay volume without sacrificing mixing efficiency

15,000 PSI High Pressure SS Static Mixers are available

HyperShearTM HPLC Mixers

HyperShearTM HPLC Mixer Features:

http://www.hplc-asi.com 43

ASI manufactures a wide range of Mixers to solve the most demanding HPLC mixing prob-lems. ASI HyperShear HPLC Mixers incorporate a highly efficient cross-flow shearing mecha-nism which produces vortex shear mixing over a wide flow range. This mixing technologytypically delivers between 25 % to 200 % better mixing efficiency compared to conventionalstir bar or tortuous path mixers. HyperShear HPLC Mixers are available in both static anddynamic formats with volumes ranging from 0.5 µL to 1.5 mL. Most mixers are available inbiocompatible PEEK.

HyperShearTM HPLC Mixers

Comparison of Baseline Noise

Note the significant reduction in baseline noise with the ASI static mixer.

Conditions:Gradient Program:CH3CN/H2O = 50/50 --> (15 min.) 90/10Flow Rate: 0.1mL/min.Temp.: 40°CSample Size: 1µLSample: Solvent frontDetection Wavelength: 254nm

The baseline of this plot has been enlarged to show the noise levels associated with each mixer.

HyperShear Static MixersMicro Flow Series, Mixing Volumes 0.5 µL to 25 µL .................. 44Low Flow Series, Mixing Volumes 50 µL to 250 µL ................... 48Analytical Flow Series, Mixing Volumes 350 µL and 500 µL ...... 52High Flow Series, Mixing Volumes 800 µL to 1.5 mL ................ 54Combo Micro Series, Mixing Volumes 1 µL to 100 µL ............... 56Static Mixer Application Notes .............................................. 58Comparison Data - LEE, Agilent & Shimadzu....................... 60

HyperShear Dynamic Mixers ....................................................... 64

Table of Contents

44 Analytical Scientific Instruments, Inc.

Micro Flow SeriesStainless Steel

In-Line Complete Assembly - Cartridge and Housing

noitpircseD rebmuNtraPISA

Lµ5.0SSylbmessArexiMeniL-nI 5.000-104

Lµ1SSylbmessArexiMeniL-nI 1000-104

Lµ2SSylbmessArexiMeniL-nI 2000-104

Lµ5SSylbmessArexiMeniL-nI 5000-104

Lµ01SSylbmessArexiMeniL-nI 0100-104

Lµ52SSylbmessArexiMeniL-nI 5200-104

In-Line Assemblies

0.5µL, 1µL, 2µL, 5µL, 10µLor 25µL Cartridge

Port Size: 10-32 CPI ( Standard HPLC Fittings for 1/16” Tube)

Static Mixers

* Please add “HP” to end of part number for High Pressure application

��������� ���� � �������� ����� ��

http://www.hplc-asi.com 45

Cartridges / Housings

Binary Tee Complete Assembly - Cartridge and Housing

Ternary Tee Complete Assembly - Cartridge and Housing

noitpircseD rebmuNtraPISA

Lµ5.0SSylbmessArexiMeeTyraniB 5.000-204

Lµ1SSylbmessArexiMeeTyraniB 1000-204

Lµ2SSylbmessArexiMeeTyraniB 2000-204

Lµ5SSylbmessArexiMeeTyraniB 5000-204

Lµ01SSylbmessArexiMeeTyraniB 0100-204

Lµ52SSylbmessArexiMeeTyraniB 5200-204

noitpircseD ISA rebmuNtraP

Lµ5.0SSylbmessArexiMeeTyranreT 5.000-304

Lµ1SSylbmessArexiMeeTyranreT 1000-304

Lµ2SSylbmessArexiMeeTyranreT 2000-304

Lµ5SSylbmessArexiMeeTyranreT 5000-304

Lµ01SSylbmessArexiMeeTyranreT 0100-304

Lµ52SSylbmessArexiMeeTyranreT 5200-304

Binary/Ternary Assemblies

0.5µL, 1µL, 2µL, 5µL, 10µLor 25µL Cartridge

noitpircseD rebmuNtraPISA

Lµ5.0SSegdirtraCrexiM 5.000-004

Lµ1SSegdirtraCrexiM 1000-004

Lµ2SSegdirtraCrexiM 2000-004

Lµ5SSegdirtraCrexiM 5000-004

Lµ01SSegdirtraCrexiM 0100-004

Lµ52SSegdirtraCrexiM 5200-004

gnisuoHSSseireSwolForciMeniL-nI 0000-104

gnisuoHSSseireSwolForciMeeTyraniB 0000-204

gnisuoHSSseireSwolForciMeeTyranreT 0000-304

Static Mixers

��������� ������ ��������� ��� ������

Port Size: 10-32 CPI

��������� ���� ���

46 Analytical Scientific Instruments, Inc.

ASI

Micro Flow SeriesBiocompatible PEEK

In-Line Complete Assembly - Cartridge and Housing

noitpircseD rebmuNtraPISA

Lµ5.0KEEPylbmessArexiMeniL-nI B5.000-104

Lµ1KEEPylbmessArexiMeniL-nI B1000-104

Lµ2KEEPylbmessArexiMeniL-nI B2000-104

Lµ5KEEPylbmessArexiMeniL-nI B5000-104

Lµ01KEEPylbmessArexiMeniL-nI B0100-104

Lµ52KEEPylbmessArexiMeniL-nI B5200-104

In-Line Assemblies

Static Mixers

Port Size: 10-32 CPI ( Standard HPLC Fittings for 1/16” Tube)

0.5µL, 1µL, 2µL, 5µL, 10µLor 25µL Cartridge

��������� ���� � �������� ����� ��

http://www.hplc-asi.com 47

ASI

Binary Tee Complete Assembly - Cartridge and HousingnoitpircseD rebmuNtraPISA

Lµ5.0KEEPylbmessArexiMeeTyraniB B5.000-204

Lµ1KEEPylbmessArexiMeeTyraniB B1000-204

Lµ2KEEPylbmessArexiMeeTyraniB B2000-204

Lµ5KEEPylbmessArexiMeeTyraniB B5000-204

Lµ01KEEPylbmessArexiMeeTyraniB B0100-204

Lµ52KEEPylbmessArexiMeeTyraniB B5200-204

Ternary Tee Complete Assembly - Cartridge and Housing

noitpircseD ISA rebmuNtraP

Lµ5.0KEEPylbmessArexiMeeTyranreT B5.000-304

Lµ1KEEPylbmessArexiMeeTyranreT B1000-304

Lµ2KEEPylbmessArexiMeeTyranreT B2000-304

Lµ5KEEPylbmessArexiMeeTyranreT B5000-304

Lµ01KEEPylbmessArexiMeeTyranreT B0100-304

Lµ52KEEPylbmessArexiMeeTyranreT B5200-304

Binary/Ternary Assemblies

Cartridges / HousingsnoitpircseD rebmuNtraPISA

Lµ5.0KEEPegdirtraCrexiM B5.000-004

Lµ1KEEPegdirtraCrexiM B1000-004

Lµ2KEEPegdirtraCrexiM B2000-004

Lµ5KEEPegdirtraCrexiM B5000-004

Lµ01KEEPegdirtraCrexiM B0100-004

Lµ52KEEPegdirtraCrexiM B5200-004

gnisuoHKEEPseireSwolForciMeniL-nI B0000-104

gnisuoHKEEPseireSwolForciMeeTyraniB B0000-204

gnisuoHKEEPseireSwolForciMeeTyranreT B0000-304

Port Size: 10-32 CPI

Static Mixers

��������� ������ ��������� ��� ������

0.5µL, 1µL, 2µL, 5µL, 10µLor 25µL Cartridge

��������� ���� ���

48 Analytical Scientific Instruments, Inc.

Low Flow SeriesStainless Steel

In-Line Complete Assembly - Cartridge and Housing

noitpircseD rebmuNtraPISA

Lµ05SSylbmessArexiMeniL-nI 0500-114

Lµ051SSylbmessArexiMeniL-nI 0510-114

Lµ052SSylbmessArexiMeniL-nI 0520-114

50µL, 150µL or 250µL Cartridge

In-Line Assemblies

Static Mixers

* Please add “HP” to end of part number for High Pressure application

Port Size: 10-32 CPI ( Standard HPLC Fittings for 1/16” Tube)

��������� ���� � �������� ����� ��

http://www.hplc-asi.com 49

Binary Tee Complete Assembly - Cartridge and Housing

Cartridges / Housings

Ternary Tee Complete Assembly - Cartridge and Housing

noitpircseD rebmuNtraPISA

Lµ05SSylbmessArexiMeeTyraniB 0500-214

Lµ051SSylbmessArexiMeeTyraniB 0510-214

Lµ052SSylbmessArexiMeeTyraniB 0520-214

noitpircseD rebmuNtraPISA

Lµ05SSylbmessArexiMeeTyranreT 0500-314

Lµ051SSylbmessArexiMeeTyranreT 0510-314

Lµ052SSylbmessArexiMeeTyranreT 0520-314

Binary/Ternary Assemblies

50µL, 150µL or 250µL Cartridge

noitpircseD rebmuNtraPISA

Lµ05SSegdirtraCrexiM 0500-014

Lµ051SSegdirtraCrexiM 0510-014

Lµ052SSegdirtraCrexiM 0520-014

gnisuoHSSseireSwolFwoLeniL-nI 0000-114

gnisuoHSSseireSwolFwoLeeTyraniB 0000-214

gnisuoHSSseireSwolFwoLeeTyranreT 0000-314

Static Mixers

��������� ������ ��������� ��� ������

Port Size: 10-32 CPI

��������� ���� ���

50 Analytical Scientific Instruments, Inc.

Low Flow SeriesBiocompatible PEEK

In-Line Complete Assembly - Cartridge and Housing

noitpircseD rebmuNtraPISA

Lµ05KEEPylbmessArexiMeniL-nI B0500-114

Lµ051KEEPylbmessArexiMeniL-nI B0510-114

Lµ052KEEPylbmessArexiMeniL-nI B0520-114

In-Line Assemblies

50µL, 150µL or 250µL Cartridge

Static Mixers

Port Size: 10-32 CPI ( Standard HPLC Fittings for 1/16” Tube)

��������� ���� � �������� ����� ��

http://www.hplc-asi.com 51

Binary Tee Complete Assembly - Cartridge and Housing

Cartridges / Housings

Ternary Tee Complete Assembly - Cartridge and Housing

noitpircseD rebmuNtraPISA

Lµ05KEEPylbmessArexiMeeTyraniB B0500-214

Lµ051KEEPylbmessArexiMeeTyraniB B0510-214

Lµ052KEEPylbmessArexiMeeTyraniB B0520-214

noitpircseD rebmuNtraPISA

Lµ05KEEPylbmessArexiMeeTyranreT B0500-314

Lµ051KEEPylbmessArexiMeeTyranreT B0510-314

Lµ052KEEPylbmessArexiMeeTyranreT B0520-314

Binary/Ternary Assemblies

50µL, 150µL or 250µL Cartridge

noitpircseD rebmuNtraPISA

Lµ05KEEPegdirtraCrexiM B0500-014

Lµ051KEEPegdirtraCrexiM B0510-014

Lµ052KEEPegdirtraCrexiM B0520-014

gnisuoHKEEPseireSwolFwoLeniL-nI B0000-114

gnisuoHKEEPseireSwolFwoLeeTyraniB B0000-214

gnisuoHKEEPseireSwolFwoLeeTyranreT B0000-314

���

Static Mixers

��������� ������ ��������� ��� ������

Port Size: 10-32 CPI

��������� ���� ���

52 Analytical Scientific Instruments, Inc.

Analytical Flow SeriesStainless Steel, Biocompatible PEEK

In-Line Complete Assembly - Cartridge and HousingStainless Steel

Biocompatible PEEK - HP is not available

In-Line Assemblies

350µL or 500µL Cartridge

noitpircseD rebmuNtraPISA

Lµ053SSylbmessArexiMeniL-nI 0530-124

Lµ005SSylbmessArexiMeniL-nI 0050-124

noitpircseD rebmuNtraPISA

Lµ053KEEPylbmessArexiMeniL-nI B0530-124

Lµ005KEEPylbmessArexiMeniL-nI B0050-124

Static Mixers

* Please add “HP” to end of part number for High Pressure application

Port Size: 10-32 CPI ( Standard HPLC Fittings for 1/16” Tube)

��������� ���� � �������� ����� ��

http://www.hplc-asi.com 53

Binary Complete Assembly, Stainless Steel - Cartridge and Housing

Cartridges / HousingsStainless Steel

Ternary Complete Assembly, Stainless Steel - Cartridge and Housing

Binary/Ternary Assemblies350µL or 500µL Cartridge

Biocompatible PEEK - HP is not available

noitpircseD rebmuNtraPISA

Lµ053SSylbmessArexiMeeTyraniB 0530-224

Lµ005SSylbmessArexiMeeTyraniB 0050-224

noitpircseD rebmuNtraPISA

Lµ053SSylbmessArexiMeeTyranreT 0530-324

Lµ005SSylbmessArexiMeeTyranreT 0050-324

noitpircseD rebmuNtraPISA

Lµ053KEEPegdirtraCrexiM B0530-024

Lµ005KEEPegdirtraCrexiM B0050-024

gnisuoHKEEPseireSwolFlacitylanAeniL-nI B0000-124

noitpircseD rebmuNtraPISA

Lµ053SSegdirtraCrexiM 0530-024

Lµ005SSegdirtraCrexiM 0050-024

gnisuoHSSseireSwolFlacitylanAeniL-nI 0000-124

gnisuoHSSseireSwolFlacitylanAeeTyraniB 0000-224

gnisuoHSSseireSwolFlacitylanAeeTyranreT 0000-324

Static Mixers

��������� ������ ��������� ��� ������

Port Size: 10-32 CPI

��������� ���� ���

54 Analytical Scientific Instruments, Inc.

2.68

1.43

ASI

800uL, 1.0mL OR 1.5mLCARTRIDGE

In-Line Complete Assembly - Cartridge and HousingStainless Steel

Biocompatible PEEK - HP is not available

In-Line Assemblies

800µL, 1.0mL or 1.5mL Cartridge

High Flow SeriesStainless Steel, Biocompatible PEEK

noitpircseD rebmuNtraPISA

Lµ008SSylbmessArexiMeniL-nI 0080-134

Lm0.1SSylbmessArexiMeniL-nI 0001-134

Lm5.1SSylbmessArexiMeniL-nI 0051-134

noitpircseD rebmuNtraPISA

Lµ008KEEPylbmessArexiMeniL-nI B0080-134

Lm0.1KEEPylbmessArexiMeniL-nI B0001-134

Lm5.1KEEPylbmessArexiMeniL-nI B0051-134

Static Mixers

* Please add “HP” to end of part number for High Pressure application

Port Size: 10-32 CPI ( Standard HPLC Fittings for 1/16” Tube)

���

��������� ���� � �������� ����� ��

http://www.hplc-asi.com 55

1.43

ASI

800uL, 1.0mL OR 1.5mLCARTRIDGE

2.60

FLOWLOCK INPUT PORTS

Binary Complete Assembly, Stainless Steel - Cartridge and Housing

Ternary Complete Assembly, Stainless Steel - Cartridge and Housing

Biocompatible PEEK - HP is not available

Cartridges / HousingsStainless Steel