Ash Formation and Partitioning in a Cyclone Fired...

Transcript of Ash Formation and Partitioning in a Cyclone Fired...

-

Ash Formation and Partitioning in a Cyclone Fired Boiler

Steven A. Benson, Shuchita Patwardhan, and Art Ruud Microbeam Technologies Inc.

Andrew Freidt, Minnkota Power Cooperative

Jodey Houn, BNI Coal Ltd

Junior Nasah, University of North Dakota, Institute for Energy Studies

-

Overview Background Project goal Field testing/sampling Coal, slag, entrained ash properties Partitioning of fuel impurities

between cyclone and fly ash Conclusions

2

-

Minnkota MRY Plant Unit 1, 250 MW, 1970 Unit 2, 460 MW, 1977 Fired with lignite from ND 95% availability Ranked among lowest cost electricity producer in US

3

-

Challenges Lignite variability Clay minerals Alkali and alkaline earth elements organically

associated

Slag freezing in cyclones Convective pass fouling Fine particulate

4

-

Ash Behavior Indices

5

-

Slag Flow Characteristics by Seam

6

-

CCSEM (Wt% Minerals, Mineral Basis)BNI # 41-132HB 41-144KC 41-144 HA 41-144HB 41-168 KC 41-168 HA 41-168 HB 41-180 KC 41-180 HA 41-180 HB 41-192 KC 41-192 HA

Total Quartz Content

3.1 17 18.8 9.8 30.3 8.7 8.8 11.4 20 3.9 15 17.4

Quartz < 10 microns

2 10.8 9.7 6.4 24.6 4.4 4 6.8 3.3 2.6 9.7 12.7

Total Kaolinite Content

5.8 10.6 16.7 10.8 7.7 6.4 1.7 9.5 4.4 2.4 14.3 28

Kaolinite Content < 10 microns

2.6 5.1 8.4 6.3 4.5 2.6 0.9 4.8 1.1 0.9 10.2 20.8

Total Montmorillonite

1.8 10.7 6 2.7 6.5 1.7 6.1 7 2.3 2.4 7.6 5.1

Total Illite 10.2 14.1 0.7 9.3 6.6 0.2 28 19.1 10.2 1.6 6.8 1.9Total Pyrite 45.4 8 28.7 26.7 18.9 67.1 19.7 9.1 10.9 57.2 22.6 32.3

Pyrite Content < 10 microns

8.9 4.5 3.5 10.5 2.8 9.8 4.7 2.5 2.5 17 6.6 7

Gypsum Content 10.6 6.5 0.6 0 1.6 2.7 0.8 5.4 0 16.1 2.2 0

-

Relationship to Slag Freezing

0

1

2

3

4

5

0.00 10.00 20.00 30.00 40.00 50.00 60.00 70.00

Illite and Montmorillonite, lb/mBTU

Freezing

Good flow

Poor flow

-

Ash Content and Cyclone Performance

0

5

10

15

20

25

30

35

40

45

0818

98 1

108

1898

13

0818

98 1

508

1898

17

1202

98 0

112

0298

09

1202

98 1

712

1598

07

1215

98 0

712

1598

07

1215

98 0

712

2698

07

1226

98 0

512

2798

19

1227

98 1

712

2798

15

0116

99 0

901

1699

09

0116

99 0

904

0699

09

0406

99 1

504

0699

21

0407

99 0

305

0499

15

0506

99 0

505

0599

07

0505

99 0

905

0499

17

0506

99 2

107

1199

21

0710

99 0

507

1299

09

0710

99 1

107

1299

21

0710

99 1

707

1399

09

Date

Ash

(moi

stur

e fr

ee)

5400

5600

5800

6000

6200

6400

6600

6800

7000

7200

Cyc

lone

Per

form

nace

9

-

Base/Acid Ratio and Cyclone Performance

0.00

0.20

0.40

0.60

0.80

1.00

1.20

1.40

0818

98 1

108

1898

15

0818

98 1

9

0818

98 2

3

1202

98 0

912

0298

19

1201

98 2

3

1215

98 2

1

1215

98 2

312

1698

01

1216

98 0

3

1227

98 0

5

1227

98 0

512

2798

05

1227

98 0

5

0116

99 0

1

0116

99 0

301

1699

05

0406

99 0

7

0406

99 1

5

0406

99 2

304

0799

07

0504

99 2

1

0506

99 1

3

0505

99 1

705

0599

21

0505

99 1

1

0710

99 1

5

0713

99 0

907

1199

01

0714

99 0

5

0711

99 1

7

0710

99 0

507

1299

13

Date

Base

/Aci

d

5400

5600

5800

6000

6200

6400

6600

6800

7000

7200

Cycl

one

Perfo

rman

ce

10

-

Coal Sorting and Blending Criteria

Base-Acid RatioB/A= (CaO+MgO+Na2O+FeO+K2O)/(SiO2+Al2O3+TiO2)

Ash Content

Optimum coal for maintaining good slag flow Base-to-acid ratio > 0.6 to 0.7 Ash content < ~17 % (mf basis)

11

-

Variability Challenge - Coal Mining and Blending

Three Seams

Upper – Low B/AHigh ash

Middle – moderate to high B/A,

moderate ash

Lower – High B/ALow ash high Na

PGNAA - elemental analysisAsh and moisture

meters

High B/ALow Ash

Moderate B/AModerate Ash

Low to ModerateB/A

High Ash

Low B/AHigh Ash

PGNAA - reclaimed coal from building

Transferred to Silos

Coal BuildingCoal Mine

12

-

Goal To determine partitioning process

between slag and fly ash as a function of the inorganic composition of the lignite enable more accurate prediction of the slag

flow behavior, entrained ash composition, ash deposition on heat transfer surfaces, and fine particle properties.

13

-

Plan – Unit 2 Test coals with three different B/A ratios.

High B/A Medium B/A Low B/A

Test each coal under 4 different O2 conditions. Sampling of coal, slag, ash and perform boiler

observations at each set of conditions.

14

-

FIELD TEST UNIT 2• Coal Sampling• Boiler Operating Parameters• NOx Levels• Particulate Loadings – Dekati Impactor/bulk filter• ESP Hopper samples • Slag samples

15

-

Field Test Matrix

Day Conditions Coal –as

fired

Slag Fly Ash Dekati

ESP Hopper

BoilerObservations

Day 1 Baseline x x x x x

Day 2 Med B/A x x x x x

Day 3 High B/A x x x x x

Day 4 Low B/A x x x x x

16

-

Diagram of processes and tools

Coal Properties Cyclone – Ash partitioning

Entrained Ash

Coal Air Vent

Slag

Transport to water wall Slagging

Transport toConvective pass

surfaces

High temperature fouling – silicate

based

Low temperature fouling – sulfate

based

Slag flow

ESP particle capture –

resistivity and cohesivity

Boiler operating parameters – air

flow

Over fire air

Tools

Inputs/processes

17

-

Schematic of Sampling Locations

18

-

Sample AnalysisNo. Sample description Analysis

1 As-fired coal samples Proximate/Ult analysis, Ash composition, CCSEM

2 Slag samples Morphology/Composition/SEMPC

3 ESP Hopper samples Morphology/Composition/CCSEM

4 Dekati Fly Ash Samples Morphology/Composition

19

-

Coal Analysis

20

-

Coal analysis – Prox/Ult resultsDescription Total Moisture

Ash As Received

Volatile Matter As Received

Fixed Carbon As Received

BTU/lb As Received

Total Sulfur As Received

Carbon As Received

Hydrogen As Received

Nitrogen As Received

Coal As-fired D1 27.37 9.84 32.73 30.06 7627 0.95 47.26 6.23 0.73

Coal As-fired D2 28.65 9.40 32.87 29.08 7488 1.06 46.84 6.33 0.71

Coal As-fired D3 28.27 9.36 32.95 29.42 7616 1.10 47.53 6.29 0.73

Coal As-fired D4 27.75 12.12 32.12 28.01 7348 1.08 45.85 6.20 0.72

21

-

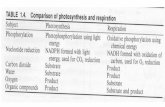

Coal analysis – Ash composition results(Weight percent equivalent oxide)

Description Silicon DioxideAluminum

DioxideTitanium Dioxide Iron Oxide

Calcium Oxide

Magnesium Oxide

Potassium Oxide

Sodium Oxide P2O5

Coal As fired D1 39.81 14.71 0.63 11.47 16.61 5.44 1.81 8.09 0.12

Coal As fired D2 40.22 13.18 0.68 12.61 17.63 5.41 1.59 7.13 0.11

Coal As fired D3 37.65 12.58 0.65 14.28 18.94 5.53 1.41 7.24 0.13

Coal As fired D4 46.93 14.47 0.75 9.93 13.96 4.53 2.06 5.79 0.13

22

-

B/A ratio – As fired coal – Unit 2

Description B/A Ratio Description

Coal As fired D1 0.79 Baseline operation

Coal As fired D2 0.82 Med B/A

Coal As fired D3 0.93 High B/A

Coal As fired D4 0.58 Low B/A

0.79 0.82

0.93

0.58

0.000.100.200.300.400.500.600.700.800.901.00

Coal As fired D1 Coal As fired D2 Coal As fired D3 Coal As fired D4

B/A Ratio

23

-

Viscosity temperature – As fired coal

0.00

1.00

2.00

3.00

4.00

5.00

6.00

7.00

1200 1400 1600 1800 2000 2200 2400

Vis

cosi

ty, L

og1

0P

oise

Temperature, °F

Coal As fired D1 Coal As fired D2 Coal As fired D3 Coal As fired D4

T250 - flow begins

molten liquid

Day 4 Low B/ADay 3 High B/ADay 2 Med B/A

24

-

CCSEM – Day 2 Composite Coal

1.24.6

2.4 4 1.53.31.4

6.5

3

5

2.8

8.6

0.6

1.7

2.2

4.7

3.2

15.3

0.1

0.2

0.1

0.4

0.4

4.3

2.2

4.6

1.8

2.8

1.2

5.3

0.7

0.7

0.3

0.7

0.3

0.9

0

5

10

15

20

25

30

35

40

1.0 - 2.2 2.2 - 4.6 4.6 - 10.0 10.0 - 22.0 22.0 - 46.0 46.0 - 400

Wei

ght

perc

ent,

min

eral

bas

is

Size Bin, µm

Others Unclassified Iron Oxide Pyrite/Pyrrhotite/Oxidized Pyrrhotite Silicate Minerals Quartz

25

-

CCSEM – Day 3 Composite Coal

2.9

11.5

2.7 4.10.9

3

4.1

9.7

3.94.9

1.5

5.60.3

1.4

1.3

2.3

2.3

13.5

0.2

0

0.3

0.9

0.4

3.5

2.3

3.8

1.5

2

1.1

2

0.8

2.4

0.4

0.7

0.3

0.8

0

5

10

15

20

25

30

35

1.0 - 2.2 2.2 - 4.6 4.6 - 10.0 10.0 - 22.0 22.0 - 46.0 46.0 - 400

Wt

% M

iner

al B

asis

Size bin, µm

Others Unclassified Iron oxide Pyrite/Pyrrhotite/Oxidized Pyrrhotite Silicate Minerals Quartz

26

-

CCSEM Day 4 – Composite Coal

2.4

5.83 4.3

1.2 1.8

3.5

7.1

5.4

7.7

3.1

100.3

0.4

1.3

3.9

2

4.6

0

0.2

0.2

1.4

0.4

2.7

2.5

3.2

2.9

4

1.4

4.8

1.4

1.9

1.2

2.4

0.7

0.8

0

5

10

15

20

25

30

1.0 - 2.2 2.2 - 4.6 4.6 - 10.0 10.0 - 22.0 22.0 - 46.0 46.0 - 400

Wt%

, Min

eral

Bas

is

Size bin, µm

Others Unclassified Iron Oxide Pyrite/Pyrrhotite/Oxidized Pyrrhotite Silicate Minerals Quartz

27

-

Slag Samples Analysis

28

-

Slag samples analysis resultsWt% equivalent oxide

Normalized Na2O MgO Al2O3 SiO2 SO3 K2O CaO TiO2 Fe2O3 BaO

D1C1 4.47 4.61 12.24 42.75 0.25 1.23 21.20 0.66 11.61 0.82

D2C1 5.15 5.32 12.27 42.03 0.18 0.88 22.73 0.56 9.83 0.88

D3C1 3.89 4.57 9.51 33.54 0.31 0.68 30.13 0.53 15.32 1.29

D4C1 3.49 3.65 11.07 46.78 0.23 1.39 19.60 0.62 11.80 1.25

29

-

Fly Ash Entrained Ash – Dekati Mass Composition by size

30

-

Dekati data – Total mass loadings

4.00E+05

2.76E+05

3.82E+05 3.85E+05

5.28E+05

6.96E+05

4.62E+05

5.71E+05

6.70E+05

5.93E+05

4.49E+05

5.17E+05

5.65E+05

4.17E+05

0.00E+00

1.00E+05

2.00E+05

3.00E+05

4.00E+05

5.00E+05

6.00E+05

7.00E+05

8.00E+05

D1C1 D2C1 D2C2 D2C3 D2C4 D3C1 D3C2 D3C3 D3C4 D3C5 D4C1 D4C2 D4C3 D4C4

Total Loading (µg/dscm)

Day 2 Med B/A Day 3 High B/A Day 4 Low B/A

31

-

Coal-Slag-Fly Ash Comparison

32

-

Day 4 Coal , Slag, Dekati data comparison (wt% equivalent oxide).

Na2O MgO Al2O3 SiO2 P2O5 SO3 K2O CaO TiO2 Fe2O3 BaO

Coal Day 4 5.79 4.53 14.47 46.93 0.13 0.00 2.06 13.96 0.75 9.93 0.98

D4C1 – Slag 3.49 3.65 11.07 46.78 0.00 0.23 1.39 19.60 0.62 11.80 1.25

D4C1 – Dekati 17.05 6.52 4.69 12.54 0.97 27.68 3.13 18.10 0.87 6.01 2.44

33

-

Partitioning

34

-

Partitioning Calculations Coal flow rate Ash content of coal (as received basis) Air flow rate at the inlet Air flow rate at the outlet Total mass loading

35

-

Partitioning Between Slag and Fly Ash

65.6372.80

44.09

67.91

34.3727.20

55.91

32.09

0.00

10.00

20.00

30.00

40.00

50.00

60.00

70.00

80.00

90.00

100.00

D1C1 D2C1 D3C1 D4C1

Per

cent

as

slag

or

fly

ash

Fly ash

Slag

36

-

Cyclone Partitioning – Day 2 Coal

Cyclone Wall

Solid Slag

Moderately thick Liquid Slag Layer

Twall

T250=2000 ºF

Slag – moderate viscosity slag –High ash retention – 73%

Low Particle Loading - ~27%

High coal/ash sticking

Coal particles –moderate B/A, low ash

Day 2 – B/A 0.82, Ash 9.4

Vaporization

-

Cyclone Partitioning – Day 3 Coal

Cyclone Wall

Solid SlagThin Liquid Slag Layer

Twall

T250= 1900 ºF

Slag – Low viscosity slag –Low ash retention – 44%

High Particle Loading - ~56%

Low coal/ash sticking

Coal particles – high B/A, low ash

Day 3 – B/A 0.93, Ash 9.4

Vaporization

-

Cyclone Partitioning – Day 4 Coal

Cyclone Wall

Solid Slag

Moderately thick Liquid Slag Layer

Twall

T250=2200 ºF

Slag – moderate viscosity slag –High ash retention – 50%

Low to moderate Particle Loading - ~50%

High coal/ash sticking coefficient – higher rebound – freezing potential

Coal particles – low B/A, high ash

Day 3 – B/A 0.58, Ash 12.1

Vaporization

-

Partitioning Process Transport to cyclone slag

Gas flow rate Size and density of particle

Sticking in the slag Viscosity of the slag layer Slag layer thickness

Volatility of element Association of the element in the coal Element chemical properties

40

-

Questions Thanks to:

41

Ash Formation and Partitioning in a Cyclone Fired Boiler�OverviewMinnkota MRY PlantChallengesAsh Behavior IndicesSlag Flow Characteristics by SeamCCSEM (Wt% Minerals, Mineral Basis)Relationship to Slag FreezingAsh Content and Cyclone PerformanceBase/Acid Ratio and Cyclone PerformanceCoal Sorting and Blending CriteriaVariability Challenge - Coal Mining and BlendingGoalPlan – Unit 2 Field Test Unit 2Field Test MatrixDiagram of processes and toolsSchematic of Sampling LocationsSample AnalysisCoal AnalysisCoal analysis – Prox/Ult resultsCoal analysis – Ash composition results�(Weight percent equivalent oxide)B/A ratio – As fired coal – Unit 2Viscosity temperature – As fired coalCCSEM – Day 2 Composite CoalCCSEM – Day 3 Composite CoalCCSEM Day 4 – Composite CoalSlag Samples AnalysisSlag samples analysis results�Wt% equivalent oxideFly AshDekati data – Total mass loadingsCoal-Slag-Fly Ash ComparisonDay 4 Coal , Slag, Dekati data comparison (wt% equivalent oxide).PartitioningPartitioning CalculationsPartitioning Between Slag and Fly AshCyclone Partitioning – Day 2 CoalCyclone Partitioning – Day 3 CoalCyclone Partitioning – Day 4 CoalPartitioning ProcessQuestions