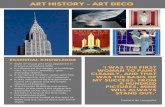

Art in New York The Seventies – Body Art – Earth Art – Conceptual Art.

art%3A10.1134%2FS0869864313060061

Click here to load reader

Transcript of art%3A10.1134%2FS0869864313060061

695

Thermophysics and Aeromechanics, 2013, Vol. 20, No. 6

Obstacle influence on the flow structure and mass transfer in a boundary layer with ethanol combustion on horizontal surface*

B.F. Boyarshinov

Kutateladze Institute of Thermophysics SB RAS, Novosibirsk, Russia

E-mail: [email protected]

(Received April 29, 2013)

Experiments with ethanol combustion on horizontal surfaces revealed the most general properties of a boundary layer with chemical and phase transformations. The list of flow features includes development of large-scale structures and manifestation of volumetric forces, which impact the flow stability and heat and mass transfer. It was demonstrated that the range of velocities ensuring flame existence is wider for flow past a rib than for flow past a backward-facing step. The nature of mass transfer in a reactive flow past an obstacle is transient and remains of that kind until the flame blow-off. For a flow above a horizontal wall at Reynolds numbers Re < 5⋅10

4, the intensity of mass transfer is twice

higher than for combustion below the wall. When the combustion occurs below the wall, the surface temperature gradients are higher.

Key words: heat and mass transfer, boundary layer, combustion, large-scale structures, flame blow-off, volumetric forces, transient regimes.

Introduction

The tools for gas mixing are instrumental for control of heat and mass transfer near the surface. This is achieved through variations in the level of mass and volumetric forces, degree of air flow turbulence, creation of zones with separated and reattached flow, and through a longitudinal pressure gradient. If gas combustion takes place, mixing and chemical reactions are mutually related; therefore, it is important to know the limits when both processes remain steady under external flow disturbances. Placement of obstacles in the flow creates direct impact on the boundary layer structure, which defines the flame blow-off velocity. The influence of an obstacle on heat and mass transfer for the cases of non-reactant boundary layer and for combustion flow has certain similarities and differences.

The results of publications [1−4] indicate that flow without combustion creates a zone of return flow past an obstacle. Downstream the obstacle, the reattachment zone with high turbulence and transfer intensity is found. Paper [5] presents an empirical rela-tionship for maximal levels of transfer coefficients in the reattachment zone. According to data from [6, 7], several zones of this type can exist on a wall. The authors of papers [8]

* Research was financially supported by RF Presidential Fund (Grant No. NSh-4349.2010.8) and by the SB RAS Integration Project (No. 24).

© B.F. Boyarshinov, 2013

B.F. Boyarshinov

696

noted that recovery of the boundary layer to the turbulent state after flow separation is very slow.

For some cases, when flow-wall interaction induces curving of streamlines, different manifestations of mass forces are observed. Quantitative measurements for axisymmetric supersonic jets from [9] revealed existence of steady azimuthal irregularities in the distribution of gas-dynamic parameters. This irregularity is associated with longitudinal vortices. The streamwise maldistribution on the jet periphery (the jet exiting a converging nozzle with the Vitoshinsky profile) was observed in experiments [10] at rather low air flow velocities (5 m/s). As the streamline curvature was reduced (this was achieved through attachment of a cylindrical section to the nozzle exit), the streamwise structures at the channel outlet dis-appeared. Visualization data for transversal cross sections in experiments [11] showed a link between the facts of streamwise structures and opposite-rotation vortices. This flow pattern has paired vortices: they interact, interlace, and merge. The authors of paper [12] believed that the growth of streamwise vortices is caused by their interaction with low-scale turbulence in outer media. The research [13] was focused on correlation measurements of hydrogen con-centration in a jet emerging into air; the authors made a conclusion about growing contribution of large-scale pulsations at high distances from the nozzle.

In paper [14], the bending of streamlines was related to supersonic gas flow past a dihe-dral obtuse angle. The streamwise vortices were observed in the boundary layer: the vortex sizes were close to dimensions of the studied object. The modern state of research in the field of large-scale structures in subsonic overflow by an isothermal air flow at low turbulence (Tu0 < 0.1 %) is presented in paper [15]. This research was focused on boundary layer stability on flat and curved surfaces. The streamwise structures were considered as intermediary forms in the laminar-to-turbulent transition.

The incentives for further studies of this type of flow require the knowledge of quantita-tive metrics for their influence on transfer processes. The authors of paper [16] noted that streamwise structures help in entrainment of liquid into a gas flow. Away from the nozzle, this process overwhelms the process of liquid entrainment by coherent structures. These effects were considered together with other cases of curvilinear gas flow ⎯ see paper [17]. It has been demonstrated that heat transfer rate almost doubles for a boundary layer with Tailor⎯Goertler vortex generation. The paper [18] emphasized the relation between streamline curvature and development of buoyancy force in stratified liquid. Accepting the analogy between momentum transfer and circulation transfer in a bent flow, as well as a hypothesis about a mixing path, the authors of [19] obtained the shear stress distribution and the heat flux distribution in a boundary layer. They demonstrated that for a concave wall, the heat transfer and skin fric-tion might increase by factor of 1.4−1.8, while for a convex geometry, these processes were attenuated by 30−40 %, depending on the enthalpy factor.

The publications [20, 21] are known: they study mixed convection on a hot horizontal plate (without combustion). These studies present data on defining the conditions for manife-station of volumetric forces (buoyancy effects). The authors of [22] concluded that for a hori-zontal boundary layer with unsteady density stratification, the heat transfer is higher. Two cas-es were considered in paper [23]: heat transfer on a “ceiling” and on a “floor”. The authors believe that a streamwise pressure gradient develops in a boundary layer: this effect might dis-tort the velocity profiles and cause the flow separation above the heated wall.

In burning technologies, it is preferable to ensure flame stability even for a situation of significant gas stratification on the density (when buoyancy develops in gravity field). The research [24] dealt with a burner without flame stabilizer. It was shown that with a higher air flow velocity, the front edge of flame shifted in the downstream direction. For a need of com-bustion stabilization, researchers used the same types of obstructions as for nonreactive flow: namely, they were ribs and steps [25] which induced gas flow rotation and formed up the mass

Thermophysics and Aeromechanics, 2013, Vol. 20, No. 6

697

forces field. It was found for a flat boundary layer past a rib that the obstacle lifts up the flame above the horizontal wall; heat fluxes become lower, but the heat transfer coefficients for case of combustion/no combustion keep their similarity. This research did not bring any comparison with other methods for flame stabilization. Combustion of a round uprising jet of natural gas fuel was considered in paper [26] for a situation of flame stabilized by a disk (axisymmetric analog of a rib) or by a backward-facing step. The research demonstrated that among the criti-cal parameters, we can name the flame holder dimensions, its configuration, and the gas flow velocity. For the first version of obstacle (disk), the flame blow-off occurs earlier than for the second version. It was proved in paper [27] that a backward-facing step ensures better flame stability. Development of coherent vortex structures past an obstacle was observed. But when the flame approaches the backward-facing step, these structures are not observed at all. The authors of this paper assumed that combustion stability in a higher degree depends on the mixing intensity than on the chemical reaction kinetics. Experiments in [28] were per-formed for a flame stabilized by a backward-facing step or by a rectangular parallelepiped. These experiments were carried out for methane blow-in through a porous wall; the flame was detected in a horizontal channel with the height of 250 mm and width of 30 mm. For the geo-metry of that narrow channel, no streamwise structures were observed; the irreversible flame blow-off took place at air velocity ~2.5−3 m/s. The same level of flame blow-off velocity was observed in [29], when the combustion data was obtained for a sample with the diameter of 20 mm.

The influence of mainstream turbulence and the rib height on mass transfer in a boundary layer above a horizontal wall with a subsonic flow was studied in paper [30]. The authors compared the data for cases of evaporation with/without combustion. It was demonstrated that for the inlet turbulence of ~1 %, the flame blow-off velocity Ub (past a rib with height h = 3 mm) can be as high as 70 m/s; this velocity becomes lower with the increase of turbulence in the main flow; this critical velocity is higher for a higher rib. The range for variation of mass transfer coefficients during combustion past an obstacle is almost twice wider than for nonreactive flow. The splitting of experimental data on mass transfer was found [7, 31].

For Reynolds numbers Re < 2⋅106, this splitting of the relative mass flow on a wall W W 0 0/ ρ=J J U

was generalized by a family of power functions 0.5W Re ,ψ −≈ ⋅J where the multiplier

1, 2,3,...,ψ = and the power index are typical of a laminar boundary layer. The authors of paper

[32] carried out measurements in a boundary layer above the upper horizontal wall of a channel with hydrogen-nitrogen mixture delivery through the wall and combustion of this mixture. The research demonstrated fulfilment of a “triple” Reynolds analogy in a reactive flow. Obviously, the task of estimating the buoyancy contribution needs com-parison of heat and mass transfer below the upper wall and above the lower wall (for the same flow regimes).

The research demonstrated different situations for developing of large-scale flow struc-tures; they have ambiguous effect on flame stability and transfer processes; this creates incen-tives for further studying of roots of developing of that type of gasdynamic maldistribution. The list of roots may include development of volumetric and mass forces due to bending of streamlines or due to changes in the gas density. The present research considers only several aspects of the mixed convection problem for combustion on horizontal walls of a channel, while the density stratification and gas rotation behind an obstacle take place. The research goal is the most general empirical data about influence of volumetric forces on the flow pattern, on flow stability and transfer processes; we want to demonstrate also that flow rotation movement (as a reason for generating the mass forces on a planar wall) retains with increasing distance from an obstacle.

B.F. Boyarshinov

698

Experimental equipment

Liquid fuel combustion was studied near a flat surface; combustion was organized in a wind tunnel [30, 33] with a working section having a rectangular cross section 100×100 mm and the length of 700 mm (Fig. 1). Transparent side walls were composed of a set of quartz plates. The working section was connected directly to a wind-tunnel contractor with compression factor equal to 6.8. The turbulence control was performed by installing at the contractor inlet of either a grid with 15 threaded holes (М 27×1.5, distance between hole centers was 43 mm), or a wire mesh with cells 1×1 mm. The turbulence level at the channel inlet (Tu0 = 8 %, 18 %, 26 %) was assigned via a number of open holes in the grid (correspondingly, 25, 9, or 5). In experiments with a mesh at the channel inlet, the turbulence was Tu0 = 1 %.

The working section configuration has been adapted to a specific experiment. For expe-riments on heat and mass transfer, the horizontal surfaces were made of porous plates with the sizes 80×80 mm (thickness 10−15 mm, porosity ~60 %); the porous plates were manufactured by sintering of stainless steel balls. The number of plates varied from four to seven, and they were installed either at the “ceiling” or at the “floor” of the rectangular channel. For experi-ments with LDA diagnostic tools, when the air flow carried quartz power particles, the porous “floor” plates were replaced with dishes filled with a bed of glass-beads (beads diameter was 0.7±0.15 mm).

When the flame was stabilized with a backward-facing step, the contractor’s surface was covered by a second wall reproducing the contractor geometry (or with deviation form original geometry). At the channel inlet, we installed a movable wall with a transverse section for con-structing a backward-facing step with a variable height h < 7 mm. When experiments on fuel combustion past a rib were conducted, we used a transverse plate at the channel inlet (the plate over the entire channel width). The plate edge was lifted above the wall by height h < 15 mm.

In our experiments with zero-acceleration configuration and without streamwise pressure gradient (dP/dx = 0), we removed the top of the channel. However, in experiments with flow acceleration, the velocity law along the channel was assigned by instating a flexible top wall (the wall length was 400 mm).

The liquid fuel was ethanol (96 % water solution). The fuel supply system ensured a con-stant level of liquid fuel in the porous plates (or in the beaded bed), which must be kept wet during experiments. The ethanol combustion rate JW (kg/s/m2) was self-regulated according to the conditions of convective heat and mass transfer with the zone of combustion. The fuel flow rate was measured for every porous plate via variation in the ethanol level in the measurement reservoirs. The measurements accuracy was ~5 %. The chromel/alumel thermocouples were welded to the side faced to the gas flow. The accuracy of assignment of wall boundary conditions (TW = const, CW = const) was ensured by the fact that evaporation and combustion process was almost adiabatic. The temperature of evaporating film was constant at the level TW ~ 340.5±0.5 K and independent of the inlet air velocity U0 (this velocity was independent of the flow turbulence Tu0, obstacle height h, and downstream distance x, if U0 > 10 m/s

[34]). The mass fraction of fuel on the wall, observed from the saturation curve, was taken equal to CW = 0.8.

Fig. 1. Boundary layer with ethanol evapo-ration and combustion “on the floor” past

an obstacle. The rib height is 3 mm, the air flows with a velocity of 10 m/s from left to right; channel without top lid. Camera Canon EOS 1000D, exposition 1/400 s. One can see streamwise irregularities with dimensions comparable to the channel length.

Thermophysics and Aeromechanics, 2013, Vol. 20, No. 6

699

The temperature in a boundary layer was measured with a platinum/platinum-rhodium thermocouple made of wire with the diameter of 50 microns. Laser Doppler anemometer was installed for measuring of local velocities. The LDA optical part on the base of LADO-2 [35] provided measurement of two components of velocity with the space resolution of 0.1×0.1×0.5 mm. This part was allocated above the working section on a 3D movable plat-form; the travel range in the longitudinal direction was Δx = 500 mm, in vertical direction Δy = 50 mm, and for transverse direction Δz = 50 mm. The measurement accuracy for average velocity was better than 2 %. The light scattering elements were the quartz particles (mean-modal size ~1 micrometer); this powder was fed into the wind tunnel in the inlet cross section of the flow contractor.

Experimental results

Figure 2 depicts pictures of a boundary layer “on the ceiling” at the air velocity reduced to 3.5 m/s, when it was possible to compare different methods of flame stabilization (air flow from left to the right, channel without the lower wall, camera Canon A490). When the flame was without stabilization (upper picture), the front edge of flame was drifted downstream from the front end of the porous plate (the light strop on the left). When the air velocity was increased to U0 > 4 m/s, combustion failed. But when the backward-facing step was installed, the front edge of the flame attaches to the obstacle (not shown) and remains nearby until the flame blow-off. Behind a 3-mm rib (lower image), the flame is “separated” from the obstacle, and several longitudinal strips are visible. The distance between strips is ~25 mm.

This type of experiments demonstrates the need for flow stabilization and proves exis-tence of certain across dimension for streamwise structures. This size had not been ensured in known experiments [28], and these streamwise structures had not been observed there. When we deal with experimental study of large-scale structures, it is important to remember that every structure is a separate element of entire flow with its own temperature and velocity distribution; they make up the whole gas flow and interact with other similar elements.

Whenever the color irregularities in flame (Fig.1) visualize the gas-dynamic fea-tures of a reactive flow, the domination of channel-length-scaled streamwise structures becomes obvious. They are movable in transversal direction; the irregularities intersect, in-termingle, and interact with each other. In the downstream direction, the number of structures becomes lower, but their sizes are bigger. When we study a boundary layer past an obstacle, it is important to see the spatial connection between gas-dynamic and heat parameters within the limits of a separate irregularity in the flow.

The existing tools do not allow tracing the development of nonstationary structures, therefore, the experimental conditions have been adapted to capabilities of our measurement technique. The distribution of irregular structures for a flow with combustion “on the floor” pro-duce contrasting images as shown in Fig. 2 (bottom picture), only when the channel has a con-verging geometry. Measurements in the y-z plane were carried out at the exit cross section at the distance from the obstacle х = 400 mm (inlet velocity was U0 = 4.9 m/s, exit velocity was U0 = 9.3 m/s, the rib size h = 3 mm, the inlet height

Fig. 2. Visual appearance of flame for com- bustion “on the ceiling”.

The view from the top, the air flow is driven to the right. The light band at the left side is the place of flow stabilizer placement. The flow at the top picture is without stabilization, the flow at the bottom picture was stabilized with 3-mm rib.

B.F. Boyarshinov

700

of the channel was 98 mm, the outlet height was 49 mm, and the channel had a plain upper wall). Experiments gave us the temperature profiles T(y, z), and the V(y, z) profile was obtained with direct LDA measurements with a transverse step equal to Δz = 5 mm. Figure 3 (top picture) demonstrates the data for coordinate у = 8 mm (V = 0, the starting point was chosen arbitrarily). The irregularities in V(z) profile demonstrate a sequence of zones with gas rotation, where the angular velocity was about ω ~ΔV/Δz ~ 40 (s−1). Figure 3 (bottom picture) shows the iso-therms in the same cross section. One can see the same nature of allocations of zones with tem-perature and velocity irregularities.

Therefore, the flame-color irregularities in a boundary layer of reactive flow past an ob-stacle correspond to streamwise vortices with opposite directions of rotation. The irregularities in temperature distributions are in the same places as the transversal velocity irregularities. The longwise velocity U(z) is almost constant for the considered scale of flow (at y = const). The data shown in Fig. 3 demonstrate that every vortex has own distribution of velocity, temperature, and angular momentum. Obviously, these features might influence the whole flow characteristics (stability, heat and mass transfer).

It has been mentioned above that the backward-facing step stabilized flame has a front edge “attached” to the obstacle until the flame blow-off takes place. This does not happen for situations of flame stabilization with a rib: a no-flame zone exists between the obstacle and the flame. The flame edge makes up a flame roll: this roll is distanced from the rib by 5−15 mm. This feature (peculiarity of flow past an obstacle) is critical for the boundary layer structure and combustion stability.

As the streamline velocity becomes higher, the flame zone past a rib or past a backward-facing step at the downstream distance ~ (25−30)⋅h becomes thinner and thinner: disruptions in flame occur. The level of air velocity when the flame disruptions occur was subjectively (with accuracy ~ 1−2 m/s) associated with the flame blow-off velocity Ub. If U0 > Ub, the flame breaks up and “reversing of combustion zone” takes place; the flame stays behind the obstacle where it was absent for U0 < Ub, and it disappears in the places of existence before blow-off. The flame blow-off velocity is a function of obstacle height and upstream turbulence. Figure 4 presents the data on flame past a rib [30] and past a backward-facing step; one can see the differ-ences between these two approaches for flame stabilization. If the intensity of external turbu-lence does not exceed 20−25 %, then the combustion stability behind a rib (1) is higher than behind a backward-facing step. For these two types of stabilization geometries, the dependency of the flame blow-off velocity on the turbulence level exhibits different laws: this dependency is weaker for a backward-facing step (2) than for situation of combustion behind a rib.

The temperature of gas flow determines the rate of chemical reaction. Possibly that pecu-liarities in the thermal boundary layer structure can impact the limiting flow velocity when

Fig. 3. Variation of gas parameters at the exit cross section of a converging channel. The top picture depicts the transversal velocity profile above the porous plates at у = 8 mm (the zero value of velocity V was assigned arbitrary; the circles show the areas with intrinsic rotation); the bottom diagram shows the isotherms in plane y-z.

Thermophysics and Aeromechanics, 2013, Vol. 20, No. 6

701

the flame blow-off occurs. Figure 5 demon-strates the gas temperature profiles at the distance from the obstacle equal to х = = 160 mm (for combustion below the upper wall (3) and on the bottom of channel). The main flow velocity was U0 = 10 m/s, Tu0 = 1 %. For this cross section, the ther-mal boundary layer thickness and tempera-ture level behind the rib “on the floor” is higher than for other variants. In the outer part of the boundary layer, this increment is as high as 300−400 K. The experience with com-bustion “on the ceiling” indicates that the change in direction of volumetric forces makes the wall temperature gradients much higher. Which of the observed flow features will influence the transfer processes and the laminar-turbulent transition?

Figure 6 shows the relative fluxes of substance W W 0 0/J j Uρ= obtained in tests with

ethanol combustion on horizontal wall past the 3-mm rib. Symbols 1 and 2 are for com-bustion “on the ceiling”, symbols 3 and 4 are for experiments for a boundary layer with combustion “on the floor”. The solid lines depict the known laws for a boundary layer.

Curves 1 and 2: WJ = ψ⋅0.332⋅Re−0.5Sc−0.6⋅CW. Here the Schmidt number is Sc = 1.3. The multi-

plier ψ = 1 is used for a “standard” laminar flow. The coefficient ψ = 2 was applied in papers [7, 17] for description of transient flows with bent streamlines, with intrinsic rotation, when the mass forces take place. Line 3 corresponds to the turbulent mass transfer law

WJ = 0.029⋅Re−0.2Sc−0.6⋅CW. Line 4 shows the relative flux law as generalization [5] for reat-

tachment zone behind an obstacle 0.335W W0.104 Re .−=J C One can see that for combustion

“on the ceiling” and for low air velocity (U0 = 2.5 m/s) the mass transfer is close to a “standard” laminar process: mass forces and mixed convection are negligible. As the air velocity becomes higher (U0 = 14.2 m/s), we observe a transition to a general law (curve 2), which is typical of flows with intrinsic rotation.

While ethanol combustion “on the floor”, the hot gas may go up due to buoyancy; the wall mass fluxes become higher. The relative fluxes behind an obstacle at velocity U0 =

= 4.03 m/s are close to line 2, but at bigger distances from the obstacle these fluxes grow to the level typical of separation flows (symbols 3 and line 4). With a higher air flow velocity, the impact of buoyancy forces on mass transfer becomes lower, but the contribution of inertia forces and mass forces gets stronger. The mass transfer

Fig. 4. Flame blow-off velocity past an obstacle with the height of 3 mm.

1 ⎯ rib, 2 ⎯ backward-facing step.

Fig. 5. Temperature profiles in a boundary layer past obstacle with height of 3 mm on the horizontal walls of channel. Combustion “on the floor”: behind the rib (1), behind a backward-facing step (2); ethanol combustion “on the ceiling”: behind the rib (3).

B.F. Boyarshinov

702

for combustion “on the floor” (symbols 4)

and “on the ceiling” (symbols 2) at Re > 105 follow the same law. All experimental data approach line 2, but at high Reynolds numbers, the experimental data do not reach

line 3, which is plotted for the case of turbulent mass transfer. It follows from publication [17] that for a boundary layer with ethanol combustion, the mass transfer does not follow turbulent law even at Re ~2⋅106.

Conclusions

Experiments with ethanol evaporation and combustion on horizontal surfaces provided us data about most general properties of a boundary layer with chemical and phase transforma-tions. Among these effects, we observe development of large-scale structures and manifesta-tion of volumetric forces, which have influence on flow stability and on heat and mass transfer. Many flow features have been nominated in this research only, and they need further study.

It was demonstrated that the flow velocity range when combustion exists in boundary layer is wider for a flow past a rib rather then a backward-facing step. The nature of mass transfer in the reactive flow past an obstacle becomes transient and remains transient until the flame blow-off occurs. For the first time, the effect of buoyancy forces on mass transfer in a boundary layer with evaporation and combustion was demonstrated (for the case of horizontal

surfaces). The essence of this effect is that for Reynolds numbers Re < 5⋅104, the rate of mass transfer for the case of fuel combustion above the wall is twice higher than for the case of combustion below the wall. But for flow with Re >105, the mass transfer has the same law both for combustion “on the floor” and “on the ceiling”: this is the transient flow mass transfer. For a flow with combustion below a wall the near-surface temperature gradient is higher.

Possibly, manifestation of law for a transient mass transfer takes place due to existence of gas-dynamic structures with typical sizes comparable with gas flow dimensions. Existence of these structures prevents randomization of a reactive gas flow. A possible reason of their development is intrinsic rotation of gas flow induced by bending of streamlines near the obstruc-tions. The streamwise large-scale structures are the twin vortices with opposite rotation: every of two vortices have their own distribution for velocity, temperature, and angular momentum.

The studied features of a reactive flow suggest that using of a transient flow mode for transfer control gives a wider range of controllable parameters of the boundary layer.

The author is grateful to his colleagues S.Yu. Fedorov and V.I. Titkov for their help in experiments and thanks academician E.P. Volchkov for problem statement and his valuable comments.

Fig. 6. Relative fluxes of ethanol in a boundary layer past a rib with height of 3 mm on the horizontal walls of channel at different air velocities. Combustion “on the ceiling”: 2.5 (1), 14.2 (2) m/s, combustion “on the floor”: 4.03 (3), 7.6 (4) m/s; 1 ⎯ laminar-boundary layer, 2 ⎯ boundary layer with large-scale structures [7], 3 ⎯ mass transfer in a turbulent flow, 4 ⎯ mass transfer in reattachment zone [5].

Thermophysics and Aeromechanics, 2013, Vol. 20, No. 6

703

References

1. E.W. Adams and J.P. Johnston, Flow structure in the near-wall zone of a turbulent separated flow, AIAA J., 1988, Vol. 26, No. 8, P. 932–939.

2. J.K. Eaton and J.P. Johnston, A review of research on subsonic turbulent flow reattachment, AIAA J., 1981, Vol. 19, P. 1093–1100.

3. V.I. Terekhov, N.I. Yarygina, and R.F. Zhdanov, Some features of a turbulent separated flow and heat transfer behind a step and a rib, Part 1. Flow structure, J. Appl. Mech. Tech. Phys., 2002, Vol. 42, No. 6, P. 888–894.

4. I.P. Castro and A. Haque, The structure of shear layer bounding a separation region. Part 2. Effects of free-stream turbulence, J. Fluid Mech., 1988, Vol. 192, P. 577−595.

5. T. Ota and H. Nishiyama, A correlation of maximum turbulent heat transfer coefficient in reattachment flow region, Int. J. Heat Mass Transfer, 1987, Vol. 30, No. 6, P. 1193−1199.

6. A.P. Brylyakov, G.M. Zharkovs, B.Yu. Zanin, V.N. Kovrizhina, and D.S. Sboev, Flow separation on a straight airfoil at increased external turbulence, Uchen. Zap. TSAG, 2004, Vol. 35, No. 1−2, P. 57−62.

7. B.F. Boyarhsinov, Analysis of experimental data on heat and mass transfer in a boundary layer, Combustion, Ex-plosion and Shock Waves, 1998, Vol. 34, No. 2, P. 183–190.

8. E.Y. Epik, L.E. Yushina, and T.T. Suprun, Heat transfer in the relaxation zone past local looped separations of different type, Proc. Second Russian National Conference of Heat Transfer, Moscow, Oct. 26–30, RNKT-2: “Forced Convection of Single-phase Fluid”, Moscow, MAI, 1998, Vol. 2, P. 282−285.

9. V.I. Zapryagaev, N.P. Kiselev, and A.A. Pavlov, Effect of streamline curvature on intensity of streamwise vor-tices in the mixing layer of supersonic jets, J. Appl. Mech. Tech. Phys., 2004, Vol. 45, No. 3, P. 335−343.

10. G.V. Kozlov, G.R. Grek, A.M. Sorokin, and Yu.A. Litvinenko, Influence of initial conditions at the nozzle exit on the structure of round jet, Thermophysics and Aeromechanics, 2008, Vol. 15, No. 1, P. 55−68.

11. L.P. Bernal and A. Roshko, Streamwise vortex structures in plane mixing layers, J. Fluid Mech., 1986, Vol. 170, P. 499−525.

12. D.W. Moore and P.G. Saffman, The density of organized vortices in a turbulent mixing layer, J. Fluid Mech., 1975, Vol. 64, P. 465−473.

13. B.F. Boyarhsinov, S.Yu. Federov, and A.A. Volkov, Measurement of correlation characteristics of immersed jet from Raman scattering, Instruments and Experimental Techniques, 1994, No 5, P. 110−116.

14. E. Shulein and V.M. Trofimov, Steady longitudinal vortices in supersonic turbulent separated flows, J. Fluid Mech., 2011, Vol. 672, P. 451−476.

15. G.P. Grek, V.V. Kozlov, and V.G. Chernoray, Hydrodynamic instability of boundary layers and separated flow, Uspekhi Mekhaniki, 2005, Vol. 3, No. 4, P. 3−40.

16. D. Liepmann and M. Gharib, The role of streamwise vorticity in the near-field entrainment of round jets, J. Fluid Mech., 1992, Vol. 245, P. 643−668.

17. B.F. Boyarhsinov, A Boundary Layer with Large-Scale Structures, Evaporation and Combustion, Technical Sc. Doct. Thesis, presented 11.04.07: affirmed 09.11.2007, Novosibirsk, 2007.

18. L. Prandtl, Gesammelte Abhandlungen, Springer-Verlag, Berlin etc., 1961, Vol. 2, P. 798−811.

19. N.A. Dvornikov and V.I. Terekhov, About momentum and heat transfer in a turbulent boundary layer on a curved surface, J. Appl. Mech. Tech. Phys., 1984, No.3, P. 53−61.

20. Y. Mori, Buoyancy effects in forced laminar convection flow over a horizontal flat plate, ASME, Transactions, Series C, Journal of Heat Transfer, 1961, Vol. 83, No. 4, P. 419–482.

21. Wan, Experimental study of heat transfer for mixed convection from a horizontal flat plate toward air, ASME, Transactions, Series C, J. Heat Transfer, 1982, Vol. 104, No. 1, P. 150−155.

22. B.S. Petukov and A.F. Polyakov, Heat Transfer for Mixed Turbulent Convection, Nauka, Moscow, 1986.

23. T.S. Chen, A. Mucoglu, and E.M. Sparrow, Mixed convection in boundary layer flow on a horizontal plate, ASME, Transactions, Series C, J. Heat Transfer, 1977, Vol. 99, P. 66–71.

24. A.L. Yarin, Detachment of the flame of a burning liquid by air flow, Combustion, Explosion, and Shock Waves, 1983, Vol. 19, Iss. 1, P. 1−8.

25. B.N. Raghunandan and G.P. Yogesh, Recirculating flow over a burning surface – flame structure and heat trans-fer augmentation, Twenty-Second Symposium (Intern.) on Combustion, The Combustion Institute, 1988, P. 1501−1507.

26. I. Esquiva-Dano, H.T. Nguyen, and D. Esqudie, Influence of a bluff-body’s shape on the stabilization regime of non-premixed flames, Combustion and Flame, 2001, Vol. 127, P. 2167−2180.

27. C.M. Coats and A.P. Richardson, Nonpremixed combustion in turbulent mixing layers, Part 1, Flame сharacter-istics, Combustion and Flame, 2000, Vol. 122, P. 253−270.

28. N.A. Rohmat, H. Katoh, T. Obara, T. Yoshibashi, and S. Ohyagi, Diffusion flame stabilized on porous plate in a parallel airstream, AIAA J., 1998, Vol. 36, No. 11, P. 1945−1952.

B.F. Boyarshinov

704

29. V.M. Maltzev, M.I. Maltzev, and L.Ya. Kashparov, Primary Characteristics of Combustion, Khimia, Moscow, 1977.

30. B.F. Boyarshinov, Some characteristics of heat and mass transfer in a turbulent air flow over a surface, J. Appl. Mech. Tech. Phys., 2000, Vol. 41, No. 4, P. 686−691.

31. B.F. Boyarshinov, V.I. Titkov, and S.Yu. Fedorov, Momentum transfer in the boundary layer when there is acceleration and combustion of ethanol as it evaporates behind a barrier, Combustion and Flame, 2010, Vol. 157, P. 1496−1509.

32. C.E. Wooldridge and R.J. Muzzy, Measurements in a turbulent boundary layer with porous wall injection and combustion, in: Int. Tenth Symp. on Combustion, The Combustion Institute, 1965, P. 1351−1362.

33. Database on characteristics of turbulent boundary layer with chemical and phase transitions, Open access at ad-dress: http://www.itp.nsc.ru/Laboratory/LAB_2_1/Flame/First%20page.html.

34. B.F. Boyarshinov, E.P. Volchkov, and V.I. Terekhov Heat and mass transfer in a boundary layer with the eva-poration and combustion of ethanol, Combustion, Explosion and Shock Waves, 1994, Vol. 30, No. 1, P. 7−14.

35. Yu.N. Dubnischev and B.S. Rinkevichus, Methods of Laser Doppler Anemometry, Nauka, Moscow, 1982.