ART 2009 ABS+PA INNOVATION FOR AUTOMOTIVE INTERIORS

Transcript of ART 2009 ABS+PA INNOVATION FOR AUTOMOTIVE INTERIORS

8/12/2019 ART 2009 ABS+PA INNOVATION FOR AUTOMOTIVE INTERIORS

http://slidepdf.com/reader/full/art-2009-abspa-innovation-for-automotive-interiors 1/5

ABS+PA INNOVATION FOR AUTOMOTIVE INTERIORS

Robert Hooker and Vineet Kapila,, BASF Corporation, Wyandotte, MI

Dr. Marko Blinzler, BASF SE, Ludwigshafen, Germany

Abstract

The need for automotive interior molded-in-color

(MIC) low gloss, rigid plastic components with good

scratch and mar resistance is well known. Typical

interior product gloss targets of automotive Original

Equipment Manufacturers (OEMs) now range from 1.5 -

2.5 units for sixty degree Gardner gloss. Interior scratch

objectives require a scratch width of less then four tenths

of a millimeter with slight whitening when a 15 Newton

load is applied via a one millimeter hemispherical tip.

Strength and rigidity requirements now range from

1.0mm to 3.0mm max deflection on high touch interiorareas when subjected to an arm or finger loading.

Recent advancements in the field of Acrylonitrile-

Butadiene-Styrene + Polyamide (ABS+PA) blends by

BASF Corporation have allowed for such a copolymer

that with the proper design and tooling considerations

allows one to meet these specifications.

Introduction

Mold-in-color (MIC) is now the primary direction for

interior automotive applications when considering doors

panels, consoles systems, instrument panels, and other

interior trim areas. Paint, film, and skin are now onlyprimarily considered in areas that are highly visible and

contactable by customers on mid-grade to luxury models

for styling, quality, and tactile perception. While the trend

in the industry is to continue to use products such as

polypropylene or thermoplastic polyolefins (TPO) to fit

this need for low gloss MIC, compromises in quality

relating to fit and finish, impact resistance, rigidity, and

scratch resistance are being made. As a result, automotive

OEMs continue to look for innovative materials that are

not only MIC with low gloss, but that can also improve

part quality by providing a rigid and durable appearance

surface. Recently, BASF Corporation has developed such

a product line. This paper will detail tooling and designconsiderations when using different grades of ABS+PA to

meet OEM interior automotive component specifications

for gloss, scratch, and strength and rigidity.

Main Section

Three grades of ABS+PA in standard black were used

in two different injection molding plaque tools for gloss

measurements, scratch ratings, and rib/wall ratio

performance. The grades included a standard unfilled and

UV stabilized grade (ABS+PA Standard), an easy flow

unfilled and UV stabilized grade (ABS+PA Easy Flow),

and an 8% glass filled and UV stabilized grade (ABS+PA

8%GF). Basic physical, mechanical, impact, and thermal

properties generated from International Organization of

Standardization (ISO) methods for the three grades of

ABS+PA used in this study are shown below in Table 1.

Table 1: Material properties for ABS+PA Standard,

ABS+PA Easy Flow, and ABS+PA 8%GF (ISO Test

Methods).

Units

ABS+PA

Standard

ABS+PA

Easy Flow

ABS+PA

8%GF

Physical Units

Mold Shrink, Linear Flow % 0.5-0.7 0.5-0.8 0.3-0.6Specific Gravity - 1.07 1.07 1.12

Mechanical Units

Tensile Modulus, 23 C MPa 2000 2100 3200

Tensile Strength, 23 C MPa 43 46 55

Flexural Modulus, 23 C MPa 1800 2000 2800

Flexural Strength, 23 C MPa 62 66 80

Impact Units

Notched IZOD @ 23C KJ/m2 65 65 10

Notched IZOD @ -30C KJ/m2 14 11 5

Thermal Units

Vicat B/50 C 103 110 108

Gloss Measurements

The molded plaques for gloss measurements and

scratch rating were 200mm x 150mm x 2.5mm and

contained grains of the following types: stipple,

geometric, and leather as illustrated in Figure 1. These

grains were selected as variations of them are widely used

in the automotive industry on MIC plastic components.

Figure 1: Grain types: stipple, geometric, and leather (left

to right).

Gardner 60o gloss measurements were taken on these

three distinct grains. Table 2 shows the average gloss

measurements for three plaques of each grain/grade

combination molded on an injection molding plaque tools

ANTEC 2009 / 1027

8/12/2019 ART 2009 ABS+PA INNOVATION FOR AUTOMOTIVE INTERIORS

http://slidepdf.com/reader/full/art-2009-abspa-innovation-for-automotive-interiors 2/5

surface finished with a high loading of glass beading.

Additionally, Table 3 shows the average of the same

grain/grade combinations with the addition of an advanced

graining technique called SGE designed by Tenibac-

Graphion, Inc. to further reduce the gloss level.

Table 2: Gardner 60

o

gloss by grade and grain for threeABS+PA grades.Grade

Stipple Geometric Leather

ABS+PA Standard 1.9 1.2 1.8

ABS+PA Easy Flow 1.7 1.1 1.6

ABS+PA 8%GF 1.9 1.4 2.1

Grain Type

Table 3: Gardner 60o gloss by grade and grain (w/SGE)

for three ABS+PA grades.Grade

Stipple Geometric Leather

ABS+PA Standard 1.7 1.1 1.6

ABS+PA Easy Flow 1.5 1.0 1.5

ABS+PA 8%GF 1.6 1.2 1.8

Grain Type

Table 2 and Table 3 illustrate that all three grades of

ABS+PA met or exceeded the 1.5 - 2.5 unit sixty degree

Gardner gloss range targeted by OEMs in the standard

grain as well as when the advanced SGE graining

technique was applied.

In addition to the three grades of ABS+PA, a standard

black mineral-filled thermoplastic elastomeric olefin

(TEO+MF) and two standard black TPOs commonly used

for interior and exterior MIC applications were also

molded in the same tooling for gloss comparison purposes

as shown in Table 4.

Table 4: Gardner 60o

gloss by grade and grain for olefin

based materials TEO+MF and TPO.Grade

Stipple Geometric Leather

TEO+MF 2.9 2.0 3.1

TPO-1 3.0 2.0 3.3

TPO-2 2.8 2.0 2.9

Grain Type

Notice in Table 4 that the olefin based materials did

not achieve the gloss target of 1.5 – 2.5 units when run in

the plaque tooling finished with a high glass bead content

blast media. In order for olefin based materials to achievethe 1.5 – 2.5 unit range, a high content of Aluminum

Oxide in the finishing media is required to create

additional microscopic peaks and valleys in the tool steel

to help disperse reflected light. High content Aluminum

Oxide blast media is not required to reduce the gloss of

ABS+PA as ABS+PA grades reproduce the tool surface

very well. In fact when an ABS+PA grade is run in a tool

finished with Aluminum Oxide, the achieved 60 degree

Gardner gloss is typically below 1.0 units. Although from

an aesthetic standpoint this may be desired, surface

performance with respect to mar is compromised as the

microscopic peaks and valleys are easily deformed

through surface contact.

Scratch Performance

Scratch testing was completed using a Taber 710 5-Finger scratch tester to apply a 15N load via a 1mm

hemispherical tip onto the same three distinct grains

without SGE shown in Figure 1 in all three grades of

ABS+PA. The same TEO+MF and two TPOs on which

gloss measurements were taken were also tested for

comparison purposes. Post testing, scratch widths were

measured with a scaled microscope and a rating was made

based on the 5 point scale shown in Table 5.

Table 5: Point scale for scratch performance rating.Rating Scratch Width Whitening

1 (best)

Less than 0.2mm wide,

almost invisible None

2

0.2 - 0.3 mm wide,

visible at close range None

3

0.3 - 0.4 mm wide,

clearly visible Slight Whitening in places

4 0.4 - 0.5 mm wide

Whitening over the entire

scratch

5 (worst)

Greater than 0.5 mm

wide

Whitening over the entire

scratch with debris

Table 6 below shows the measured scratch widths and

subsequent ratings for the three tested grades of ABS+PA

including ABS+PA Standard, ABS+PA Easy Flow, and

ABS+PA 8%GF. Similarly Table 7 shows the measured

scratch width and subsequent ratings for the TEO+MF and

TPOs tested.

Table 6: Scratch width and ratings for ABS+PA.Grade

Stipple Geometric Leather

ABS+PA Standard

Scratch Width (mm) 0.35 0.35 0.40ABS+PA Standard

Scratch Rating 3 3 3

ABS+PA Easy Flow

Scratch Width (mm) 0.35 0.30 0.40ABS+PA Easy Flow

Scratch Rating 3 2 3

ABS+PA 8%GFScratch Width (mm) 0.30 0.30 0.30

ABS+PA 8%GF

Scratch Rating 2 2 2

Grain Type

1028 / ANTEC 2009

8/12/2019 ART 2009 ABS+PA INNOVATION FOR AUTOMOTIVE INTERIORS

http://slidepdf.com/reader/full/art-2009-abspa-innovation-for-automotive-interiors 3/5

8/12/2019 ART 2009 ABS+PA INNOVATION FOR AUTOMOTIVE INTERIORS

http://slidepdf.com/reader/full/art-2009-abspa-innovation-for-automotive-interiors 4/5

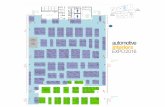

Figure 3: Illustration of rib/wall ratio plaque used for sink

depth study.

ABS+PA Sink Depth verses Rib/Wall Ratio

0.000

0.005

0.010

0.015

0.020

0.025

0.030

ABS+PA

Standard

ABS+PA Easy

Flow

ABS+PA 8%GF

S i n k D e p t h ( m m )

Sink Depth 40% Rib (mm)

Sink Depth 60% Rib (mm)

Sink Depth 80% Rib (mm)

Sink Depth 100% Rib (mm)

Figure 4: ABS+PA sink depth verse rib/wall ratio

The bar chart in Figure 4 shows that ABS+PA

Standard and ABS+PA Easy Flow did not have a

measureable sink on the grained surface over the rib

pattern while ABS+PA 8%GF had a measureable sink

over both the 80% and 100% ribs.

PC/ABS and PP+20%TF Sink Depth ve rse s Rib/Wall Ratio

0.000

0.010

0.020

0.030

0.040

0.050

0.060

PC/ABS PP+20%TF

S i n k D e p t h ( m m

)

Sink Depth 40% Rib (mm)

Sink Depth 60% Rib (mm)

Sink Depth 80% Rib (mm)

Sink Depth 100% Rib (mm)

Figure 5: PC/ABS and PP+20%TF sink depth verse

rib/wall ratio.

The bar chart in Figure 5 shows that PC/ABS had a

measureable sink on the grained surface over the ribs

designed at both 80% and 100% of the wall thickness and

that PP+20%TF had a measureable sink over the 60%,

80% and 100% structural ribs.

Table 8. Injection molding conditions for PA+ABS

rib/wall ratio plaque samples.

Product

ABS+PA

Standard

ABS+PA

Easy Flow

ABS+PA

8%GF

emp Rear Zone,o F 480 480 480

emp Middle Zone,o F 490 490 490

Temp Front Zone,

o

F 490 490 490Temp Nozzle,

o F 490 490 490

ctual Melt

Screw % , 80 rpm 80 rpm 80 rpm

Recovery time, sec 8.07 8.06 7.88

Shot size, in 2.6 2.6 2.6

ushion, in 0.22 0.16 0.19

Position- actual, in 0.4 0.4 0.4

Pressure - actual, psi 783 770 749

ime set \ Fill Time 2.64 2.64 2.64

Hold pressure, psi 600 600 600

Hold time, sec 15 15 15

ure time, sec 20 20 20

elocity ( %ss ) 1 .85 in/sec .85 in/sec .85 in/sec

elocity ( %ss ) 2 .85 in/sec .85 in/sec .85 in/secelocity ( %ss ) 3 .85 in/sec .85 in/sec .85 in/sec

elocity ( %ss ) 4 .85 in/sec .85 in/sec .85 in/sec

Mold temperture A plate 140 140 160

Mold temperture B plate 140 140 160

MACHINE: TK 110 ton TK 110 ton TK 110 ton

1030 / ANTEC 2009

8/12/2019 ART 2009 ABS+PA INNOVATION FOR AUTOMOTIVE INTERIORS

http://slidepdf.com/reader/full/art-2009-abspa-innovation-for-automotive-interiors 5/5

Table 9. Injection molding conditions for PC/ABS and

PP+20%TF rib/wall ratio plaque samples

Product PP+20%TF PC/ABS

Temp Rear Zone,o F 410 500

Temp Middle Zone,

o

F 420 510Temp Front Zone, o F 420 510

Temp Nozzle, o F 420 510

Actual Melt

Screw % , 80 rpm 80 rpm

Recovery time, sec 8.06 6.39

Shot size, in 2.5 2.5

Cushion, in 0.16 0.29

Position- actual, in 0.55 0.4

Pressure - actual, psi 443 816

Time set \ Fill Time 1.68 3.46

Hold pressure, psi 600 600

Hold time, sec 15 15

Cure time, sec 20 20

Velocity ( %ss ) 1 1.25 in/sec .65 in/secVelocity ( %ss ) 2 1.25 in/sec .65 in/sec

Velocity ( %ss ) 3 1.25 in/sec .65 in/sec

Velocity ( %ss ) 4 1.25 in/sec .65 in/sec

Mold temperture A plate 100 140

Mold temperture B plate 100 140

MACHINE: TK 110 ton TK 110 ton

Conclusions

ABS+PA is a copolymer that can be used by

injection molders to create a molded-in-color, low gloss,

scratch resistant, interior plastic component with good

strength and rigidity. All three grades of ABS+PAevaluated for gloss met or exceeded the 1.5-2.5 unit

target for 60 degree Gardner gloss. Additionally, all

three grades of ABS+PA evaluated for scratch

performance met or exceeded the automotive industry

standards of a scratch width of less then 0.4mm and

slight whitening when subjected to a 15N load over a

1mm tip. Finally, ABS+PA allow for higher rib to wall

ratios then industry standard olefin based materials and

comparable ratios for industry standard PC/ABS.

References

1. BASF Plastic Design Guide, Wyandotte, MI (2008).2. BASF Terblend N Product Literature, Ludwigshafen,

Germany (2007).

3. A.H. Sharma and J.H. Botkin, Additive approaches to

improving scratch and mar resistance in automotive

polyolefins, SPE Automotive TPO Global Conference

Geneva, Switzerland (2005).

ANTEC 2009 / 1031