April Connections Spread:Newsletter Layoutan average of over 175 orders. In addition, over 200...

Transcript of April Connections Spread:Newsletter Layoutan average of over 175 orders. In addition, over 200...

Robust 1.3 hp (970 W) Air Motor- Governor-controlled air motor delivers powerful, efficient performance.

Cast Aluminum Construction- Tool housing and handle are made of solid cast aluminum.

Insulated Throttle Handle- Reduces cold air transmission to operator’s hand.Fully adjustable to optimum position.

Rotational Exhaust System- Rotates 360˚ to direct exhaust away from operator.

“Wick Lube” System- Extends gear life with simple lubrication. (All models include Gear Oil & Gear Oil Gun.)

Vibration Dampening Side Handle- Reduces vibration transfer to operator and repositions for left or right hand use.

Convenient Spindle Lock- Allows quick, easy change of grinding wheel orabrasive disc. Reduces downtime!

Safety-Lock Throttle Lever- Prevents accidental start-up of tool.

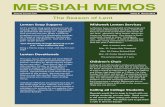

April 200“Linking Company News to Employees”

Introduced in North America

Inside:

Dynabrade Europe 2

Customer Service 3

New Backdrops 3

Tool Clinics 4

Engineering Update 5

CESVI Certified 5

Stationary Equipment 6

Meet Your Coworker 7

New Faces 8

Story Page

NEW 1.3 hpTOOL SERIES

By Gary Lojacono - Manager of Marketing Communications

March 2008 brought a highly anticipated announcement from Dynabrade:the introduction of our new Right Angle Tool Series, including 1.3 hp Depressed Center Wheel Grinders and Disc Sanders. These exciting new tools were formally presented to industrial distribution in the USA and Canada, along with Mexico and Central America. Introductions to other regions of the world will be forthcoming.

Representing a vital addition to the Dynabrade stable, our new Grinders and Sandersare small tools that deliver BIG power and performance. They offer countless material

removal solutions to industries such as metal/stainless steel fabrication, masonry, ironwork, composites and general welding. Most importantly they are designed to the Dynabrade standard of excellence, with ergonomic features and a variety of selling points:

During the beautiful week spent in Valencia, Spain forour semi-annual meeting, I had the opportunity to discuss the topic of quality with many people and on numerous occasions. Some of them asked me questions aboutspecific products, while others talked about the quality of ournew consumables. In other cases, the subject of quality arosewhile talking about warranties but the topic was always a

dominant theme in our discussions, as well as in the official, theoretical and practical presentations forming the core content of the meeting.

The View From Europe

2

By Jonathan Kissov - Managing Director, Dynabrade Europe

Quality is Theme ofValencia Meetings

Site of the semi-annual European meetings in Valencia, Spain.

There is no doubt that thequality of our production isamong the best in the world inpneumatic tools and, althoughwe are enjoying an extremelypositive period where nothingappears to disturb our techni-cal leadership, we are quite sensitive towards this very particular subject.

Our keen attention to an apparently non-urgent aspectled me to reflect on how, overrecent years, there have been

enormous socio-economicchanges that have highlightedthe importance of quality as a useful tool for businesses to constantly improve their position in the market.

This has paved the way tothe conviction that it is eco-nomically logical for a businessto have a control activity thatembraces not only the prod-ucts, but also all processes. This is the only way to reducecosts and ensure the resulting

satisfaction of the end users.Thus we arrive at the concept

of total quality, meaning a con-stant striving for higher levelsof quality throughout the entire structure of the business,with regard to all activities and not just technical and production activities.

From this new perspective,quality is no longer regarded asa technical matter to be left tothe specialists. The entire business must focus on these

objectives, and every one of usis called upon to make his orher contribution to quality.

The decisions made by eachof us with regard to quality areof strategic importance.

All of this is so revolutionarythat even in linguistic terms,the mere word “quality” nolonger seems adequate. Weshould probably combine it with “system” or “policy”, oreven the magical prefix “Dyna.”

Ubaldo Zocchi (left), Regional Sales Manager of Italy, presents new abrasive products during a practical session at the meetings.

As businessgrows and num-bers increase,the challenge oftaking good careof customersalso increases.

The reality is, it also increasesthe potential risk of errors,product failures and the like.During a typical day USACustomer Service handlesabout 300 calls, and processesan average of over 175 orders.In addition, over 200 invoicesand credit memos areprocessed daily. Our shipping

department sends out between250 to 300 packages per day,including product shipments,sales literature and shipmentsto our Territory Managersthroughout the country.

Each contact provides another opportunity to shine,by providing exceptional service in the form of qualityproducts, prompt, error-freeshipments and smooth transactions. Fortunately forDynabrade, we continue toshine despite the ever-growingdemand for our products.

When mistakes happen, and

they inevitably do, we endeavour to address the problem and give a swift reso-lution. Customers appreciatean honest response or sincereapology, and are often surpris-ingly willing to overlook the occasional mix-up when handled properly.

In addition to what happenson the front lines, often overlooked are the multitudesof personnel in departmentslike Credit, Purchasing, Parts,Engineering and Production,all of which contribute to the overall picture. These

often-unsung heroes provide a key role in Dynabrade’sgrowth and success.

Given the lofty sales goalsthat have been set, we’ll need everyone’s continued cooperation as we start the second half of fiscal 2008!

A Word From Customer Service

3

By Casey Maziarz - USA Customer Service Manager

Dynabrade Exhibits at K/BIS

USA Customer Service by the Numbers

The Dynabrade team is hard atwork during the K/BIS(Kitchen/Bath Industry Show),held in Chicago from April 11-13, 2008. This industrytrade show proved to be a great opportunity for demonstratingtools, talking applications and gathering sales inquiries.Pictured from left to right are Chris Lanam (behind cus-tomer), John Smith, MikeTingue and Andy Mandell.

On a Typical Day, USA Customer Service

Handles 300 Calls and Processes Over 175 Orders!

Tool Clinics Around the World

4

Guangzhou, ChinaMarch 5-7, 2008Tony Schiavitti (left) observesan attendee running the Dynafile® III. Directly be-hind the operator is ChrisChang, and Steven Pan is atfar right.

Santo Andre, Brasil February 18-22, 2008Bob Cartwright (upper left)demonstrates woodworkingapplications to a large group.This clinic was visited by278 attendees from over 60 distributors, possibly thelargest training event inDynabrade’s history!

Brasil Tool Clinic

China Tool Clinic

There are manytypes of rapidprototyping sys-tems, such asstereo lithogra-phy machines,starch printers,

selective laser sinteringand 3D printers. But upuntil a few years ago, thesemachines were expensive and payback was on the distant horizon.

In time, the prices graduallycame down and accuracy improved. So two years ago,

a 3D printer was added to Dynabrade’s EngineeringDepartment. Our goals wereto cut down on prototypetime, reduce costs and increaseaccuracy. The machine Ichose was the Dimensions™SST by Stratasys, Inc. Itworks hand-in-hand with ourSolidWorks CAD software.

Our engineers can now design parts during the day, transfer the solid geometry to the 3D

printer software, and have themachine make the partovernight. It can create partsin an 8" x 8" x 12" envelope.The parts are made of 0.010"layers of ABS plastic at 500° F.

We are now able to producecomplicated geometry over-night, creating molds thatonce took several weeks andcost thousands of dollars – allfor under $100!

This has been a valuableprototyping tool in the de-

velopment of our Vac-uum Shroud program.It has also been helpful in designing motor housings, interconnecthousings, seals and

muffler assemblies,just to name a few.

With the need for new product on the rise now morethan ever, and the interactionwith our international groupsbringing us new ideas, Engineering is poised to meetthe challenge!

5

By Mark Lampka - Engineering Manager

Update From Engineering

Engineering’s 3D PrinterBrings Rapid Results

The president of CESVI (left) presents a plaque to Cesar Cabello ofMexico, recognizing Dynabrade as a “new supplier” to CESVI-authorized automotive body shops. CESVI is a certifying agency that is highly regarded throughout Latin America. CESVI certification assures that a body shop uses only high-quality products, such asDynabrade tools. At right is Alejandro Salinas.

Dynabrade NowCESVI Certified

3D printer produces the final product.

MarkLampka sets the controls.

Dimensions™ SST 3D Printer

Since the last issue of Connections, Stationary Equipment has introduced two products: the

36" Metal Finishing Station and the new SuperFinisher. These two products should help us

improve our sales considerably in the coming year!

SuperFinisherThis unit promises to be a real winner.

Four of these units have been sold todate, and there is interest in many more– all before our formal distributor intro-duction! Priced to sell, these machinesoffer more features and versatility thanthe competition. Our machine can beconverted to accept abrasive widths of1", 2", 3" or 4", allowing more flexibilitythan competitive machines that run only one width. We also have the ability to assemble the machine as “right hand” or“left hand,” depending on whether thecustomer wants to mount the unit on the front or back of the lathe.

The SuperFinisher is capable of advancing the abrasive as slow as 1/16"per minute, allowing full use of the newdiamond super-abrasives available on the market today. The machine’s control knobs lock in place, eliminatingthe possibility of inadvertently changingthe settings by bumping the knob. In addition, this feature creates a positive

setting for the abrasive “recipe” to attaina repeatable finish every time.

We are developing several videos topromote the new SuperFinisher. Onewill target potential customers to informthem of the unit’s capabilities. A secondone will help the customer set up his machine, reviewing the features and settings that are available.

When promoting the machine, athree-step process will be followed. Thevideo will be presented to the customerto show him the SuperFinisher’s capabilities. If his work piece is smallenough, we will have it sent toDynabrade to prove our ability to meethis finishing needs. If the customer approves, the Stationary EquipmentSalesman will pursue a trial order.

The SuperFinisher was featured at the WESTEC show in Los Angeles (3/31 – 4/3/08), and will also be shownat the EASTEC show in Springfield (5/20 – 5/22/08).

36" Metal Finishing StationThis machine has been a real success

since its introduction. The capture of potentially explosive metal dust hasbecome an urgent safety issue at many shops. By capturing metal dustin water, the chance of combustion

is eliminated. We have sold ten of these units, with customers using them as a workstation for deburringmetal parts.

Interest is escalating as word gets out that we have an inexpensive andportable solution to a problem that usually costs many thousands of dollars to solve, requiring the installation of a central system with fire suppression capabilities.

We are also looking at a modificationto this machine that will increase the work surface to 36" x 27", allowingfor larger work pieces.

6

Product Development News

By Larry Van Duesen - Stationary Equipment Manager

New Stationary MachinesContinue Growth of Line

Model 64300

Model 64000

Meet Your Coworker

Team Dynabrade

Where were you born?I was born in Buffalo, NY.

What cities have you lived in?I have lived in the WesternNew York area all of my life.

Where did you go to college?I have a degree in Business Administration from a com-munity college, and have takensome additional business courses.

What jobs did you have before Dynabrade?I worked as a customer servicerep for a marketing company.Before that I was at a printingcompany in positions such asplant secretary, transportationcoordinator and financialplanning coordinator.

What year did you joinDynabrade?I started in June, 1994.

What is your current position at Dynabrade?Export Manager.

What is the most challengingpart of your job?Language barriers with dist-ributors around the world, andshipping orders completelyand on time.

What is the most rewardingpart of your job?Fulfilling requests promptly andefficiently. It is great to be partof a winning team, and con-tribute to the expansion ofDynabrade International.

How would you describeyour work ethic or philosophy?My work ethic is to put in anhonest day. If I can look in themirror and know I did that, Iam satisfied. My philosophy isthat all of Dynabrade personnel

are breaking bread at one table,and in that sense we are a family.

What do you like mostabout working forDynabrade?I enjoy the friendly and informal atmosphere here.

Tell us about your family.I am one of eight children, andI am the only girl! I have threechildren and four grandchildren.

What are your hobbies?I like traveling, reading, garden-ing and walking. I also belongto the Irish Heritage Society ofBuffalo. This group is active inpreserving customs and raisingfunds for the Belfast relief pro-gram, to bring Belfast childrento Buffalo each summer.

Where were you born?I was born and raised in Buffalo, NY. Our two-familyhome housed my parents, mygrandmother, my uncle, myselfand my dog. Another uncleand aunt lived upstairs.

Where have you lived before?I spent over 10 years in militaryservice, traveling to Texas,Florida, Massachusetts, SouthCarolina, Virginia, Hawaiiand Southeast Asia.

What jobs did you have before Dynabrade?I found a 20-year career in salesat Enos & Sanderson Co. andAbrasive Tool Corporation.

What year did you joinDynabrade?In March, 1996 I was hired as acustomer service representative.

What is your current position at Dynabrade?Repair Coordinator for theUnited States.

What is the most challengingpart of your job?Coordinating repair servicesfor our customers in a timelymanner. Bringing together allof the elements can be difficultat times.

What is the most rewardingpart of your job?The gratitude received whenmy customers have been wellserved.

How would you describeyour work ethic or philosophy?I pride myself on determina-tion and perseverance, and Iwon’t stop until I am satisfiedwith the services provided tomy customers.

What do you like mostabout working forDynabrade?Wally Welsch and family haveworked hard to make this asuccessful company, and I amproud to be part of it.

Tell us about your family.My wife Marcia and I havebeen married for 38 years.Our daughter Karen hasgiven us two beautiful grand-children and we are expectingour third in September!

What are your hobbies?I am involved in Pastoral CareMinistry at my church andwith Hospice. In my spare time,I also enjoy fishing.

ANITA McPHEE- Dynabrade International

RON SLAWINOWSKI- Dynabrade Inc.

7

New Faces at Dynabrade

DYNABRADE, INC. • DYNABRADE INTERNATIONAL8989 Sheridan Drive • Clarence, NY 14031-1490 • Phone: (716) 631-0100 • Fax: 716-631-2073 • Int’l Fax: 716-631-2524

DYNABRADE EUROPE S.à r.l.Zone Artisanale • L-5485 Wormeldange––Haut, Luxembourg • Phone: +352 768 494 1 • Fax: +352 768 495

DYNABRADE DO BRASILRua Oneda, 632 • Sao Bernardo do Camp • SP - CEP 09895-280 • Phone: 55-11-4390-0133 • Fax: 55-11-4399-1067

DYNABRADE INDIA ABRASIVE POWER TOOLS Pvt Ltd.EL-54, TTC Industrial Area, M.I.D.C. Mahape, Electronic Zone, Navi Mumbai - 400705, Maharashtra, IndiaPhone: +91 22 2763 2226 • Fax: +91 22 2763 2228

CHRIS CHANGRegional Manager-S.Korea, Japan

SYLVIE TASLERCustomer Service Assistant

PAWEL WIACEKApplication Engineer-Poland

JORGE RIVERAApplication Engineer-North Mexico

GRZEGORZ KUNICKIApplication Engineer-Poland

JOHN SMITHTerritory Manager-St. Louis

BLANCHE BECKIUSHuman Resources Assistant

FRANCESCO ROSAApplication Engineer-Italy

CAMILLE ALLIMANTSales & Marketing Assistant

LONNIE PENNEYTerritory Manager-Oregon

TOM ORSZAGHDesign Engineer

MEXICO

APAC

USA EUROPE

©DYNABRADE, INC., 2008