April 2012 eMagazine

-

Upload

industry-network -

Category

Documents

-

view

233 -

download

5

description

Transcript of April 2012 eMagazine

eMagazine April 2012

Know Your Plastics - Introduction to Plastics2 Locations -- July 2012

View details

PlastixANZ eMagazine April 2012 Page: 2

In this issueAmbassador Travel 17

Applied Machinery 2

Astor Base Metals 13

AutoDesk 9

Australasian Bioplastics Association

10

BASF 8

BFA Group 7

Copywriting that sells 4

Corporate Finance 12

HBM 10

Holden Australia 12

Husky 6

Isis C-Insure 9

Know Your Plastics 11

KogaRecyclingtech 5

Lanxess 6

P. D. Plastics 15

Plastics Industry Awards 18

PMG Engineering 16

PTTA 11

Steinert Australia 13, 14

Tasman Machinery 9, 14

PlastixANZ eMagazine April 2012 Issue

Published for the Australian & New Zealand plastics industry

by PlastixANZ 68 Parkhurst Dve.,

Knoxfield 3180 Victoria Australia

ph: 03 9018 7674 email: [email protected]

www.plastixanz.com.au

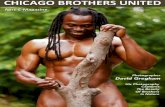

Front Cover

Subscribe to PlastixANZ eMagazineClick Here

Husky is the largest supplier of primary processing equipment to the plastic closure industry, offering the most experience and versatility in injection molding systems yielding lightweight, high quality parts. Our injection molding systems are designed to meet the challenging demands of our customers’ diverse closure applications. Our customers can count on us for the world’s most productive closure system. HyCAP, Husky’s closure system is one element of our complete beverage packaging solution. Our customers can look to us to be their single-source supplier optimizing design so all elements – neck finish, bottle and closure – work together as a complete package. And by enhancing our system with new plasticizing rates, improved controls for faster cycle times and better integration of auxiliary equipment – we help customers achieve tighter tolerances and higher yields.

PlastixANZ eMagazine April 2012 Page: 3

Why My Wife is Scared of Party-Plan By Scott Bywater A few years ago my wife was invited to a party-plan event which sold plastic containers & gadgets for organising your kitchen. Her love of organisation went crazy at this party and she ended up walking away with about $800 worth of the product. And it’s been put to good use ever since. So why am I telling you this? Well, recently she was invited to another party-plan party. And she told the lady who invited her that she couldn’t trust herself in that environment because of what happened last time. What’s my point? Simply that many of your customers may be the same. They worry about being in front of a salesperson because they might get carried away and influenced to buy more than they anticipated. That’s why I am a big believer that you should use education to build trust in the first instance. Think of it like this: There’s some guy who’s selling a financial planning service. He’s got a great service and could really help you retire more financially free. What’s going to be the best way for him to approach you?

1. Cold calling you on the phone and trying to get you into a meeting where he can SELL you in a few minutes when you don’t know him from Adam?

2. Cold calling you on the phone and trying to get you onto a webinar where he is going to give you a presentation about “7 Steps You Can Take to Retire Financially Free”

3. Sending you a letter for a special report or webinar you can attend on the “7 Steps You Can Take to Retire Financially Free”

4. Offering you a report or webinar which you request, then sending it to you. Then following you up with a regular ongoing newsletter until you say: “This guy knows what he’s talking about and he’s the guy for me”

I think most people will agree that option #4 is going to be the way you would like to be sold while option #1 would be the least ‘ideal’ way to sell you. Why? Because until you like and trust someone, you don’t want to be in a meeting where you might be persuaded to make a decision you might later regret. But when that trust is built up over time, then people are already 80% sold before the meeting. And isn’t that better for everyone: both seller and buyer? Scott Bywater Do you want to learn the easiest way to get more customers fast? Leading advertising copywriter, Scott Bywater, has just completed his brand new guide "7 Ways to Get More Customers" where he outline everything so it's as easy as 1, 2... 3. Download it for free by visiting http://www.copywritingthatsells.com.au!!

!

PlastixANZ eMagazine March 2012 Page: 4

LKR raises recycling efficiency with energy-saving shredder technology from Lindner reSource

The two new VEGA L 1100 and a Micromat 2000 single-shaft shredders from Lindner resource, installed at Lohner Kunststoffrecycling GmbH (LKR), need only half as much power as previously employed machines while achieving the same throughput.

With the installation of two new VEGA L 1100 and a Micromat Plus 2000 single-shaft shredders from Lindner reSource (www.lindner-resource.com), Lohner Kunststoffrecycling GmbH (LKR, www.recyclate.de) of Vechta/Germany has vastly improved its

engineering polymers. Jan-Hendrik Wilming, LKR’s managing director, comments: "By opting for the VEGA L 1100, we have been able to reduce the connected loads of our single-shaft

VEGA single-shaft shredders made by Lindner reSource deliver throughputs of between 300 and 1500

diameters (282 and 434 mm), three rotor lengths (540, 1,080 and 1,620 mm), and two blade types

shredding hard plastics at low rotational speeds. Due to the special blade arrangement on the rotor, only one blade is engaged at any given time. This

pellet output. Beyond this, the machine features easy access for screen changes and maintenance

KogaRecyclingtech is the Exclusive Australasian representative for Lindner ReSource (specifically plastics) and Lindner Recyclingtech (Resource recovery and alternative fuels)

Contact Geof Pile: 0419 558 600email: [email protected]

Know Your Plastics - Introduction to Plastics

2 Half Days -- 2 Locations

PlastixANZ eMagazine April 2012 Page: 5

Don’t Miss Husky at Chinaplas 2012

Husky is looking forward to Chinaplas 2012 where we will be showcasing our latest technologies for the

beverage packaging, closures, medical and hot runner markets, demonstrating solutions that provide

customers with the highest levels of quality, productivity and consistency.

Located at Booth #E2E01, we will have two systems running at our booth including our revolutionary

HyCAPTMHPP a fully integrated injection molding system for high-output beverage closure manufacturing

that maximizes efficiencies through the integration of machine mold technologies.

Also running at Husky’s booth will be our H-PET AETM(all-electric) preform manufacturing system. H-PET

AE is an efficient, affordable solution for the lower volume market offering unbeatable value with absolutely

no compromise in quality.

Husky will also be showing its latest hot runner and controller technologies. Chinaplas will mark the Asian

introduction of our innovative Ultra SideGate hot runner which allows for direct gating of demanding

applications that previously required a cold runner. Running at our Shanghai Technical Center will be a

medical workcell consisting of our H-MED AE all electric machine for clean room medical molding and

Ultra SideGate hot runner.

For a sneak preview of what Husky will be demonstrating at Chinaplas or if you are unable to attend the

show, please visit our enhanced events Showcase page.

We look forward to seeing you in Shanghai.

Detachable adhesive film simplifies logistics

Any company wanting to make its mark in the increasingly fragmented beverage market not only needs good products, it must also have good marketing ideas. UV-resistant, halogen-free Levamelt synthetic rubber from specialty chemicals company LANXESS that can be processed without any plasticizer provides a good opportunity for such an idea to be realized. Levamelt is used, for instance, for the production of detachable labels made of Jet-Folio Tacklite from Bremen-based company NOPAR International GmbH. Applied to beer crates, the innovative labels can help small, medium-sized and large breweries make their premium products even more attractive for their respective target group – and at the same time save logistic costs when returned to the deposit system.Stefan Schmitt, general manager of NOPAR International GmbH, explains: “Breweries are adapting to the changing demands of their customers by extending their product range with so-called trendy beers. The beverage suppliers are enriching their traditional alcoholic and non-alcoholic products by adding exotic fruit juices, for example, to give them an exciting taste. These beers are even popular among consumers who are otherwise not very keen on Pilsener and wheat beer.” On the other hand, the diversity of brands causes logistical problems. The new products need to have their own crates with the advertising geared to the respective target group. “The problem is that large breweries usually produce several types of beer at different sites,” says Schmitt, “so it is always difficult to assign the returned crates from the deposit system to precisely the right bottling plant with the relevant labels.Some breweries are already using advertising labels from Jet-Folio Tacklite. We have now developed, in partnership with brewery experts, LANXESS rubber specialists and our logistics and printing partners, a new type of label that can be easily washed off in the bottling plant. That not only saves suppliers from driving considerable distances, it also cuts transport costs. Furthermore, it spares the environment from unnecessary emissions.”... More

PlastixANZ eMagazine April 2012 Page: 6

LANXESS elastomer for innovative crate labels

Head Office - Melbourne Sydney Branch 40-44 Remington Drive 19/13 Swaffham Road Dandenong South Vic 3175 Minto NSW 2566 Telephone: + 61 3 9799 8800 Telephone: + 61 2 9820 9244 Facsimile: + 61 3 9799 8811 Facsimile: + 61 2 9820 9233

[email protected] www.bf.com.au

Innovation is a key success factor in a competitive global environment with technology constantly on the move. Moretto Italy, one of Europe’s leading suppliers of Plastics Automation equipment have continued to innovate, develop, expand and evolve their already extensive production range and push the technological boundaries while maintaining a price competitive position within the industry.

With recent new releases in their material drying, mould temperature controllers and feeding equipment, Moretto continue to be at the forefront of plastics processing technology.

The extensive Moretto range includes:

Centralized material feeding systems Centralized and mobile desiccant drying systems Mould temperature control units (oil and water) Gravimetric and Volumetric colour feeders Granulators Water Chillers Hopper loaders Conveyors

Moretto is attending the Chinaplas 2012 Exhibition with the support of BFA (located at Hall E2 Stand G41) showcasing a range of new technology and equipment including:

DGM gravimetric blender with touch screen control. New TEKO mould temperature controllers. X dryer system including the new OTX hopper system that

greatly reduces drying time.

BFA have a well established relationship as a Moretto strategic partner. As the sole Australian distributor, BFA continue to offer the complete range of Moretto products, tailored material handling solutions, from initial consultation and systems design, installation, training and continued maintenance and support.

Our experienced sales and service team can provide full sales and after market support from initial enquires to full implementation of your plastics automation equipment including on going back up

service and spare parts stocks. BFA provide full state-wide coverage from both our Melbourne and Sydney branches for all plastics automation equipment providing complete piece of mind for our clients. BFA offer the largest after-sales support team in the Australian Plastics Industry. If attending Chinaplas 2012 arrange to have a chat with Troy Parker our Moretto specialist.

PlastixANZ eMagazine March 2012 Page: 7

BASF Australia launches Innovation in Engineering Plastics By Natalie Ware -- BASF

BASF Australia recently launched a range of new offerings from the KTE Innovation Pipeline, for the first time in ANZ. Through a series of events, the BASF team, along with Marplex, BASF’s distributor in Australia launched Ultramid® Structure, Ultramid® Balance, Ultramid® Endure and the new HMG product range, as well as presenting on ULTRASIM™ to key stakeholders within the Australian Plastics industry.

During a series of launch events held over three consecutive nights in Melbourne, Sydney and Adelaide, Ken Briggs and Alex Hofmann from BAL, Jimmy Jin from BASF’s Technical Centre in China, and Melanie Dodman from Marplex presented on the features and benefits of these new products, as well as the exciting new potential applications, all of which have scope for development in the markets that our industry is seeking to explore and develop.

To further reinforce the capabilities of BASF’s engineering plastics, Jimmy Jin presented on ULTRASIM™- BASF’s innovative software package. This new range of engineering products, along with ULTRASIM, allow for innovative applications in markets beyond the scope of conventional plastics, to be designed, virtually tested, optimized and produced in the shortest possible time.

Ken Briggs, Applications Development Manager, KTE BASF Australia, said “throughout the events, customers were encouraged to think about new applications for these materials and the more traditional and well known products that BASF offers, and to challenge themselves to think beyond current applications and automotive applications and to consider the translatable properties that these products can bring with them” .

As a response to the contracting automotive market in Australia, the engineering plastics industry is finding it increasingly difficult to find applications in traditional markets. This has in turn generated interest in applications for metal replacement from many industries that would not normally have been in BAL’s scope of thinking such as Mining, B&C, Water and Fluid Engineering and Oil Exploration.

BAL hopes that the series of product launches will not only be thought provoking and informative, but also serve as a starting point for companies when looking for life after traditional applications, and ways to keep their companies running well into the next decade.

PlastixANZ eMagazine April 2012 Page: 8

contact the insurance experts with a commitment to the plastics industry.

Isis & C Insure

Contact: Caryn Cramp: mobile: 0418 553 762email: [email protected]

Simon Coldwell: mobile 0410 705 687email: [email protected]

www.cinsure.net

RedEye On Demand Broadens Low-Volume Manufacturing Capabilities With Addition Of Cast Urethane Molding

RedEye On Demand, a rapid prototyping and direct digital manufacturing service provider, and business unit of Stratasys Inc. (NASDAQ: SSYS), today announced it has added cast urethane molding to its services offering. A complementary capability to RedEye On Demand`s existing Fused Deposition Modeling (FDM) and PolyJet services, the addition of cast urethane strengthens the company`s ability to support its customers` rapid prototyping and manufacturing needs through the entire product development cycle."With pressure to decrease the time and costs associated with bringing a product to market, there is increased demand for suppliers with full-service production capabilities - particularly in the medical, automotive and heavy machinery industries," said Richard Garrity, Stratasys vice president of RedEye On Demand. "With the addition of cast urethane services our customers will realize the benefits in time and money associated with utilizing one source for their conceptual 3D modeling, rapid prototyping and short-run production needs."Typically used to produce durable, short-run production components quickly, cast urethane molding is ideally suited for a wide range of materials for prototyping or end-use applications. A bridge between rapid prototyping and injection molding, cast urethane molding combines the durability of an FDM additive-manufactured part with the surface finish of a traditionally manufactured part.Because of the urethanes` ability to simulate thermoplastic material characteristics, such as heat deflection, impact strength and durometer, the technology is often used to produce parts for visual models in color and texture studies, product testing and verification, and low-volume production of fewer than 100 parts.

Industry First: Injection Molding Simulation Software Now Available With Real-Time

Feedback

Autodesk, Inc. announced the availability of Autodesk Simulation DFM (Design for Manufacturing) software, the industry`s first real-time injection molding simulation software that provides real-time feedback. The CAD software plug-in provides designers of plastic parts with a faster and easier way to determine the impact of design decisions on manufacturability, cost and sustainability concerns.

Based on Autodesk Labs technology also known as Project Krypton, Autodesk Simulation DFM seamlessly integrates with Autodesk Product Design Suite software, and specifically Autodesk Inventor software, and provides a complementary technology to Autodesk Simulation Moldflow software. Autodesk Simulation DFM also works with Dassault, SolidWorks and PTC Creo software to support companies working in a multi-CAD environment.

"With Autodesk Simulation DFM, designers of plastic parts can more easily ... More

PlastixANZ eMagazine April 2012 Page: 9

What is the AS4736 standard for biodegradable plastics?If a plastic material claims to be biodegradable and compostable in Australia, it must comply with Australian standard AS 4736‐ 2006. This standard provides assessment criteria for plastic materials that are to be biodegraded in municipal and industrial aerobic composting facilities. This Australian standard is similar to the widely known European EN 13432 standard, but has an additional requirement of a worm test. In order to comply with the AS 4736‐2006, plastic materials need to meet the following requirements:

minimum of 90% biodegradation of plastic materials within 180 days in compostminimum of 90% of plastic materials should disintegrate into less than 2mm pieces in compost within 12 weeksno toxic effect of the resulting compost on plants and earthworms.hazardous substances such as heavy metals should not be present above the maximum allowed levelsplastic materials should contain more than 50% organic materials.

This standard was prepared by the Standards Australia (ww.standards.org.au) to assist authorities regulate polymeric materialsentering into the Australian market. In turn, the Australian Bioplastics Association (ABA) leverages a third‐party verification systemto assist manufacturers, distributors and retailers to communicate their compliance to this standard hence verify product qualitywith respect to biodegradability claims.

ALPS showcase new `Speed Glider` Leak Inspection System

ALPS (Air Logic Power Systems), of Wisconsin USA, a global leader of in-line container leak inspection equipment, will showcase their new `Speed Glider` Multi Station Moving Head Leak Tester at the NPE 2012 International Plastics Exhibition in Orlando USA from the 1st -5th April.

The Linear tester can process 250 -300 containers per minute.

ALPS is represented in Oceania by HBM Plastics Technologies. HBM Plastics Technologies

Plastics Industry Awards September 12, 2012Kooyong Lawn Tennis Club

PlastixANZ eMagazine April 2012 Page: 10

“Our Industry is without doubt very dependent for its future on effective workforce skills training.

Alan Mikkelsen, well – known member of Plastics Pioneers and proprietor of of Practical Technology Training Australia (‘PTTA’ www.competencytraining.com 03 9852 7600), has advised us of an important new initiative launched by his major Licensor, A

Routsis Associates, Inc, of Massachusetts RightStart ™

program.

ARA is the leading international developer and supplier of online, interactive skills training resources for the plastics industry, from introductory to diploma standard, and alan / PTTA is their representative in Australia. Here’s more on RightStart ™, and what’s happening at NPE 2012 in Orlando, where ARA’s president, Andy Routsis (who last visited Australia for Ausplas in 2011) will be delighted to welcome any Aussie guests to the ARA exhibit. Just click on the link.”

Tr a i n i n g f o r t h e P l a s t i c s i n d u s t r y

Presented as 2 half day sessions AT EACH LOCATION Chisholm Institute Dandenong Program details - click here Kangan Institute BroadmeadowsProgram details - click here When:Chisholm – July 4, July 11 Kangan – July 3, July 10 Topics to be covered include; Introduction -- History -- Raw materials Styrenics Engineering Plastics PVC Elastomers Compounding & Formulating Injection Moulding -- Blow Moulding Extrusion -- Thermo/Vacuum Forming Design -- Processing -- Testing Presenters will be current day specialists for each section. Registration will be available shortly

PlastixANZ eMagazine April 2012 Page: 11

About PPSRPersonal Property Securities Register

OverviewPPSR stands for Personal Property Securities Register. Personal Property Security (PPS) reform brings the different Commonwealth, State and Territory laws and registers regarding security interests in personal property under one national system. PPS reform introduces the Personal Property Securities Act 2009 (Cth) and a single national online PPS Register.What is personal property?Personal property is any property other than land. It includes tangibles such as goods, crops and livestock, intangibles such as licenses, investment instruments, negotiable instruments and accounts.What are personal property securities?A personal property security is when a secured party takes an interest in personal property as security for a loan or other obligation, or enters into a transaction that involves the supply of secured finance.An example is when a person or a corporation borrows money from a bank and offers it as security for the loan. The bank’s interest over the collateral is a personal property security.

Financing Equipment and Motor VehiclesIt is not possible to cover all aspects of the PPSR Act as the legislation is 300 plus pages. What I will endeavour to do is give a broad overview of what effect it will have on individuals and businesses when they purchase or dispose of equipment or motor vehicles.The two most significant changes are (a) there is now one centralised Australia wide registry (b) a lot more items will have interest lodged over them. This is particularly in the case of equipment and plant & machinery. In many instances there will be multiple interests recorded on a particular item.As a general rule provided full settlement is made when purchasing a new item be it motor vehicle or equipment from a dealer it will be clear of any Personal Property Security Interest. If a financier funds the purchase they will then record there priority interest over the goods. Subsequent interest from other parties may then also be registered.The real trap for many will come when purchasing second hand equipment or vehicles. There is a definite search process to be undertaken to ensure buyers obtains clear title and while everyone has access to the registry for the uninitiated this can become a mine field particularly when private sales are involved. If you happen to be the vendor you may well need to arrange a release of any interest a third party may hold in the goods you sell.

Services to PlastixANZ MembersCorporate Finance Pty Ltd is dealing with PPSR issues on a daily basis. If you have any concerns in relation to buying or selling plant, equipment or motor vehicle I would be glad the discuss them you.

For more information contact: Bob Montgomery, Director -- mobile: 0418-310 138email: [email protected]

Holden commits to 10-year car programA $275 million taxpayer lifeline will save GM Holden from shutting down its 156-year-old Australian operations and secure its car-making operations at least until 2022, the federal government says.Labor will provide $215 million, with the South Australian and Victorian governments contributing the remainder, to help Holden build two next-generation cars in Elizabeth, SA.Holden has agreed to spend more than $1 billion to ensure it continues to provide jobs in Australia designing, engineering and building cars until at least 2022.

PlastixANZ eMagazine April 2012 Page: 12

Steinert Australia Sponsor Plastics Industry Environment Award

Steinert Australia are proud to sponsor the Plastics Industry Environment Achievement Award for the PlastixANZ Plastics Industry Awards.

This award will recognise achievement for the environment in the plastics industry.

A company like STEINERT, with more than 120 years of experience, excels with its extensive process know-how.

A crucial knowledge edge that enables STEINERT to expertly advise its customers when it comes to the specific selection of sorting technologies.

Not only are our engineers experienced with each and every machine, they also keep your entire process chain in focus when developing solutions. Moreover, in our large testing centre, we also conduct informative test runs with your materials.The best conditions for designing your specific, customised solution.

Astor Base Metals is an industry leader in automotive decorative badges, injection moulding, electroplating, decorative plastic products, doming, souvenirs, printed

labels and signage.

From humble beginnings the company began business in 1957 as a metal casting company that became Astor Base Metals Pty. Ltd in August 1960.

Since these humble beginnings, Astor Base Metals has become an internationally recognised supplier of quality decorative name plates to the automotive industry, still maintaining its focus on traditional attitudes to quality and service.

Welcome to Astor Base Metals

PlastixANZ eMagazine April 2012 Page: 13

Steinert Australia is growing….. up!

2012 is the year of the Dragon in the Chinese calendar and it is generally said to deliver prosperity and good fortune to those who are innovative and

2011 with record sales and a strong order book and certainly experiencing good fortune. However, for Steinert to prosper in 2012 and beyond, we have seen the last 2 months further resources added in design, project management, production, planning and a dedicated service technician.

Cayden from NSW looking after his special Steinert hat

This year is shaping up to be the most enterprising yet as we have also been given the green light to proceed with 2 major capital projects.

projects to improve the manufacturing capability of the existing factory. Following an extensive investigation, it was found

could be achieved with the addition and reorganising the facility. Secondly, the addition of more staff means that we need

will maximise the usage of the land available to us and provide capacity for more staff additions as and when needed. 2012 will also see site testing of our XRT Ore Sorter in central Queensland, a number of technical papers presented

Sorter in the region is being displayed in Singapore at WasteMet in July and a host of important trade shows and exhibitions. Keep an eye on our web site and we hope to see you soon.

Ezio Viti - Managing Director

UltraTape Announces First Cleanroom

premier supplier of Cleanroom tape and labels

Barricade tape. These non-adhesive barricade tapes

suitable for critical environments.

in 3" width with bold two-inch black characters that

barricade tape printed with "DANGER DO NOT ENTER." Both tapes are processed through

individually inspected, double bagged and sealed in

contamination to critical environments. Custom printed barricade tapes are also available.Background:

Delphon Industries in 2007, manufactures particle-free, residue-free adhesive tapes and labels for the Semiconductor, Pharmaceutical, Aerospace, Medical

ISO, REACH and RoHS compliant.

PlastixANZ eMagazine April 2012 Page: 14

Xaloy is well regarded as the global leader in high-performance machinery components and

Xaloy supply screws and barrels to the most famous names in the plastics industry, including, Sumitomo, Engel, Toshiba, Demag, Battenfeld and the list goes on.Xaloy can supply screws and barrels to suit any application and machine at competitive prices, while

industries most stringent purchasing and manufacturing controls, when you purchase Xaloy, you know you are purchasing a product of the

possible ROI.Xaloy offers a full range of gear pumps and screen changers, from the smallest throughputs to large capacity automatically controlled systems.Other products include screw tip assemblies, chill rolls, and NxHeat™ induction control systems.Xaloy’s adage of “Every Pellet knows our name” has never been truer!

New high temperature Thermoplastic Polyurethane now available in Australia.For years BASF Elastollan TPU has been mee�ng the temperature demands of automo�ve and industrial cabling ranging from -‐40 to +125°C, firmly establishing itself as the jacke�ng material for both ABS and ESP cabling in the European and American markets. But with the con�nual development and growing popularity of electric and hybrid cars there are increased demands placed on OEMs and automo�ve manufactures to offer cable harnesses and leads capable of withstanding the increased voltage (1000 volts or more) and higher temperatures.

In response to this BASF Elastollan TPU have developed a range of high temperature TPUs that exceed the standards required for such applica�ons. Elastollan 785 A 10 HPM polyester TPU can withstand temperatures up to 150°C for up to 3000 hours and undergo required mandrel tests without displaying cracks, deforma�on, s�ckiness or excessive colour changes, whilst s�ll offering excellent proper�es normally associated with thermoplas�c polyurethanes – lower compression set, good wear and chemical resistance plus high tear and tensile strength. This grade has a hardness of Shore A 85, with hardness Shore D 55 also available.

The en�re BASF Elastollan TPU range, including ether, ester, alipha�c and specialty grades are available throughout Australia through P.D. Plas�cs (Aust) Pty Ltd.

Contact Paul or Stephen DillonPh: 03 9708 8740

email: [email protected]

PlastixANZ eMagazine April 2012 Page: 15

Introducing Lucian Anders

Steinert Australia’s Operations Manager A little something about Lucian in his own words….

Born in the Year of the Dragon – how ironic! I grew up in the north of England and started my working career in Purchasing and Stock Control for machine tool manufacturers. I left England in 1982 and came to sunny Melbourne to work for Phillips in Clayton. From there I moved on to have a successful career at Linatex Melbourne as Logistics Manager and then moved to Brisbane to be the Operations Manager and discovered the real sun in 1995. Ludowici took me on as Group Purchasing Manager in

Operations Manager for the Screen division, and decided to send me to their China factory doing the same job for 4 great years. I have recently joined Steinert Australia and look forward to the challenges ahead (although may have some slight misgivings about the Melbourne weather!) …and your goals for the future of Steinert Australia? I plan to put in the most effective operations structure so that I can to take Steinert to the next level to meet the needs for the anticipated sales forseen in the region over the next 5-10 years. The future growth of the industries that Steinert operates in (mining and resource recycling) have a strong sales

we can get the product out the door, the happier our sales staff and their customers are! Finally, your favourite Steinert product and why? Would have to be the DFC – because everyone has a difference in opinion of what the letters stand for!

Gutter Flow GateManufactured in Australia by:� P.M.G. Engineering Pty Ltdph: 03 9580 0455 email: [email protected]

and rectangular down pipes, or cut/grind edge down to suit.

Ensure the gutter above down pipe is clear of debris and dry.

Apply silicone around base of the Gutter Flow Gate.

Place Gutter Flow Gate over the middle of the down pipe and press into place and allow silicone to set.

The Gutter Flow Gate will now be ready to use.Please note:

The more down pipes you close with the Gutter Flow Gate,

direction.

The Gutter Flow Gate can also be used for other applications.

MegaWatt Heating ElementsFor all your industrial heating elements needs. MegaWatt Heating Elements are manufacturers and suppliers of industrial heating elements.

We specialise in the plastics industry supplying Nozzle Heaters, Ceramic Band Heaters, Welded and Flex Band Type Heaters to suit Injection Moulders, Blow Moulders, Film Extruders and Rigid Extrusion Plastics Machines...More

PlastixANZ eMagazine April 2012 Page: 16

Travel to Trade Fairs Around the World

Ambassador Travel

For more information and expert advice on ALL your travel needs, call Graeme or Paul on 039500 8355or visit our websites

www.tradefairs.com.au or www.travelcentre.com.au

Ambassador Travel (Division of Passport Travel) Level 1, 12-14 Glenferrie Road, Malvern 3144 Licence 31054 Phone: 61 (3) 9500 8355 Fax: 61 (3) 9509 0111 Email: [email protected]

Milan , Italy 8 - 12 May More than in the past, in fact, thanks to a wide network of supporting partners and Associations, PLAST 2012 is not only a wide international showcase of machinery and equipment but also a relevant window for semi-finished and finished products, materials (raw and recycled) and of the most innovative appliances.

1st April NPE Orlando The Plastics Exposition & Conference 11th April INDOPLAS Jakarta Indonesian International Plastics Exhibition 17th April UTECH Europe Masstricht International Polyurethane Industry Exhibition & Conference 18th April CHINAPLAS Shanghai International Exhibition on Plastics & Rubber Industries 24th April VietnamPlas Hanoi Hanoi Vietnam Int Plastics, Packaging, Printing & Foodtech Industry Exh 8th May PLAST Milan International Exhibition for Plastics & Rubber 15th May Petersberg Chemical Forum St Petersburg Specialised Exhibition 29th May PLASTPOL Kielce International Fair for Plastics Processing 11th June ARGENPLAS Buenos Aires International Plastics Exhibition 19th June Vietnam Plastics Fair Ho Chi Minh International Exhibition of Plastics Technology Machinery & Material 21st June InterPlas Thailand Bangkok International Plastics & Rubber Trade Exhibition & Symposium 21st September Taipei PLAS Taiwan International Plastics & Rubber Industry Show 16th October Fakuma Friedrichshafen International Trade Fair for Plastics Processing 14th November Plastics & Rubber Indonesia Jakarta International Plastics & Rubber Processing & Materials Exhibition

TRADE FAIRS 2012

Travel packages

Costs per person based from Melbourne (costs other cities available) Based on airfares, taxes and exchange rates as at 7 mar 12 and subject to change

Westin Palace 5* Central Milan Top quality hotel at very good price Incl. full breakfasts $2806 share double $3545 single room

Manin Hotel 4* Historic Central Milan Italian style hotel Incl. full breakfasts $2576 share double $3062 single room

Gamma Hotel 3* Central Milan Close to transport Good value hotel Incl. Cont b’fasts $2150 share double $2435 single room

PlastixANZ eMagazine April 2012 Page: 17

PlastixANZ Plastics Industry Achievement Awards

September 12, 2012Kooyong Lawn Tennis Club

7 Industry AwardsNominations open May

Award Sponsors

BASF Australia -- Plastics Industry Achievement Award for Design, Innovation

Isis C Insure Consulting Plastics Industry Achievement Award for Manufacturing and Best Practice Award

Plastics Pioneers Plastics Industry Encouragement Award

Steinert Australia Plastics Industry Achievement Award for Environment

PlastixANZ eMagazine April 2012 Page: 18