Applications of 3D printers in construction industry - Nithin N

-

Upload

nithin-n -

Category

Engineering

-

view

46 -

download

7

Transcript of Applications of 3D printers in construction industry - Nithin N

BY NITHIN N

(1AY11CT015)

8th SEM

GUIDE –

Ms. SIRISHA REDDY

Asst. Prof.

APPLICATIONS OF 3D Printers IN

CONSTRUCTION INDUSTRY

Contents

Details of 3D printing Applications

Applications in

construction industry

Future development

(Print a building)Conclusion

Outline What is 3-d printing ?

History

How it works ?

General principles

Different methods of 3-d Printing

APPLICATIONS IN CONSTRUCTION INDUSTRY

Advantages

Disadvantages

Conclusion

References

Project Objectives

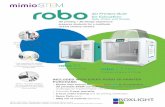

APPLICATIONS OF 3D

PRINTERS IN

AEC Pre - fabricationsDevelopment of

building elements

Erection of contours,

topologies and urban planning

details

Printing a building

What Is 3D Printing?

3D printing is a form of additive manufacturing in which components are fabricated in an additive fashion by adding successive layers of material together

It is also known as:

Rapid prototypingAdditive manufacturing

Additive Manufacturing:

A process of making three dimensional solid objects from a digital file (CAD model)

The creation of a 3D printed object is achieved using additive processes

In an additive process an object is created by laying down successive layers of material until the entire object is created. Each of these layers can be seen as a thinly sliced horizontal cross-section of the eventual object

History The technology for printing physical 3D objects from digital data was first developed by Chuck Hull in 1984.

He named the technique as Stereo lithography and obtained a patent for the technique in 1986

History1986

• Hull coined the term Stereo lithography when he patented his new system

1992

• The first Stereolithographic Apparatus (SLA) is made by 3D Systems

1999

• The first ever 3D organ, a bladder, is created with the patient’s own cells. This means that there is little chance of the organ being rejected by the body

2002

• A miniture kidney is created that can filter blood and produce diluted urine in an animal.

2006

• The Selective Laser Sintering machine is built and allows for mass customisation in manufacturing industrial parts

2008

• A prosthetic leg is created with a complex structure that requires no assembly. This opens the doorway to customized prosthetic limbs. Revolution in technology by rooting of REPRAP concept

2009

• Innovative bioprinting company, Organovo, creates the first blood vessel to be bioprinted

2011

• Printing Service, I - materialize, starts offering 14K gold and sterling silver as a printable material.

2012

• Alternative 3D printing processes were introduced at the entry level of the market

2014

• New era of industrial revolution - Big firms started acquiring start-ups. Theoretical and practical structures were aimed at.

How 3D Printing Works

A person creates a 3D image of an item using a computer-aided design

(CAD) software program.

The CAD information is sent to the printer.

The printer forms the item by depositing the material

in layers—starting from the bottom layer—onto a platform. In some cases

light or lasers are used to harden the material.

Modeling

Additive manufacturing takes virtual blueprints from computer aided design (CAD) or animation modeling software and "slices" them into digital cross-sections for the machine to successively use as a guideline for printing

Printing

To perform a print, the machine reads the design and lays down successive layers of liquid, powder, or sheet material to build the model from a series of cross sections. These layers, which correspond to the virtual cross sections from the CAD model, are joined together or automatically fused to create the final shape.

The primary advantage of this technique is its ability to create almost any shape or geometric feature

Finishing

Though the printer-produced resolution is sufficient for many applications, printing a slightly oversized version of the desired object in standard resolution, and then removing material with a higher-resolution subtractive process can achieve a higher-resolution

Different Methods

• Stereo lithography

• Selective laser sintering (SLS)

• Fused deposition modeling (FDM)

• Ink-Jet 3D printing

Stereo lithography Stereo lithography is a process for creating three-dimensional objects using a computer-

controlled laser to build the required structure, layer by layer. It does this by using a resin known as liquid photopolymer that hardens when in contact with the air

Selective laser sintering (SLS) Selective laser sintering (SLS) is an additive manufacturing technique that uses a high

power laser to fuse small particles of plastic, metal (direct metal laser sintering),ceramic or glass powders into a mass that has a desired 3-dimensional shape

Fused deposition modeling (FDM)• Commonly used for modeling, prototyping, and production applications.

• Here a hot thermoplastic is extruded from a temperature-controlled print head to produce fairly robust objects to a high degree of accuracy.

Ink-Jet 3D Printing It creates the model one layer at a time by spreading a layer of powder and inkjet printing

binder in the cross-section of the part.

It is the most widely used 3-D Printing technology these days

While all inkjet technologies can fundamentally be described as the digitally controlled ejection of drops of fluid from a print head onto a substrate, this is accomplished in a variety of ways.

There are 2-types of print head for the generation of liquid drops

Drop-On-Demand (DOD) and Continuous-Jet (CJ)

Applications

Apparel

Education and research

Art / AEC Rapid manufacturing

Mass customization

Automobiles

Electric Motors and Generators

Spaceflight

Domestic use

Medical

LITERATURE REVIEW Using Contour Crafting, Khoshnevis reports that he has created walls that are six feet high, by

adding layers of concrete six inches high and four inches thick. The walls have a compressive stress of 10,000 pounds per square inch. This technology, Khoshnevis projects, will be able to print a 2,500 square foot house in less than a day [1]

A Dutch firm named Universe Architecture is planning on building a 12,000 square foot, Möbius strip shaped home by 3D printing sections on-site and then assembling them. It plans to use a printer capable of printing structures as large as 6 X 9 meters [2]

Similarly, the Amsterdam-based firm Dus Artchitects is in the process of printing a canal house [3]

WinSun, unlike the innovators previously discussed, uses a massive printer – 490’ X 33’ X 20’ – to print pieces of houses in a factory and then assembles them on-site. WinSun makes the houses using recycled construction material, industrial waste, and tailings which are then reinforced with fiberglass. And, most impressively, WinSun has printed ten houses in less than a day, each measuring 200 square meters and costing less than $5,000. The company even constructed its own 10,000 square meter office in a month using an assembly line of four 3D printers [4]

Steps needed to make the customer's building ready to print

Throughout the design project, the process of dividing a building into printable parts was informallyreferred to as chunking (i.e. converting into multiple chunks)

REFERENCES

[1] A video of the Contour Crafter performing its basic operations may be viewed here:http://www.youtube.com/watch?v=-yv-IWdSdns, and the Contour Crafting website may be viewed here: http://craft.usc.edu/CC/modem.html.

[2] An article explaining Universe Architecture’s project may be accessed at:http://www.dezeen.com/2013/01/20/dutch-architects-to-use-3d-printer-to-build-a-house/. And, Universe Architecture’s website may be accessed here: http://www.universearchitecture.com/.

[3] Read more: http://www.dailymail.co.uk/sciencetech/article-2594234/The-3D-printed-HOUSE-Technology-used-construct-entire-building-including-furniture-Amsterdam.html#ixzz3WXL1ePwj

[4] An article further describing WinSun’s process may be found here:http://blogs.wsj.com/corporate-intelligence/2014/04/15/how-a-chinese-company-built-10-homes-in-24-hours/?mod=e2fb. And, a video may be found here:https://www.youtube.com/watch?v=SObzNdyRTBs.