Anutone (4)

-

Upload

shivansh-singh-gautam -

Category

Documents

-

view

12 -

download

0

Transcript of Anutone (4)

Release 1.1 • August 2010

Tufbloc

now includes Tufbloc Plus, Tufbloc Lite, Tufbloc Vin

2 Tufbloc

CONTENTSINTRODUCTION .................................................... 4

APPLICATIONS ..................................................... 5

PRODUCT SELECTOR .......................................... 6

INSTALLATION ...................................................... 8

FINISHING ............................................................. 9

TECHNICAL ......................................................... 10

COMPARATIVE .................................................... 11

PROPERTIES ...................................................... 12• ENVIRONMENT, HEALTH & SAFETY• IMPACT, DURABILITY• FIRE• WATER• ACOUSTICS

SYSTEM COMBOS .............................................. 14

OTHER PROPERTIES ......................................... 15• CHEMICAL• THERMAL• LIGHT REFLECTIVITY• SIESMIC

SITE GUIDELINES ............................................... 16

TUFBLOC VIN ..................................................... 17

SERVICES ........................................................... 18

LIMITATIONS ....................................................... 19

SPECIFICATIONS ................................................ 20

LIMITED WARRANTY .......................................... 21

FREQUENTLY ASKED QUESTIONS ................... 22

3Tufbloc

Tufbloc HDFR Board

Step up to the top of the evolution in building boards

The next-generation buildingboard for the rest of the 21stcentury is here.

Step up from the traditional wood-based or cement-content orpaper-wrapped boards to Tufbloc!

Tufbloc is highly impact-resistant,incombustible, water-resistant,noise-isolating and a greenbuilding material.

Use Tufbloc for external andinternal walls, ceilings, floors ...and enhance the value of yourbuildings!

WO

OD

PLA

NK

S

PLY

WO

OD

PA

RT

ICLE

BO

AR

D

OR

IEN

TED

ST

RA

ND

BO

AR

D

GY

PS

UM

BO

AR

D

CA

LCIU

M S

ILIC

AT

E B

OA

RD

CEM

ENT

BO

AR

D

MET

AL

BO

AR

D

TU

FBLO

C

TUFBLOC

IMPACT RESISTANT

INCOMBUSTIBLE

WATER RESISTANT

NOISE ISOLANT

SLIM FOOTPRINT

GREEN CREDENTIALS

4 Tufbloc

Tufbloc is High Density Fibremesh Reinforced (HDFR) magnesia board. The FRalso means Fire Rated as Tufbloc enjoys a very high fire-rating - upto 4 hours!

Tufbloc is an economically viable alternative and superior to existing buildingboards in the market - a technologically advanced, compact construction panelthat does what other products - traditional wood, gypsum and cement basedboards - combinedly do.

Tufbloc has a monolithic core and is the ideal building product for the mostdemanding of projects and has a positive and lasting impact on health andsafety aspects even as it extends the lifecycle of investment in a building.

ManufacturerTufbloc comes from Anutone that has almost five decades of expertise andexperience in similar products.

Right from woodwool boards introduced to India in 1966 to its many variants inthe 1990s and the invention of best-selling microfibre panels in 2000, Anutone’sEkcel division has been at the forefront of innovation in magnesium-basedproducts, refractory chemicals and inorganic bonded composites.

After the mega success of microfibre panels (MAT) in the year 2000, the designand development (D&D) team at Anutone’s Ekcel, since 2005, researchengineered for five years and now after thorough in-house testing andevaluation, has introduced Tufbloc.

Thus Anutone’s Ekcel division, which is ISO 9001 2008 and 14001 2004certified, now boasts of three major product categories:• Woodwool Boards• Microfibre Tiles• Tufbloc HDFR

StandardsTufbloc conforms to all current international building codes and standards.Extensive testing has been performed in-house at the Anutone’s BildwareResearch Facility (BRF) and also submitted to independent testing laboratories(includes CBRI, NPL, IPIRTI in India and TUV SUD overseas) for validation.

ClassificationClass 19 – Building Material. Basic # 190186 - Xylolith

CSI MasterFormatSection 061653 – Moisture-resistant Sheathing Board

078200 – Fireproofing Board

ICC-ES AC386. International Code Council’s Evaluation Service for AcceptanceCriteria as mandated by International Building Code (IBC).

VariantsTufbloc is available as the original in Normal and Mirror finishes. See next page.

The highest quality of Tufbloc made with the purest ingredients is Tufbloc Plusfor premium projects that demand greater value from the product and system.

A lighter version of Tufbloc with a density of 900~1,000kgs/m3 for budgetprojects will be progressively available as Tufbloc Lite.

And as has become habit with Anutone, a value-added variant is Tufbloc Vinwhich is laminated tiles for grid ceilings. See page 17.

INTRODUCTION

ISO 9001:2008 CERTIFIED

ISO 14001:2004 CERTIFIED

5Tufbloc

APPLICATIONS

Tufbloc is used wherever the ecosystem places a high value on a building. When a building and its occupants, includingequipment, need fire protection. Where there is a high concern for safety and health. And for green buildings where everyproduct needs to add to the LEED rating of the project.

Surface-wise

Interiors– drywall and ceiling,

backer board orunderlayment

Speciality– shaft walls, data

centre shells,firewalls, doors

Structures– steel and concrete

fire protection

Encasement– cable trays, pipes &

tubes, ducts

Exteriors– siding, sheathing,fascia, canopy soffits

Area-wise

High-risk fire areas–kitchens, warehouses,

labs, shafts

High-security areas– data centres, safe-

deposit lockers, banks

Wet areas– washrooms, kitchens,

swimming pools

High-humid areas– laundry, saunas, markets,

factories

High-usage areas– corridors, schools,

hospitals, retail shops

High-grade finishes– hotels, apartments, high-

end commercials

High-bracing areas– earthquake bracing,

windload bracing

Noise isolation areas– offices, hotels, hospitals,

theatres, studios

Segment-wise

Offices Hotels Hospitals Education Transport

Leisure Sports Public Residential Industrial

6 Tufbloc

PRODUCT SELECTOR

Tufbloc is available at Anutone Shoppes and distributor stockpoints, from July2010, as precut sheets in matt surface ‘Normal’ or smooth-glossy ‘Mirror’ finishboth of which with a rough rear-side. Taper edge option is available in Normal8, 10,12mm thickness. Also available is Tufbloc Vin which is a laminated tile forgrid ceilings.

From September 2010 the highest quality version, Tufbloc Plus, will beavailable, followed by a lighter version for budget projects, called Tufbloc Lite byNovember 2010. So, the product category, riding on unprecedented demand, israpidly expanding to ensure solutions to every kind of building needs.

Given Anutone’s innovative track record, expect more from Tufbloc in the future.More in making building interiors faster, better, cheaper, meeting higheststandards of quality, safety and good practices.

While selecting the right product for your project, you must make the followingthree choices:

• By variant – choose the variant that best suits your building - the original,premium Plus, budget Lite or accessible ceilings via Vin

• By thickness – choose the thickness from 4mm to 16mm that best suits theapplication

• By surface finish – for the original Tufbloc choose either ‘Normal’ if beingused as a backer board or ‘Mirror’ if being used as a finished, exposedsurface that requires Level 5 trim (eggshell finish)

Thickness Edge Size Surface Density Weight / Board(mm) (mm) (kgs/m2) (kgs)

4 Square 1200x2400 4.8 13.8

6 Square 1200x2400 7.2 20.7

8 Taper 1200x2400 9.6 27.7

10 Taper 1200x2400 12.0 34.6

12 Taper 1200x2400 14.4 41.5

Tufbloc Normal

Thickness Edge Size Surface Density Weight / Board(mm) (mm) (kgs/m2) (kgs)

4 Square 1200x2400 4.8 13.8

6 Square 1200x2400 7.2 20.7

8 Square 1200x2400 9.6 27.7

10 Square 1200x2400 12.0 34.6

12 Square 1200x2400 14.4 41.5

Tufbloc Mirror

7Tufbloc

Tufbloc VinPlease refer page 17

NoteDensity for Tufbloc and Tufbloc Plus is 1100~1200 kgs/m3

Approximate Average ~1150 kgs/m3

Density for Tufbloc Lite and Tufbloc Vin is 900~1000 kgs/m3

Approximate Average ~950 kgs/m3

Surface density and weight per board are approximate and based on maximumdensity basis

1200x2400mm boards can be field cut in half to 1200x1200mm for easyhandling in high ceiling applications, if necessary

Thickness Edge Size Surface Density Weight / Board(mm) (mm) (kgs/m2) (kgs)

4 Square 1200x2400 4.8 13.8

6 Taper 1200x2400 7.2 20.7

8 Taper 1200x2400 9.6 27.7

10 Taper 1200x2400 12.0 34.6

12 Taper 1200x2400 14.4 41.5

14 Taper 1200x2400 16.8 48.4

16 Taper 1200x2400 19.2 55.3

Tufbloc Plus

Thickness Edge Size Surface Density Weight / Board(mm) (mm) (kgs/m2) (kgs)

4 Square 1200x2400 4.0 11.5

6 Taper 1200x2400 6.0 17.3

8 Taper 1200x2400 8.0 23.0

10 Taper 1200x2400 10.0 28.8

12 Taper 1200x2400 12.0 34.6

14 Taper 1200x2400 14.0 40.3

16 Taper 1200x2400 16.0 46.1

Tufbloc Lite

8 Tufbloc

Tufbloc is very easy to handle and install. It is easier to work with, using all typesof hand tools and wood working equipment. It can also be cut with a quick saw,and it snaps off faster than plasterboard, as it is paperless.

Tufbloc can be installed on wood and/or metal framing or directly on to steelstructure and masonry work with mechanical fasteners (screws, bolts, rivets,staples, nails) and can also be used to laminate over existing surfaces usingadhesives and cements.

Cutting - Circular saw with carbide blade

Screw fixing – self drilling screws, self countersinking; no pre-drilling necessary

Nailing – Pneumatic nails, pressure dependant on thickness and framework

Tufbloc is installed with a variety of joint fillers for different levels of functionalresistance as desired or demanded by specific applications in projects. These jointfillers are the same as used for building boards and easily available in the market.

Tufbloc is a smooth-finished lining board. It can be painted, stucco, papered ortiled to create complementary design looks. With options of taper edge for flushjointing, smooth and seamless surface is possible.

The front-side of Tufbloc is smooth to take any paint finish. The rear-side isrough, breathable and porous for strong coating and adhesive bond.

INSTALLATION

9Tufbloc

FINISHING

Tufbloc can be finished just about any way including but not limited to:

Exterior

Paint Stucco Stone

Brick ACP Tile

Interior

Paint Stucco Stone

Brick Wallpaper Fabrics

Plaster Tile

10 Tufbloc

Summary technical data below is for 8mm thick Tufbloc unless otherwise stated.For detailed data please view the following pages.

Strength• Compressive Strength (perpendicular to surface) ~20Mpa.

Meets requirement of ASTM D2394.

• Flexural Strength (longitudinal) > 18Mpa.Meets requirement of ASTM C1185.

• Tensile Strength (rupture) > 7.5Mpa

• Modulus of Elasticity ~6045 N/mm2

• Impact Strength > 6kJ/m²

• Screw holding < 50N/mm(4mm 28N; 6mm 32N; 10mm 65N; 12mm 70N)

Fire• Fire Resistance < 180 minutes under 1200°C

Water• Moisture Absorption < 1% in 2 hours as per ASTM C1185

< 25% maximum saturation

• Wet expansion < 0.02% from ambient to saturation

• Dry Contraction < 0.02% from ambient to evaporation

• Moisture Movement – Meets requirement of ASTM C1185

• Freeze/Thaw – Meets 25 cycles requirement of ASTM C666-B

Sound• Acoustic Rating upto 54 Rw dB - see acoustics section for details

Thermal• Thermal Conductivity < 0.047W/mk

• Specific Heat ~930J/kgK

• Thermal Expansion - 0.01mm/mC (+20oC to -20oC)

Physical• Surface Density < 9.6 kgs/m2

• Face Density < 1300kgs/m³

• Volume Density < 1200kg/m³

• Moisture Content < 10%

Green• Toxicity, Pollutants – Nil (below measurable level of instruments)

• Heavy Metals – Nil (below measurable level of instruments)

As per EN 12457-2

Tolerances• Thickness + 0.5mm

• Width + 1mm

• Length + 1mm

• Diagonal + 1mm

As per ASTM C1186

TECHNICAL

11Tufbloc

Tufbloc Comparative

Value Tufbloc Cement Plywood Gypsum GypsumBoard Board Sheathing

Flame Spread 0 0 High Low/15 Low/10

Smoke Developed None None High Low Low

Water Resistance Yes Low No No No

Mould Resistance Yes Yes No No No

Termite Resistance Yes Yes No Yes Yes

Thermal Insulation 1.2 0.8 1.2 0.9 1.1R-value per 25mm

Impact Strength High Medium High Low Low

Combustibility Non Non Burns Facing Facing

Structural Yes No Yes No No

Environmental Good Good Good OK OK

Freeze/Thaw Cycle Good Good Good Poor Poor

Finish

Interior Tape & Provide cladding Provide cladding Tape & joint/paint Tape &joint/paint joint/paint

Exterior Apply stucco N/A Apply paper N/A Apply stuccoor cladding and stucco or cladding

or cladding

COMPARATIVE

Tufbloc is one product that suits everyapplication. It is a hard, inert board thatis integrated (homogeneous),paperless – hence there is nodelamination.

Tufbloc boasts of superiorcharacteristics over cement, gypsum,wood, pulp. Research studies provethe equivalent use of 8mm Tufblocinstead of 12.5mm gypsum or 10mmTufbloc instead of 15mm gypsum.

The ceramic-like properties makeTufbloc superior to cement board,calcium silicate boards, waterresistant drywall, gypsum board,plywood and particle board in diverseapplications. While moisture-resistant(MR or WR grade) gypsum boarddoes not absorb water as fast asnormal gypsum board, it still doesabsorb some water which results inits softening and failing.

There is a dramatic improvement inproject sites when Tufbloc is used inlieu of gypsum drywall and cementboard as it is usable for both indoorand outdoor purposes. It provides avery hard, long lasting surface that

look and feel like hard cementplastering but is fireproof and resistantto damage from water, humidity,freeze/thaw, organisms, salt and more.

As a component for light steel framing,Tufbloc allows structures to be taller,bigger and lighter, much faster thanother board products. With more optionsin thickness, for interior and exteriorapplications, it can be left natural withclear finishes or ready to receivefinishings, better than other boards byinherent superior bonding property.

Tufbloc offers a faster and betteralternative to plastering and henceused to line masonry walls andconcrete roofs. Tufbloc can be installedwith taped joints like a drywallplasterboard; or spliced using specificfillers without taping; or without anyfilling or taping to save time and moneyfor plastered tough walls at less cost. Agreat substrate to receive exterior andinterior decorative coatings directly toits surface.

Tufbloc is used for fast drywallboarding that is installed and paintedwithin hours using fast setting fillers

trimmed with a sharp blade (reducingsandpaper and sanding). Fillers canbe cut flush without a tape over thepanel joints and without needingcorner-bead, metal trims etc. whilegiving perfectly true square cornersand edges naturally. Panels can bespliced between studs withoutneeding to land joints over studs. i.e.,using strips of Tufbloc behind theseam as a back-blocking splicerstapled or screwed together results inseamless flush joints on the front.

A concrete-hard dry wall material idealfor high impact areas, hot wet andhumid areas. It receives paint directlyor as a wall tile or floor tilebackerboard. A backerboard thatprovides a strong substrate for wall tile,screwed or nailed in place without pre-drilling or laminated in layers to obtainany thickness. When nailed in placewith a light nail gun a whole room canbe made ready to tile in minutes. Everythickness from 4mm to 12mm can benailed in place to wood studs, plywoodsubfloors, particleboards ... evenTufbloc to Tufbloc with pneumaticallyapplied nails.

12 Tufbloc

GreenTufbloc is one of the most environment friendly building boards in the industry.

It is made from the world’s eighth largest resource – magnesium mineral –which makes up 2% of earth’s crust. Magnesium mineral is also the third mostplentiful material dissolved in the oceans.

Tufbloc consumes only 50% of energy to manufacture compared to cementboard and gypsum board. It is produced without wasting large amounts of fossilfuel or releasing significant CO2 into the atmosphere in production.

The entire production process is conducted at room temperature, and scraps ordrop-offs are reground and recycled in the production.

Tufbloc does not contain any organic solvents, formaldehyde, asbestos, oils,methyl alcohols or any other toxic substances that adversely impact theenvironment. Further, Tufbloc is non-hazardous, natural, non-toxic, non-radioactive and disposable as crushable clean fill in sites without contaminationor environmental damage to land, streams or bodies of water.

HealthTufbloc is termite, mildew and insect proof. It is non-nutrient and hence does notfeed mould, bacteria, fungus, rodents and other organisms as per ASTM G21.

Tufbloc has no VOCs. Hence it does not adversely affect IAQ (Indoor AirQuality).

StrengthTufbloc boasts very high impact resistance. It can be safely used at pedestrianheight in corridors. It lowers maintenance costs while ensuring higher finish.Thus it eliminates the damage due to rough tenants which is always an issue forspace owners, and helps protect assets.

Impact testing as per ASTM D5628 shows superficial crack from a drop height of150mm and hairline crack from a height of 300mm which meets the standard.

Being stronger and more rigid, it allows thinner material to do the same job andhence is not only economical but space saving – a boon in the current boom ofskyrocketing real estate prices!

BracingTufbloc boasts a high level of bracing ability. All lined areas will provide thesame brace rating when installed using the approved fixing design.

FlexibilityThe diaphragm stiffness is high which means it can be bent like thin plywood.Hence Tufbloc can be used for barrel-vaulted ceilings and other curvedsurfaces, including domes, provided the radius of curvature is narrow.

The screw-holding ability is superb and hence it eliminates the need for plybetween plasterboards which has become the norm in commercial interiorstoday to facilitate suspension of wall fixtures.

PROPERTIES

ENVIRONMENT, HEALTH & SAFETY

IMPACT, DURABILITY

13Tufbloc

DurabilityTufbloc resists swelling, losing strength or deterioration in wet applications.It maintains dimensional stability even when wet and hence is a very durableproduct.

Only Anutone offers an unique 25-year warranty on product life, which is asupreme confidence on its longevity.

Tufbloc is made from refractory xylolith – the same material used to pyrolineblast furnaces in steel mills. Hence it has an inherent, natural ability to resist fire.It is inherently non-flammable.

Tufbloc as a product is non-combustible and as a system offers upto four hoursfire resistance. It qualifies as a Class O/A building material fulfilling all fire coderequirements across geographies.

Tufbloc is Class A1 – Non-combustible material - as per EN 13501-1 Reactionto Fire standard. It is rated Class O as per the older BS 476-4 Non-combustibility test and 476-7 Surface Spread of Flame standards.

As per ASTM

• E136 – Non-combustible

• E84 – Flame spread and smoke developed – 0

• E662 – Smoke density – NA; Non-toxic

The use of Tufbloc results in zero spread of flame and hence it is perfect forfireproofing wooden frame construction, structural steel and concrete. Used as alining material it prevents damage to the structure and hence has the ability toinfluence a reduction in insurance premiums.

FIRE

WATER

Tufbloc is water resistant more than any other building board. Accidental watercontact is no problem as it causes no swelling, melting or delamination.

Water permeability is nil with no water drops observed on the rear when water issprinkled on the front surface.

Tufbloc boasts humidity resistance of upto RH99 and hence suits tropical Asia’shot, humid climate. Can be safely used in coastal regions near the equator thatexperience harsh climates of heat, humidity and excessive rainfall.

Tufbloc does not alter its physical appearance or mechanical stabilitysignificantly after exposure to water. After evaporation or gravity flow of water,Tufbloc returns to its original state.

Tufbloc is weatherproof. It has been subjected to numerous freeze/thaw cyclesand hence is suitable for cold, temperate climes too. No change in the producthas been observed with an accelerated 25 year freeze/thaw cycle. Theprocedure is to subject Tufbloc to controlled immersion test wherein samplesare placed in closed container of water and exposed to continuous freeze thawcycles for 36 months since 2007. In 2010 the sample showed no change inphysical properties.

Tufbloc can be safely used to line the walls and ceilings of wet areas likewashrooms and kitchens.

14 Tufbloc

SYSTEM COMBOS

Tufbloc is an excellent acoustic dampening material with high density andelasticity. The panel has mass more than known building boards but theflexibility of bending like plywood. Sound Transmission Loss Test as per ISO‘140-3 - Standard Test Method for Laboratory Measurement of Airborne SoundTransmission Loss of Building Partitions and Elements.

1 layer of 12mm Tufbloc on

100mm Studd framework

100mm Rockwool infill (96kgs/m3 density)

1 layer of 12mm Tufbloc

Joints & perimeter – Soundfire caulking

3 hour fire-rating - 54 Rw

Hz STL (dB)125 30250 45500 551000 602000 534000 68

Compare this to gypsum board that gives only 2 hour fire-rating with special fire-rated boards andsimilar acoustic rating with multiple layers of gypsum board on either side of framework.

ACOUSTICS

1 layer of 10mm Tufbloc on

72mm Studd framework

75mm Rockwool infill (96kgs/m3 density)

1 layer of 10mm Tufbloc

Joints & perimeter – Soundfire caulking

3 hour fire-rating – 46 Rw

Hz STL (dB)125 25250 35500 471000 502000 454000 58

Tufbloc achieves much more with single layers that are slimmer too thus saving valuable space, money and labour timefor installation.

Caution! Laboratory results are under ideal testing conditions. Field results are usually lower by 5dB and 0.5 hour. Otherfield factors like flanking transmission paths of noise and fire need to be considered. The services of professionalconsultants is recommended.

System thickness (mm) Fire-rating (hours) Acoustics (Rw dB)

74 2.5 4012mm Tufbloc50mm Studd50mm Rockwool

86 3.0 448mm Tufbloc72mm Studd75mm Rockwool

90 3.5 4610mm Tufbloc72mm Studd75mm Rockwool

144 4.0 5410+12mm Tufbloc100mm Studd100mm Rockwool

15Tufbloc

OTHER PROPERTIES

Tufbloc being a strong, durable material, makes it the perfect choice for seismic-proof constructions.

CHEMICAL

Tufbloc is chemical-resistant. It is an inert material and can be safely used inresearch labs and chemical-intensive spaces.

Tufbloc resists the debilitating effects of salt (sodium chloride) brines and saltwater, chlorine bleach (sodium hypochlorite) and related pool chemicals andhence can be safely used in indoor swimming pools.

Tufbloc also resists ammonia (ammonium hydroxide) & related chemicals.Surface alkalinity is ~10pH.

MSDS data• Magnesia minerals• Natural silicates• Perlite• Wood flour• Water• Proprietary additives• Other trace substances

Anutone will provide detailed data on request.

THERMAL

Tufbloc is made from refractory chemicals that are used to line the blastfurnaces at steel mills. Hence it naturally resists changes in temperature upto800oC.

Tufbloc can be safely used as a refractory material for infrared radiation (heat)assisting to reduce loss of energy when heating or cooling by reducingconductivity.

LIGHT REFLECTIVITY

Tufbloc is available naturally in a off-white colour and hence reflects light.Unlike wood-based boards it does not need excessive paint to render its surfaceinto light-reflectivity.

SIESMIC

16 Tufbloc

Store Tufbloc flat on pallet trays that allow air movement. Stack each lot to amaximum height of 1m and each stack to a maximum of 3 lots or 3m. Protectfrom exposure to harmful environment.

Verify site is ready for install and all wetworks are completed. If Tufbloc isaccidentally wetted then allow to dry prior to installation. Constructionguidelines issued by central, state and local government must be observed atall times. In case of conflict with Anutone guidelines, the government guidelineswill override. Please contact Anutone for clarification.

CuttingPosition cutting station so that wind will blow dust away from user or others inworking area and allow for ample dust dissipation. Always wear protective gearincluding dust mask, goggles and earplugs. Use of gloves is recommended toprevent abrasion injuries.

Use one of the following methods based on the required cutting rate and jobsiteconditions.

Best Under score and snap using carbide-tipped scoring knife or utility knife(Ability to use this method depends on thickness being installed.)

Better Dust reducing circular saw equipped with appropriate blade and vacuumextraction.

Good (for low to moderate cutting only) Dust reducing circular saw withappropriate saw blade.

NOTES• Always use correct tools when executing cutting operations.

• Even though Tufbloc is a non-toxic building material, always wear a duskmask, safety glasses and follow MSDS Guidelines.

• Tufbloc panel ends must always be supported on metal framework. Tufblocmust not be cantilevered.

• Any surface coverings or fixtures must be supported by driving the fastenersthrough the Tufbloc onto the metal framing. Do not fasten such fixturesdirectly and independently on Tufbloc alone.

CleaningDuring clean-up, dust and debris, never dry sweep as it may excite dustparticles into the user’s breathing area. Instead, wet debris down with a fine mistto suppress dust during sweeping, or use vacuum to collect particles.

NOTES

• For maximum protection (lowest respirable dust production), Anutonerecommends always using “Best” level cutting methods where feasible.

• Never use a power saw indoors.

• Never use a circular saw blade that is inappropriate for the specific operationbeing undertaken.

• Never dry sweep - use wet suppression methods or vacuum.

• Never use a grinder or continuous rim diamond blade for cutting.

SITE GUIDELINES

17Tufbloc

Tufbloc vin

Thickness Edge Size Surface Density Weight / Board(mm) (mm) (kgs/m2) (kgs)

6 Square 595x595 6.0 2.1

8 Square 595x595 8.0 2.8

Tufbloc Vin

Stratus Shingle Shale Stella

Density for Tufbloc Vin is 900~1000 kgs/m3 Approximate Average ~950 kgs/m3

Surface density and weight per tile are approximate and based on maximumdensity basis.

Tufbloc Vin is ceiling tiles for grid applications. The tiles are laminated on theexposed surface with vinyl film and on the non-exposed surface with metallisedpolyester film. All edges are sealed so the product is safe for cleanroomapplications in pharmaceutical, food processing, biotechnology, electronics,research labs, medicine and healthcare.

Tufbloc Vin tiles are lightweight, safe to handle, easy to install on Skeletframeworks like Omni O15 and Trelis T15. Complete ceiling systems includingA-chain accessories are offered by Anutone.

Visual VariantsTufbloc Vin will progressively be available in the following visual variants.Please check with an Anutone rep for the currently available options.

Pharmaceutical Food Processing

Electronics Research Labs

Biotechnology

Healthcare

18 Tufbloc

SERVICES

AvailabilityTufbloc is stocked by Anutone at its own warehouses in India Bengaluru andBhiwandi apart from stockpoints at distributors in India and overseas from July2010, with gradual stock build-up.

PackingTufbloc is available in loose sheets for retail that requires careful handling or aspallet packing for forklift movement and storage.

IdentificationLook for the Anutone and Tufbloc brand printed on the backside of each panel.Trace product origin from Anutone and contact a rep in case of any doubt.

SupportOur technical service can provide complete assistance for detailed installationmethods and design solutions including unique applications that are notpossible with other board material. The use of specialist consultants like fire andacoustical consultants is however recommended for speciality spaces asperformance is system-dependant on other elements of the building.

Our products, together with our high-level expertise in general buildingapplications and manufacturing, make Anutone a leader in developing uniqueinnovative applications based on our core competency of refractory materialsand inorganic bonded composites.

MaintenanceTufbloc is long-service, durable, maintenance-free product. It requires virtuallyno maintenance services.

19Tufbloc

LIMITATIONS

Though Tufbloc is a strong board and impact-resistant, it is brittle andsusceptible to chipping during handling and installation. So handle carefully.

Tufbloc can only be used for non-load bearing applications. The head channelneeds deflection gap for slab movement when used in wall partitions. Maxheight of partitions is 4000 mm.

Joints between panels, whether used in walls or ceilings, must be aligned to theexpansion joint of the building.

Where exposed to continuous damp or moisture conditions, the panelsincluding edges must be sealed by primer painting or equivalent to preventwater absorption and staining.

When Tufbloc is used as a noise isolating medium care must be taken offlanking noise transmission and other issues related to acoustics. Services of aprofessional acoustical consultant is recommended.

Most of the properties are reported on the basis of laboratory tests undercontrolled conditions. The specifier/purchase must determine the suitability ofthe product to suit site conditions.

Most of the properties are claimed on the basis of complete system that mayinclude metal framing, sealants, infill etc. Use of the product with accessories byothers may render the performance and warranty void.

Tufbloc has been researched by Anutone since five years. It has beenextensively tested in-house and field trials. It is undergoing third party validationand such test reports will be available from October 2010. Being a new productfrom Anutone, its proven use, as an Anutone brand, in projects, is limited.

CEILING Supply and Installation of Tufbloc of size 1200mmx2400mm & ____ thick, assupplied by Anutone, using Strut suspended ceiling system. Strut WC25 is fixed tothe wall along the perimeter with fasteners. Strut MC45 at 1200mm cc is tied tosuspenders Strut SA25 and Strut CC25 at 600mm cc is then fixed perpendicular tothe MC45. The suspension is done with all accessories like soffit cleat and wire rodsas per drawings. Tufbloc is screw-fixed to Strut CC25 at 300mm cc. Joints are taped,filled and finished.

PARTITION Supply and Installation of Tufbloc as supplied by Anutone. The perimeter framing(floor channels and head channels to abutments) is securely fixed by usingfasteners at 300mm staggered centers with an underlay of Silica caulkingcompound. The Studs are then placed into the floor and ceiling channels at 600mmcenters and turned into position.

Resultant airgap between studs to be lined with Synth PF. On either side of the studpartition system, layers of Tufbloc of size 1200x2400mm _____ mm thick, is fixed onto the studs by using self-tapping screws. Tapered joints between two panels shallbe lined with Seam+Strap+Seam.

LINING Supply and Installation of Tufbloc as supplied by Anutone. Strut CC10/CC22/CC50to be screw fixed on existing masonry wall at 600mm centres to which Tufblock isscrew fixed and joints taped to smooth finish.

Tufbloc is a smooth-finished lining board. It can be painted, stucco, papered or tiledto create complementary design looks. With options of taper edge for flush jointing,smooth, seamless surface

INTERIOR SPECIFICATIONS – 3-LINE

20 Tufbloc

PART 1 - GENERAL

1.01 - SUMMARYRelated Sections:

• Metal Framing: Division 05 structuralmetal stud framing sections.

• Wood Framing: Division 06, roughcarpentry sections.

1.02 - REFERENCESASTM International (ASTM)

• ASTM C1280 StandardSpecification for Application ofGypsum Sheathing.

• ASTM D6109 Standard TestMethods for Flexural Properties ofUnreinforced and Reinforced PlasticLumber and Related Products.

• ASTM E84 Standard Test Methodfor Surface Burning Characteristicsof Building Materials.

• ASTM E119 Standard TestMethods for Fire Tests of BuildingConstruction and Materials.

• ASTM G21 Standard Practice forDetermining Resistance of SyntheticPolymeric Materials to Fungi.

1.03 - SYSTEM DESCRIPTIONPerformance Requirements:

Fire Performance:

• Fire-Rated Assemblies: Providepanels suitable for use in fire-rated assemblies in accordancewith ASTM E119.

• Surface burning characteristicswhen tested in accordance withASTM E84:

• Flamespread: 25, maximum

• Smoke Developed: 450, maximum

1.04 - SUBMITTALSGeneral: Submit listed submittals inaccordance with Conditions of theContract and Section [01 33 00 -Submittal Procedures] [___________].

Product Data: Submit product data,for specified products.

Quality Control Submittals:

• Manufacturer’s Instructions:Manufacturer’s installationinstructions.

DETAILED SPECIFICATIONS

ARCHITECTURAL SPECIFICATIONS – 3-PART

Closeout Submittals:

• Warranty: Manufacturer’s standardwarranty document executed byauthorised company official.Manufacturer’s warranty is inaddition to, and not a limitation of,other rights Owner may haveunder Contract Documents.

1.05 - QUALITY ASSURANCERegulatory Requirements: Inaccordance with Section [01 41 00 -Regulatory Requirements] [______].

1.06 - DELIVERY, STORAGE & HANDLINGGeneral: Comply with Section [01 6100 - Common Product Requirements][______].

Delivery: Deliver materials inmanufacturer’s original, unopened,undamaged containers withidentification labels intact.

Storage and Protection: Store materialsprotected from exposure to harmfulenvironmental conditions and attemperature and humidity conditionsrecommended by the manufacturer.

1.07 - WARRANTYProject Warranty: Refer to Conditionsof the Contract for project warrantyprovisions.

Manufacturer’s Warranty: Submit inaccordance with Section [01 78 36 -Warranties] [______] for Owner’sacceptance, manufacturer’s standardwarranty document executed byauthorized company official.Manufacturer’s warranty is in addition to,and not a limitation of, other rights Ownermay have under Contract Documents.

Warranty Period: [______] yearscommencing on Date of SubstantialCompletion.

PART 2 - PRODUCTS

2.01 - MOISTURE-RESISTANT BOARDManufacturer: Anutone AcousticsLimited

Contact: 231, 7th Cross, Indiranagar1st Stage, Bangalore 560038, India

Tufbloc

Size: 1200 x 2400mm

Thickness (mm): 4, 6, 8, 10, 12

Edges: [Square] [Taper]

Physical Characteristics:• Flexural Modulus:• Flexural Strength:• Shear Strength:• Fungus/Mould:

2.02 - ACCESSORIESMetal framing, Infill, Fasteners.

2.03 - PRODUCT SUBSTITUTIONSSubstitutions: Substitutions inaccordance with Section [01 25 13 -Product Substitution Procedures] [Nosubstitutions permitted] [______].

PART 3 - EXECUTION

3.01 - MANUFACTURER’S INSTRUCTIONSCompliance: Comply withmanufacturer’s product data,including product technical bulletins,product catalog installationinstructions and product packinstructions for installation.

3.02 - EXAMINATIONSite Verification of Conditions: Verifythat substrate conditions, which havebeen previously installed under othersections, are acceptable for productinstallation in accordance withmanufacturer’s instructions.

3.03 - INSTALLATIONIn accordance with ASTM C1280.

3.04 - CLEANUPProceed in accordance with Section[01 74 23 - Final Cleaning] [______].

Upon completion and verification ofperformance of installation, removesurplus materials, excess materials,rubbish, tools and equipment.

21Tufbloc

LIMITED WARRANTY

1. CoverageAnutone warrants to the first owner of thestructure to which all Tufbloc (hereinafterProduct) is applied and the first transfereeof such structure that, for a period of 25years from the date of purchase, theProduct will be free from manufacturingdefects, including rotting, swelling,delamination and damage from termites,when properly installed and maintainedaccording to Anutone publishedinstallation instructions. Should any suchdefect appear, Anutone will providereplacement material ex-works, at itsoption, for the defective Product. Anutonealso reserves the right to replace theProduct, subject to the prorating scheduleset forth herein.

Under no circumstances and in noevent shall Anutone be liable for anyproduct payment refund, any labourcharges or other expenses whatsoeverin connection with the removal orinstallation of either the original orreplacement Product. In the event ofrepair or replacement under the termsof this warranty, the original warrantyshall apply to the replaced or repairedproduct and will extend for the balanceof the warranty period in effect at thetime the Product proved defective.

The coverage offered by this warranty isintended to cover first purchasers only. Ifduring the Warranty period, any Productproves to be defective, Anutone, in itssole discretion, will replace the defectiveProduct before it is installed, during thefirst year. During the 2nd through the25th year, the Warranty replacement willbe reduced by 3% each year such thatafter the 25th year no warranty will beapplicable.

If the original cost cannot beestablished by the covered person,the cost will be determined byAnutone in its sole and reasonablediscretion. Anutone replacement ofthe defective Product shall be thesole exclusive remedy available tothe covered persons with respect toany defect. Anutone will not refund orpay any costs in connection withmoney refund, labour or accessorymaterials. Any material replacementby Anutone shall constitute a fullsettlement and release of all claims ofany covered person hereunder fordamages or other relief, and shall bea complete bar to any litigation filedsubsequently to the covered person’sacceptance of such agreement.

2. Conditions of WarrantyThe Product must be stored according tothe manufacturer’s instructions at alltimes between purchase andinstallation. The Product must beinstalled according to Anutone printedinstallation instructions with Anutoneaccessories and all building codesadopted by central, state or localgovernments or government agenciesand applicable to the installation. Failureto install and finish the Product per themanufacturer’s published instructionsand accessories may affect Productperformance and voids the Warranty.

3. What the Customer must doThe claimant must provide proof that he/she is a covered person and notifyAnutone in writing within 7 days afterdiscovery of any claimed defect orfailure covered by this Warranty andbefore beginning any permanent repair.

The claimant must provide proof ofthe date of purchase and installation,as well as proof of propertyownership. All notifications should besent to Anutone.

Upon discovery of a possible defector failure, the covered person mustimmediately, and at the coveredperson’s own expense, provideprotection of all property that could beaffected until the defect or failure isremedied.

The property owner will be requiredto submit a sample and photographsof the defective material to Anutonefor the analysis. Anutone will theninvestigate the claim and examine thematerial claimed to be defective.

If requested, the property owner mustprovide access for examination by anAnutone rep. If a defect covered bythis warranty is confirmed, Anutone,within a reasonable amount of timeafter the inspection, will repair orreplace the Product, pursuant to theterms of this warranty.

4. LimitationsThis warranty does not provideprotection against any failure, defect ordamage caused by situations andevents beyond normal exposureconditions, including but not limited to:• Misuse, abuse, neglect or improper

handling, shipping, storage orinstallation of the Product.

• Improper application or applicationnot in strict adherence to Anutonewritten application instructions.

• Improper installation of stubs orother accessories.

• Settlement or structural movementand /or movement of materials towhich the Product is attached.

• Damage from incorrect design ofthe structure.

• Exceeding the maximum designedwind loads.

• Use of accessories that do not properlyreceive and/or secure the Product.

• Impact of foreign objects, fire,earthquake, flood, lightning,hurricane, tornado, severe weather(including, but not limited to,unusual climate conditions) or othercasualty or act of God.

• Growth of mold, mildew, fungi,bacteria, or any organism on anysurface of the Product (whether onthe exposed or unexposedsurfaces) and in this respect, anyclaims of damage caused by moldor mildew are expressly excluded.

• Lack of proper maintenance or anycause other than manufacturingdefects attributable to Anutone.Anutone will have no responsibilityhereunder for defective Productsubjected to further processing oralteration after shipment.

• Anutone reserves the right todiscontinue or modify any of itsProducts without notice to the propertyowner/consumer and shall not beliable as a result of suchdiscontinuance or modification. IfAnutone replaces any material underthis warranty, it may substitute Productdesignated by Anutone to be ofcomparable quality or price range inthe event the Product initially installedhas been discontinued or modified.

5. Other Conditions:IN NO EVENT WILL ANUTONE BELIABLE FOR ANY INCIDENTAL,SPECIAL, INDIRECT, ORCONSEQUENTIAL DAMAGES OFANY KIND, INCLUDING ANYDAMAGE TO THE BUILDING, ITSCONTENTS OR ANY PERSONSTHEREIN, WHETHER RESULTINGFROM NONDELIVERY OR FROMTHE USE, MISUSE, OR INABIITY TOUSE THE PRODUCT OR FROMDEFECTS IN THE PRODUCT.

22 Tufbloc

FREQUENTLY ASKED QUESTIONS (FAQs)

What is Tufbloc?

Tufbloc is a mineral based product that meets the criteria established to beconsidered the best for a building board or construction panel.

Why use Tufbloc?

Tufbloc is a unique product that combines the features of several products inone. It has been engineered to eliminate the toughest problems facingarchitects, engineers, contractors, builders and consumers today: Fire, Water,Sound, Insects, Fungus and Toxins.

Tufbloc is virtually impervious to fire, water and insects; is non-flammable andnon-combustible; does not feed mould or mildew; is unaffected by any insectsand termites; and is non-toxic. Literally crores of rupees or millions of dollarsget spent every year as a result of damage caused by these problems, and moreon the deaths directly resulting from these problems.

Is Tufbloc a green building product?

Yes. Tufbloc is a mineral product, completely free of toxins such as asbestos,formaldehyde or silica. It is manufactured completely at ambient temperature,and is considered a green product.

Has Tufbloc been tested?

Yes. Tufbloc has been subjected to some of the toughest tests conductedon building materials today including the freeze/thaw and 2,000 hourweathering test which is a 20 year accelerated weathering test. It thus farexceeds ASTM requirements. All testing has been done in-house asrequired by AC386 issued by the International Code Council (ICC) and inaccordance with ASTM requirements. Anutone is ISO certified and isaudited periodically to ensure consistent quality in every order. Externalvalidation is under progress.

Is Tufbloc dimensionally stable in freeze, thaw, heat and humidity cycles?

Yes it is. Unlike cement type materials, the coefficient of expansion for Tufblocis extremely low; therefore, when selecting and installing products such as ourexterior lap siding, there is no need to leave gaps between butt joints toaccommodate for such expansion and contraction. This provides a much moreaesthetically pleasing finish for many years to come.

What are the adhesion values of Tufbloc?

Excellent. Allows you to finish with any product you desire such as paint, cementstucco, synthetic stucco, wallpaper, stone, tile, brick, metal as in ACP and muchmore. The excellent adhesion properties of Tufbloc also make it a perfectproduct for Structural Insulated Panels (SIPS), Exterior Insulated Finish Systems(EIFS) and interior wall systems using fabric cladding.

Is Tufbloc cost competitive with other products?

Yes, considering overall installation and lifecycle costs. By using Tufblocyou don’t have to worry about such things as insect damage caused bytermites, ants and other such pests; decay caused by moisture and UV;warping, swelling and rot caused by water; mould and mildew; and, toxinsthat are found in many wood, plastics, gypsum and cement basedproducts. Much thinner panels achieve much higher saving youexpensive space costs.

23Tufbloc

Can I order non-standard sizes?

Yes. But Minimum Order Quantity (MOQ) applies.

How do I store Tufbloc?

Storage and handling of Tufbloc is easy. It does not require the same attentionas wood or gypsum type products do. Tufbloc can actually be submerged inwater for months with virtually no dimensional change whatsoever; and, itleaches water quickly, never feeding fungus or mildew or suffering decay orwarping as do most wood and gypsum products. And since Tufbloc is ahomogenous product, there is no delamination ever.

Is Tufbloc easy to install?

Yes. Tufbloc installs with mechanical fasteners - screws or pneumatic nailers -depending on the application. Always follow the Anutone installationrecommendations. Finishing interior walls and ceilings is also easy using standard jointcompound and glassfibre joint tape. Since Tufbloc is smooth on one side, you canachieve a level 5 trim with much less work (man-hours) than typical gypsum board.

When installing Tufbloc as underlayment or backer board there are no changesin preparation for installation from processes being used today when installingother materials; however, use only thin set materials and not mastics.

Is Tufbloc safe for installers?

Yes. In fact installing Tufbloc is as safe if not safer than installing any othermaterial in the market today. Tufbloc is a mineral-based product free ofcarcinogens and silica. It has been tested and found to be non-toxic. So, Tufblocis extremely safe for installers and consumers alike. You may obtain a copy ofour Material Safety Data Sheets (MSDS).

How can Tufbloc be finished?

Tufbloc can be finished with just about anything in the market today includingpaint, cement stuccos, synthetic stuccos, wallpaper, plaster, brick and stone andmuch more. As with most products, manufacturers of these products will guideand in some cases their authorised applicators will perform the installation.

Where can I purchase Tufbloc products?

To accommodate your needs, we are in the process of establishing distributionpoints around the country and overseas. Please contact us to find out thenearest location to your project. If you are interested in becoming a Distributor,call us and we can tell you how we can make it rock together!

How does the Tufbloc warranty compare to other product warranties?

Anutone warrants Tufbloc lifecycle for 25 years. No other building board comes close.

Other applications (OEM)• Structural Insulated Panels (SIPs)• Exterior Insulated Finish Systems (EIFS)• Room Dividers• Office cubicle wall panels• Liners for Safes• Shaft liner

For the interior• wallboard• ceiling board• tile backer• underlayment• ceiling tiles• fire walls

For the exterior• sheathing• fascia• soffit• trim• lap siding

In what applications can I use Tufbloc?

Tufbloc is extremely versatile and a product available for a most everyapplication. For example:

• Overview

• Design Revue 4.0 DVD

• What’s New– Serge Span– Salon Series– Tufbloc (this brochure)– Noizkon

• edesign52 volume1

• Applications Guide

• QuickGuide

• Technical Guide

• Corporate Guide

• Reference Guide

Do you have them all? If not, please view atwww.issuu.com/anutone or download from ourwebsite www.anutone.com/infobin/downloads orcontact Anutone

Coming this summer are a full range of content-indexed product brochures. Reserve your copy today!

• Soft• Snazz• Salon• Serge• Synth• Ekcel

Do

cum

en

t #

01

211

0-1

00

0

231, 7th Cross, Indiranagar 1st Stage, Bengaluru 560 038, IndiaPhone +9180 2520 3114 Fax +9180 2520 3115 [email protected]

Anutone® is a registered trademark of Anutone Acoustics Limited. Specs are subject to change due to continuous improvement programmes at Anutone®. Contents under copyright registration. No part of this brochure maybe reproduced, stored in a retrieval system, scanned or transmitted in any form or by any means electronic, photocopying, recording or otherwise, without the prior written permission of Anutone®.

www.anutone.com

Anutone is member of

ISO 9001:2008 CERTIFIED ISO 14001:2004 CERTIFIED

ANUTONE WALLS & CEILINGSa division of Anutone Acoustics Limited

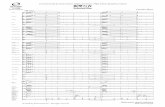

![Welcome [s3.eu-central-1.amazonaws.com]...bb bb bb bb bb # # # # # b b bb bb bb bb bb bb bb bb 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 44 4](https://static.fdocuments.us/doc/165x107/5e9f761d9d1aa23b1a09f03e/welcome-s3eu-central-1-bb-bb-bb-bb-bb-b-b-bb-bb-bb-bb-bb-bb-bb.jpg)

![Finale 2005a - [Untitled1]h).pdf · 2014-02-18 · 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 Picc. Flutes Oboe Bassoon Bb](https://static.fdocuments.us/doc/165x107/5b737b707f8b9a95348e2e6f/finale-2005a-untitled1-hpdf-2014-02-18-4-4-4-4-4-4-4-4-4-4-4-4-4-4.jpg)

![Chemical Resistance Chart for Metal - ARC Industrial … Chloride [CH3CH2Cl] 4 4 4 4 3 4 4 4 4 4 4 4 4 4 4 4 4 2 4 ethylene Dichloride [ClCH2CH2Cl] 4 4 4 4 3 4 4 4 4 4 4 4 4 4 4 4](https://static.fdocuments.us/doc/165x107/5ac7280c7f8b9a220b8e82c8/chemical-resistance-chart-for-metal-arc-industrial-chloride-ch3ch2cl-4-4.jpg)

![Oh Pretty Woman4sc].pdfã ### ### ### ### ### ### ### ### 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 2 4 2 4 2 4 2 4 2 4 2 4 2 4 2 4 2 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4 4](https://static.fdocuments.us/doc/165x107/60cfb349cd0cbb00d32b6774/oh-pretty-woman-4scpdf-4-4-4-4-4-4-4-4-4-4.jpg)