Analysis of the characteristics of short-cut nitrifying granular sludge and pollutant removal...

-

Upload

zhang-ying -

Category

Documents

-

view

217 -

download

3

Transcript of Analysis of the characteristics of short-cut nitrifying granular sludge and pollutant removal...

ORIGINAL PAPER

Analysis of the characteristics of short-cut nitrifying granularsludge and pollutant removal processes in a sequencing batchreactor

Yan Li-long • Liu Yu • Ren Yuan • Zhang Ying

Received: 4 April 2013 / Accepted: 14 May 2013

� Springer-Verlag Berlin Heidelberg 2013

Abstract Aerobic granular sludge is a new type of

microbe auto-immobilization technology; in this paper,

short-cut nitrification and denitrification were effectively

combined with the granular sludge technology. Simulta-

neous nitrification and denitrification granules were

developed in a sequencing batch reactor (SBR) using

synthetic wastewater with a high concentration of ammonia

nitrogen at 25 �C with a dissolved oxygen concentration

above 2.0 mg/L and a 15 days sludge retention time. The

characteristics of the sludge and the removal efficiency

were studied, and the removal mechanisms of the pollu-

tants and the process of short-cut nitrification were ana-

lyzed. The average granule diameter of the granular sludge

was 704.0 lm. The removal rates of pollutants and the

accumulation rate of nitrite in the SBR were studied.

During treatment of wastewater with a high concentration

of ammonia nitrogen, simultaneous nitrification, and

denitrification and the stripping process could contribute to

the removal of total nitrogen. The high pH value, the high

concentration of free ammonia, and the delamination of

granular sludge were the main factors contributing to the

short-cut nitrification property of granular sludge in the

reaction process.

Keywords Granular sludge � Short-cut nitrification �Simultaneous nitrification–denitrification � SBR

Introduction

Excessive emission of nitrogen is one of the causes of water

eutrophication. Increasing attention is being paid to the issue

of nitrogen removal given the intensification of eutrophica-

tion and the improvement in emission standards. Biological

nitrification and denitrification are the most commonly used

methods of biological nitrogen removal. Because nitrifying

bacteria have a lower specific growth rate and are more

sensitive to environmental conditions, they are easily lost to

the reactor effluent. The quantity of nitrifying bacteria in the

reactor must be increased to improve the effectiveness of

ammonia nitrogen wastewater treatment. The process of

immobilization is a very effective method, and sludge

granulation is considered to be a promising technology.

Aerobic granular sludge, a new type of microbe auto-

immobilization technology, is attracting widespread atten-

tion among researchers due to its advantages, such as high

settle ability, high biomass, and the ability to withstand high

organic loading [1, 2]. In recent years, much research has

been published on heterotrophic granular sludge [3]. This

research focuses on the fast start of granular sludge reactor;

the factors influencing granular sludge formation and the

characteristics of granular sludge; and the theoretical study,

operating conditions (substrates, organic loading rate, reac-

tor configuration, settling time, exchange ratio, and hydro-

dynamic shear force), microbiological properties, and

physicochemical characteristics of granular sludge [4–13].

Aerobic granular sludge technology is used to treat all

components of wastewater, including organic matter, nitro-

gen, phosphorus, and toxic substances [6, 14–17].

Y. Li-long � L. Yu � Z. Ying (&)

College of Resource and Environment,

Northeast Agricultural University, Harbin 150030, China

e-mail: [email protected]

Y. Li-long

e-mail: [email protected]

R. Yuan

School of Municipal and Environmental Engineering,

Harbin Institute of Technology, Harbin 150090, China

123

Bioprocess Biosyst Eng

DOI 10.1007/s00449-013-1006-3

Nitrifying granular sludge technology has broad poten-

tial for application as a new biological nitrification process

[18]. The formation of nitrifying granular sludge can

enhance the concentration of nitrifying sludge in the

reactor and the denitrification ability of the reactor [19, 20].

However, it is difficult to effect the granulation of nitri-

fying sludge due to the autologous characteristics of nitri-

fying bacteria. Tsuneda and Belmonte [21, 22] measured

the particle sizes of nitrifying granular sludge as 0.2 and

0.9 mm after operating for 100 and 400 days, respectively.

When the concentration of ammonia nitrogen was 150 mg/L,

the particle size of mature granular sludge was no more

than 0.5 mm [23]. In recent years, while nitrifying sludge

granulation characteristics were being studied [24], gran-

ular sludge technology was combined with a new denitri-

fication process to treat ammonia nitrogen wastewater

efficiently [15, 17, 25].

Short-cut nitrification and denitrification shows the

advantages of a low operating cost, decreased sludge pro-

duction, fast reaction time, and a low carbon source demand

[26]. The emergence of shortcut nitrification technology

provides a new option for treating wastewater containing a

high concentration of ammonia nitrogen with high efficiency

and low consumption of resources. Because of the unique

structure and mode of operation of sequencing batch reactor

(SBR) reactors, granular sludge is cultivated during the

treatment process. In this paper, flocculated sludge was

studied, and short-cut nitrification and denitrification were

effectively combined with granular sludge technology. The

granular sludge was developed in an SBR reactor through

short-cut nitrification and denitrification. The physical and

chemical properties of granular sludge, the removal effi-

ciency of pollutants and the mechanism of pollutant removal

were analyzed to provide a foundation for further theoretical

research and engineering applications.

Materials and methods

Reactor description

A plexiglass column SBR reactor was used in the experi-

mental set-up. The reactor had a height of 30 cm, an inner

diameter of 26 cm and a working volume of 13 L. Air was

circulated by an air pump and aerator, and a mass flow

controller system was used to keep the airflow constant. A

time controller was used at each stage. The cycle was as

follows: 5 min of feeding, 480 min of aeration, 10 min of

settling, and 10 min of effluent withdrawal. The volumetric

liquid exchange ratio was 50 %. The control parameters

were as follows: the temperature was maintained at 25 �C,

dissolved oxygen (DO) was maintained above 2.0 mg/L,

and the sludge retention time (SRT) was 15 days.

Experimental wastewater and seed sludge

Synthetic wastewater was used. Glucose and sodium ace-

tate [with a chemical oxygen demand (COD) mass ratio

1:1] acted as carbon sources, and ammonium chloride acted

as a nitrogen source; details of the synthetic wastewater

composition are given in Table 1. Trace elements were

added to the wastewater at a total volumetric concentration

of 0.5 mL/L to supply the necessary elements for microbial

growth; the components were 1.50 g/L FeCl3�6H2O,

0.15 g/L H3BO3, 0.03 g/L CuSO4�5H2O, 0.18 g/L KI,

0.12 g/L MnCl2�4H2O, 0.06 g/L Na2MoO4�2H2O, 0.12 g/L

ZnSO4�7H2O, 0.15 g/L CoCl2�6H2O, and 10.00 g/L

EDTA.

Activated sludge was collected from the secondary

sedimentation tank of the Taiping wastewater treatment

plant in Harbin, China. Nitrifying sludge with an improved

nitrification efficiency was observed after 2 months of

cultivation, at which time the sludge concentration was

2.50 g/L and the settled volume rate of sludge was 28 %.

Sequencing batch experiments

Air stripping

The air stripping experiment was performed in a 3,000 mL

beaker. Aeration was achieved using an air pump and

aerator identical to those in the reactor. At room temper-

ature, 3,000 mL of synthetic wastewater was added to the

beaker, the pH in reactor was adjusted to 7.6 by adding 1:3

H2SO4 and 0.5 mol/L NaOH, and the DO in the reactor

was controlled at 4.0 mg/L to maintain stable conditions.

The effect of air stripping on the removal efficiency of

ammonia nitrogen (total nitrogen) was investigated by

timed sampling measurements of the ammonia nitrogen

content of the residual wastewater.

Denitrification

The reaction system consisted of synthetic wastewater and

sludge. The mixed liquid taken from the reactor was

transferred into a 2,000 mL beaker and allowed to settle for

Table 1 Components of the synthetic wastewater

Components Concentration (mg/L, except for pH)

COD 200–350

NH4?–N 100–250

PO43-–P 5–10

pH 7.4–8.0

CaCl2�2H2O 10

MgSO4�7H2O 20

Bioprocess Biosyst Eng

123

10 min. The supernatant was decanted; leaving a final

sludge concentration of 1,904 mg/L, the final volume after

mixing with the wastewater was 2,000 mL. The final

concentrations of nitrite and organic nitrogen were 194.4

and 342.8 mg/L, respectively, after adding sodium nitrite

and glucose. To avoid the settling of granular sludge and

promote better contact between sludge and wastewater, the

beaker was stirred by magnetic stirrers at a speed of 150 r/min.

The wastewater quality was monitored by timed sampling

measurements of the effect of bio-denitrification.

Analytical methods

The analysis of COD, ammonium nitrogen, nitrite nitrogen,

nitrate nitrogen, and mixed liquid suspended solids was

performed in accordance with standard methods [27]. UV

absorbance was measured with a UV-1800 spectropho-

tometer (Shimadzu Co., Tokyo, Japan). The measurement

of pH was carried out with a pHS-3C precision pH meter

(Shanghai Weiye Co., Ltd, China). The measurement of

DO was carried out with a DO meter (Shanghai Lei-ci Co.,

Ltd, JPB-607, China). The size of sludge granules was

determined using a laser particle-size analysis system

(Malvern Instruments Ltd. Mastersizer Series 2000, UK).

The operating-temperature concentrations of NH3 and

HNO2 were calculated from the NH4? and NO2

- concen-

trations and the pH in the bulk liquid using Eqs. (1) and (2),

according to the expressions proposed by Anthonisen et al.

[28]:

CFA ¼17

14�

C½NHþ4�N� � 10p

e½6334=ð273þtÞ� þ 10pð1Þ

CFNA ¼46

14�

C½NO�2 N�

e½�2300=ð273þtÞ� � 10pð2Þ

where t is absolute temperature (K), C is mass concentra-

tion (mg/L), p is the pH value, and e is the natural

logarithm.

Results and discussion

Physical and chemical characteristics of granular sludge

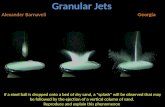

Morphology and concentration of granular sludge

The inoculated sludge was floc sludge from the wastewater

treatment plant, cultivated in the laboratory. The sludge

appeared faint yellow after 30 days of cultivation. The

particle size increased significantly after granulation of the

flocs but retained its tawny color. The sludge shape chan-

ged from initial flocs to spherical or rod-shaped particles.

When mature granular sludge was cultivated, the sludge

concentration was 2.56 g/L, lower than the values reported

in the literature [29, 30]. According to the analysis, this

might result from the long reaction cycle and aeration time.

The operation cycle influenced the specific growth rate of

granular sludge and the sludge yield. When the operation

cycle increased from 1.5 to 8.0 h, the specific growth rate

of granular sludge decreased from 0.27 to 0.031 days-1,

and the corresponding sludge yield (VSS/COD) decreased

from 0.32 to 0.063 [31]. The bacterial growth rate was

directly related to the load. In general, the higher the load

was, the faster the bacterial growth rate was. In contrast, a

longer operating cycle and reaction time (480 min) and a

low volumetric exchange rate (50 %) reduced the reactor

load and therefore reduced the sludge concentration in the

reactor. In addition, a low height/diameter ratio is adverse

to sludge granulation [30] and promotes the loss of sludge;

this low ratio may be one of the reasons for the low sludge

concentration (Fig. 1).

Particle size distribution characteristics of granular sludge

Figure 2 shows the particle size distribution of granules in

a stable operation reactor. The average particle size of the

granular sludge was 704.0 lm; the granules with a particle

size [200.0, 447.7, 502.4, 632.5, 709.6, 893.4, 1,002.4,

1,261.9, and 1,588.8 lm represented 87.3, 67.6, 62.8, 51.2,

44.6, 30.7, 24.0, 12.1, and 3.9 % of the total volume,

respectively. Nitrifying granular sludge cultivated by dif-

ferent researchers varied in size, ranging between 0.3 and

8.0 mm. The particle size of the granules was influenced by

Fig. 1 Photos of granular sludge

Bioprocess Biosyst Eng

123

many factors, such as their composition, the reactor

structure, and the dewatering ratio. The particle size of the

nitrifying granular sludge was slightly smaller than that of

heterotrophic granular sludge. Gao [20] measured the

average particle size of mature aerobic nitrifying granular

sludge to be approximately 500 lm, using actual waste-

water. Tsuneda et al. [21] produced nitrifying granules with

a diameter of 0.346 mm in an aerobic upflow fluidized bed

reactor within 300 days. Shi et al. [32] reported that nitri-

fying granules with a mean diameter of 0.85 mm were

accumulated in a pulsing SBR after 160 days of operation.

The results from the present study did not support the

above-mentioned conclusions, which might be attributed to

the COD/N ratio, the short operation time (60 days) and the

configuration of the reactors in this study [33]. The COD/N

ratio plays a significant role in nitrifying sludge granula-

tion. To some extent, an average granule diameter was

found, and there was a trend towards larger granules under

higher COD/N ratio and load [33, 34]. In contrast, because

the influent did not contain organic substrates, the diameter

of granular sludge obtained by Tsuneda et al. was smaller

and took longer time [21], while because of the lower

substrate load, the granule diameter obtained by Gao [20]

was smaller. Moreover, the granule diameter of granular

sludge was related to the operating time and configuration

of reactors; diameter generally increased with longer

operating times [32]. Smaller granular sludge was obtained

after a shorter operating time. However, the effect of

reactor configuration on the granule diameter of the gran-

ular sludge is complicated and should be the topic of fur-

ther research [33].

Removal efficiency of SBR on pollutants

Figure 3 shows the removal efficiency of SBR on COD and

total nitrogen. The removal of organics by granular sludge

occurred in stages, in which the organics concentration

decreased rapidly, then decreased slowly. The organics

concentration decreased from 353.2 to 184.7 mg/L in

15 min, and this decrease might be the result of adsorption.

The removal of organics by microbes passed through an

adsorption phase and stable phase, in which adsorption was

completed in a short time. After adsorption, the adsorbed

organics were released slowly back into the liquid phase.

While it took a long time to reach a stable phase, it was

observed that the organics concentration decreased slowly

from 15 to 180 min. Moreover, the slight rise in organics

concentration might be the result of long aeration time,

leading to microbe lysis. The removal rate of COD was

only 63.7 % for the whole process; this removal rate is not

high. After analysis, we found that ammonia nitrogen was

converted to nitrite nitrogen in the experimental process.

The presence of nitrite nitrogen would affect the mea-

surement process for COD. Therefore, we determined the

actual removal rate of COD to be 77.6 % after eliminating

the influence of nitrite nitrogen.

Meanwhile, Fig. 3 shows that a certain denitrification

process occurred in the reactor. The removal rate of total

nitrogen was 39.3 %.

Fig. 2 Particle size distribution of granular sludge

Fig. 3 Profiles of the effluent concentration of COD and TN over

time. Symbols (square), determined COD (open diamond), TN (filled

triangle), actual COD

Bioprocess Biosyst Eng

123

Analysis of denitrification process

Previous results showed that granular sludge was capable

of simultaneous nitrification and denitrification. What

happened in the experimental process was short-cut nitri-

fication. The removal of total nitrogen in wastewater was

achieved by assimilation, bio-sorption, ammonia nitrogen

air stripping, and biological nitrification–denitrification.

The COD concentration of the influent was 300–400 mg/L

in the experimental process, and the removal quantity of

total nitrogen was \15–20 mg/L via assimilation. The

effect of assimilation on total nitrogen removal was lim-

ited. Bio-sorption could remove part of ammonia nitrogen

and then achieve the removal of total nitrogen. The process

of bio-sorption could be completed in 5 min, and 90 % of

the ammonia nitrogen was absorbed into the liquid phase

[35]; therefore, air stripping and biological nitrification–

denitrification were the main mechanisms of total nitrogen

removal in the reactor.

Figure 4 presents the change of ammonia nitrogen

concentration with the air stripping time. As shown in

Fig. 4, the residual ammonia nitrogen concentration in

wastewater gradually decreased as the reaction time

increased. When the ammonia nitrogen concentration of

the influent was 125.7 mg/L, the ammonia nitrogen con-

centration of the effluent was 100.1 mg/L. The removal

rate of ammonia nitrogen during air stripping was 20.3 %.

Thus, air stripping made some contribution to total nitrogen

removal under these test conditions.

Figure 5 shows the change of the wastewater quality with

respect to time during the denitrification process. As shown

in Fig. 5, the substrate concentration gradually decreased as

the reaction time increased. When the initial concentration of

ammonia nitrogen, nitrite nitrogen, nitrate nitrogen, total

nitrogen and organics were 34.6, 194.4, 33.8, 262.8, and

342.8 mg/L, and their final concentrations were 23.0, 41.6,

5.4, 69.9, and 62.2 mg/L, respectively. The removal of total

nitrogen was 192.9 mg/L in 3 h. It was apparent that this

sludge system was capable of effective biological denitrifi-

cation. Biological denitrification might be the main reason

for total nitrogen removal in this system. The overall ratio

between COD removal and total nitrogen removal was 1.84;

the ratio was 1.71 in the short-cut nitrification and denitrifi-

cation process and 2.86 in the nitrification and denitrification

process. In general, biological denitrification requires a

hypoxic environment, with a DO concentration lower than

0.5 mg/L. In this experiment, the DO concentration in the

reactor was between 2.0 and 4.0 mg/L, and the removal

efficiency of total nitrogen was nearly 40 %. This removal

was thought to be caused by simultaneous nitrification and

denitrification in the reactor. Because the granular sludge

was hard-packed with an average particle size of 704.0 lm, a

concentration gradient existed during the transfer of DO

from the granule surface to its interior. This resulted in

anaerobic conditions in the granule interior. Thus, the

granule microenvironment, consisting of an aerobic exterior

and anaerobic interior, appears to have created sufficient

conditions for simultaneous nitrification and denitrification

[36].

As shown in Fig. 6, the concentration of ammonia

nitrogen gradually decreased, the concentration of nitrite

nitrogen gradually rose, and the concentration of nitrate

nitrogen remained below 7.0 mg/L in reactor. Over the

course of the reaction, the effluent concentrations of

ammonia nitrogen, nitrite nitrogen and nitrate nitrogen and

the removal rate of ammonia nitrogen were 34.1, 44.0, and

6.1 mg/L and 72.9 %, respectively. Short-cut nitrification

Fig. 4 Effect of air stripping time on removal of ammonium

(temperature 25 �C, pH 7.5)

Fig. 5 Profiles of wastewater quality with respect to time in the

denitrification process (temperature 22.5 �C, reaction time 180 min,

sludge concentration 1.90 g/L). Square ammonium, filled triangle

nitrite, filled diamond nitrate, triangle TN, asterisk COD

Bioprocess Biosyst Eng

123

occurred in the reactor. The accumulation rate of nitrite

(NO2-–N)/(NO2

-–N ? NO3-–N) was 87.8 %.

Analysis of short-cut nitrification

The accumulation of nitrite was achieved by controlling the

DO concentration, temperature, SRT, pH value, free

ammonia (FA), and free nitrous acid (FNA) in the reactor.

In this experiment, experimental conditions [DO above

2.0 mg/L, nitrite nitrogen of the influent below 4 mg/L,

room temperature (25 �C), and 15 days SRT] did not favor

the accumulation of nitrite. Therefore, it appears that high

pH and FA might be the main reasons for the accumulation

of nitrite.

The pH of the influent was between 7.5 and 8.0, cor-

responding to the pH values in the literature [37, 38].

Accumulation of nitrite was achieved by utilizing the

optimum pH range for nitrite bacteria and nitrate bacteria.

Fang and Li [37] thought that the accumulation of nitrite

was achieved by controlling pH, and Tokutomi [38]

thought that it was achieved at high pH. In contrast, Jenicek

[39] thought that adjusting the pH could not lead to the

accumulation of nitrite. Short-cut nitrification occurred

throughout the whole experimental process. We believe

that factors other than pH might have resulted in the

accumulation of nitrite.

As shown in Fig. 6, the pH first rose and then decreased

after the beginning of aeration, which was consistent with

the results published by Yang et al. [40]. The change of pH

in the reactor is due to a combination of stripping, deni-

trification and nitrification. When the pH increase due to

stripping is greater than the decrease in pH due to nitrifi-

cation, the total pH rises. When the reverse is true, the pH

falls. At the beginning of the experiment (120 min), most

of the organic matter was degraded and consumed by

denitrification; organic matter (glucose and sodium acetate)

was transformed to CO2 by heterotrophic bacteria. The

degradation of acetate, stripping of CO2 and nitrification

led to the increase in pH. As the reaction proceeded, most

of the organic matter was consumed, and biological nitri-

fication occurred primarily during this time. Bicarbonate

alkalinity was consumed and H? ions were produced dur-

ing nitrification, leading to a decrease in the pH in the

reactor.

FA and FNA showed an inhibitory effect on nitrite

bacteria and nitrate bacteria [41], which is a widely

acknowledged trend. However, the minimum inhibitory

concentrations of FA and FNA varied among reports in the

literature. Anthonisen [28] found that the inhibitory con-

centration of FA on nitrite bacteria was 10–150 mg/L,

while the inhibitory concentration of FA on nitrate bacteria

was 0.1–1.0 mg/L; the inhibitory concentration of FNA on

nitrate bacteria was 0.22–2.80 mg/L. Chang [42] found that

when FA was 0.20 mg/L, an accumulation of nitrite

appeared in the system. Hellinga [41] reported that the

minimum concentration of FNA required to inhibit nitrite

oxidation was 0.20 mg/L.

To investigate the reason for nitrite accumulation, under

the conditions at a concentration of 125.7 mg/L ammonia

nitrogen at 22.5 �C with DO above 2.0 mg/L, the con-

centrations of FA and FNA in reactor were calculated, and

the results are shown in Fig. 7.

As shown in Fig. 7, the FA and FNA concentrations

displayed different trends over time. The concentration of

Fig. 6 Profiles of the concentration of ammonium, nitrite, and nitrate

nitrogen and the pH change with time (temperature 25 �C, aeration

time 480 min, DO 2.0 and 4.0 mg/L, SRT 15 days). Block nitrate,

filled triangle ammonium, triangle nitrite, lozenge pH

Fig. 7 Change of FA and FNA concentration with time (temperature

22.50 �C, aeration time 480 min, DO 2.0 and 4.0 mg/L, SRT

15 days). Square concentration of FA, filled triangle concentration

of FNA

Bioprocess Biosyst Eng

123

FA increased first and then decreased, while the concen-

tration of FNA decreased first and then increased. As

shown in Eq. 1. FA is a function of the influent ammonia

nitrogen concentration, the pH of the mixed liquid and the

temperature, and the pH showed the greatest influence. For

a given temperature, the concentration of ammonia nitro-

gen gradually decreased as nitrification proceeded. The pH

of the mixed liquid initially increased and then decreased,

which notably impacted the concentration of FA in the

reactor. However, the lowest concentration of FA in the

reactor was 2.1 mg/L, which exceeded the minimum

inhibitory concentration of FA against nitrifying bacteria.

Moreover, the concentration of FNA throughout the reac-

tion cycle was \0.2 mg/L; therefore FA was thought to

cause the accumulation of nitrite in the reactor.

Another reason for the accumulation of nitrite might be

the delamination of aerobic granular sludge. Shi et al. [32]

reported that the concentration of nitrite bacteria was

greater than that of nitrate bacteria in aerobic granular

sludge, and the nitrite bacteria primarily distributed at the

granule surface could obtain sufficient DO to oxidize

ammonia to nitrite. In contrast, the effectiveness of the

nitrate bacteria distributed on the inner layer of the granule

was inhibited by a lack of DO. This was in accordance with

the experimental results.

Conclusion

Using an SBR at 25 �C, with DO above 2.0 mg/L and a

15 days SRT, the simultaneous nitrification and denitrifi-

cation of granular sludge was performed. The average

particle size of the granular sludge was 704.0 lm. The

removal rates of COD, ammonia nitrogen and total nitro-

gen by granular sludge were 77.6, 72.9, and 39.3 %,

respectively. The accumulation rate of nitrite reached

87.8 %. The delamination of granular sludge and a diffu-

sion gradient of DO created the conditions for simulta-

neous nitrification and denitrification. Simultaneous

nitrification and denitrification were the main processes

responsible for total nitrogen removal in the system. A high

pH value, a high concentration of FA and the delamination

of granular sludge were the main mechanisms contributing

to the short-cut nitrification of granular sludge during this

reaction process.

Acknowledgments This research was supported by National

Natural Science Foundation for Young Scholars of China (NO.

51208084); Youth Foundation of Heilongjiang Province of China

(NO. QC2012C089); Science and Technology Research Projects of

Education Department of Heilongjiang Province of China (NO.

12521006); Heilong Jiang Postdoctoral Funds for scientific research

initiation of China (NO. LBH-Q11166); National Science and Tech-

nology Pillar Program of China (NO. 2013BAJ12B02-4).

References

1. Thanh BX, Visvanathan C, Aim RB (2009) Characterization of

aerobic granular sludge at various organic loading rates. Process

Biochem 44(2):242–245

2. Gao DW, Yuan XJ, Liang H (2012) Reactivation performance of

aerobic granules under different storage strategies. Water Res

46:3315–3322

3. Wang JL, Zhang ZJ, Wu WW (2009) Research advances in

aerobic granular sludge. Acta Scientiae Circumstantiae 29(3):

449–473 (in Chinese)

4. Coma M, Verawaty M, Pijuan M, Yuan Z, Bond PL (2012)

Enhancing aerobic granulation for biological nutrient removal

from domestic wastewater. Bioresour Technol 103:101–108

5. Su KZ, Yu HQ (2005) Formation and characterization of aerobic

granules in a sequencing batch reactor treating soy-bean pro-

cessing wastewater. Environ Sci Technol 39:2818–2827

6. Wu CY, Peng YZ, Wang RD, Zhou YX (2012) Understanding the

granulation process of activated sludge in a biological phosphorus

removal sequencing batch reactor. Chemosphere 86(8):767–773

7. Weber SD, Ludwig W, Schleifer KH, Schleifer JFried (2007)

Microbial composition and structure of aerobic granular sewage

biofilms. Appl Environ Microbiol 73:6233–6240

8. Wu L, Peng C, Peng YZ, Li LY, Wang SY, Ma Y (2012) Effect

of wastewater COD/N ratio on aerobic nitrifying sludge granu-

lation and microbial population shift. J Environ Sci 24(2):

234–241

9. Lv Yi, Wan Chunli, Liu Xiang, Zhang Yi, Lee Duu-Jong, Tay

Joo-Hwa (2013) Drying and re-cultivation of aerobic granules.

Bioresour Technol 129:700–703

10. Liu Y, Yang SF, Qin L, Tay JH (2004) A thermodynamic

interpretation of cell hydrophobic in aerobic granulation. Appl

Microbiol Biotechnol 64(3):410–415

11. Liu Y, Yang SF, Tay JH, Liu QS, Qin L, Li Y (2004) Cell

hydrophobicity is a triggering force of biogranulation. Enzym

Microbial Technol 34(5):371–379

12. Liu YQ, Liu Y, Tay JH (2004) The effects of extracellular

polymeric substances on the formation and stability of biog-

ranules. Appl Microbiol Biotechnol 65(2):143–148

13. McSwain BS, Irvine RI, Hausner M et al (2005) Composition

and distribution of extracellular polymeric substances in aerobic

flocs and granular sludge. Appl Environ Microbiol 71(2):

1051–1057

14. Basheer F, Farooqi IH (2012) Biodegradation of p-cresol by

aerobic granules in sequencing batch reactor. J Environ Sci

24(11):2012–2018

15. Wang XH, Jiang X, Shi YJ, Gao MM, Yang S, Wang SG (2012)

Effects of step-feed on granulation processes and nitrogen

removal performances of partial nitrifying granules. Bioresour

Technol 123:375–381

16. Chen FY, Liu YQ, Tay JH, Ning P (2011) Operational strategies

for nitrogen removal in granular sequencing batch reactor.

J Hazard Mater 189:342–348

17. Othman I, Anuar AN, Ujang Z, Hasyimah NR, Harun H,

Chelliapan S (2013) Livestock wastewater treatment using

aerobic granular sludge. Bioresour Technol 133:630–634

18. Tay JH, Yang SF, Liu Y (2002) Hydraulic selection pressure-

induced nitrifying granulation in sequencing batch reactors.

Appl Microbiol Biotechnol 59:332–337

19. Li AJ, Li XY, Yu HQ (2013) Aerobic sludge granulation facil-

itated by activated carbon for partial nitrification treatment of

ammonia-rich wastewater. Chem Eng J 218:253–259

20. Gao JF (2007) Effects of settling time and biofilm on the cul-

tivation of nitrifying aerobic granular sludge. Environ Sci

28(6):1245–1251 (in Chinese)

Bioprocess Biosyst Eng

123

21. Tsuneda S, Nagano T, Hoshino T, Ejiri Y, Noda N (2003)

Characterization of nitrifying granules produced in an aerobic

up flow fluidized bed reactor. Water Res 37:4965–4973

22. Belmonte M, Vazquez-Padın JR, Figueroa M, Francob A,

Mosquera-Corralb A, Camposb JL, Mendezb R (2009) Char-

acteristics of nitrifying granules developed in an air pulsing

SBR. Process Biochem 44:602–606

23. Liu Y, Yang SF, Tay JH (2004) Improved stability of aerobic

granules by selecting slow-growing nitrifying bacteria. J Bio-

technol 108:161–169

24. Zhong C, Wang YQ, Wang YJ, Lv JP, Li YC, Zhu JR (2013)

High-ratenitrogen removal and its behavior of granular sequence

batch Reactor under step-feed operational strategy. Bio Resour

Technol 134:101–106

25. Song YJ, Ishii S, Rathnayake L, Tsukasa I, Satoh H, Okabe S

(2013) Development and characterization of the partial nitrifi-

cation aerobic granules in a sequencing batch airlift reactor.

http://dx.doi.org/10.1016/j.biortech.2013.04.018

26. Aslan S, Miller L, Dahab M (2009) Ammonium oxidation via

nitrite accumulation under limited oxygen concentration in

sequencing batch reactors. Bio Resour Technol 100:659–664

27. APHA (1992) Standard methods for the examination of water

and wastewater�18th ed�washington DC: American Public

Health Association[M], America Water Works Association and

Water Environment Federation

28. Anthonisen AC, Loehr RC, Prakasam TBS, Srinath EG (1976)

Inhibition of nitrification by ammonia and nitrous acid. J Water

Pollut Control Federation 48(5):835–852

29. Wu L, Peng YZ, Wang SY (2010) Quick start and maintenance

of nitrifying granular sludge in SBR process. CIESC J

11(11):2931–2937 (in Chinese)

30. Gao JF, Guo JQ, Chen RN, Su K, Peng YZ (2008) Influence of

SBR drainage height and diameter ratio on aerobic sludge

granulation. China Environ Sci 28(6):512–516

31. L iu YQ, Tay JH (2007) In flu ence of cycle t im e on k inetic beh

aviors of steady-state aerob ic granu les in sequen cing batch

reactors. Enzym Microbial Technol 41(4):516–522

32. Shi XY, Yu HQ, Sun YJ, Huang X (2009) Characteristics of

aerobic granules rich in autotrophic ammonium-oxidizing bac-

teria in a sequencing batch reactor. Chem Eng J 47:102–109

33. Wu L, Peng CY, Peng YZ, Li LY, Wang Shuying, Ma Yong

(2012) Effect of wastewater COD/N ratio on aerobic nitrifying

sludge granulation and microbial population shift. J Environ Sci

24(2):234–241

34. Li AJ, Yang SF, Li XY, Gu JD (2008) Microbial population

dynamics during aerobic sludge granulation at different organic

loading rates. Water Res 42:3552–3560

35. Bassin JP, Pronk M, Kraan R (2011) Ammonium adsorption in

aerobic granular sludge, activated Sludge and anammox gran-

ules. Water Res 45:5257–5265

36. Pochana K, Keller J (1999) Study of factors affecting simulta-

neous nitrification and denitrification (SND). Water Sci Technol

39(6):61–68

37. Fang S, Li XH (2001) The effect of pH on partial nitrification-

denitrification rate of high ammonia-containing wastewater.

J Chem Eng Chin Univ 15(4):346–350 (in Chinese)

38. Tokutomi T (2004) Operation of a nitrite-type airlift reactor at

low DO concentration. Water Sci Technol 49(5–6):81–88

39. Jenicek P, Svehla P, Zabranska J, Dohanyos M (2004) Factors

affecting nitrogen removal by nitritation/denitritation. Water Sci

Technol 9(5–6):73–79

40. Yang SF, Tay JH, Liu Yu (2004) Inhibition of free ammonia to

the formation of aerobic granules. Biochem Eng J 1:41–48

41. Hellinga C, Schellen AAJC, Mulder JW, van Loosdrecht MCM,

Heijnen JJ (1998) The SHARON process: an innovative method

for nitrogen removal from ammonium-rich wastewater. Wat Sci

Technol 37:135–142

42. Chang JS, Cha GC, Kim DJ (2002) Nitrite accumulation char-

acteristics in the nitrification of high strength ammonia waste-

water with biofilm airlift suspension reactor. J Korean Inst Chem

Eng 40:114–120

Bioprocess Biosyst Eng

123