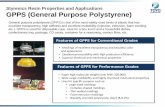

Research On General Purpose Polystyrene (GPPS) Industry Report 2019

An Update on Regulations - ASIQUR · An Update on Global Regulations EPR (Extended Producer...

Transcript of An Update on Regulations - ASIQUR · An Update on Global Regulations EPR (Extended Producer...

An Update on Global Regulations

EPR (Extended Producer Responsibility)GPPS

ISO Packaging RequirementsBio‐Based vs. Degradable vs. Compostable

Victor BellP id t EPIPresident, EPI

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Environmental Packaging International

• Specialists in global environmental packaging & product stewardship requirementsrequirements

• Offices:• Rhode Island, US• New Hampshire, USp ,• Toronto, CA

• Our clients include:

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

What is Extended Producer b l ?

Manufacturer

Responsibility? RetailerConsumer

• Producers take responsibility for their packaging at the post‐consumer stage.

• Shifts responsibility for recycling and waste disposal from local government to private industry, e.g. “producers.”

• Idea behind EPR programs usually is to increase recycling; programs often contain mandated recycling targets.

• EPR also impacts how companies design and choose materials for their products. If producers pay for post‐consumer waste created by their products, it creates an incentive for them to make products that are less wasteful.

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International3

European Packaging Regulations – Present

Packaging fees or eco-tax

Deposits on one-way containers

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International4

Packaging fee and deposit in place. Deposit containers not subject to fees.Eco-tax and fee in place. Containers subject to both regulations.

Asian Packaging Regulations – Present

South Korea

Japan

Turkey

Cyprus Israel

Taiwan

Passed in China!

Packaging fees or eco-tax

Deposits on one-way containers

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International5

Packaging fee and deposit in place. Deposit containers not subject to fees.Eco-tax and fee in place. Containers subject to both regulations.

EPR in Latin America

•Uruguay: EPR for packaging is currently being implemented.

B il•Brazil:•Brazil’s President signed the Omnibus Waste law, which created a National Policy on Solid Waste. The bill calls for EPR of packaging. A committee to oversee implementation of an EPR program has beencommittee to oversee implementation of an EPR program has been formed. It is expected that regulations to create producer take‐back programs should be adopted later this year.•Some cities and states require companies who market products toSome cities and states require companies who market products to “buy back” a percentage of plastic packaging for certain products types such as beverages, foods, lubricating oils, cosmetics, cleaning products and chemical products (but not pesticide packaging).p ( p p g g)

•Argentina and Mexico: Both countries are piloting packaging waste integrated management systems in some regions.

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International6

Packaging & Printed Paperg g p

f ll l b l

see inset

white‐washed symbols mean program proposed

full‐color symbols mean program in‐place or pending

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International© StewardEdge,

program proposed or under consideration

Canadian Stewardship Programsp g

full‐color symbols

white‐washed symbols mean program proposed or under consideration

mean program in‐place or pending

see inset

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International© StewardEdge, Jan. 2011

under consideration

Current Canadian Models for Packaging EPRg g

Jurisdiction Industry Cost Share Trends

Ontario 50% of verified municipal net costs

Government announced transition to 100% industry pay

Quebec 50% of negotiated municipal costs

Government announced transition to 100% industry pay

Manitoba 80% of calculated Launched April 1 2010Manitoba municipal costs Launched April 1, 2010

Saskatchewan (Proposed) 75% of costs (TBD) Regulation expected soon( p )

British Columbia 100% of municipal costs Regulation expected soon

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

North American Packaging Regulations – Present

Saskatchewan may have EPR next in Canada

BC Canada passes k i EPRpackaging EPR

May 2011

Packaging fees or eco‐tax

Deposits on one‐way containers

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International10

Packaging fee and deposit in place. Deposit containers not subject to fees.Eco‐tax and fee in place. Containers subject to both regulations.

EPR in the United States

• Currently – 69 EPR laws in 32 states

• Mostly concerning one product such as waste electronics, batteries or y g p ,mercury switches in automobiles

• Bottle Bills – in 10 states

• States are considering the “framework approach”• States are considering the framework approach

• Establishes EPR as state policy and provides authority to address additional products over time

• The “Perfect Storm”

• States and cities have no $$$

• CPG wants their materials (packaging) recycled

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging InternationalThis information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Principles p

• Internalize costs• Internalize costs

• Brand owner financing

• Brand owner management• Brand owner management

• Achieve high rates and quality

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International12

Packaging Feesg g

• Packaging fees worldwide• In general, fees are based on the amount of packaging (weight) and

material type• More packaging = more $$$ (higher fees)• The more difficult the material is to recycle, the higher the fees• Plastics, laminates and composites can cost up to 500% more than other

materials

• Upcoming Trend• Disruptor fees (very high fees for packaging that negatively impacts

recycling)PLA b l i• PLA bottle, composite can

• LCI‐based fees

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International13

France Disrupter Materialsp

• Glass: Packaging with ceramic or porcelain cap. + 50% FEE

• Liquid food packaging made from a majority of paper/cardboard, but comprising of less than 50% fiber. + 50% FEE

• Plastic: PET Bottles containing aluminum (labels, plugs, caps, inks) or using PVC sleeves or silicone. The density of aluminum, PVC and silicone all are greater than one and therefore these materials cannot be removed by flotation in the recyclingone and therefore these materials cannot be removed by flotation in the recycling process. +50 % FEE

• Packaging paper and cardboard reinforced with polyester (this type of Kraft paper is used for transport packaging that needs to be watertight and has a grid of polyester p p g g g g p yin it to increase the strength of the paper). + 50% FEE

• Non‐recoverable packaging or packing with sorting instructions but without a recycling stream. + 100% FEE

• Examples of non‐recoverable packaging include stoneware and those packages like PVC or PLA bottles and flasks.

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International14

France Disrupter Materialsp

• Bonus/Penalty Factors

• Two percent bonus is given for packaging which has implemented a preventative measure or eco‐design, including weight reduction, volume reduction, re‐use for refills.

• An additional two percent bonus is given for packaging which has a recycling sorting messagesorting message

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International15

Ontario Disrupter Plasticsp

All plastic packaging that contaminates or disrupts the recycling process

• PVC, PLA, PHA and PHB

• Non‐coded rigid plastic

• Multi‐polymer or blended plastics including polymers blended with cellulose and starch

• Examples:

• PVC tubs and cosmetic bags

• PHA hot drink cups and soup cups

• PLA yogurt containers and chip bags

• Cellulose blister packs for salads

• Starch foam package peanuts

• NO FEE DIFFERENCE THIS YEAR BUT MUST BE REPORTED SEPARATELY

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International16

Packaging System ComparisonsPackage 1 – Reese’s Giant BarPackage 1 Reese s Giant BarPackage 2 – Hershey’s Giant Bar

Packaging WeightPackaging Description Packaging Component Material Type Weight

(grams)

Reese’s Giant BarOutside Wrapper Plastic - PP 2.00

Reese s Giant Bar192g

Total Weight 2.00

Outside Wrapper Coated Freesheet 3.00

Hershey’s Giant Bar184g Aluminum Wrapper Aluminum 3.40

Total Weight 6.40

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

International Fee Comparison (per 1000 units)

Country Reese’s Giant Bar Hershey’s Bar

Austria $0.37 $2.55

Belgium $0.81 $0.24

Canada (Ontario) $0.33 $0.52

Czech Republic $0.59 $0.82

France $1.10 $1.60

Germany $3.82 $4.44

Japan $0 49 $0 01Japan $0.49 $0.01

Poland $0.02 $0.16

United Kingdom $0.27 $0.39

Average Fees $0.87 $1.19Average Fees $0.87 $1.19

Fees based on 12/01/ 2008 exchange rates: 1USD = 0.79164 EUR, 1.2375 CAD, 93.683 JPY, 0.6739 GBP

* Number in red denotes the highest fee among the four packaging systems,; number in green denotes the lowest.

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Coffee in Steel vs Plastic vs Composite Bag

Steel Can Coffee HDPE Can Coffee Composite Bag CoffeeSteel Can Coffee

(11.3 oz)

HDPE Can Coffee

(11.3 oz)

Composite Bag Coffee

(12 oz)

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging InternationalThis information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Packaging System Comparisons

Packaging Description Packaging Functional Unit Component Material Type

Weight

(grams)

Steel Can Coffee

Container Steel Container Steel 98.20

Container Lid Lid LDPE 5.90

Container Seal Seal Aluminum 1.70(11.3 oz) Container Label Label PS 1.80

Total Weight 107.60Container Plastic Container HDPE 47.20

HDPE Coffee(11.3 oz)

Container Lid Lid LDPE 10.10

Container Seal Seal Aluminum 1.00

Container Label Label PS 1.00

Total Weight 59 30Total Weight 59.30

Composite Bag

Coffee Bag Coffee BagComposite

LDPE 55% - PET 28% - Aluminum 17%

14.30

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging InternationalThis information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Bag(12 oz) Bag Tie Tie Composite

PP 80% - Steel 20% 10.10

Total Weight 24.40

International Fee Comparison (per 1000 units / 12 oz)

Country Steel (11.3 oz) HDPE(11.3 oz) Composite Bag(12 oz)

Belgium $12.30 $25.28 $13.97Canada (Ontario) $8.02 $9.42 $6.17Canada (Quebec) $7.48 $7.36 $4.79Canada (Manitoba) $13.41 $10.52 $7.91Germany $70.57 $141.88 $43.33$70.57 $141.88 $43.33Japan $4.21 $31.83 $12.55Taiwan $6.43 $15.54 $6.11

F P U i 0 42 1 34 C 0 4 3 18 C 0 48 1 39 CFees Per Unit 0.42 to 1.34 Cents 0.74 to 3.18 Cents 0.48 to 1.39 Cents

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

EPR: Current Status of Related Initiatives

• State Legislation

• U S EPA Dialogue• U.S. EPA Dialogue

• PAC NEXT Initiative

• Ameripen and Sustainable Packaging CoalitionAmeripen and Sustainable Packaging Coalition

• Future 500 Meetings

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International22

Update on CA Rigid Plastic Packaging Container RegulationsRegulations

Compliance Options for RPPCs:

• Be made from 25% post‐consumer materials• Be source reduced – cannot be achieved by changing material type

bl fill bl• Be reusable or refillable• SB 1344 added a new compliance option. Allows the purchase of CA

post‐consumer plastic material for use in other products.• New updated regulations passed 1/2012 (Office of Administrative Law• New, updated regulations passed 1/2012 (Office of Administrative Law

to approval ASAP)

Most companies choose to meet the requirement by adding 25% post ‐Most companies choose to meet the requirement by adding 25% post consumer materials to their RPPC. This could present challenges for bio‐based plastics.

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International23

Packaging Sustainabilitya global project by The Consumer Goods Forum

Who’s Involved - The Team

Consultant supportRetailers Manufacturers Associations

pp• Quantis• GreenBlue• EPI

Academic Academic participation

• University of Arkansas• University of Minnesota• University of Manchester• Rochester Institute of• Rochester Institute ofTechnology

Packaging manufacturers

Common Terms Used to Describe Packaging Typesg g ypPrimary Packaging • Constitutes the packaging designed to come in direct contact with the product.

d k i ( k i )Secondary Packaging (or group packaging) • Groups a given number of primary packaging units together into a convenient unit at

the point of sale.

T i P k i ( k i )Tertiary Packaging (or transport packaging) • Is normally a shipping unit such as an outer case, a pallet, or a crate.

Sales Packaging • Is packaging with which the consumer leaves a store.

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Which Metrics to Use?

• Type of Business Decision

• Simple analysis p y

• Optimizations analysis for a given functional unit

• Comparative analysis (one or more packaging formats/material)

• Full system design and analysis• Full system design and analysis

• Choice of Indicators

• Relevance and significance

• Life cycle phases

• Part of your business

• Role in decision makingg

• Level at which the indicator is used

• How does it align with your company’s goals and objectives

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Which Metrics to Use?

• Availability of Data

• Physical property data• Physical property data

• Data for driving selected indicators (LCI dataset)

• Linkages between different indicatorsLinkages between different indicators

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Walmart Metric Data

Post CO2

Renewable EMaterial

Category Material Name Preferred Preferred Name

Consumer content

Walmart recycle rate

CO2 (metric tons co2 per short ton of material)

Energy (Metric ton BTU per short ton BTU) Total Energy

Number of Uses

Metal & Other Aluminum 1 High 0.51 62 8.29 88.87 117.32 1

Wood/PaperCoated Freesheet (e.g., high‐end magazine)

1 High 0 100 1.03 13.42 37.27 1

Wood/PaperCoated Groundwood (e.g., standard magazine)

1 High 0 100 1.7 22.76 33.25 1

Wood/Paper Corrugated: Bleached 3 Low 0.35 23 0.87 10.59 21.89 1

Wood/Paper Corrugated: Semi‐bleached 3 Low 0.35 23 0.87 10.59 21.89 1

Wood/Paper Corrugated: Unbleached 1 High 0.35 23 0.87 10.59 21.89 1

Wood/Paper Dimensional Lumber 1 High 0 85 0 18 2 38 3 53 1Wood/Paper Dimensional Lumber 1 High 0 85 0.18 2.38 3.53 1

Metal & Other Glass 1 High 0.23 72 0.58 7.36 7.54 1

Polymer HDPE 1 High 0.1 85 1.39 21.49 23.08 1

Polymer LDPE 1 High 0.04 88 1.66 25.28 27.91 1

Wood/Paper Medium‐density Fiberboard 1 High 0.35 100 0.4 5.78 11.88 1

Wood/Paper Paperboard: Coated Recycled 1 High 0 35 65 0 71 10 8 12 19 1Wood/Paper Paperboard: Coated Recycled 1 High 0.35 65 0.71 10.8 12.19 1

Wood/PaperPaperboard: Coated Unbleached Kraft (CUK) 1 High 0 65 0.83 10.31 26.76 1

Wood/PaperPaperboard: Solid Bleached Sulfate (SBS) 1 High 0 65 1.03 13.42 37.27 1

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Role in Communication

Internal vs. External Communication • Marketing• Marketing

• show how a product package has been improved

• Corporate reporting

h d f• to show some improvement over time, e.g. reduction of GHG per unit sold

If the indicators are being used in a decision‐making process, then it is also crucial that the audience be presented with clearly‐stated goals in order to understand what is importantclearly stated goals in order to understand what is important for the company.

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Levels of Significance

The metrics proposed in this protocol, even in the case of life cycle assessment indicators only attempt to estimate “thecycle assessment indicators, only attempt to estimate the true” environmental consequences by estimating potential impacts.

Rule of thumb that differences in LCA metrics such as climate change or energy consumption of less than 10% should notchange or energy consumption of less than 10% should not be considered significant as long as the differences of compared alternatives are not one‐directional.

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Environmental – Attribute Indicators / Metrics /

• An attribute is an indicator that provides partial and/or indirect information with respect to the environmental performance ofinformation with respect to the environmental performance of packaging across its life cycle.

• Attributes provide information, but not assessment.

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

GPPS Attributes

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Attributes Examplep

Packaging Weight and Optimization (Includes Primary, Secondary and Tertiary Packaging)

• Definition ‐ The weight and identity of a packaging constituent, component or system which changes hands in the supply chain and demonstration that the packaging has been optimized by weight or volume in accordance with EN 13428 or ISO/CD 18602 once finalized13428 or ISO/CD 18602, once finalized.

• Metric ‐Weight per packaging constituent, component or system and demonstration of optimization as described by EN 13428 or ISO/CD 18602 once finalized.

• Examples

1. Proof of minimum adequate packaging weight∙ (yes / no)

2. Packaging weight∙ Kilograms / packaging constituent, component, or system

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Packaging to Product Weight Ratio g g g

Definition

• The ratio of the weight of all packaging material used to the weight of the g p g g gproduct or functional unit delivered.

Metric

• Weight of all packaging components used in the packaging system per• Weight of all packaging components used in the packaging system per functional unit.

Examples

• Packaging weight (kg) / FU• Packaging weight (kg) / FU

What to Measure

• Calculate the total weight of the packaging components used in the k i di h l f P k i W i h dpackaging system according to the protocol for Packaging Weight and

Optimization. Determine the ratio to the mass of product or amount of product service delivered per functional unit.

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Environmental – Life Cycle Indicators / Metrics y /

• Life Cycle Assessment (LCA) is a multi‐criteria methodology to quantify the environmental impacts associated with the life cycle of a good or service, from the extraction of the product’s raw material to its final disposal after use.

• According to ISO 14040, a LCA study shall include the following phases: definition of goal and scope, inventory analysis, impact assessment and interpretation of results

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

LCA Analysis y

• Conventional LCA Tools • Conventional LCA tools allow for flexibility on all levels of a LCA. This flexibility

also contributes to some of their draw‐backs: they require considerable expertise and are laborious and costly.

• Ecodesign Tools (Streamline LCA Tools)• LCA‐based tools which open LCA to non‐experts, allowing rapid assessment of

environmental consequences of design decisions already at the concept stage.

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Life Cycle Indicatorsy

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Life Cycle Indicators (What to Consider)y ( )

Functional Unit (FU)

Inventory analysisy y

• Allocation

• Consistency between databases and datasets

• Data quality• Data quality

Impact assessment

• Representative set of impact categories

• Data consistency with impact assessment methodology

• Global, regional and local impacts

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Impact on Climate / Atmosphere

Global Warming Potential (GWP)

1. Definition Gl b l i i l i f ’ ib i li• Global warming potential is a measure of a process’ contribution to climate change.

2. Metric • Mass of CO2 equivalents, e.g. [kg CO2 eq / FU], using the characterization

factors of the 4th assessment report of the Intergovernmental Panel on Climate Change (IPCC).

3. Who/what at the end am I damaging?

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Global Warming Potential (GWP) g ( )

4. How do I damage?

5 Why does it matter?5. Why does it matter?

6. What do I have to check, take into account in my supply chain?

7. When do I have to use/select/consider this indicator?7. When do I have to use/select/consider this indicator?

8. How specific can I interpret the resulting indicator?

9. How can I reduce uncertainty and evaluate the significance of an impact?

10. Who to ask, where to look?

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Economic & Social Attributes and Corporate ChecklistsChecklists

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

Corporate Performance Attributesp

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

International Standards Organization

Subcommittee 4Packaging and the Environmentg g

Voluntary standards will provide theVoluntary standards will provide the packaging value chain with guidance and environmentally responsible approachesenvironmentally responsible approaches to packaging production, use and post-use managementmanagement.

Voluntary Standards• Voluntary standards but prescriptive y p p

– (i.e. if you claim to meet a standard, you must meet all of its requirements)

• Countries could require compliance with the standards• Countries could require compliance with the standards – (like the EU’s Essential Requirements)

• Companies could require application of standardsp q pp– (e.g. a brand owner could say all its packaging will meet by

20xx)

• Retailers could require their suppliers to meet the• Retailers could require their suppliers to meet the standards

Timeline• First meeting in Stockholm – December 2009First meeting in Stockholm December 2009• Second meeting in Beijing – June 2010• Tokyo – October 2010 draft standards completeTokyo October 2010 draft standards complete• Atlanta – May 2011• S Korea May 20 25 2012• S Korea – May 20 - 25, 2012• Final standards scheduled for publication – 2012

EU Essential Requirementsq• The EU Packaging Directive mandates that all packaging

sold in Europe meet a set of “Essential Requirements” related to:related to: – Source Reduction (mandatory)– Recovery (must meet at least one)

– Recyclability– Recyclability– Organic recovery – Energy recovery

– Reuse (optional)– Heavy metals in packaging (mandatory)– Reduction of other hazardous substances (mandatory)

• Packaging that does not comply with these Essential Requirements can legally be banned from EU markets.

• More enforcement coming in both Western and Eastern Europe• NOW become ISO Standards

47

Bio‐Based vs. Degradable vs. Compostableg p

• What is the most likely EOL for bio‐based packaging?

• Where (which country are they going to)? ( y y g g )

• What is the SW infrastructure?

• Can degradable or compostable packaging be recycled?• Can degradable or compostable packaging be recycled?

• If it not composted, what happens?

• Will it be landfilled? What kind of landfill?

• Will it go to resource recovery?

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International48

Where will Compostable Packaging End Up?

Since it’s designed for degradability, there’s concern over methane emissions in

areas which still landfill.

• When biodegradable bioplastics degrade within a landfill, methane (a powerful h h h l b l l f bgreenhouse gas, with over 62 times the Global Warming Potential of carbon

dioxide) is released uncontrollably into the atmosphere at a fast rate (compared to other materials).

• Recent studies have shown that the potential degradability of bio‐based plastics can contribute to rapid anaerobic biodegradation of materials within a landfill, emitting carbon dioxide and methane.

• According to recent estimates by the US EPA, of all the methane generated by U.S. landfills in 2009, 39% was emitted and 57% was captured and combusted. 53% of the combusted amount (30% of the total generated landfill methane) was used for energy recovery. The GHG benefits from this recovery only offset the impacts of emitting about 4% of the methane generated from landfills in 2009. Overall, biodegradation in landfills currently incurs a large harmful greenhouse gas impact

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International49

biodegradation in landfills currently incurs a large harmful greenhouse gas impact and a relatively small greenhouse gas benefit.

Prevalence of Collection and Treatment Infrastructure: US and Canada

Country Past - 2001 MSW

Current - 2011 MSW

Predicted - 2021 MSW

14% 12% 12%

United States

57%

7%

22%54%

26%

54%26%

States

242.5 million tons 249 million tons 278.6 million tons

7%8%

8%

3%3% 5%

Canada22%

3%

25% 27%

30.5 million tons 34.3 million tons 39.6 million tons

75%73% 70%

d f d / f l

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International50

Source: Gershman, Brickner & Bratton, Inc. , 2011

Note: “Composted” refers to organic MSW treated in AD/Composting facilities;. Organic fraction does not include plastic film .“Recycled” includes recyclable rigid plastics.

Prevalence of Collection and Treatment Infrastructure: Germany and Austria

Country Past - 2001 MSW

Current - 2011 MSW

Predicted - 2021 MSW

0.5% 0.5%

Germany30%

24% 18%

34%

18%

34%

41.1 million tons 40.1 million tons 38.7 million tons

17%29% 48%48%

0.4% 0.4%

Austria 29%

41%

16% 18.8%

38.7%

18.8%

38.7%

3.1 million tons 3.8 million tons 3.9 million tons

15%41%42.1% 42.1%

d f d / f l

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International51

Source: Gershman, Brickner & Bratton, Inc. , 2011

Note: “Composted” refers to organic MSW treated in AD/Composting facilities. Organic fraction does not include plastic film .“Recycled” includes recyclable rigid plastics.

Past - 2001 Current - 2011 Predicted - 2021

Prevalence of Collection and Treatment Infrastructure: Latin America

CountryPast - 2001

MSWCurrent - 2011

MSWPredicted - 2021

MSW

B ilBrazil

52 3 million tons 58 9 million tons 68 6 million tons

Argentina

52.3 million tons 58.9 million tons 68.6 million tons

7.2 million tons 8.3 million tons 9.5 million tons

Mexico

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International52

34.8 million tons 38.4 million tons 47 million tons Note: Improper disposal includes open dumps, roadside ditches, and other non-controlled locations.

Source: Gershman, Brickner & Bratton, Inc. , 2011

Path to Organic Recycling

Barrier 2:Compostable plastics not

accepted into

Barrier 1:Inconsistent labeling of

compostable plastics p

industrial facilities

plastics

Compostable plasticsCompostable plasticsUS - ASTM 6400 certified/labeled With BPI logo

Canada - CAN/BNQ 0017-988certified/labeled with BNQ logo Influence communication within waste

t f t bl l tistream for compostable plastics

Increase market share of compostable plastics in existing markets

SPC study showed many composting facilities consider promoting compostable packaging*

Responsible brand owner introduction needed

Focused scenarios for placing compostable plastic on the market

closed loop food discard composting operations (e.g. restaurants, sporting events)

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International53

*SPC Report “Compostable Packaging: The Reality on the Ground 2010

Bio‐Based Plastic

Rigid Plastic

• Stick to commonly

Flexible Plastic

• Limited recycling (mainly yrecycled resin (PET, HDPE, etc.)

• No degradables

y g ( yclosed‐loop)

• No degradables

• Be careful withg

• Be careful with compostables

• Understand where the

• Be careful with compostables

• Understand where the packaging will goUnderstand where the

packaging will go

• No greenwashing!!!

packaging will go

• Which countries

• What is the EOL

N hi !!!• No greenwashing!!!

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International54

The Solution: Overview offers an innovative solution for worldwide compliance reporting,

corporate benchmarking and data management needs, including:

•Extended Producer Responsibility (packaging, electronics and battery fee reports to authorities and waste recovery organizations and submission of reports to support worldwide compliance with environmental legislation)

•What‐if costing tool•Allows suppliers to report directly into retailer (Walmart) sustainable packaging scorecards•GPP tool (streamlined LCA)•Corporate environmental benchmarking•Comprehensive Bill of Materials (BOM) data management•Design‐for‐Environment analyses for evaluating packaging and product designs•Provides REAL Data

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International

redipoint Reports

• redipoint features a powerful reporting component that enables users to generate customizable reports on demand.

p p

• Six different report types are available:

• Material Usage

• Retailer Report• Retailer Report

• Obligation

• Fee Calculator

i• Metric Report

• Retailer Scorecard Calculator

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International56

Questions?

Contact EPI at:Victor BellVictor BellEnvironmental Packaging International41 Narragansett AvenueJamestown, RI, 02835 USATel: (401) 423 2225Fax: (401) 423 2226www.enviro-pac.com

This information is copyrighted and cannot be copied or distributed without prior written consent from Environmental Packaging International57

![11B 14B (k) vs vs vs vs vs vs vs vs vs vs vs vs vs vs vs ...sanspo-dbls-golf.com/pdf/2017/20171114c.pdf · 11B 14B (k) vs vs vs vs vs vs vs vs vs vs vs vs vs vs vs *7+1 Y—F2 Ll.]](https://static.fdocuments.us/doc/165x107/5bf8a68d09d3f294138c8536/11b-14b-k-vs-vs-vs-vs-vs-vs-vs-vs-vs-vs-vs-vs-vs-vs-vs-sanspo-dbls-golfcompdf2017.jpg)