An intelligent view box system for cephalometry

Click here to load reader

-

Upload

yen-ting-chen -

Category

Documents

-

view

225 -

download

5

Transcript of An intelligent view box system for cephalometry

98 IEEE TRANSACTIONS ON INSTRUMENTATION AND MEASUREMENT, VOL. 54, NO. 1, FEBRUARY 2005

An Intelligent View Box System for CephalometryYen-Ting Chen, Member, IEEE, Kuo-Sheng Cheng, Senior Member, IEEE, Jia-Kuang Liu, and Ji-Jer Huang

Abstract—In the routine analysis of cephalometry, the orthodon-tist usually needs to manually draw the tracing paper with the helpof the view box, and then some cephalometric measurements areperformed to evaluate growth aspects of the skull and the effects oftreatment. Due to the varied display quality and clinical training,many orthodontists rely heavily on the view box rather than thecomputer monitor for cephalometry. Without the appropriate andaffordable digital imaging devices, the computerized analysis forcephalometry is hard to apply in practice. In this paper, a noveldesign of an intelligent view box that combines an X-ray film viewbox, a touch panel, and analysis software is proposed. It is de-signed for acquiring both the landmarks and feature curves of thecephalogram for the automated cephalometric system use. Thereare two merits of the proposed system. One is that the relationshipbetween the label and position for manually defined landmarksmay be automatically corrected, and the other is that the manualdrawing process may be automatically followed and guided basedon the cephalogram. In addition, the proposed system also includesan image manipulation system. Thus, both the landmarks and fea-ture curves may be automatically and correctly overlaid on thecephalogram for further assessment. From the experimental re-sults, the repeated repositioning of the pen in ten times only pro-duces a standard deviation not more than 0.5 mm in and direc-tions. The spatial resolution for the proposed intelligent view boxsystem is about 164 pixels/inch. It is demonstrated to be very usefulin the clinics for the automated cephalometric analysis.

Index Terms—Cephalometry, touch panel, view box, X-ray film.

I. INTRODUCTION

I N THE routine cephalometric analysis, the commonly usedmethod is to place a semitransparent sheet of tracing paper

over the headfilm, then trace the salient anatomical features,identify the landmarks, and finally perform the associatedmeasurements of distances and angles among the landmarklocations [1]. To date, several computer-assisted systems forcephalometric analysis and automated landmarking have beenproposed. Halazonetis [2] developed the software for cephalo-metric analysis and released the package named “Viewbox.”The user may manually locate the landmarks on the computerscreen. The cephalometric measurements and analysis werethen made. The images of the cephalogram, a panoramic, anda facial photograph had to be captured by digital camera or

Manuscript received August 28, 2002; revised May 12, 2004. This work wassupported in part by the National Science Council, R.O.C., under ContractsNSC86-2745-B-006-001-M08 and NSC 90-2213-E-230-002.

Y.-T. Chen is with the Department of Electrical Engineering, Southern TaiwanUniversity of Technology, Tainan, 710 Taiwan, R.O.C.

K.-S. Cheng is with the Institute of Biomedical Engineering, Na-tional Cheng Kung University, Tainan, 701 Taiwan, R.O.C. (e-mail:[email protected]).

J.-K. Liu is with the Department of Dentistry, College of Medicine, NationalCheng Kung University, Tainan, 701 Taiwan, R.O.C.

J.-J. Huang is with the Precision Instrument Development Center, Hsinchu,300 Taiwan, R.O.C.

Digital Object Identifier 10.1109/TIM.2004.840232

scanner. Other proposed ideas [3]–[7] focused on the processfor automatically locating the landmarks. They put the effortson computerizing the work for analyses with a digitized image.Besides, the method and procedure for image acquisition is alsoan important issue. The digitized image with bad quality maymiss some important features and make the image processingbecome complicated. Thus, the computerized cephalometricanalysis system is vastly needed in clinics.

In general, an ideal computerized cephalometric analysissystem should require the following features.

1) This system should integrate the appropriate input/outputdevices for acquiring image data of both the cephalogramand tracing paper, and printing the patient records. This isvery important for modern hospitals in electronic patientrecords.

2) The image analysis software should be included forformat transformation of image data, file handling, auto-mated landmarking, cephalometric analysis, cephalogramsuperimposition, and the related manipulation.

3) A friendly user interface should be designed in this systemto ease the usage and training. Online help and tutorialswill be very helpful in this clinical application for thecomputer novice.

4) The computer network is also needed for image archivingand communications inside hospitals or among hospitals.

5) The measured patient’s data and their norms (means andstandard deviations) of the general population in age andgender should be included for easy look-up, comparison,and case tracing.

Above all, the input device for cephalogram and tracing paperis the most important issue. With the computerized system, thelandmarking, superimposition, and parameters measurementprocedure can be facilitated and become more efficient. Theprecision and reliability can be significantly improved. Errorsarising from manual measurement can be significantly reduced.The work for computerized cephalometric analysis system isstill developing. This paper will focus on the development ofnew device with the touch panel for directly digitizing tracingdata.

As mentioned above, the image-acquiring device is veryimportant for a computerized cephalometric system. It easesthe job to acquire the images of X-ray films. Besides, adigitized image with poor quality will make the follow-upprocedures of image processing and data analysis more dif-ficult. In recent years, commercially-available scanners anddigital cameras have become cheaper with higher resolution.Those medical images are easier to be digitized than before.However, the input device for cephalometric analysis is stilllimited in use. For example, the frequently used device for thework of landmark locating and feature tracing is a digitizer,

0018-9456/$20.00 © 2005 IEEE

CHEN et al.: INTELLIGENT VIEW BOX SYSTEM FOR CEPHALOMETRY 99

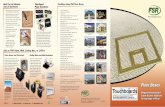

Fig. 1. (a) Configuration of the proposed system. (b) View box and the controller circuit board.

or computer monitor with a mouse. Unfortunately, they arenot easily operated for obtaining smooth feature lines. More-over, due to the varied display quality and clinical training,the orthodontists rely more heavily on the view box than themonitor for cephalometry.

Now, a touch panel is available to provide an interactiveinterface for a user to operate with a finger or pen [8]–[10]. Thewell-known applications include electronic books, portablecomputers, cell phones, etc. In this paper, we developed anintelligent view box system that combines a view box and

a touch panel to directly acquire the information of spatialanatomical features, as lines and points from the X-ray film. APentium-based PC is employed as the system kernel to controlthe proposed system. Besides, an image manipulation systemis also included for handling the images and files. The imagedata for X-ray film is acquired using a camera or scanner. Theconfiguration of this proposed system is illustrated in Fig. 1(a).The picture of the view box is shown in Fig. 1(b), and thecontroller attached in the box is displayed on the top rightcorner.

100 IEEE TRANSACTIONS ON INSTRUMENTATION AND MEASUREMENT, VOL. 54, NO. 1, FEBRUARY 2005

Fig. 2. (a) Pen dents the top layer to touch the bottom layer. (b) Illustrates thedesign for pen position measurement.

II. SYSTEM DESIGNS

A. Hardware Designs

The hardware part for the proposed system contains aview box, touch panel, hand supporter, and a main controlcircuit board including a touch screen controller ADS7843(Burr-Brown Corp. Dallas, TX), a microprocessor 89C51,and the related peripheral circuits. It communicates with thecomputer via the RS-232 port.

The touch panel has a four-wire output with two switchlayers. The top switch layer is a thin flexible polyester film;one side of which is coated with an abrasion and chemicalresistant high-gloss hardcoat, while the other side is sputteredwith a uniform coating of indium tin oxide (ITO), a transparentconductive material. The bottom switch layer is ITO-coatedglass. The two layers are separated with uniformly distributedimperceptible particles. As the panel is pressed or touched,the force dents the flexible polyester film of the top layer atthe pressed position as shown in Fig. 2(a). Thus, the voltagevariation can be measured from the electrodes on the sides ofpanel.

The ADS7843 is a 12-b analog-to-digital converter (ADC)with a synchronous serial interface and low on-resistanceswitches for driving the touch panel. It works in the specificmode called Differential Reference Mode. This mode convertsthe analog signal into a digital signal in a constant ratio. Themeasurement is made in two phases. In one phase, the voltagegradient method is applied to measure the horizontal voltagevariation from the -electrode while a constant voltage is ap-plied to the -electrode. The other phase measures the verticalelectrical variation from the -poles with the application ofthe same constant voltage to the -electrode. The measuredvoltages are then converted to be the digital values of andcoordinates, respectively. The details for this technology can befound on the website www.burr-brown.com. Fig. 2(b) shows a

Fig. 3. (a) Data format of the output. (b) Flow chart of control routines forthe touch panel.

measurement of a voltage difference for the -electrode with avoltage applied to -electrode.

The 89C51 is a low-power, high-performance, 8-b CMOS mi-crocontroller with 4 kB of flash programmable and erasable readonly memory (PEROM). It handles the functions of the maincontrol circuit board for acquiring the serial data string fromthe ADS7843 and communicating with the computer via theRS-232 port. The baud rate is set to be 9600 b/s, and every datastring is in 6 B format as depicted in Fig. 3(a). The start bytes

CHEN et al.: INTELLIGENT VIEW BOX SYSTEM FOR CEPHALOMETRY 101

are defined as 0xF0 and 0xFF, followed by the low byte and thehigh byte of -value, and then those of -value. In application,200 sample points can be obtained within a second.

B. Control Routines

The data handling routine and a window-based image manip-ulation system has been developed. The data handling routineis responsible for data acquisition, coordinate registration, noiseelimination, and position calibration tasks as shown in Fig. 3(b).The resolution of the mouse is not the same as that of the panelsystem. Therefore, the procedure of registration is to match twocoordinates of the mouse and touch panel. While a tracing line isdrawn on the panel, it inevitably receives a more or less unstablesignal coupled with noise arisen from uncertain touches. The ac-quired data points are processed by a median filter [11] to elimi-nate the spatial variation for representing the stable touched po-sition. The procedure of calibration is performed to correct thepoint position in reference with the look-up table as describedin the following section. The calibrated position of the touchedpoint is shown on the displaying monitor. While the touch is re-leased, i.e., a tracing line is finished, the system will enter in awaiting state for detecting a new touch.

C. Generation of Look-Up Table

A look-up table approach is applied for mapping eachtouched point on the panel to its real coordinate. In order toconstructing this look-up table with required performance, aprinted circuit board (PCB) engraving machine (EverprecisionTech. Corp.’s EP9702III, Taiwan, R.O.C.) is employed forresolution and stability tests. It has the traveling ranges of up to310 and 220 mm with the resolution of 0.005 mm along andabscissas, respectively. The drill is substituted by an elastic penso as not to damage the touch panel. A point-position matrixwith 8*10 points in equal spaces is located to cover the mainoperation area of the panel. It is 2 cm between points in thecolumns and rows, and the points are set by using the engravingmachine to acquire the real positions as dictated by the panel.Each point is taken ten times, and the difference between thestandard position and the average of the located positions forthe same point is calculated out to be the corresponding entryin the look-up table. Fig. 4 shows the positions drift for thetest points. The circle represents the real touch position ofthe tested point located by the PCB engraving machine andthe cross labels the acquired position of the same touch pointresponded from the touch panel. It is seen that some areas havesignificant drifts. Therefore, the look-up table recording thedrifting distance of points is built. For every touch point, theLagrangian interpolation [12] is applied to correct the positionof extracted points referring to the standard points drifting.

D. Image Manipulation System

The associated system developed with Microsoft VC++ 6.0provides a user-friendly environment for image data manage-ment and analysis. Fig. 5 illustrates the tree graph of the menufunctions. The following is a list of the main functions includedin the image manipulation system:

Fig. 4. Drifts for touch points. Circles are the touch points located by the PCBengraving machine and the crosses are the acquired position of those touchpoints.

Fig. 5. The tree graph of the functions for the automated cephalometic system.

1) File: The images, including X-ray films and tracing pa-pers, may be combined to help understand the morpho-logical relation of the obtained data. The landmarks ac-quired with a mouse or touch panel, which characterizethe geometry of the skull, are involved in the cephalo-metric measurements for clinical use.

102 IEEE TRANSACTIONS ON INSTRUMENTATION AND MEASUREMENT, VOL. 54, NO. 1, FEBRUARY 2005

2) Data Acquisition: The data of the landmarks and fea-ture curves are acquired from the proposed view box ora mouse. The corresponding image can be taken with anadditional camera or scanner.

3) Calibration and Registration: The calibration determinesthe spatial resolution of the panel by locating two assignedpoints at the left-top and the right-bottom corners of a rect-angular area. After that, the registration helps to registerthe real X-ray film on the panel and the displayed imageon the monitor according to the orientation of two pointsmarked on the film. A sequence of the geometrical trans-formations of scaling, translation, and rotation would helpto align the image and the panel coordinates.

4) Cephalometric Analysis: The cephalometric analysisprovides a series of linear and angular measurementsbased on the landmarks and feature curves that are devel-oped currently used in National Cheng Kung UniversityHospital for orthodontic analysis. These computed mea-surements would be more reliable and accurate than themanual measurements [13].

5) Print: The images and the resulting analysis can be se-lectively combined as a part of patient record and printedin hardcopy for diagnosis, documentation, and treatmentplaning, and evaluation.

III. EXPERIMENTAL RESULTS AND DISCUSSION

A. Performance Evaluation

The performance of the proposed system was tested in regardsto the resolution, stability, and reproducibility. These terms con-cerning in this study are defined as follows.

1) Resolution: How close two points can be discriminatedfrom each other?

2) Stability: How much does the signal of a long-time touchdrift?

3) Reproducibility: Is the same position read out when thesame place is touched a certain number of times?

The PCB engraving machine is used to perform these tests. Theprocedures and the results for these tests are elaborated in thefollowing.

1) Resolution: Five sequences of point-array on five areas(I: right-top, II: left-top, III: left-bottom, IV: right-bottom, andV: center area) of the panel are uniformly distributed and se-lected as illustrated in Fig. 6. Each sequence has nine pointswith different intervals varying from 0.04 to 5.00 mm, and everypoint is repeatedly located 20 times. A student -test is then ap-plied to evaluate the distributions of each pair of adjacent points.The results of the -values are summarized in Table I. The firstrow lists the labels for the pair of points and the distance be-tween them. The data for each point-pair from 1–2 to 6–7 re-veals the significant difference with a high level of confidence,i.e., 99.5%. The extracted from the Student -table is2.71 with the degree of freedom 38. This shows that the resolu-tion of the panel with X-ray film is about 0.155 mm (164 dpi).According to our experiences, it is small enough for the cephalo-metric analysis to reflect the subtle feature curves drawings.

Fig. 6. Test areas on the touch panel.

TABLE IT-VALUES OF POINT PAIRS GROUP IN RESOLUTION TEST

2) Stability: This test evaluates the stability of the outputsignal of the control circuit when a position at the panel is con-tinually pressed. The stability mainly depends on the perfor-mance of the A/D converter and the related circuits. Ten indi-vidual points are randomly sampled on the panel. Then, a plasticpen held by the PCB engraving machine is placed on each po-sition with a constant force for a while, and the output signal ofthe control circuit is uniformly sampled 300 times. The standarddeviations for these data of ten points range from 0.15 to 0.24mm on the -axis and 0.32 to 0.50 mm on the -axis, respec-tively. It is shown that this proposed system is very stable for aconstant touch.

3) Reproducibility: Because of its intrinsic characteristics,the output signal from the touch panel will return to a range ofvalues after each touch. Therefore, it is important to test whetherthe generated signal retains the same value to represent the sameplace for several touches. This reproducibility characteristic de-pends on the charging capabilities of the panel, and is assessedas follows. Each of four randomly selected positions on thepanel is touched ten times. The results show that the standard de-viations of these data range from 0.07 to 0.16 mm on the -axisand 0.07 to 0.26 mm on the -axis, respectively. It is demon-strated that the measurement precision of the proposed systemis very suitable and useful for cephalometric analysis.

B. Application Example

An example of the traced feature lines from the X-rayheadfilm drawn on the proposed intelligent view box for theorthodontic application is demonstrated in Fig. 7(a). The pa-tient’s information can be edited in the Patient Informationdialog. Three kinds of methods can be selected to locatethe landmarks: fully computerized landmarking, interactive

CHEN et al.: INTELLIGENT VIEW BOX SYSTEM FOR CEPHALOMETRY 103

Fig. 7. (a) Example of orthodontic analysis for drawing the feature curves using the proposed system. (b) Determined landmarks and their associatedcephalometic printout.

manual landmarking with mouse, or touch panel. We have alsodeveloped a heuristic image processing system for computer-ized landmarking. Almost all of the defined landmarks can belocated automatically. The orthodontist can manually locatethe landmarks or modify the position of landmarks located by

computerized landmarking. The landmarks can be defined onthe screen using the mouse or on the touch panel using the touchpen. Fig. 7(b) shows the window for print preview. Two pagesare displayed, one for the obtained landmarks and the otherfor the patient’s information and associated measurements.

104 IEEE TRANSACTIONS ON INSTRUMENTATION AND MEASUREMENT, VOL. 54, NO. 1, FEBRUARY 2005

The corresponding head X-ray film is also exhibited for visualscreening. The traced lines can pertinently represent the featurecurves or edges of the X-ray film.

IV. CONCLUSION

In this paper, the X-ray film view box and touch panel arecombined and used for the cephalometric analysis system. Theimage manipulation system is designed and included to help theorthodontist to directly acquire spatial data from X-ray film onthe panel for the cephalometric application. With this intelligentview box, not only may the orthodontist draw the feature curvesand landmarks with automatic correction in his traditional wayon the view box, but the image data may also be passed to andstored in a computer for later processing. In addition, the imagedata may be used independently for clinical measurements aswell as combined with the feature curves and landmarks forvisual screening. A four-wire touch panel is adopted in thissystem. The other kinds of touch panels could be used as well.However, the calibration and tests proposed in the paper shouldbe performed for the adopted panel. From the experimental re-sults, the look-up-table-based calibration is shown to provide ahighly accurate spatial response for the four-wire panel. Overall,the performance tests demonstrate that the touch panel is quitestable and has high resolutions suitable for cephalometric anal-ysis.

Furthermore, the image manipulation system, including theautomated landmarking, cephalometric analysis, and cephalo-gram superimposition, significantly advances the add-on valueof this proposed system for orthodontic analysis. With this novelproposed system, most of the functions for the ideal computer-ized cephalometric analysis may be achieved. In addition, it maybe integrated and extended to other applications for acquiringimage data of different types. Currently, the functions for com-munication and networking for image archiving are under de-velopment for e-orthodontics.

ACKNOWLEDGMENT

The authors would like to thank Dr. Y.-H. Chiu with the In-stitute of Biomedical Engineering, National Cheng Kung Uni-versity and Y.-M. Chen with the Project Information Company,Ltd. for helpful comments in the circuit design.

REFERENCES

[1] A. Jacobson, Radiographic Cephalometry: From Basics toVideoimaging. Chicago, IL: Quintessence, 1995.

[2] D. J. Halazonetis, “Computer-assisted cephalometric analysis,” Amer. J.Orthod. Dentofac. Orthop., vol. 105, no. 5, pp. 517–521, 1994.

[3] A. D. Lévy-mandel, A. N. Venetsanopoulos, and J. K. Tsotsos, “Knowl-edge-based landmarking of cephalograms,” Comput. Biomed. Res., vol.19, pp. 282–309, 1986.

[4] S. Parthasarathy, S. T. Nugent, P. G. Gregson, and D. F. Fay, “Auto-matic landmarking of cephalograms,” Comput. Biomed. Res., vol. 22,pp. 248–269, 1989.

[5] W. Tong, S. T. Nugent, P. H. Gregson, G. M. Jensen, and D. F. Fay,“Landmarking of cephalograms using a microcomputer system,”Comput. Biomed. Res., vol. 23, pp. 358–379, 1990.

[6] J. Cardillo and M. A. Sid-Ahmed, “An image processing system for lo-cating craniofacial landmarks,” IEEE Trans. Med. Imag., vol. 13, no. 2,pp. 275–289, Feb. 1994.

[7] D. J. Rudolph, P. M. Sinclair, and J. M. Coggins, “Automatic comput-erized radiographic identification of cephalometric landmarks,” Amer. J.Orthod. Dentofac. Orthop., vol. 113, no. 2, pp. 173–179, 1998.

[8] J. A. Pickering, “Touch-sensitive screens: The technologies and theirapplications,” Int. J. Man-Manchine Studies, vol. 25, pp. 249–269, 1986.

[9] B. Shneiderman, “Touch screens now offer compelling uses,” IEEESoftw., vol. 8, no. 2, pp. 93–94, 107, Mar./Apr. 1991.

[10] T. Sato, J. Ichikawa, M. Mitsuishi, H. Miyazaki, and Y. Hatamura,“Micro-teleoperation with manual task execution posture,” IEEE Con-trol Syst. Mag., vol. 15, no. 1, pp. 22–29, Feb. 1995.

[11] R. C. Gonzalez and R. E. Woods, Digital Image Processing, 2nded. Reading, MA: Addison-Wesley, 1992.

[12] W. B. Bickford, Finite Element Method. Burr Ridge, IL: Irwin, 1994.[13] J. K. Liu, Y. T. Chen, and K. S. Cheng, “Accuracy of computerized

automatic identification of cephalometric landmarks,” Amer. J. Orthod.Dentofac. Orthop, vol. 118, no. 5, pp. 535–540, 2000.

Yen-Ting Chen (M’03) was born in Chia-Yi, Taiwan,R.O.C., on November 10, 1966. He received the B.S.degree in electrical engineering from Feng Chia Uni-versity, Taichung, Taiwan, in 1989, and the M.S. andPh.D. degrees in biomedical engineering from Na-tional Cheng Kung University, Taiwan, in 1991 and2000, respectively.

He is currently an Assistant Professor with theDepartment of Electrical Engineering, SouthernTaiwan University of Technology, Tainan, Taiwan.His research interests are in the field of medical

image processing and applications.

Kuo-Sheng Cheng (S’82–M’90–SM’97) was bornin Taipei, Taiwan, R.O.C., on February 4, 1958. Hereceived the B.Sc. and M.Sc. degrees in electrical en-gineering from the National Cheng Kung University,Tainan, Taiwan, in 1980 and 1982, respectively, theM.S. degree in biomedical engineering from Rensse-laer Polytechnic Institute, Troy, NY, in 1988, and thePh.D. degree in electrical engineering from the Na-tional Cheng Kung University in 1990.

He is now a Professor with the Institute of Biomed-ical Engineering, National Cheng Kung University.

His research interests include medical image processing, electrical impedanceimaging, and microcomputer-based biomedical instrumentation.

Jia-Kuang Liu was born in Taiwan, R.O.C., in 1957.She received the B.D.S. degree from National TaiwanUniversity, Taipei, Taiwan, in 1981.

She is currently an Associate Professor with theCollege of Medicine, National Cheng Kung Univer-sity, Tainan, Taiwan, and Chair with the Division ofOrthodontics, Dental Department, National ChengKung University Hospital. She also has been Chairof the Dental Department, National Cheng KungUniversity Hospital since 2002 and from 1997 to2000. Her research interests are orthodontic material,

dental image and biomechanics in orthodontics.

Ji-Jer Huang was born in Nan-Tou, Taiwan, R.O.C.,in 1968. He received the B.S. degree in electricalengineering from Feng Chia University, Taiwan, in1992 and the M.S. and Ph.D. degrees in biomedicalengineering from National Cheng Kung University,Taiwan, in 1994 and 2001, respectively.

He is currently Associate Researcher with the Pre-cision Instrument Development Center, Hsinchu Sci-ence-Based Industrial Park, Taiwan. His research in-terests include electronic circuits design, microcom-puter-based biomedical instrumentation, as well as

electrical impedance imaging.