American Honda Motor Company - BF25D BF30D Owner’s Manual · 2013. 6. 18. · Honda Motor Co.,...

Transcript of American Honda Motor Company - BF25D BF30D Owner’s Manual · 2013. 6. 18. · Honda Motor Co.,...

-

BF25D•BF30DOwner’s Manual

©2004 Honda Motor Co., Ltd. -All Rights Reserved31ZW260200X31-ZW2-6020

2eY11000.2004.04Printed in JapanN

PANTONE 288 DIC F101 31ZW2602 00X31-ZW2-6020BLACK

2005

-

The engine exhaust from thisproduct contains chemicalsknown to the State of California tocause cancer, birth defects, orother reproductive harm.

The information and specifications included in this publication were in effect at thetime of approval for printing. Honda Motor Co., Ltd. reserves the right, however, todiscontinue or change specifications or design at any time without notice and withoutincurring any obligation whatever. No part of this publication may be reproducedwithout written permission.

Keep this owner’s manual handy, so you can refer to it at any time. This owner’smanual is considered a permanent part of the outboard motor and should remain withthe outboard motor if resold.

04/03/15 17:54:12 31ZW2600_001

-

1

INTRODUCTION

Congratulations on your selection ofa Honda outboard motor. We arecertain you will be pleased with yourpurchase of one of the finestoutboard motors on the market.

We want to help you get the bestresults from your new outboardmotor and to operate it safely. Thismanual contains the information onhow to do that; please read itcarefully.

As you read this manual you willfind information preceded by a

symbol. That informationis intended to help you avoid damageto your outboard motor, otherproperty, or the environment.

We suggest you read the warrantypolicy to fully understand itscoverage and your responsibilities ofownership.

When your outboard motor needsscheduled maintenance, keep in mindthat your Honda marine dealer isspecially trained in servicing Hondaoutboard motors. Your Honda marinedealer is dedicated to yoursatisfaction and will be pleased toanswer your questions and concerns.

2004 Honda Motor Co., Ltd. AllRights Reserved

04/03/15 17:54:18 31ZW2600_002

-

-

-

-

-

-

-

2

A FEW WORDS ABOUTSAFETY

INTRODUCTION

Safety Messages

Safety Headings

Safety Labels

Safety Section

Instructions

IMPORTANT SAFETY INFORMATION.

OUTBOARD MOTOR SAFETY.

Your safety and the safety of othersare very important. And using thisoutboard motor safely is an importantresponsibility.

To help you make informeddecisions about safety, we haveprovided operating procedures andother information on labels and inthis manual. This information alertsyou to potential hazards that couldhurt you or others.

Of course, it is not practical orpossible to warn you about all thehazards associated with operating ormaintaining an outboard motor. Youmust use your own good judgment.

You will find important safety information in a variety of forms, including:

This entire book is filled with important safety information please read itcarefully.

preceded by a safety alert symbol and one ofthree signal words, DANGER, WARNING, or CAUTION.

These signal words mean:

such as

on the outboard motor.

such as

how to use this outboard motor correctly and safely.

You WILL be KILLED or SERIOUSLYHURT if you don’t follow instructions.

You CAN be KILLED or SERIOUSLYHURT if you don’t follow instructions.

You CAN be HURT if you don’t followinstructions.

04/03/15 17:54:31 31ZW2600_003

-

3

CONTENTS

...................................OUTBOARD MOTOR SAFETY . 7................IMPORTANT SAFETY INFORMATION . 7

................................SAFETY LABEL LOCATIONS . 9

..................................CONTROLS AND FEATURES . 10CONTROL AND FEATURE

................................IDENTIFICATION CODES . 10....COMPONENT AND CONTROL LOCATIONS . 11

..............................................................CONTROLS . 16SH, LH, SHG and LHT Types (long tiller handle)

.................Recoil Starter Grip (SH and LH types) . 16

.................Ignition Switch (SHG and LHT types) . 16.............Emergency Stop Switch and Switch Clip . 17

..........................................................Throttle Grip . 17.....................................Throttle Friction Adjuster . 18

.....................................................Gearshift Lever . 18.....................................Steering Friction Adjuster . 18

Tilt Lever..........................(manual tilt/SH and LH types) . 19

(gas assist tilt/SHG, SRG.............................................and LRG types) . 19

SRG, LRG, SRT and LRT Types (remote control)........................Ignition Switch (side-mount type) . 20

Switch Clip and Emergency Stop Switch..............................................(side-mount type) . 21

.........................Fast Idle Lever (side-mount type) . 21

Gearshift/Throttle Control Lever..............................................(side-mount type) . 22

Common ControlsPower Trim/Tilt Switch

..........(SRT and LRT types) (side-mount type) . 23........................................................(LHT type) . 23

....Power Tilt Switch (LHT, SRT and LRT types) . 23Manual Relief Valve

..............................(LHT, SRT and LRT types) . 24Tilt Lock Lever

(SHG, LHT, SRG, LRG, SRT.............................................and LRT types) . 24...........................................Engine Cover Latches . 24

.............................Transom Angle Adjusting Rod . 25................................................................Trim Tab . 25

.......................................................INSTRUMENTS . 26.........................Trim Meter (optional equipment) . 26

............................................................Tachometer . 26

............................................................Fuel Gauge . 26...........................................................INDICATORS . 27

............................................Oil Pressure Indicator . 27.................................................Overheat Indicator . 28

.....................................Cooling System Indicator . 29

04/03/15 17:54:35 31ZW2600_004

-

?

?

4

CONTENTS

................................................OTHER FEATURES . 29.....................................................Overrev Limiter . 29

...................................................................Anodes . 29................................................Portable Fuel Tank . 30

.............................................Fuel Cap Vent Knob . 30.................................................Fuel Priming Bulb . 31

..........................................................INSTALLATION . 32.....................................POWER REQUIREMENTS . 32

...................BOAT TRANSOM REQUIREMENTS . 32..................................INSTALLATION POSITION . 32

.......................................................ATTACHMENT . 33.....................TRANSOM ANGLE ADJUSTMENT . 34

...................................BATTERY CONNECTIONS . 34

................................................BEFORE OPERATION . 37.....ARE YOU READY TO GET UNDER WAY . 37

IS YOUR OUTBOARD MOTOR................................................READY TO GO . 37

................................................................OPERATION . 39....................SAFE OPERATING PRECAUTIONS . 39

.......................................BREAK-IN PROCEDURE . 39.....................TRANSOM ANGLE ADJUSTMENT . 40

.......................................PORTABLE FUEL TANK . 42................................FUEL HOSE CONNECTIONS . 42

.......................................................FUEL PRIMING . 43

......................................STARTING THE ENGINE . 43SH, LH, SHG and LHT Types

.............................................(long tiller handle) . 43SRG, LRG, SRT and LRT Types

.................................................(remote control) . 46.....................................EMERGENCY STARTING . 48

.......................................STOPPING THE ENGINE . 51................................Emergency Engine Stopping . 51

.......................................Normal Engine Stopping . 51GEARSHIFTING AND

..............................THROTTLE OPERATION . 53SH, LH, SHG and LHT Types

.............................................(long tiller handle) . 53SRG, LRG, SRT and LRT Types

.................................................(remote control) . 54...............................................................STEERING . 55

SH, LH, SHG and LHT Types.............................................(long tiller handle) . 55

SRG, LRG, SRT and LRT Types.................................................(remote control) . 55

................................................................CRUISING . 56

................................................................TRIM TAB . 58......................SHALLOW WATER OPERATIONS . 58

...............MOORING, BEACHING, LAUNCHING . 61

04/03/15 17:54:39 31ZW2600_005

-

5

CONTENTS

..............SERVICING YOUR OUTBOARD MOTOR . 64...........THE IMPORTANCE OF MAINTENANCE . 64

.....................................MAINTENANCE SAFETY . 65TOOL KIT AND

.......................EMERGENCY STARTER ROPE . 66...............................MAINTENANCE SCHEDULE . 67

....................................TRIM TAB ADJUSTMENT . 69

....................................MANUAL RELIEF VALVE . 70ENGINE COVER REMOVAL AND

.............................................INSTALLATION . 70........................................Engine Oil Level Check . 71

................................................Engine Oil Change . 72..............................Engine Oil Recommendations . 73

.................................................Lubrication Points . 74................................................Spark Plug Service . 75

.............................................................REFUELING . 77...............................FUEL RECOMMENDATIONS . 78

.....Fuel Pump Filter Inspection and Replacement . 79................Portable Fuel Tank and Filter Cleaning . 81

..............................................Anode Replacement . 82..........................................Propeller Replacement . 83

....................................................................STORAGE . 84...................................STORAGE PREPARATION . 84

..........................................Cleaning and Flushing . 84........................................................................Fuel . 87

.............................................................Engine Oil . 89...................................STORAGE PRECAUTIONS . 89

...............................REMOVAL FROM STORAGE . 90

........................................................TRANSPORTING . 91WITH OUTBOARD MOTOR INSTALLED

.............................................................ON BOAT . 91WITH OUTBOARD MOTOR REMOVED

.......................................................FROM BOAT . 92

TAKING CARE OF UNEXPECTED..........................................................PROBLEMS . 94

BATTERY WILL NOT CHARGE AND.ELECTRIC STARTER WILL NOT OPERATE . 99

.................................................Fuse Replacement . 99OIL PRESSURE INDICATOR LIGHT GOES OFF

................AND ENGINE SPEED IS LIMITED . 100OVERHEAT INDICATOR LIGHT COMES

..........ON AND ENGINE SPEED IS LIMITED . 101........................................SUBMERGED MOTOR . 102

04/03/15 17:54:43 31ZW2600_006

-

-

6

CONTENTS

TECHNICAL AND CONSUMER.................................................INFORMATION . 104

.............................TECHNICAL INFORMATION . 104....................................Serial Number Locations . 104

Carburetor Modification for High Altitude.........................................................Operation . 105

.................................................................Battery . 105................................................Oxygenated Fuels . 106

...............Emission Control System Information . 107............................................................Star Label . 109

......................................................Specifications . 111.............................CONSUMER INFORMATION . 115

.............................................Honda Publications . 115............................Customer Service Information . 115

.............Distributors Limited Warranty 2005 . 116...................Emission Control System Warranty . 118

.........................................................................INDEX . 120

........................WIRING DIAGRAMS . Inside Back Cover

04/03/15 17:54:47 31ZW2600_007

-

7

IMPORTANT SAFETYINFORMATION

Operator Responsibility

OUTBOARD MOTOR SAFETY

Most accidents can be prevented ifyou follow all instructions in thismanual and on the outboard motor.The most common hazards arediscussed below, along with the bestway to protect yourself and others.

It is the operator’s responsibility toprovide the necessary safeguardsto protect people and property.Know how to stop the enginequickly in case of emergency.Understand the use of all controls.

Attach the emergency stop switchlanyard securely to the operator.

Stop the engine immediately ifanyone falls overboard, and do notrun the engine while the boat isnear anyone in the water.

Always stop the engine if youmust leave the controls for anyreason.

Always wear a PFD (PersonalFlotation Device) while on theboat.

Familiarize yourself with all lawsand regulations relating to boatingand the use of outboard motors.

Be sure that anyone who operatesthe outboard motor receives properinstruction.

Be sure the outboard motor isproperly mounted on the boat.

Do not remove the engine coverwhile the engine is running.

Honda BF25D and BF30D outboardmotors are designed for use withboats that have a suitablemanufacturer’s powerrecommendation. Other uses canresult in injury to the operator ordamage to the outboard motor andother property.

04/03/15 17:54:58 31ZW2600_008

-

8

Carbon Monoxide HazardRefuel With Care

OUTBOARD MOTOR SAFETY

Exhaust gas contains poisonouscarbon monoxide. Avoid inhalationof exhaust gas. Never run the enginein a closed garage or confined area.

Gasoline is extremely flammable,and gasoline vapor can explode.Refuel outdoors, in a well-ventilated area, with the enginestopped. Never smoke neargasoline, and keep other flamesand sparks away.

Remove any portable fuel tankfrom the boat for refueling. Keepthe portable fuel tank away fromthe battery or other potential sparksources.

Refuel carefully to avoid spillingfuel. Avoid overfilling the fueltank.

After refueling, tighten the fillercap securely. If any fuel is spilled,make sure the area is dry beforestarting the engine.

04/03/15 17:55:05 31ZW2600_009

-

9

SAFETY LABEL LOCATIONS

OUTBOARD MOTOR SAFETY

The labels shown here contain important safety information. Please read them carefully. These labels are consideredpermanent parts of your outboard motor. If a label comes off or becomes hard to read, contact an authorized HondaMarine servicing dealer for a replacement.

(SHG, SRG and LRG types)

04/03/15 17:55:23 31ZW2600_010

-

10

CONTROL AND FEATURE IDENTIFICATION CODES

CONTROLS AND FEATURES

Model

Type

Shaft Length

Power Trim/Tilt

Long Tiller HandleRemote Control

BF25D BF30D

Recoil StarterElectric StarterManual TiltGas Assist Tilt

Trim Meter (optional equipment)Battery Charging DC Receptacle

Tachometer

SL

SHG LHT SRG LRG SRT LRT LHT LRG SRT LRTSHGSH LH LH

Refer to this chart for an explanation of the Type Codes used in this manual to identify control and feature applications.

R=Remote Control

L

T=Power Trim/Tilt

R TTYPE CODE (Example)

H=Long Tiller Handle

S=Short ShaftL=Long Shaft

G=Gas assist Tilt

04/03/15 17:55:39 31ZW2600_011

-

11

COMPONENT AND CONTROL LOCATIONSSH, LH, SHG and LHT Types(long tiller handle)

CONTROLS AND FEATURES

OIL FILLER CAP

OIL LEVELDIPSTICK

EXHAUST PORT

ENGINE COVER

POWER TILTSWITCH(LHT type)

ANTIVENTILATIONPLATE

TRIM TAB (anode)

GEAR OIL LEVELCHECK PLUG

TRANSOM ANGLEADJUSTING ROD

LONG TILLERHANDLE

COOLING SYSTEMINDICATOR

FUEL HOSE CONNECTOR

CLAMPSCREW

ANODE(SHG andLHT types)

GEAR OILDRAIN/FILLPLUG

ENGINE OILDRAIN PLUG

WATER INTAKE

TILT LEVER(SHG type)

TILT LOCK LEVER(SHG and LHT types)

TILT LEVER(SH and LH types)

STERNBRACKET

WASH PLUG(flush plug)

MANUAL RELIEF VALVE(LHT type)

PROPELLER

04/03/15 17:55:47 31ZW2600_012

-

12

CONTROLS AND FEATURES

SWITCH CLIP

LANYARD

POWER TRIM/TILT SWITCH(LHT type)

THROTTLE GRIP

EMERGENCY STOPSWITCH

THROTTLE FRICTIONADJUSTER

OIL PRESSUREINDICATOR LIGHT(SHG and LHT types)

OVERHEATINDICATOR LIGHT(SHG and LHT types)

OIL PRESSUREINDICATOR LIGHT(SH and LH types)

STEERING FRICTIONADJUSTER

RECOIL STARTER GRIP(Recoil starter type/SH andLH types)

IGNITION SWITCH(Electric starter type/SHG and LHT types)

IGNITION SWITCH KEY(Electric starter type/SHG andLHT types)

GEARSHIFT LEVER

04/03/15 17:55:53 31ZW2600_013

-

13

SRG, LRG, SRT and LRT Types (remote control)

CONTROLS AND FEATURES

OIL LEVELDIPSTICK

EXHAUST PORTANTIVENTILATIONPLATE

FUEL HOSECONNECTOR

TRIM TAB(anode)

ENGINE COVER

GEAR OIL LEVELCHECK PLUG

WATER INTAKE

TILT LOCK LEVER

COOLING SYSTEMINDICATOR

STEERINGPLATE

TRANSOM ANGLEADJUSTING ROD

ANODE

GEAR OIL DRAIN/FILL PLUG

ENGINE OILDRAIN PLUG

OIL FILLER CAP

TILT LEVER(SRG and LRG types)

WASH PLUG(flush plug)

MANUAL RELIEFVALVE(SRT and LRT types)

POWER TILT SWITCH(SRT and LRT types)

STERNBRACKET

PROPELLER

04/03/15 17:55:59 31ZW2600_014

-

14

Remote Control box (side-mount type)

CONTROLS AND FEATURES

SWITCH CLIP

LANYARD

GEARSHIFT/THROTTLECONTROL LEVER

NEUTRAL RELEASE LEVER

OIL PRESSURE INDICATOR LIGHT

SPARE SWITCH CLIP

BUZZER (inside of the box)

EMERGENCY STOP SWITCH

IGNITION SWITCH IGNITION SWITCH KEY

FAST IDLE LEVER

THROTTLE FRICTION ADJUSTER

OVERHEAT INDICATOR LIGHT

POWER TRIM/TILT SWITCH(SRT and LRT types)

04/03/15 17:56:04 31ZW2600_015

-

15

Trim Meter(optional equipment)

TachometerFuel Tank

CONTROLS AND FEATURES

FUEL HOSE CONNECTOR(female)

FUEL GAUGEVENT KNOB

FUEL CAP

PRIMING BULB

FUEL TANK

FUEL HOSE

04/03/15 17:56:12 31ZW2600_016

-

16

CONTROLS

SH, LH, SHG and LHT Types(long tiller handle)

CONTROLS AND FEATURES

OFF

ONSTART

STARTER GRIP

IGNITION SWITCH

Recoil Starter Grip(SH and LH types)

Ignition Switch(SHG and LHT types)

Turning the ignition switch key to theSTART position operates the startermotor. The key automatically returnsto the ON position when releasedfrom the START position.

The ignition switch can be used tostart the engine only when thegearshift lever (p. ) is in the N(neutral) position, and the switch clipis in the emergency stop switch.

Turning the ignition switch to theOFF position stops the engine.

The ignition switch controls theignition system and starter motor.

The engine will not start unless thegearshift lever (p. ) is in the N(neutral) position, and the clip is inthe engine stop switch.

Pull the starter grip to operate therecoil starter for starting the enginemanually.

18

18

04/03/15 17:56:23 31ZW2600_017

-

17

CONTROLS AND FEATURES

THROTTLE GRIP

INCREASE

THROTTLEINDEX MARK

LANYARD SWITCH CLIP

SWITCH CLIP

LANYARD

EMERGENCY STOPSWITCH

Throttle GripEmergency Stop Switch andSwitch Clip

The throttle grip controls enginespeed.

The switch clip must be inserted inthe engine stop switch in order forthe engine to start and run. Thelanyard should be attached to theoperator’s PFD (Personal FlotationDevice) or worn around the wrist asshown.

When used as described, theemergency stop switch and lanyardsystem stops the engine if theoperator falls away from the controls.

An index mark on the tiller armshows throttle position and is helpfulfor setting the throttle correctly whenstarting (p. ).

A spare switch clip is supplied withthe motor (p. ).

44

66

04/03/15 17:56:34 31ZW2600_018

-

18

CONTROLS AND FEATURES

THROTTLE GRIP

RELEASE

FIX

THROTTLE FRICTIONADJUSTER

GEARSHIFTLEVER

STEERING FRICTION ADJUSTER

F(forward)

N (neutral) R (reverse)

INCREASE

DDEECCRREEAASSEE

IINNCCRREEAASSEE

STEERINGFRICTIONADJUSTERBOLT

DECREASE

Gearshif t LeverThrottle Friction Adjuster Steering Friction Adjuster

(SH and LH types)

(SHG and LHT types)The gearshift lever is used to select F(forward), N (neutral), or R (reverse)gears.

The engine can be started with thegearshift lever in the N (neutral)position only.

The throttle friction adjuster adjustsresistance to throttle grip rotation.

Turn the adjuster clockwise toincrease friction for holding a throttlesetting while cruising.

Turn the adjuster counterclockwise todecrease friction for easy throttle griprotation.

04/03/15 17:56:45 31ZW2600_019

-

19

CONTROLS AND FEATURES

TILT LEVER

TTIILLTT

RRUUNN((LLOOCCKK))

TTIILLTT

RRUUNN((LLOOCCKK))

TTIILLTT LLEEVVEERR

Tilt Lever(manual tilt/SH and LH types)

(gas assist tilt/SHG, SRG andLRG types)

The steering friction adjuster adjustssteering resistance.

Less friction allows the outboardmotor to turn more easily. Morefriction helps to hold steady coursewhile cruising or to prevent theoutboard motor from swinging whiletrailering the boat.

The tilt lever enables the outboardmotor to be raised for shallow wateroperation, beaching, launching, ormooring.

Moving the tilt lever to the TILTposition allows the outboard motor tobe tilted and moving the tilt lever tothe RUN (LOCK) position locks theoutboard motor in the desiredposition. Use the tilt lever totemporarily tilt the outboard motorwhen the boat is operating in shallowwater, or mooring in shallow water.The tilt lever must be in the RUN(LOCK) position before operatingthe outboard motor or the motorcould tilt up when operating inreverse.

To tilt, move the lever to the TILTposition, then raise the outboardmotor until the tilt mechanismengages at 30°, 45°, 75° (p. and

).60

61

04/03/15 17:56:56 31ZW2600_020

-

20

SRG, LRG, SRT and LRTTypes (remote control)

CONTROLS AND FEATURES

EMERGENCYSTOP SWITCH

SWITCH CLIPLANYARD

SWITCH CLIPLANYARD

EMERGENCYSTOP SWITCH

SWITCH CLIP

ON START

IGNITIONSWITCH

OOFFFF

Switch Clip and Emergency StopSwitch (side-mount type)

Ignition Switch(side-mount type)

Turning the ignition switch key to theSTART position operates the startermotor. The key automatically returnsto the ON position when releasedfrom the START position.

The ignition switch can be used tostart the engine only when thegearshift lever (p. ) is in the N(neutral) position, and the switch clipis in the emergency stop switch.

Turning the ignition switch to theOFF position stops the engine.

For panel mount or top mount remotecontrol information, refer to theinstructions provided with the remotecontrol equipment.

The ignition switch controls theignition system and starter motor.

22

04/03/15 17:57:07 31ZW2600_021

-

21

CONTROLS AND FEATURES

N (neutral)

GEARSHIFT/THROTTLECONTROL LEVER FAST IDLE

FAST IDLE LEVER

SPARE SWITCH CLIP

START

Fast Idle Lever(side-mount type)

Leave the fast idle lever in theSTART position to provide a richfuel mixture for starting a coldengine.

Lift the fast idle lever to warm up acold engine after starting and to starta warm engine.

The fast idle lever is used to set idlespeed during warm-up.

The lever will not move unless thegearshift/throttle control lever is inthe N (neutral) position. Conversely,the gearshift/throttle control leverwill not move unless the fast idlelever is in the lowest position.

The switch clip must be inserted inthe emergency stop switch in orderfor the engine to start and run. Thelanyard must be attached to theoperator’s PFD (Personal FlotationDevice) or worn around the wrist asshown.

When used as described, theemergency stop switch and lanyardsystem stops the engine if theoperator falls away from the controls.

A spare switch clip is stored in a slotin the control housing.

04/03/15 17:57:18 31ZW2600_022

-

22

CONTROLS AND FEATURES

HIGH

GEARSHIFT/THROTTLECONTROL LEVER

N (neutral)

R (reverse)F (forward)

EENNGGIINNEESSPPEEEEDD

EENNGGIINNEESSPPEEEEDD

HHIIGGHH

GEARSHIFT/THROTTLECONTROL LEVER

NEUTRALRELEASELEVER

Gearshif t/Throttle ControlLever (side-mount type)

Moving the control lever 30° from N(neutral) selects the gear, and furthermovement increases engine speed.

The gearshift/throttle control levercontrols engine speed and selects F(forward), N (neutral), or R (reverse)gears.

Less friction allows easier controllever movement. More friction helpsto hold a steady throttle setting whilecruising.

A friction adjuster near the base ofthe control lever adjusts the operatingresistance of the control lever (p. ).

The control lever automatically locksitself in the N (neutral) position. Tomove the lever out of the N (neutral)position, you must squeeze theneutral release lever on the undersideof the lever handle.

54

04/03/15 17:57:27 31ZW2600_023

-

23

Common Controls

CONTROLS AND FEATURES

POWER TILT SWITCH

CONTROL LEVERPress UP to trimor tilt the motorup.

Press DN to trimor tilt the motordown.

POWER TILT SWITCH

POWER TRIM/TILT SWITCH

PPrreessss UUPP ttoo ttrriimm oorrttiilltt tthhee mmoottoorr uupp..

PPrreessss DDNN ttoo ttrriimm oorrttiilltt tthhee mmoottoorr ddoowwnn..

Power Trim/Tilt SwitchPower Tilt Switch(LHT, SRT and LRT types)

(LHT type)

[SRT and LRT types (side-mounttype)]

The power tilt switch is located onthe engine pan. It is a rocker switchwith UP and DN (down) positionsfor changing the angle of theoutboard motor.

The power tilt switch will operatewithout turning the ignition switchON.

This switch is used with the enginestopped to raise the outboard motorfor mooring, trailering ormaintenance.

The power trim/tilt switch is locatedon the control lever or the tillerhandle. It is a rocker switch with UPand DN (down) positions forchanging the angle of the outboardmotor.

Tilt the outboard motor for shallowwater operation, beaching, launching,or mooring.

Trim the outboard motor to obtainthe best performance and stability(p. ).

You can use the power tilt switchanytime the ignition switch is ON,whether the boat is underway orstopped.

56

04/03/15 17:57:41 31ZW2600_024

-

24

CONTROLS AND FEATURES

LLOOCCKK

FRONT

REAR

MANUAL RELIEF VALVE

MANUAL(To release)

FFRREEEE

UNLATCH

FFIIXX

RIGHT STERN BRACKET

POWER(To fix)

TTIILLTT LLOOCCKKLLEEVVEERR

ENGINE COVERLATCH

Manual Relief Valve Tilt Lock Lever Engine Cover Latches(LHT, SRT and LRT types) (SHG, LHT, SRG, LRG, SRT

and LRT types)

When the boat is to be moored for along time, tilt the outboard motor asfar as it will go. Then move the tiltlock lever to the LOCK position, andgently lower the outboard motor untilthe lever contacts the stern bracket.

The tilt lock lever is used to supportthe outboard motor in the fully-raisedposition.

The outboard motor can be tiltedmanually after opening the manualrelief valve. This allows the outboardmotor to be tilted when no battery isconnected.

The engine cover latches fasten theengine cover to the outboard motor.

04/03/15 17:57:52 31ZW2600_025

-

25

CONTROLS AND FEATURES

TRIM TAB

TIGHTENING BOLT

PROPELLER

TRANSOM ANGLEADJUSTING ROD

TRANSOM ANGLEADJUSTING ROD

Transom Angle Adjusting Rod Trim Tab(SH and LH types)

(SHG, LHT, SRG, SRT andLRT types)

The transom angle adjusting rodlimits the tilt angle of the outboardmotor when fully lowered.

Proper adjustment prevents theoutboard motor from being trimmedtoo low (p. ).

The trim tab compensates for‘‘torque steer,’’ which is a reaction ofthe outboard motor to propellerrotation.

If uncompensated, torque steer wouldmake the outboard motor tend to turnto one side.

When the trim tab is correctlyadjusted (p. ), steering effort isequal in either direction.

56

69

04/03/15 17:58:03 31ZW2600_026

-

26

INSTRUMENTS

Trim Meter

Tachometer Fuel Gauge

[optional equipment (SRT andLRT Types)]

(SHG, LHT, SRG, LRG, SRTand LRT Types)

CONTROLS AND FEATURES

TRIM METER

FUEL GAUGE

TACHOMETER

Refer to the trim meter when usingthe power trim/tilt switch to achieveproper boat performance.

The trim meter has a range of 0° to16° and indicates the trim angle ofthe outboard motor.

A fuel gauge is built into the cap ofthe portable fuel tank.

The tachometer shows engine speedin revolutions per minute.

Refer to the tachometer when usingthe throttle and power trim/tiltcontrols to achieve the bestperformance from the boat.

04/03/15 17:58:15 31ZW2600_027

-

27

INDICATORS

Oil Pressure Indicator

CONTROLS AND FEATURES

BUZZER

((GGRREEEENN))

((GGRREEEENN))

((GGRREEEENN))

(side-mount type)SRG, LRG, SRT and LRT Types

SHG and LHT Types

SH and LH Types

When the green light is lit, oilpressure is OK.

If oil pressure becomes low, thegreen light will go off, and theengine protection system will limitengine speed. Refer to TAKINGCARE OF UNEXPECTEDPROBLEMS, p. .

Remote controls are also equippedwith a buzzer that sounds when thegreen light goes off.The buzzer sound stops below anengine speed of 1,400 rpm.

Low oil pressure indicates that theengine oil level is low, or that there isa problem with the engine lubricationsystem.

100

04/03/15 17:58:28 31ZW2600_028

-

28

Overheat Indicator

CONTROLS AND FEATURES

(RED)(RED)

BUZZER

(side-mount type)SHG and LHT Types

SRT and LRT Types

TAKING CARE OFUNEXPECTED PROBLEMS

If the engine overheats, the red lightwill come on, and the engineprotection system will limit enginespeed.

If the condition persists for another20 seconds, the engine will shut off.When normal engine temperature isrestored, the engine speed willgradually rise to normal engine speed.Refer to

, p. .

Remote controls are also equippedwith a buzzer that sounds when thered light comes on.

Engine overheating may be the resultof clogged water intakes.

101

04/03/15 17:58:37 31ZW2600_029

-

29

Cooling System Indicator OTHER FEATURES

Overrev Limiter

Anodes

CONTROLS AND FEATURES

COOLING SYSTEM INDICATOR

LEFT STERNBRACKET

ANODE(time tab)

ANODE(SHG, LHT, SRG, LRG, SRT andLRT types only)

The engine is equipped with anoverrev limiter to prevent thepossibility of mechanical damagefrom excessive engine speed.

The overrev limiter may be activatedduring operation, limiting enginespeed, if the outboard motor is tiltedexcessively, or when propellerventilation occurs during a sharp turn.

If the overrev limiter is activated,check the trim angle of the outboardmotor.

The cooling system indicatordischarge port can also becomeplugged.

Water should flow from the coolingsystem indicator while the engine isrunning. This shows that water iscirculating through the coolingsystem.

If water stops flowing while theengine is running, that indicates acooling system problem, such asclogged water intakes, which willcause engine overheating.

04/03/15 17:58:47 31ZW2600_030

-

30

Portable Fuel Tank Fuel Cap Vent Knob

CONTROLS AND FEATURES

VENT KNOB

FUEL CAP

OOPPEENNCCLLOOSSEE

The anodes are made of a sacrificialmaterial that helps to protect theoutboard motor from corrosion.

There are two anodes on the gearcase, one on the stern bracket, andanother is the trim tab.

The portable fuel tank has a capacityof US gal ( ) and has a fuelgauge built into the cap.

The cap is provided with a vent knobto seal the portable fuel tank forcarrying it to and from the boat.Open the vent knob 2 or 3 turnsbefore starting the engine (p. ).

256.6

42

04/03/15 17:58:56 31ZW2600_031

-

31

Fuel Priming Bulb

CONTROLS AND FEATURES

PRIMING BULB

INLET END(TANK)

OUTLET END(MOTOR)

UP

A priming bulb is built into the fuelhose that connects the fuel tank to theoutboard motor.

Before starting the engine, hold thepriming bulb up in the direction ofthe arrow, then squeeze the primingbulb until it feels firm. This willensure that fuel is supplied to theengine (p. ).43

04/03/15 17:59:02 31ZW2600_032

-

-

- -

--

17.0 in (431 mm)21.7 in (552 mm)

32

POWER REQUIREMENTS

BOAT TRANSOMREQUIREMENTS

INSTALLATION POSITION

INSTALLATION

CENTER LINE

TTRRAANNSSOOMMHHEEIIGGHHTT

IIDDLLEEPPOORRTT

0 50 mm(0 2.0 in)

Correct and secure installation isessential for safe boating and goodperformance. Follow the installationinstructions provided in this manual.

Before installation, check to be surethat the outboard motor does notexceed the recommended maximumhorsepower for the boat on which itis to be installed. Refer to the boat’scertification plate for recommendedmaximum horsepower. If thecertification plate information is notavailable, contact the boat dealer ormanufacturer.

For most applications, the outboardmotor should have a horsepowerrating which provides 80% of themaximum recommended horsepowerfor the boat.

The antiventilation plate of theoutboard motor should be 0 2.0inches below the bottom of the boat.

Transom Height

Honda BF25D and BF30D outboardmotors can be installed on a boattransom having a thickness range of1.3 2.2 inches (35 57 mm).

Install the outboard motor on thecenter of the boat transom.

TypeSL

04/03/15 17:59:15 31ZW2600_033

-

33

ATTACHMENT

INSTALLATION

WASHERBOLT

MOUNTING HOLE

WASHERTRANSOMBOARD

ROPE

LOCKNUT

LOCK NUT

CLAMP SCREW(tiller handle type)

WASHER

Attach the stern bracket to the boattransom by tightening the clampscrews.

Attach a rope from the boat to thehole in the stern bracket. This willhelp to prevent accidental loss of theoutboard motor.

You may further secure the outboardmotor by bolting the stern bracket tothe boat transom. Use the optionalmounting bolt and nut kit or othergood quality stainless steel bolts, nuts,and washers. Apply silicone sealantto the bolt holes.

When the outboard motor is installedextremely low, the idle port may beimmersed and the engine maybecome hard to start or may runpoorly. Check that the idle port ishigh enough from the water levelwhen the engine is stopped with theboat fully loaded.

If the outboard motor is installed toohigh, that will cause ventilation.

Optimum installation height varieswith boat type and bottom shape.Contact the boat manufacturer forany special recommendations that areunique to a specific model of boat.

If the transom needs to be modifiedto accommodate the outboard motor,contact the boat manufacturer andfollow their recommendations forcorrective action.

04/03/15 17:59:27 31ZW2600_034

-

+-

34

TRANSOM ANGLEADJUSTMENT

BATTERY CONNECTIONS

Types With Electric Starter

Types With Recoil Starter

INSTALLATION

BLACK

RED

( ) TERMINAL

( ) TERMINAL

The battery should be kept in acorrosion-resistant battery box that issecurely mounted in a location awayfrom the fuel tank and protectedfrom water and direct sunlight.

These types are equipped withbattery cables. The positive (+) cablehas a red band at the batteryconnector. The negative (-) cable hasa black band at the battery connector.

These types are equipped with a 12-volt DC battery-charging receptaclewhich can be wired to a 12-voltbattery to power lights and electricalaccessories for the boat.

Use the transom angle adjusting rod(p. ) to adjust the angle of theoutboard motor so the propeller isperpendicular to the surface of thewater.

Honda BF25D and BF30D outboardmotors produce a 12-volt, 4 or 10-ampere battery-charging current andare equipped for connection to a 12-volt battery. The battery-chargingcircuit is protected by a 15-amperefuse located in the enginecompartment.

For electric starter operation, use a12-volt battery with an ampere-hourrating of at least 65 Ah (CCA 420).

The outboard motor’s 12-volt outputis intended for battery charging only.Lights and electrical accessories forthe boat should be connected to thebattery.

40

04/03/15 17:59:39 31ZW2600_035

-

-

--

+

12V-65Ah (CCA 420)

35

Plug and Receptacle

Battery

Battery Terminals

Minimum Requirements

(types with recoil starter)

INSTALLATION

RED

BATTERY

DC RECEPTACLE

( ) TERMINAL

TTOO BBAATTTTEERRYY

( ) TERMINAL

BLACK

To prepare the outboard motor forconnection to a battery, pull the coverout of the DC receptacle, connectyour battery charging wires to thereceptacle. Attach the connected DCreceptacle on the holder on the tillerarm.

The receptacle is provided with acover, which should be attachedwhen the plug is removed, in order tokeep the receptacle clean and dry.

The negative (-) battery cable shouldalways be removed from the batterywhen connecting or disconnectingthe positive (+) battery cable, so toolscannot cause a short circuit if theytouch a grounded part while beingused on the positive (+) batteryterminal fitting.

Connect the positive (+) battery cableto the positive (+) battery terminal,then connect the negative (-) batterycable to the negative (-) batteryterminal.

For complete information, refer tothe battery manufacturer’sinstructions.

04/03/15 17:59:52 31ZW2600_036

-

36

INSTALLATION

Be caref ul to avoid connecting thebattery in reverse polarity, as thatwill damage the battery-chargingsystem in the outboard motor.

04/03/15 17:59:55 31ZW2600_037

-

Improperly maintainingthis outboard motor, orfailing to correct a problembefore operation, can causea malfunction in which youcould be seriously hurt orkilled.

Always perform apreoperation inspectionbefore each operation, andcorrect any problem.

37

ARE YOU READY TO GETUNDER WAY?

Safety

KnowledgeIS YOUR OUTBOARDMOTOR READY TO GO?

BEFORE OPERATION

Your safety is your responsibility. Alittle time spent in preparation willsignificantly reduce your risk ofinjury.

Read and understand this manual.Know what the controls do and howto operate them.

Familiarize yourself with theoutboard motor and its operationbefore you get under way. Knowwhat to do in case of emergencies.

Familiarize yourself with all lawsand regulations relating to boatingand the use of outboard motors.

Always wear a PFD (PersonalFlotation Device) while on the boat.

Attach the emergency stop switchlanyard securely to your PFD or toyour wrist.

For your safety, and to maximize theservice life of your equipment, it isvery important to take a fewmoments before you operate theoutboard motor to check its condition.Be sure to take care of any problemyou find, or have your authorizedHonda marine dealer correct it,before you operate the outboardmotor.

Before beginning your preoperationchecks, be sure the ignition switch isin the OFF position.

04/03/15 18:00:08 31ZW2600_038

-

38

Safety Inspection Maintenance Inspection

BEFORE OPERATION

Look around the outboard motorfor signs of oil or gasoline leaks.

Check the engine oil level (p. ).Running the engine with a low oillevel can cause engine damage.

Check to be sure the propeller isundamaged, and the castle nut issecured with the cotter pin (p. ).

Check that the anodes are securelyattached to the gear case (p. )and are not excessively worn. Theanodes help to protect the outboardmotor from corrosion.

Check the fuel level in the fueltank (p. ).

Check that all fasteners are inplace and securely tightened.

If you are using the portable fueltank, make sure it is in goodcondition and properly secured inthe boat (p. ).

Check that the fuel hose isundamaged and properlyconnected (p. ).

Wipe up any spills before startingthe engine.

Check the stern bracket to be surethe outboard motor is securelyinstalled.

Check that all controls areoperating properly.

Replace any damaged parts. Check that the battery fluid isbetween the upper and lower levels,and the battery leads are connectedsecurely (electric starter type).

Make sure the tool kit andemergency starter rope areonboard (p. ). Replace anymissing items.

42

42

71

83

82

77

66

04/03/15 18:00:23 31ZW2600_039

-

39

SAFE OPERATINGPRECAUTIONS

BREAK-IN PROCEDURE

Break-in period: 10 hours

First 15 minutes:

Next 45 minutes:

Next 60 minutes:

Next 8 hours:

OPERATION

IMPORTANT SAFETYINFORMATION

BEFORE OPERATION.

To safely realize the full potential ofthis outboard motor, you need acomplete understanding of itsoperation and a certain amount ofpractice with its controls.

Before operating the outboard motorfor the first time, please review the

on page and thechapter titled

For your safety, avoid starting oroperating the engine in an enclosedarea. Your engine’s exhaust containspoisonous carbon monoxide gaswhich can collect rapidly in anenclosed area and cause illness ordeath.

Proper break-in operation allows themoving parts to wear in smoothly forbest performance and long servicelife.

Run the engine at trolling speed. Usethe minimum throttle openingnecessary to operate the boat at a safetrolling speed.

Run the engine up to a maximum of2,000 to 3,000 rpm, which is about10% to 30% of maximum throttleopening.

Run the engine up to a maximum of4,000 to 5,000 rpm, which is about50% to 80% of maximum throttleopening.

Short full-throttle bursts are OK, butdo not operate the enginecontinuously at full throttle.

For boats that plane easily, bring theboat up on plane, and then reduce thethrottle opening to the recommendedrpm range.

Do not run the engine at full throttlefor more than 5 minutes at a time.

7

04/03/15 18:00:38 31ZW2600_040

-

40

TRANSOM ANGLEADJUSTMENT

OPERATION

TO LOCKLOCKED POSITION

TO CHANGE

TTUURRNN UUPP

UNLOCKEDPOSITION

TRANSOM ANGLEADJUSTING ROD

PPUUSSHH

TRANSOM ANGLEADJUSTING ROD

IDLE EXHAUST PORT

Do not allow water to enter the idleexhaust port or the engine can bedamaged.

The transom angle adjusting rodlimits the tilt angle of the outboardmotor when fully lowered.

To adjust, first tilt the outboardmotor so it is not resting on the rod.

Proper adjustment prevents theoutboard motor from being trimmedtoo low (p. ).

Push the rod in and turn the end ofthe rod up, so the latch will fall intoline with the rod.

Remove the rod and reinsert it in thedesired position.

Push the rod in and turn the end ofthe rod down, so the latch will fall tothe locked position. Then release therod.

56

04/03/15 18:00:49 31ZW2600_041

-

41

Motor Angle Inspection(Cruising)

OPERATION

INCORRECTCAUSES BOAT TO ‘‘SQUAT’’

CORRECTGIVES MAXIMUM PERFORMANCE

O. K

INCORRECTCAUSES BOAT TO ‘‘bow steer’’

Trim angle too large: Incorrectcauses boat to ‘‘squat’’.

Install the outboard motor at the besttrim angle for stable cruising andmaximum power.

The trim angle differs according tothe combination of the boat, outboardmotor, and propeller, and theoperating condition.

Trim angle too small: Incorrectcauses boat to ‘‘bow steer’’.

04/03/15 18:00:58 31ZW2600_042

-

Gasoline is highlyflammable and explosive.

You can be burned orseriously injured whenhandling fuel.

Stop the engine and keepheat, sparks, and flameaway.Handle fuel onlyoutdoors.Wipe up spillsimmediately.

42

PORTABLE FUEL TANK FUEL HOSE CONNECTIONS

OPERATION

FUEL HOSE CONNECTOR

(OUTBOARD MOTOR SIDE)

FUEL HOSE CONNECTOR

(FUEL TANK SIDE)FUELHOSE

Secure the portable fuel tank in theboat, so it won’t move around andbecome damaged.

Before use, open the fuel tank ventby turning the vent knob at least 2 or3 turns counterclockwise.

Connect the fuel hose to the tank andthe outboard motor, as shown. Besure both connectors snap securelyinto place.

Place the portable fuel tank in a well-ventilated location, away from directsunlight, to reduce the possibility of agasoline vapor explosion.

To ensure that the outboard motorwill be able to draw fuel from thetank, place the tank within 6 feet ofthe outboard motor and not morethan 3 feet below the fuel connectoron the outboard motor.

04/03/15 18:01:11 31ZW2600_043

-

43

FUEL PRIMING STARTING THE ENGINE

OPERATION

OUTLET END(MOTOR)

INLET END(TANK)

PRIMING BULB

LANYARD

UP

SWITCH CLIP

EMERGENCY STOP SWITCH

SH, LH, SHG and LHT Types(long tiller handle)

Do not squeeze the priming bulbwhen the engine is running becausethat could flood the carburetor.

Check to be sure there are no fuelleaks before starting the engine.

Hold the priming bulb with the outletend higher than the inlet end.Squeeze the priming bulb severaltimes, until it feels firm, indicatingthat fuel has reached the carburetor.

The engine will not start or run,unless the clip is in the switch.

The emergency stop switch clipand lanyard system is a safetydevice that will stop the engine ifyou fall away from the controlswhile operating the boat.

Always attach the lanyard to yourPFD, or to your wrist, beforestarting the engine.

Put the emergency stop switch clipin the emergency stop switch, andattach the lanyard to your PFD(Personal Flotation Device) or toyour wrist, as shown.

1.

04/03/15 18:01:23 31ZW2600_044

-

44

OPERATION

THROTTLE GRIP

STARTPOSITION

POINTER

IGNITION SWITCH KEY

STARTON

OFF

N (neutral)

SHIFT LEVER

RECOIL STARTER GRIP

Check the position of the gearshiftlever. It must be in the N (neutral)position for starting.

The engine will not start if thegearshift lever is in the F (forward)or R (reverse) position.

Align the engine start symbol‘‘ ’’ on the tiller handle with thepointer ‘‘ ’’ on the throttle grip.

2. 3.

04/03/15 18:01:33 31ZW2600_045

-

45

OPERATION

TAKING CARE OFUNEXPECTED PROBLEMS

Using the electric starter f or morethan 5 seconds at a time willoverheat the starter motor and candamage it.

Turning the ignition switch key tothe START position while theengine is running can damage thestarter motor and f lywheel.

During the warm-up period, checkthe oil pressure indicator (p. ),overheat indicator (p. ) andcooling system indicator (p. ).

If the indicators show anyabnormal condition, immediatelystop the engine and determine thecause of the problem. Refer to

from p. .Also, as the engine warms up, thethrottle grip can be turned to theSLOW position without stalling.

Before getting under way, allowthe engine to warm up sufficientlyto ensure good performance.

Above 41°F (5°C), warm up theengine for 2 or 3 minutes.

Below 41°F (5°C), warm up theengine for at least 10 minutes at2,000 rpm.

Recoil starter type:Pull the recoil starter grip slowlyuntil you feel resistance, then pullbriskly.

Return the starter grip gently.

Electric starter type:Turn the ignition switch key to theSTART position and hold it thereuntil the engine starts.

When the engine starts, release thekey, allowing it to return to the ONposition.

If the engine fails to start within 5seconds, release the key and waitat least 10 seconds beforeoperating the starter again.

5.

27

29

4.

28

94

04/03/15 18:01:45 31ZW2600_046

-

46

OPERATION

CONTROLLEVER

N (neutral)

EMERGENCY STOPSWITCH

SWITCH CLIP LANYARD

Side-Mount Type

SRG, LRG, SRT and LRT Types(remote control)

Set the control lever in the N(neutral) position.

The engine will not start if the F(forward) or R (reverse) gears areengaged.

The engine will not start or run,unless the clip is in the switch.

The emergency stop switch clipand lanyard system is a safetydevice that will stop the engine ifyou fall away from the controlswhile operating the boat.

Always attach the lanyard to yourPFD, or to your wrist, beforestarting the engine.

For panel mount or top mount remotecontrol information, refer to theinstructions provided with the remotecontrol equipment.

Put the emergency stop switch clipin the emergency stop switch, andattach the lanyard to your PFD(Personal Flotation Device) or toyour wrist, as shown.

2.

1.

04/03/15 18:01:56 31ZW2600_047

-

47

OPERATION

IGNITION SWITCH KEY

ONSTARTOFF

START

FAST IDLE LEVER

FAST IDLEUsing the electric starter f or morethan 5 seconds at a time willoverheat the starter motor and candamage it.

Turning the ignition switch key tothe START position while theengine is running can damage thestarter motor and f lywheel.

When the engine starts, release thekey, allowing it to return to the ONposition.

If the engine fails to start within 5seconds, release the key and waitat least 10 seconds beforeoperating the starter again.

To restart a warm engine, raise thefast idle lever.

Fast idle lever cannot be raisedunless the control lever is in the N(neutral) position.

The control lever cannot be movedaway from the N (neutral) positionunless the fast idle lever is lowered.

To start a cold engine, leave thefast idle lever in the START (fullylowered) position.

To start a cold engine, leave thefast idle lever in the START (fullylowered) position.

4.3.

04/03/15 18:02:07 31ZW2600_048

-

48

EMERGENCY STARTING

OPERATION

(REAR)

FAST IDLE LEVER

UUNNLLAATTCCHH

ENGINE COVERLATCH

TAKING CARE OFUNEXPECTED PROBLEMS

If the battery is discharged, the startermotor is inoperative, you can start theengine manually using theemergency starter rope supplied withthe motor.

Unlatch and remove the enginecover.

Before getting under way, allowthe engine to warm up sufficientlyto ensure good performance.

Above 41°F (5°C), warm up theengine for 2 or 3 minutes.

Below 41°F (5°C), warm up theengine for at least 10 minutes at2,000 rpm.

During the warm-up period, checkthe oil pressure indicator (p. ),overheat indicator (p. ), andcooling system indicator (p. ).

If the indicators show anyabnormal condition, immediatelystop the engine and determine thecause of the problem. Refer to

from p. .

If the fast idle lever was used tostart the engine, gradually lowerthe lever as the engine warms up.

When the fast idle lever is fullylowered, the control lever can bemoved away from the N (neutral)position.

6.

1.

5.27

2928

94

04/03/15 18:02:19 31ZW2600_049

-

-

× ×

49

OPERATION

6 22 mmBOLT

RECOIL STARTERASSEMBLY

(Recoil starter type)

NEUTRALSTARTCABLE

FLYWHEELCOVER

(Electric starter type)

KNOT

FLYWHEEL

EMERGENCYSTARTERROPE

6 22 mm BOLTS

Remove the recoil starter assemblyby unscrewing the four starterassembly bolts.

Electric starter type:Turn the ignition switch key to theON position.

Remove the flywheel cover byunscrewing the four cover bolts.

Set the controls the same as fornormal starting (see pages

). Use the fast idle control ifneeded.

Loosen the neutral start cable locknut and disconnect the neutral startcable.

Set the knotted end of theemergency starter rope in the notchin the flywheel. Wind the ropeclockwise around the flywheel, asshown.

Recoil starter type: Electric starter type:

3.

4.

4843

2.

04/03/15 18:02:31 31ZW2600_050

-

Exposed moving parts cancause injury.

Do not operate theoutboard motor withoutthe engine cover.Use extreme care wheninstalling the enginecover.

50

OPERATION

EMERGENCYSTARTER ROPE

TAKING CARE OFUNEXPECTED PROBLEMS,

Pull the emergency starter ropeslowly until resistance is felt, thenpull briskly.

Keep away from moving partswhile pulling the rope.

If necessary, rewind the rope andpull again. If the engine does notstart after several attempts, refer to

p..

If the fast idle control(s) was usedto start the engine, return thecontrol(s) to the normal operatingposition as the engine warms up.

During the warm-up period, checkthe oil pressure indicator (p. ),overheat indicator (p. ), andcooling system indicator (p. ).

Leave the recoil starter assemblyoff, but install the engine cover (p.

), and lock it in place bylatching the engine cover latch.

If it was necessary to remove theemergency stop switch lanyardfrom your wrist to perform theemergency starting procedure, besure the lanyard is attached to yourwrist before operating theoutboard motor.

Have your closest authorizedHonda marine dealer check yourelectrical system and correct theproblem, so you can use theelectric starter.

5.

6.

7.

8.

9.

27

29

70

94

28

04/03/15 18:02:43 31ZW2600_051

-

51

Normal Engine StoppingSTOPPING THE ENGINE

Emergency Engine Stopping

OPERATION

SLOW

THROTTLE GRIP

N (neutral)SWITCH CLIP

SWITCH CLIP

LANYARD

EMERGENCYSTOP SWITCH

GEARSHIFT LEVER

PULL

EMERGENCYSTOP SWITCH

PPUULLLL

LANYARD

SRG, LRG, SRT and LRT Types(remote control)

SH, LH, SHG and LHT Types(long tiller handle)

SH, LH, SHG and LHT Types(long tiller handle)

To stop the engine in an emergency,pull the clip out of the emergencystop switch by pulling the lanyard.

We suggest that you stop the enginethis way occasionally to verify thatthe emergency stop switch isoperating properly.

Turn the engine switch key to theOFF position (electric starter type).

04/03/15 18:02:54 31ZW2600_052

-

52

OPERATION

CONTROLLEVER

N (neutral)

OOFFFF

IGNITION SWITCH KEY

OFF

IGNITIONSWITCH KEY

EMERGENCY STOP SWITCH

PPRREESSSS

SRG, LRG, SRT and LRT Types(remote control)

SHG and LHT Types(long tiller handle)

SRG, LRG, SRT and LRT Types(remote control)

SH and LH Types(long tiller handle)

Move the throttle grip to theslowest speed and control gears toN (neutral) position.

Turn the ignition switch key to theOFF position to stop the engine orpress the emergency stop switchuntil the engine stops.

When the boat is not in use,remove and store the ignition keyand the emergency stop switch clipand lanyard.

3.

2.1.

04/03/15 18:03:06 31ZW2600_053

-

53

GEARSHIFTING ANDTHROTTLE OPERATION

OPERATION

POINTER

SLOW

FAST

FIX

RELEASE

THROTTLEGRIP

GEARSHIFTLEVER

F(forward)

N(neutral)

R(reverse)

THROTTLE FRICTION ADJUSTER

THROTTLEGRIPSH, LH, SHG and LHT Types(long tiller handle)

To shift gears, turn the throttle grip tothe SLOW position, then move thegearshift lever to select F (forward),N (neutral) or R (reverse) gears.

The engine can be started with thegearshift lever in the N (neutral)position only.

The throttle grip can be turned to theFAST position only when thegearshift lever is in the F (forward)position.

Use the throttle friction adjuster tohelp hold a constant throttle settingwhile cruising.

Turn the adjuster clockwise toincrease throttle grip friction forholding a constant speed.

Turn the adjuster counterclockwise todecrease friction for easy griprotation.

04/03/15 18:03:17 31ZW2600_054

-

54

OPERATION

CONTROLLEVER

NEUTRALRELEASE LEVER

THROTTLEFRICTIONADJUSTER

TO INCREASEFRICTION

TO DECREASEFRICTION

Side-Mount Type

SRG, LRG, SRT and LRT Types(remote control)

To shift gears, move the control leverto select F (forward), N (neutral) andR (reverse) gears.

The control lever cannot be movedfrom the N (neutral) position unlessthe neutral release lever is squeezed.

Moving the control lever beyond thegear selection range increases enginespeed.

Adjust the throttle friction adjuster sothe control lever will hold a constantthrottle setting while cruising.

04/03/15 18:03:27 31ZW2600_055

-

55

STEERING

OPERATION

FRICTIONPLATE

TO DECREASEFRICTION(FREE)

TTOO IINNCCRREEAASSEEFFRRIICCTTIIOONN((LLOOCCKK))

TTOO IINNCCRREEAASSEEFFRRIICCTTIIOONN((LLOOCCKK))

STEERING FRICTION ADJUSTER

TTOO DDEECCRREEAASSEEFFRRIICCTTIIOONN((FFRREEEE))

STEERINGFRICTIONADJUSTERBOLT

Steering Friction Adjuster

SH, LH, SHG and LHT Types(long tiller handle)

SRG, LRG, SRT and LRT Types(remote control)

SHG and LHT Types

SH and LH Types

Do not apply grease or oil on thef riction plate. Grease or oil willreduce the f riction of the adjuster.

Steer by moving the tiller handleopposite the direction you want theboat to turn.

Use the steering friction adjuster tohelp hold a steady course whilecruising.

Move the adjuster to the LOCKdirection to increase steering frictionfor holding a steady course.

Move the adjuster to the FREEdirection to decrease friction for easyturning.

Steer the boat in the same manner asan automobile.

04/03/15 18:03:40 31ZW2600_056

-

56

CRUISING

Engine Speed

Trim

OPERATION

SH, LH, SHG, SRG and LRGTypes

LHT, SRT and LRT Types

If engine speed becomes unstable athigh speed due to activation of theoverrev limiter, reduce speed andcheck the trim angle of the outboardmotor.

If, for example, the outboard motoris tilted excessively, or propellerventilation occurs during a sharp turn,the engine may overrev, activatingthe overrev limiter.

The engine is equipped with anoverrev limiter to prevent thepossibility of mechanical damagefrom excessive engine speed.

For rough water conditions or largewaves, slow down to prevent thepropeller from rising out of the water.

For best fuel economy, limit thethrottle opening to 80%. Use thethrottle friction control (p. and

) to help you hold a steady speed.

Under normal conditions, the boat

will perform best when theantiventilation plate is level with thewater.

It is necessary to trim the angle of theoutboard motor to compensate forchanges in boat load, weightdistribution, water conditions, orpropeller selection.

Trim angle too small: Incorrectcauses boat to ‘‘plow’’.

Trim angle too large: Incorrectcauses boat to ‘‘squat’’.

Install the outboard motor at the besttrim angle for stable cruising andmaximum power.

When cruising into a high wind, trimthe outboard motor down slightly tolevel the boat and improve stability.With a tail wind, trim the outboardmotor up slightly.

Use the power trim/tilt switch to trimthe outboard motor for the bestperformance and stability.

You can use the power trim/tiltswitch at any time, whether the boatis under way or stopped.

Press the UP or DN (down) side ofthe switch to adjust the angle of theoutboard motor.

Refer to the trim meter (p. ) for anindication of whether the motor istrimmed high or low.

5354

26

04/03/15 18:03:57 31ZW2600_057

-

57

OPERATION

CONTROL LEVER

ROUGHWAVES

POWER TRIM/TILT SWITCH

Press UP to trim ortilt the motor up.

Press DN to trim ortilt the motor down.

PPrreessss UUPP ttoo ttrriimm oorrttiilltt tthhee mmoottoorr uupp..

PPrreessss DDNN ttoo ttrriimm oorrttiilltt tthhee mmoottoorr ddoowwnn..

POWER TRIM/TILT SWITCH

CORRECTGIVES MAXIMUM PERFORMANCE

MOTOR ANGLEADJUSTED TOOLOW

MOTOR ANGLEADJUSTED TOOHIGH

MOTOR ANGLEADJUSTEDCORRECTLY

SRT and LRT Types

LHT Type(long tiller handle)

Excessive trim/tilt angle duringoperation can cause propellerventilation, overheating, and waterpump damage.

It is necessary to trim the angle of theoutboard motor to compensate forchanges in boat load, weightdistribution, water conditions, orpropeller selection.

Under normal conditions, the boatwill perform best when theantiventilation plate is level with thewater.

When cruising into a high wind,adjust the outboard motor downslightly to level the boat and improvestability. With a tail wind, adjust theoutboard motor up slightly.

04/03/15 18:04:08 31ZW2600_058

-

58

SHALLOW WATEROPERATION

TRIM TAB

OPERATION

TRIM TAB

PROPELLER

TIGHTENING BOLT

1.2.

1.2.

BOW TOO LOW DUE TO

BOW TOO HIGH DUE TO

LOAD IN THE FRONTMOTOR ANGLE ADJUSTED TOOLOW

LOAD IN THE REARMOTOR ANGLE ADJUSTED TOOHIGH

LHT, SRT and LRT Types

An excessive trim/tilt angle duringoperation can cause propellerventilation, overheating, and waterpump damage.

When operating in shallow water, usethe power trim/tilt switch (p. ) totilt the outboard motor, so thepropeller and gear case won’t hit thebottom.

Proceed at low speed, and monitorwater flow from the cooling systemindicator (p. ) to be sure theoutboard motor is not tilted so highthat the water intakes are out of thewater.

If steering effort is not equal in bothdirections, adjust the trim tab tocompensate for ‘‘torque steer,’’which is the reaction of the outboardmotor to propeller rotation.

Adjust the trim tab with the enginestopped. Loosen the bolt above thetrim tab, turn the trim tab, thentighten the bolt securely.

When the trim tab is correctlyadjusted, steering effort will be equalin both directions.

57

29

04/03/15 18:04:22 31ZW2600_059

-

59

OPERATION

ENGINE COVER GRIP

TILT ANGLE

TRIM ANGLE

0°

68°

16°

TTIILLTT

TILT LEVER

RUN(LOCK)

SHG, SRG and LRG Types

An excessive tilt angle duringoperation can cause propellerventilation, overheating, and waterpump damage.

Do not use the tiller handle as alever to raise the outboard motor.Applying excessive f orce to the tillerhandle can damage it.

While the outboard motor is tilted,proceed at a low speed, and do notoperate the outboard motor in reverse.The outboard motor will risesuddenly if operated in reverse.

When operating in shallow water, tiltthe outboard motor, using the tiltlever, so the propeller and gear casewon’t hit the bottom.

Monitor water flow from the coolingsystem indicator (p. ) to be surethe outboard motor is not tilted sohigh the water intake is out of thewater.

To return the outboard motor to thenormal operating position, move thetilt lever to the RUN (LOCK)position, you may need to raise theoutboard motor slightly to disengagethe tilt mechanism, then slowly lowerthe outboard motor.

To tilt the outboard motor, move thetilt lever to the TILT position, thenraise the outboard motor to thedesired position by pulling on theengine cover grip.

29

04/03/15 18:04:33 31ZW2600_060

-

60

OPERATION

45°

30°

ENGINE COVER GRIP

ENGINE COVER GRIP

TILT LEVER

TTIILLTT

RRUUNN((LLOOCCKK))

45°

30°

75°

POSITION

SH and LH Types

Do not use the tiller handle as alever to raise the outboard motor.Applying excessive f orce to the tillerhandle can damage it.

To tilt the outboard motor, move thetilt lever to the TILT position, thenraise the outboard motor to the 30° or45° position by pulling on the enginecover grip.

While the outboard motor is tilted,proceed at a low speed, and do notoperate the outboard motor in reverse.The outboard motor will risesuddenly if operated in reverse.

Monitor water flow from the coolingsystem indicator (p. ) to be surethe outboard motor is not tilted sohigh the water intake is out of thewater.

When operating in shallow water, tiltthe outboard motor, using the tiltlever, so the propeller and gear casewon’t hit the bottom.

29

04/03/15 18:04:46 31ZW2600_061

-

61

MOORING, BEACHING,LAUNCHING

OPERATION

75° POSITION

SH and LH Types

SHG, SRG and LRG Types

LHT, SRT and LRT Types

An excessive tilt angle duringoperation can cause propellerventilation, overheating, and waterpump damage.

Do not use the tiller handle as alever to raise the outboard motor.Applying excessive f orce to the tillerhandle can damage it.

Use the tilt lever to raise and lowerthe outboard motor as described onp. .

To raise the outboard motor out ofthe water while the engine is stoppedand the boat is moored, or formaximum clearance when beachingor launching, use the power tiltswitch on the engine pan to tilt theoutboard motor as far as it will go,move the tilt lock lever to the LOCKposition, then gently lower theoutboard motor until the levercontacts the stern bracket.To tilt the outboard motor, move the

tilt lever to the TILT position, thenraise the outboard motor to the 75°position by pulling on the enginecover grip as described on p. .

59

60

04/03/15 18:04:55 31ZW2600_062

-

62

OPERATION

POWER TILT SWITCH

FFRREEEE

LLOOCCKK

TILT LOCK LEVER(lock position)

RIGHT STERN BRACKET

MANUAL RELIEF VALVE

POWER(To fix)

MANUAL(To release)

Do not attempt to use the power tiltswitch to tilt the outboard motordown while the tilt lock lever is in thelock position. Damage to the powertilt system may occur.

For manual tilting, use a screwdriverto turn the valve counterclockwise 2and a half turns. Close the valvefirmly after positioning the engine.

The outboard motor can also be tiltedmanually after opening the manualrelief valve. This feature enables theoutboard motor to be tilted when nobattery is connected.

To lower the outboard motor, tilt up,move the tilt lock lever to the FREEposition, then lower the outboardmotor to the desired position.

If more clearance is needed to swingthe tilt lock lever into the LOCKposition, rock the outboard motorforward slightly by pulling on theengine cover grip.

04/03/15 18:05:05 31ZW2600_063

-

63

OPERATION

Be sure the valve is closed beforeoperating the outboard motor. If thevalve is not closed, the outboardmotor will tilt up when operated inreverse.

04/03/15 18:05:08 31ZW2600_064

-

Improperly maintainingthis outboard motor, orfailure to correct a problembefore operation, can causea malfunction in which youcould be seriously hurt orkilled.

Always follow theinspection andmaintenancerecommendations andschedules in this owner’smanual.

64

THE IMPORTANCE OFMAINTENANCE

Maintenance, replacement, orrepair of the emission controldevices and systems may beperformed by any marine enginerepair establishment or individual,using parts that are ‘‘certified’’ toEPA standards.

SERVICING YOUR OUTBOARD MOTOR

Good maintenance is essential forsafe, economical, and trouble-freeoperation. It will also help reduce airpollution.

To help you properly care for youroutboard motor, the following pagesinclude a maintenance schedule,routine inspection procedures, andsimple maintenance procedures usingbasic hand tools. Other service tasksthat are more difficult, or requirespecial tools, are best handled byprofessionals and are normallyperformed by a Honda technician orother qualified mechanic.

The maintenance schedule applies tonormal operating conditions. If youoperate your outboard motor underunusual conditions, consult anauthorized Honda marine dealer forrecommendations applicable to yourindividual needs and use.

Remember that your authorizedHonda marine dealer knows youroutboard motor best and is fullyequipped to maintain and repair it.

To ensure the best quality andreliability, use only new, genuineHonda parts or their equivalents forrepair and replacement.

04/03/15 18:05:18 31ZW2600_065

-

-

-

-

Failure to properly followmaintenance instructionsand precautions can causeyou to be seriously hurt orkilled.

Always follow theprocedures andprecautions in the owner’smanual.

65

MAINTENANCE SAFETY Safety Precautions

Burns from hot parts.

Injury from moving parts.

Carbon monoxide poisoningfrom engine exhaust.

SERVICING YOUR OUTBOARD MOTOR

Some of the most important safetyprecautions follow. However, wecannot warn you of everyconceivable hazard that can arise inperforming maintenance. Only youcan decide whether or not you shouldperform a given task.

Make sure the engine is off beforeyou begin any maintenance orrepairs. This will eliminate severalpotential hazards:

Read the instructions before youbegin, and make sure you have thetools and skills required.

To reduce the possibility of fire orexplosion, be careful whenworking around gasoline. Use onlya nonflammable solvent, notgasoline, to clean parts. Keepcigarettes, sparks, and flames awayfrom all fuel-related parts.

Wear gloves when handling thepropeller to protect your handsfrom sharp edges.Let the engine and exhaust

system cool before touching.

Do not run the engine unlessinstructed to do so.

Be sure there is adequateventilation whenever youoperate the engine.

04/03/15 18:05:28 31ZW2600_066

-

×

×

66

TOOL KITSPARE EMERGENCY STOPSWITCH CLIP (long tillerhandle type) ANDEMERGENCY STARTERROPE

SERVICING YOUR OUTBOARD MOTOR

10 12 mm WRENCH

OIL CHECK SCREWDRIVER

PLIERS

TOOL BAG

8 mm WRENCH

FLAT SCREWDRIVER

SCREWDRIVER HANDLE

18 19 mm SOCKET WRENCH

PHILLIPS SCREWDRIVER

EMERGENCY STARTER ROPE

SPARE EMERGENCY STOP SWITCHCLIP (long tiller handle type)

The above tool kit can be purchased from an authorized Honda marine dealerand may be used for simple maintenance procedures and/or emergencyrepairs. Keep this tool kit or an equivalent onboard, so they will always beavailable if you need them.

Always carry the spare emergencystop switch clip and the emergencystarter rope onboard. The spare clipmay either be stored in the tool bagor in an easily accessible location onthe boat along with the emergencystarter rope.

If your tool kit needs replacement, it is not available as a kit and each itemmust be ordered individually.

04/03/15 18:05:37 31ZW2600_067

-

○

○○

○○

○

○○

○

○

○

○

○

○

○

○○

○○

○

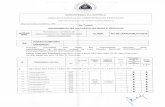

67

MAINTENANCE SCHEDULE

SERVICING YOUR OUTBOARD MOTOR

REGULAR SERVICE PERIODEvery 2 years

or400 hrs.

Perform at every indicated month or operatinghour interval, whichever comes first. After use

Check levelChangeChangeReplaceCheckCheck-adjustCheck-adjustCheck-adjustCheck-adjustCheck-adjustReplaceCheckCheckGreaseClean

Each useEvery 6 months

or100 hrs.

(2)

(2)(2)

(1)

Every yearor

200 hrs.

(2)

(2)

(2)

ITEMEngine oil

Gear case oilEngine oil filterStarter ropeTiming beltCarburetor linkageIdle speedValve clearanceSpark plug

Propeller and Cotter pinAnodeLubricationFuel tank and tank filter

First monthor

20 hrs.

(2)

(2)(2)

(1)

(3)

Lubricate more frequently when used in salt water.

These items should be serviced by an authorized Honda marine dealer, unless you have the proper tools and are mechanically proficient.Refer to the Honda shop manual for service procedures.

For professional commercial use, log hours of operation to determine proper maintenance intervals.

(1)

(2)

(3)

04/03/15 18:05:50 31ZW2600_068

-

○

○

○

○

○

○

○

○

○

○

68

SERVICING YOUR OUTBOARD MOTOR

REGULAR SERVICE PERIODPerform at every indicated month or operatinghour interval, whichever comes first. Each use After use

(4)

First monthor

20 hrs.

(2)

Every 6 monthsor

100 hrs.

(2)

Every 2 yearsor

400 hrs.

Every 2 years (If necessary) (2)

ITEMThermostatFuel filter

Fuel line

Battery and cableconnectionBolts and nutsCrankcase breather tubeCooling water passagesWater pump

CheckCheckReplaceCheckReplaceCheck level-tightness

Check-tightnessCheckCleanCheck

Every yearor

200 hrs.

(2)

(2)

(2)

(3)

When operating in salt water, turbid or muddy water, the engine should be flushed with clean water after each use.

For professional/commercial use, log hours of operation to determine proper maintenance intervals.

These items should be serviced by an authorized Honda marine dealer, unless you have the proper tools and are mechanically proficient.Refer to the Honda shop manual for service procedures.

Lubricate more frequently when used in salt water.(1)

(2)

(3)

(4)

04/03/15 18:06:04 31ZW2600_069

-

69

TRIM TAB ADJUSTMENT

SERVICING YOUR OUTBOARD MOTOR

TRIM TAB TRIM TABTIGHTENING BOLTTIGHTENINGBOLT

LLEEFFTT RRIIGGHHTT

The trim tab compensates for‘‘torque steer’’ which is a reaction ofthe outboard motor to propellerrotation.

If uncompensated, torque steer wouldmake the outboard motor tend to turnto one side.

When the trim tab is correctlyadjusted, steering effort is equal ineither direction.

If steering effort is unequal, loosenthe trim tab bolt and adjust the angleof the trim tab. Retighten the trim tabbolt securely. If less effort is required to make left

turns, move the back of the trim tableft.

Adjust the trim tab in smallincrements, and retest steering effortwith the boat evenly loaded andrunning at cruising speed.

If less effort is required to make rightturns, move the back of the trim tabright.

04/03/15 18:06:16 31ZW2600_070

-

70

MANUAL RELIEF VALVE

ENGINE COVER REMOVALAND INSTALLATION

SERVICING YOUR OUTBOARD MOTOR

(REAR)

(FRONT)

ENGINE COVERLATCH

RIGHT STERN BRACKET

UUNNLLAATTCCHH

MANUAL RELIEF VALVE

MMAANNUUAALL((TToo rreelleeaassee))

PPOOWWEERR((TToo ffiixx))

FFIIXX

LHT, SRT and LRT Types

The outboard motor can be tiltedmanually after opening the manualrelief valve. This feature enables theoutboard motor to be tilted when nobattery is connected.

Be sure the valve is closed beforeoperating the outboard motor. If thevalve is not closed, the outboardmotor will tilt up when operated inreverse.

For manual tilting, use a screwdriverto turn the valve counterclockwise 2and a half turns. Close the valvefirmly after positioning the outboardmotor.

To remove the engine cover, unlatchthe engine cover latch, then lift theengine cover off the outboard motor.

To install the engine cover, place thecover on the outboard motor, thenlatch the engine cover latch securely.

The engine cover latch fastens theengine cover to the outboard motor.

04/03/15 18:06:27 31ZW2600_071

-

71

Engine Oil Level Check

SERVICING YOUR OUTBOARD MOTOR

UPPERLIMIT

LOWERLIMIT

OIL FILLER CAP

OIL LEVEL DIPSTICK

Running the engine with a low oillevel can cause engine damage.

Check the engine oil level with theengine stopped and the outboardmotor in the vertical position.

Remove the dipstick and wipe itclean.

Insert the dipstick all the way in,then remove it and check the oillevel shown on the dipstick.

Install the oil filler cap and tightenit securely.

Install and lock the engine cover.

Unlatch and remove the enginecover.

If the oil level is low, remove theoil filler cap, and add oil to reachthe upper limit mark shown on thedipstick. Use the oil recommendedon p. .

1.

2.

3.

4.

5.

6.

(P.70)

73