ALU-POWER - Simetri Teknik - Kesici Takımlar ve Ölçü...

Transcript of ALU-POWER - Simetri Teknik - Kesici Takımlar ve Ölçü...

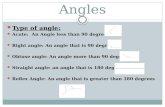

ALU-POWERALU-POWER FRÄSER- Aluminium Alloys and Silent Cutting- Für Aluminiumlegierungen in schwerem und ruhigem Schnitt

Being the best through innovationCARBIDE

CARBIDE, 2 FLUTE 25°HELIX CORNER RADIUS TiCN COATEDVOLLHARTMETALL, 2 SCHNEIDEN 25°RECHTSSPIRALE ECKENRADIUS TiCN-BESCHICHTET

CARBIDE, 2 FLUTE 45°HELIXVOLLHARTMETALL, 2 SCHNEIDEN 45°RECHTSSPIRALE

CARBIDE, 2 FLUTE CORNER RADIUS TiCN COATEDVOLLHARTMETALL, 2 SCHNEIDEN ECKENRADIUS TiCN-BESCHICHTET

CARBIDE, 2 FLUTE 50。HELIX BALL NOSE TiCN COATEDVOLLHARTMETALL, 2 SCHNEIDEN 50。RECHTSSPIRALE STIRNRADIUS TiCN-BESCHICHTET

CARBIDE, 3 FLUTE 40。HELIX BALL NOSE TiCN COATEDVOLLHARTMETALL, 3 SCHNEIDEN 40。RECHTSSPIRALE STIRNRADIUS TiCN-BESCHICHTET

PREMIUM HSS-PM, 3 FLUTE 42。HELIX SHORT LENGTH ROUGHING TiAlN COATEDPREMIUM HSS-PM, 3 SCHNEIDEN 42。RECHTSSPIRALE KURZ SCHRUPPFRÄSER TiAlN-BESCHICHTET

PREMIUM HSS-PM, 3 FLUTE 42。HELIX LONG LENGTH ROUGHING TiAlN COATEDPREMIUM HSS-PM, 3 SCHNEIDEN 42。RECHTSSPIRALE LANG SCHRUPPFRÄSER TiAlN-BESCHICHTET

RECOMMENDED CUTTING CONDITIONSEMPFOHLENE SCHNEIDKONDITIONEN

EG930

E5522E5521

EG909

EG910

EG908

EP922EP923EP924EP925

D2.0

D3.0

D4.0

R3.0

R1.0

D12.0

D12.0

D20.0

D20.0

D20.0

R10.0

R8.0

D32.0

D32.0

SELECTION GUIDE

724• phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:[email protected]

726

727

728

729

730

731

732

733

ITEM MODEL DESCRIPTIONSIZE

MIN MAXPAGE

ALU-POWER END MILLS

725•phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:[email protected]

○

○

○

○

○

○

○

○

○

◎

◎

◎

◎

◎

◎

◎

CarbonSteels

AlloySteels

Prehardened Steels

Copper Graphite Cast Iron Aluminum StainlessSteels Titanium Inconel

Hardened Steels High HardenedSteels

~HB225 HB225~325 HRc30~40 HRc40~45 HRc45~55 HRc55~70

◎ : Excellent, ◯ : Good

726• phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:[email protected]

CBN END MILLS

i-XmillEND MILLS

X5070END MILLS

X-POWEREND MILLS

JET-POWEREND MILLS

V7 Mill INOXEND MILLS

V7 Mill STEELEND MILLS

ALU-POWEREND MILLS

D-POWEREND MILLS

K-2 CARBIDEEND MILLS

GENERALCARBIDEEND MILLS

TANK-POWEREND MILLS

GENERALHSSEND MILLS

MILLINGCUTTERS

TECHNICALDATA

CARBIDE

HSSALU-POWEREND MILLS EG930 SERIES

PLAIN SHANKGLATTER ZYLINDERSCHAFT

P.733

▶Designed for the machining aluminum and its alloys, non-ferrousmaterials.

▶ Increased tool life and higher cutting accuracy.▶Maximum-stock removal, chip ejection, stability.▶Corner Radius for avoiding the chipping.

▶Geeignet zum Fräsen von Aluminium, Aluminiunlegierungen undNE-Metallen.

▶Höhere standzeit und höhere Schneidgenauigkeit.▶Sehr gute Spanabfuhr.▶Eckenradius zur Vermeidung von Abbröckelungen.

R↙

L3

L1

L2

D2

R

D1

D3

EG930020EG930030EG930040EG930050EG930060EG930080EG930100EG930120EG930160EG930200

R0.2R0.2R0.2R0.2R0.2R0.2R0.2R0.2R0.2R0.2

2.03.04.05.06.08.0

10.012.016.020.0

33456810121620

345881014162025

681214182228354050

404050506570809090

100

1.92.93.84.85.77.79.7

11.515.519.5

EDP No.

PLAIN

NeckDiameter

D3

OverallLength

L2

LengthBelow Shank

L3

Lengthof Cut

L1

ShankDiameter

D2

MillDiameter

D1

CornerRadius

R

Mill Dia.Tolerance(mm)

0~-0.03

Shank Dia.Tolerance

h6

CARBIDE, 2 FLUTE 25°HELIX CORNER RADIUS TiCN COATEDVOLLHARTMETALL, 2 SCHNEIDEN 25°RECHTSSPIRALE ECKENRADIUS TiCN-BESCHICHTET

Unit : mm

○ ◎

CarbonSteels

~HB225

AlloySteels

HB225~325

Prehardened Steels

HRc30~40

Hardened Steels High HardenedSteels

HRc40~45 HRc45~55 HRc55~70Copper Graphite Cast Iron Aluminum Stainless

Steels Titanium Inconel

◎ : Excellent ◯ : Good

727•phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:[email protected]

CBN END MILLS

i-XmillEND MILLS

X5070END MILLS

X-POWEREND MILLS

JET-POWEREND MILLS

V7 Mill INOXEND MILLS

V7 Mill STEELEND MILLS

ALU-POWEREND MILLS

D-POWEREND MILLS

K-2 CARBIDEEND MILLS

GENERALCARBIDEEND MILLS

TANK-POWEREND MILLS

GENERALHSSEND MILLS

MILLINGCUTTERS

TECHNICALDATA

CARBIDE

HSSALU-POWEREND MILLS E5521 SERIES

CARBIDE, 2 FLUTE 45°HELIXVOLLHARTMETALL, 2 SCHNEIDEN 45°RECHTSSPIRALE

FLAT SHANK SEITLICHE MITNAHMEFLÄCHEN

E5522 SERIESPLAIN SHANKGLATTER ZYLINDERSCHAFT

P.734

▶ Suitable for high speed machining in aluminum and other non-ferrous materials, excellent surface finishes, superior chipremoval.

▶Zur HSC- Bearbeitung von Aluminium und anderenNichteisenmetallen.

E5522030E5522040E5522050E5522060E5522080E5522100E5522120E5522140E5522160E5522180E5522200

E5521030E5521040E5521050E5521060E5521080E5521100E5521120E5521140E5521160E5521180E5521200

3.04.05.06.08.0

10.012.014.016.018.020.0

66668101214161820

811131319222626323238

57575757637283839292104

OverallLength

Lengthof Cut

MillDiameter

Unit : mm

Mill Dia.Tolerance(mm)

0~-0.03

Shank Dia.Tolerance

h6

EDP No. ShankDiameter

FLATPLAIN

▶TiN, TiCN - coating & TiAIN - coating is available on your request.

•High performance in machining aluminum and non-ferrous materials•Special designed geometry with high rigidity cutting edge•Improved surface roughness - cylindrical margin which is controlled tightly.•Excellent chip removal - higher rake angle, higher helix angle(45°), bigger chip pocket.

•Corner radius, Corner chamfer, Neck design is available on your request.•TiN, TiCN & TiAlN coating is available on your request.

CYLINDRICAL MARGIN

ECCENTRIC PRIMARY RELIEF

CHIPPOCKET

PLAIN SHANKFLAT SHANK

E5522E5521

E6522E6521

EG522EG521

EH522EH521

TiAlNTiCNTiNUNCOATED

○ ◎

CarbonSteels

~HB225

AlloySteels

HB225~325

Prehardened Steels

HRc30~40

Hardened Steels High HardenedSteels

HRc40~45 HRc45~55 HRc55~70Copper Graphite Cast Iron Aluminum Stainless

Steels Titanium Inconel

◎ : Excellent ◯ : Good

728• phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:[email protected]

CBN END MILLS

i-XmillEND MILLS

X5070END MILLS

X-POWEREND MILLS

JET-POWEREND MILLS

V7 Mill INOXEND MILLS

V7 Mill STEELEND MILLS

ALU-POWEREND MILLS

D-POWEREND MILLS

K-2 CARBIDEEND MILLS

GENERALCARBIDEEND MILLS

TANK-POWEREND MILLS

GENERALHSSEND MILLS

MILLINGCUTTERS

TECHNICALDATA

CARBIDE

HSSALU-POWEREND MILLS EG909 SERIES

PLAIN SHANKGLATTER ZYLINDERSCHAFT

P.735

▶Excellent cutting qualities on stainless steel, Aluminum, copper.▶ Increased tool life and higher cutting accuracy.

▶Zur Bearbeitung von Aluminium und anderen Nichteisenmetallen sowie rostfreien Stählen.

▶Höhere standzeit und höhere Schneidgenauigkeit.

R↙

L1

L2

L3

D2

R

D

D3

EG909040EG909060EG909080EG909100EG909120EG909160EG909200

R0.3R0.5R0.6R0.8R1.0R1.3R1.6

4.06.08.0

10.012.016.020.0

66810121620

10203036404545

581012141824

5060708090

100100

3.65.47.2911

14.518

EDP No.

PLAIN

NeckDiameter

D3

OverallLength

L3

Lengthof Cut

L2

LengthBelow Shank

L1

ShankDiameter

D2

MillDiameter

D

CornerRadius

R

Mill Dia.Tolerance(mm)

0~-0.03

Shank Dia.Tolerance

h6

CARBIDE, 2 FLUTE CORNER RADIUS TiCN COATEDVOLLHARTMETALL, 2 SCHNEIDEN ECKENRADIUS TiCN-BESCHICHTET

Unit : mm

○ ◎

CarbonSteels

~HB225

AlloySteels

HB225~325

Prehardened Steels

HRc30~40

Hardened Steels High HardenedSteels

HRc40~45 HRc45~55 HRc55~70Copper Graphite Cast Iron Aluminum Stainless

Steels Titanium Inconel

◎ : Excellent ◯ : Good

729•phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:[email protected]

CBN END MILLS

i-XmillEND MILLS

X5070END MILLS

X-POWEREND MILLS

JET-POWEREND MILLS

V7 Mill INOXEND MILLS

V7 Mill STEELEND MILLS

ALU-POWEREND MILLS

D-POWEREND MILLS

K-2 CARBIDEEND MILLS

GENERALCARBIDEEND MILLS

TANK-POWEREND MILLS

GENERALHSSEND MILLS

MILLINGCUTTERS

TECHNICALDATA

CARBIDE

HSSALU-POWEREND MILLS EG910 SERIES

PLAIN SHANKGLATTER ZYLINDERSCHAFT

P.735

▶Excellent cutting qualities on stainless steel, Aluminum, copper.▶Increased tool life and higher cutting accuracy.

▶Zur Bearbeitung von Aluminium und anderen Nichteisenmetallen sowie rostfreien Stählen.

▶Höhere standzeit und höhere Schneidgenauigkeit.

R↙

L3

L1

L2

D2

R

D1

D3

EG910060EG910080EG910100EG910120EG910160EG910200

R3.0R4.0R5.0R6.0R8.0R10.0

6.08.0

10.012.016.020.0

68

10121620

5.57

8.510.51417

253035405050

5565757590

100

5.47.2911

14.518

EDP No.

PLAIN

NeckDiameter

D3

OverallLength

L2

LengthBelow Shank

L3

Lengthof Cut

L1

ShankDiameter

D2

MillDiameter

D1

Radius ofBall NoseR (±0.01)

Mill Dia.Tolerance(mm)

±0.02

Shank Dia.Tolerance

h6

CARBIDE, 2 FLUTE 50。HELIX BALL NOSE TiCN COATEDVOLLHARTMETALL, 2 SCHNEIDEN 50。RECHTSSPIRALE STIRNRADIUS TiCN-BESCHICHTET

Unit : mm

○ ◎

CarbonSteels

~HB225

AlloySteels

HB225~325

Prehardened Steels

HRc30~40

Hardened Steels High HardenedSteels

HRc40~45 HRc45~55 HRc55~70Copper Graphite Cast Iron Aluminum Stainless

Steels Titanium Inconel

◎ : Excellent ◯ : Good

730• phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:[email protected]

CBN END MILLS

i-XmillEND MILLS

X5070END MILLS

X-POWEREND MILLS

JET-POWEREND MILLS

V7 Mill INOXEND MILLS

V7 Mill STEELEND MILLS

ALU-POWEREND MILLS

D-POWEREND MILLS

K-2 CARBIDEEND MILLS

GENERALCARBIDEEND MILLS

TANK-POWEREND MILLS

GENERALHSSEND MILLS

MILLINGCUTTERS

TECHNICALDATA

CARBIDE

HSSALU-POWEREND MILLS EG908 SERIES

PLAIN SHANKGLATTER ZYLINDERSCHAFT

P.736

▶Excellent cutting qualities on stainless steel, Aluminum, copper.▶Increased tool life and higher cutting accuracy.

▶Zur Bearbeitung von Aluminium und anderen Nichteisenmetallen sowie rostfreien Stählen.

▶Höhere standzeit und höhere Schneidgenauigkeit.

R↙

L3

L1

L2

D2

R

D1

D3

EG908020EG908025EG908030EG908035EG908040EG908050EG908060EG908080EG908100EG908120EG908160

R1.0R1.25R1.5R1.75R2.0R2.5R3.0R4.0R5.0R6.0R8.0

2.02.53.03.54.05.06.08.0

10.012.016.0

66666668101216

34

4.556

7.5912151824

56

6.578101225303640

60606065656575758090

100

1.92.42.83.23.74.65.67.49.4

11.415.4

EDP No.

PLAIN

NeckDiameter

D3

OverallLength

L2

LengthBelow Shank

L3

Lengthof Cut

L1

ShankDiameter

D2

MillDiameter

D1

Radius ofBall NoseR (±0.01)

Mill Dia.Tolerance(mm)

0~-0.03

Shank Dia.Tolerance

h6

CARBIDE, 3 FLUTE 40。HELIX BALL NOSE TiCN COATEDVOLLHARTMETALL, 3 SCHNEIDEN 40。RECHTSSPIRALE STIRNRADIUS TiCN-BESCHICHTET

Unit : mm

○ ◎

CarbonSteels

~HB225

AlloySteels

HB225~325

Prehardened Steels

HRc30~40

Hardened Steels High HardenedSteels

HRc40~45 HRc45~55 HRc55~70Copper Graphite Cast Iron Aluminum Stainless

Steels Titanium Inconel

◎ : Excellent ◯ : Good

731•phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:[email protected]

CBN END MILLS

i-XmillEND MILLS

X5070END MILLS

X-POWEREND MILLS

JET-POWEREND MILLS

V7 Mill INOXEND MILLS

V7 Mill STEELEND MILLS

ALU-POWEREND MILLS

D-POWEREND MILLS

K-2 CARBIDEEND MILLS

GENERALCARBIDEEND MILLS

TANK-POWEREND MILLS

GENERALHSSEND MILLS

MILLINGCUTTERS

TECHNICALDATA

CARBIDE

HSSALU-POWEREND MILLS EP923 SERIES

FLAT SHANK SEITLICHE MITNAHMEFLÄCHEN

EP922 SERIESPLAIN SHANKGLATTER ZYLINDERSCHAFT

P.736

▶ Maximum stock removal rates at High Speed Condition.▶ Reduces vibrations and improves surface roughness.

▶Sehr gute Spanabfuhr auch bei Hochgeschwindigkeitsfräsen.▶Reduziert Vibrieren und verbessert Oberflächenrauheit.

EP922120EP922140EP922160EP922180EP922200EP922220EP922250EP922280EP922320

EP923120EP923140EP923160EP923180EP923200EP923220EP923250EP923280EP923320

12.014.016.018.020.022.025.028.032.0

121216162020252532

262632323838454553

83839292104104121121133

OverallLength

Lengthof Cut

MillDiameter

js12

Unit : mm

EDP No. ShankDiameter

h6FLATPLAIN

Tolerances according to DIN 7160 & 7161Toleranzen nach DIN 7160 & 7161

Tolerance range in ㎛ / Toleranzwerte in ㎛Nominal-Diameter in ㎜ / Nennmaßbereich in ㎜

js12

h6

from 1 to 3von 1 bis 3

over 3 to 6über 3 bis 6

over 6 to 10über 6 bis 10

over 10 to 18über 10 bis 18

over 18 to 30über 18 bis 30

over 30 to 50über 30 bis 50

± 50 ± 60 ± 75 ± 90 ± 105 ± 125

0— 6

0— 8

0— 9

0— 11

0— 13

0— 16

PREMIUM HSS-PM, 3 FLUTE 42。HELIX ROUGHING SHORT LENGTH TiAlN COATEDPREMIUM HSS-PM, 3 SCHNEIDEN 42。RECHTSSPIRALE SCHRUPPFRÄSER KURZ TiAlN-BESCHICHTET

○ ○ ◎

CarbonSteels

~HB225

AlloySteels

HB225~325

Prehardened Steels

HRc30~40

Hardened Steels High HardenedSteels

HRc40~45 HRc45~55 HRc55~70Copper Graphite Cast Iron Aluminum Stainless

Steels Titanium Inconel

◎ : Excellent ◯ : Good

732• phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:[email protected]

CBN END MILLS

i-XmillEND MILLS

X5070END MILLS

X-POWEREND MILLS

JET-POWEREND MILLS

V7 Mill INOXEND MILLS

V7 Mill STEELEND MILLS

ALU-POWEREND MILLS

D-POWEREND MILLS

K-2 CARBIDEEND MILLS

GENERALCARBIDEEND MILLS

TANK-POWEREND MILLS

GENERALHSSEND MILLS

MILLINGCUTTERS

TECHNICALDATA

CARBIDE

HSSALU-POWEREND MILLS EP925 SERIES

FLAT SHANK SEITLICHE MITNAHMEFLÄCHEN

EP924 SERIESPLAIN SHANKGLATTER ZYLINDERSCHAFT

▶ Maximum stock removal rates at High Speed Condition.▶ Reduces vibrations and improves surface roughness.

▶Sehr gute Spanabfuhr auch bei Hochgeschwindigkeitfräsen.▶Reduziert Vibrieren und verbessert Oberflächenrauheit.

EP924120EP924140EP924160EP924180EP924200EP924220EP924250EP924280EP924320

EP925120EP925140EP925160EP925180EP925200EP925220EP925250EP925280EP925320

12.014.016.018.020.022.025.028.032.0

121216162020252532

5353636375759090106

110110123123141141166166186

Lengthof Cut

OverallLength

MillDiameter

js12

EDP No. ShankDiameter

h6FLATPLAIN

Tolerances according to DIN 7160 & 7161Toleranzen nach DIN 7160 & 7161

Tolerance range in ㎛ / Toleranzwerte in ㎛Nominal-Diameter in ㎜ / Nennmaßbereich in ㎜

js12

h6

from 1 to 3von 1 bis 3

over 3 to 6über 3 bis 6

over 6 to 10über 6 bis 10

over 10 to 18über 10 bis 18

over 18 to 30über 18 bis 30

over 30 to 50über 30 bis 50

± 50 ± 60 ± 75 ± 90 ± 105 ± 125

0— 6

0— 8

0— 9

0— 11

0— 13

0— 16

P.736

PREMIUM HSS-PM, 3 FLUTE 42。HELIX ROUGHING LONG LENGTH TiAlN COATEDPREMIUM HSS-PM, 3 SCHNEIDEN 42。RECHTSSPIRALE SCHRUPPFRÄSER LANG TiAlN-BESCHICHTET

○ ○ ◎

CarbonSteels

~HB225

AlloySteels

HB225~325

Prehardened Steels

HRc30~40

Hardened Steels High HardenedSteels

HRc40~45 HRc45~55 HRc55~70Copper Graphite Cast Iron Aluminum Stainless

Steels Titanium Inconel

◎ : Excellent ◯ : Good

733•phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:[email protected]

RECOMMENDED CUTTING CONDITIONSEMPFOHLENE SCHNEIDKONDITIONEN

CBN END MILLS

i-XmillEND MILLS

X5070END MILLS

X-POWEREND MILLS

JET-POWEREND MILLS

V7 Mill INOXEND MILLS

V7 Mill STEELEND MILLS

ALU-POWEREND MILLS

D-POWEREND MILLS

K-2 CARBIDEEND MILLS

GENERALCARBIDEEND MILLS

TANK-POWEREND MILLS

GENERALHSSEND MILLS

MILLINGCUTTERS

TECHNICALDATA

CARBIDE

HSSALU-POWEREND MILLS

CARBIDE, 2 FLUTE 25°HELIX CORNER RADIUS TiCN COATEDVOLLHARTMETALL, 2 SCHNEIDEN 25°RECHTSSPIRALE ECKENRADIUS TiCN-BESCHICHTET

RPM = rev./min.FEED = mm/min.

EG930 SERIES

3.04.05.06.08.0

10.012.016.020.0

1300013000130001300010000100001000080005000

90012001300150018002200270025002000

1300013000130001300010000100001000080005000

120014001700200023002700340031002500

MATERIAL

DIAMETER FEEDRPMFEEDRPM

ALUMINUMLOW SILICON ALUMINUM

A : Ø3 ~Ø10 = 0.25×DØ12 ~ Ø20 = 0.5×D

D

0.5DA

1.0D

RECOMMENDED CUTTING CONDITIONSEMPFOHLENE SCHNEIDKONDITIONEN

734• phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:[email protected]

CBN END MILLS

i-XmillEND MILLS

X5070END MILLS

X-POWEREND MILLS

JET-POWEREND MILLS

V7 Mill INOXEND MILLS

V7 Mill STEELEND MILLS

ALU-POWEREND MILLS

D-POWEREND MILLS

K-2 CARBIDEEND MILLS

GENERALCARBIDEEND MILLS

TANK-POWEREND MILLS

GENERALHSSEND MILLS

MILLINGCUTTERS

TECHNICALDATA

CARBIDE

HSSALU-POWEREND MILLS

CARBIDE, 2 FLUTE 45°HELIXVOLLHARTMETALL, 2 SCHNEIDEN 45°RECHTSSPIRALE

E5522, E5521 SERIES

RPM = rev./min.FEED = mm/min.

3.04.05.06.08.0

10.012.014.016.018.020.0

100001000010000100008000800080006000600040004000

700900100012001400170021001800190014001600

100001000010000100008000800080006000600040004000

9001100130015001800210026002200240018001900

MATERIAL

DIAMETER FEEDRPMFEEDRPM

ALUMINUMLOW SILICON ALUMINUM

CARBIDE, 2 FLUTE 45°HELIX TiCN COATEDVOLLHARTMETALL, 2 SCHNEIDEN 45°RECHTSSPIRALE TICN-BESCHICHTET

EG522, EG521 SERIES

RPM = rev./min.FEED = mm/min.

3.04.05.06.08.0

10.012.014.016.018.020.0

130001300013000130001000010000100008000800050005000

9001200130015001800220027002300250018002000

130001300013000130001000010000100008000800050005000

12001400170020002300270034002800310023002500

MATERIAL

DIAMETER FEEDRPMFEEDRPM

ALUMINUMLOW SILICON ALUMINUM

A : Ø3 ~Ø10 = 0.25×DØ12 ~ Ø20 = 0.5×DD

0.5D

A

1.0D

A : Ø3 ~Ø10 = 0.25×DØ12 ~ Ø20 = 0.5×DD

0.5D

A

1.0D

735•phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:[email protected]

RECOMMENDED CUTTING CONDITIONSEMPFOHLENE SCHNEIDKONDITIONEN

CBN END MILLS

i-XmillEND MILLS

X5070END MILLS

X-POWEREND MILLS

JET-POWEREND MILLS

V7 Mill INOXEND MILLS

V7 Mill STEELEND MILLS

ALU-POWEREND MILLS

D-POWEREND MILLS

K-2 CARBIDEEND MILLS

GENERALCARBIDEEND MILLS

TANK-POWEREND MILLS

GENERALHSSEND MILLS

MILLINGCUTTERS

TECHNICALDATA

CARBIDE

HSSALU-POWEREND MILLS

CARBIDE, 2 FLUTE CORNER RADIUS TiCN COATEDVOLLHARTMETALL, 2 SCHNEIDEN ECKENRADIUS TiCN-BESCHICHTET

4.06.08.0

10.012.016.020.0

130001300010000100001000080005000

1200150018002200270025002000

130001300010000100001000080005000

1400200023002700340031002500

3900390030003000300024001500

300380450550680630500

3900390030003000300024001500

350500580680850780630

MATERIAL

DIAMETER FEED

RPM = rev./min.FEED = mm/min.

RPM FEED RPM FEED RPM FEED RPM

ALUMINUMALUMINUM ALLOY COPPER ALLOY

EG909 SERIES

CARBIDE, 2 FLUTE 50。HELIX BALL NOSE TiCN COATEDVOLLHARTMETALL, 2 SCHNEIDEN 50。RECHTSSPIRALE STIRNRADIUS TiCN-BESCHICHTET

RPM = rev./min.FEED = mm/min.

EG910 SERIES

R3.0 × 6.0R4.0 × 8.0R5.0 × 10.0R6.0 × 12.0R8.0 × 16.0R10.0 × 20.0

18000140001400014000110007000

175020002350300027002200

550042004200420033002100

440500580750670550

MATERIAL

DIAMETER FEEDRPM

COPPER ALLOY

FEEDRPM

ALUMINUMALUMINUM ALLOY

ap=0.2×Dae=0.5×D

A : ~Ø10=0.25DØ12~Ø20=0.5D

D

0.5D A

1.0D

A : ~Ø10=0.25DØ12~Ø20=0.5D

D

0.5D A

1.0D

ap

ae

RECOMMENDED CUTTING CONDITIONSEMPFOHLENE SCHNEIDKONDITIONEN

736• phone:+82-32-526-0909, fax:+82-32-526-4373, www.yg1.kr, E-mail:[email protected]

CBN END MILLS

i-XmillEND MILLS

X5070END MILLS

X-POWEREND MILLS

JET-POWEREND MILLS

V7 Mill INOXEND MILLS

V7 Mill STEELEND MILLS

ALU-POWEREND MILLS

D-POWEREND MILLS

K-2 CARBIDEEND MILLS

GENERALCARBIDEEND MILLS

TANK-POWEREND MILLS

GENERALHSSEND MILLS

MILLINGCUTTERS

TECHNICALDATA

CARBIDE

HSSALU-POWEREND MILLS

CARBIDE, 3 FLUTE 40。HELIX BALL NOSE TiCN COATEDVOLLHARTMETALL, 3 SCHNEIDEN 40。RECHTSSPIRALE STIRNRADIUS TiCN-BESCHICHTET

EG908 SERIES

RPM = rev./min.FEED = mm/min.

R1.0 ×2.0R1.25×2.5R1.5 ×3.0R2.0 ×4.0R2.5 ×5.0R3.0 ×6.0R4.0 ×8.0R5.0 ×10.0R6.0 ×12.0R8.0 ×16.0

27000220001800018000180001800014000140001400011000

950950950

1250135017502000235030002700

8000650055005500550055004200420042003300

240240240310340440500580750670

MATERIAL

DIAMETER RPM FEED RPM FEED

ALUMINUMLOW SILICON ALUMINUM COPPER ALLOY

ap=0.2×Dae=0.5×D

PREMIUM HSS-PM, 3 FLUTE 42。。HELIX ROUGHING TiAlN COATEDPREMIUM HSS-PM, 3 SCHNEIDEN 42。RECHTSSPIRALE SCHRUPPFRÄSER TiAlN-BESCHICHTET

RPM = rev./min.FEED = mm/min.

12.016.020.025.032.0

28002200170014001100

550625700625700

28002200170014001100

410465525465525

MATERIAL

DIAMETER FEEDRPMFEEDRPM

ALUMINUMALUMINUM ALLOY

EP922, EP923, EP924, EP925 SERIES

0.5D

1.5D

D

0.5D

ap

ae