ALTEC Automated Gang Lock Final Presentation

-

Upload

xaviera-bowers -

Category

Documents

-

view

31 -

download

0

description

Transcript of ALTEC Automated Gang Lock Final Presentation

ALTEC Automated Gang LockFinal Presentation

Presented ByRandy Turner

Michael ThompsonJustin Rutledge

Ben MizeDrew Mardis

Richard Moyer

The system fits in the narrowest boxes

The mechanism fits in a single box, protecting it from impact and corrosion.

The module can be welded, bolted, or riveted in place Can use mounting brackets, or can be mounted directlyto the

box by the housing.

A car-door style latch is employed to lock the bar in place

These latches are mass produced and can be bought for 5 dollars in large quantities.

A rack and pinion design was explored.

An appropriate motor cost as much as the solenoid in the final design

The rack and pinion design also increased complexity and part count.

Manual override must be locked out

An access panel can lock out the mechanism directly

Alternatively, a release mechanism can be keyed to the outside.

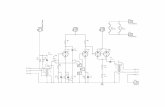

Rivet Strength Calculations

Tensile Strength under moment force = 314lbs (FOS 2)

Tensile Strength = 1780 lbs (FOS 2) Shear Strength =2600 lbs (FOS 2)

Spring force calculations

Item Coefficient of Friction

Weight Friction Force Deflection@ 3.06 lbs. Spring

Tension

Initial Tension Tension @ 1’’ Deflection

Greased Bar 0.251 12.252 3.06 lbs

Spring 0.103’’ 2.54 lbs. 7.58 lbs.

Resistive ForceOn Solenoid

5.6 lbs. 10.64 lbs.

Force From Solenoid

16.6 lbs. 45 lbs.

Cost Estimation

Total Units 501 1001 1501 2001Latch Three 2505 5005 7505 10005Striker Three 581.16 1161.16 1741.16 2321.16Small Solenoid 4363.71 8718.71 13073.71 17428.71Large Solenoid 10020 17017 24016 28014Springs 831.66 1661.66 2491.66 3321.66Sheet Metal 2640.27 5275.27 7910.27 10545.27Round Stock 721.44 1441.44 2161.44 2881.44Wire 6.513 13.013 19.513 26.0131/4'' Bolts 325.65 650.65 975.65 1300.65Brackets 1843.68 3683.68 5523.68 7363.68Cost Per Unit 47.583 44.583 43.583 41.583

Articles shown in gray are conservative estimates

The wireless controller is simple to integrate into the system

No wiring takes place inside the box after assembly Wires can be run along with the lights The receiver is specifically designed to work on

12VDC automobile power.

Wireless modules cannot work inside closed metal boxes

Wireless signals cannot transmit through a conductive metal cage (Faraday Cage Effect). The receiver can be placed outside the box An antenna could be run to the outside of the

box The box itself can be made to act as an

antenna.

Wiring

Wiring the system is relatively straight-forward. Each solenoid requires a relay to protect the wireless unit

and to function reliably.

Conclusions

Cost Estimate: $45 per box in parts $35 estimate labor costs per box Final Estimated Cost for 3 box truck: $320

Design uses mostly inexpensive manufactured parts

Can be installed in boxes large and small